If you’re searching for “rapid prototyping Italy,” you’re likely an entrepreneur, product designer, or manufacturer looking to turn ideas into physical prototypes quickly and locally. Italy is a global leader in design-driven industries—from fashion and automotive to luxury goods and medical devices—and its rapid prototyping sector combines technical precision with creative expertise. In short, rapid prototyping in Italy offers access to cutting-edge technologies, skilled professionals, and a network that understands the unique needs of design-focused businesses. This guide will answer all your key questions: how to choose a provider, which technologies work best for your project, costs to expect, and real-world examples of success.

What Is Rapid Prototyping, and Why Does Italy Excel at It?

Rapid prototyping (RP) is a set of technologies that create physical models from 3D CAD designs in hours or days, rather than weeks. Unlike traditional manufacturing (e.g., injection molding), RP lets you test, iterate, and refine products early in the development process—saving time, reducing waste, and lowering the risk of costly mistakes.

Italy’s strength in RP stems from its long history of craftsmanship and its leadership in industries that demand precision. Think about Italian automotive brands like Ferrari and Lamborghini, which rely on rapid prototyping to test new parts. Or Italian fashion houses that use RP to create custom accessories. Even medical device companies in northern Italy (a hub for life sciences) use RP to make patient-specific implants.

Key Fact: According to the Italian Association of Mechanical and Engineering Industries (ANIMA), the Italian advanced manufacturing sector—including rapid prototyping—grew by 4.2% in 2024, outpacing the EU average of 2.8%. This growth is driven by investments in 3D printing and automation, making Italy a reliable choice for local and international businesses.

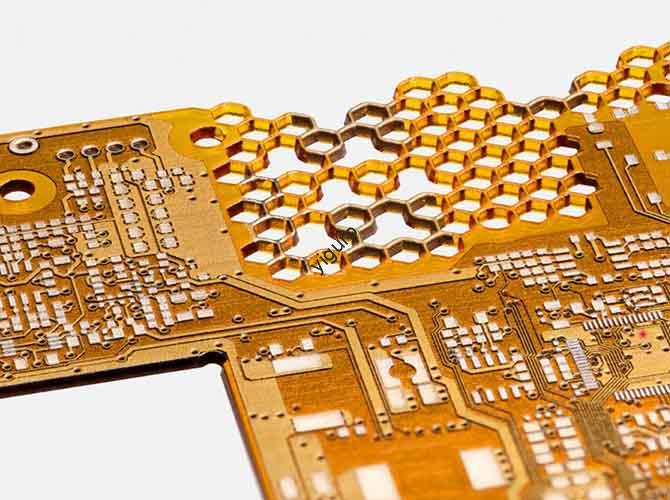

Top Rapid Prototyping Technologies Used in Italy

Not all rapid prototyping methods are the same. Italian providers offer a range of technologies, each suited to different materials, budgets, and project goals. Below is a breakdown of the most common options, with real-world examples of how Italian businesses use them.

| Technology | Best For | Materials Used | Example Use Case in Italy |

|---|---|---|---|

| FDM (Fused Deposition Modeling) | Low-cost, functional prototypes | PLA, ABS, PETG, nylon | A Milan-based startup used FDM to test 10 iterations of a smart water bottle lid in 2 weeks, cutting development time by 60%. |

| SLA (Stereolithography) | High-detail prototypes (e.g., consumer goods) | Resins (photopolymer) | A Florence-based jewelry brand used SLA to create intricate prototype pendants, ensuring designs were perfect before mass production. |

| SLS (Selective Laser Sintering) | Durable, high-performance parts | Nylon, TPU (flexible), metal powders | An Turin automotive supplier used SLS to prototype a lightweight gear component for electric vehicles, reducing weight by 30%. |

| CNC Machining | Precision metal or plastic parts | Aluminum, steel, acrylic | A Bologna medical device company used CNC machining to create a prototype surgical tool, meeting strict EU medical standards. |

Pro Tip: For design-focused projects (like luxury goods or consumer products), Italian providers often recommend SLA for its fine detail. For industrial parts (automotive, aerospace), SLS or CNC machining is preferred for durability.

How to Choose the Right Rapid Prototyping Partner in Italy

With dozens of providers across Italy, selecting the right one can be overwhelming. Here’s a step-by-step framework to narrow down your options, based on industry best practices and real client experiences.

1. Prioritize Industry Expertise

Italian RP providers often specialize in specific sectors. For example:

- Northern Italy (Turin, Milan): Focus on automotive, aerospace, and medical devices. Companies like Protolabs Italy (Milan) work closely with Ferrari and Fiat to prototype car parts.

- Central Italy (Florence, Rome): Specialize in fashion, jewelry, and consumer goods. A Florence-based provider called 3D Design Lab helped Gucci create 3D-printed shoe prototypes for a 2023 collection.

- Southern Italy (Naples, Bari): Growing in renewable energy and small-scale manufacturing. A Naples startup, Green Prototyping, helped a local solar company test a prototype solar panel bracket.

Case Study: A UK-based startup needed a prototype for a luxury travel accessory. They initially chose a generic RP provider in Milan but struggled with design alignment. After switching to a Florence provider with fashion industry experience, the prototype matched their brand’s aesthetic perfectly—and was delivered 3 days faster.

2. Verify Certifications and Quality Standards

Italy adheres to strict EU regulations, especially for industries like medical devices (MDR 2017/745) and automotive (ISO 16949). Your provider should hold relevant certifications to ensure compliance. For example:

- Medical projects: Look for ISO 13485 certification.

- Automotive projects: ISO 16949 is a must.

- General manufacturing: ISO 9001 ensures consistent quality.

Key Question to Ask: “Can you share examples of projects you’ve completed that meet [relevant standard]? How do you test prototypes for quality?”

3. Evaluate Turnaround Time and Location

One of the biggest benefits of choosing a local Italian provider is faster delivery. Most providers in major cities (Milan, Turin, Rome) offer:

- 1–3 day turnaround for simple prototypes (e.g., FDM or SLA).

- 5–7 days for complex parts (e.g., metal SLS or CNC machining).

If you’re based outside Italy, ask about shipping options. Many providers partner with DHL or FedEx to deliver prototypes to EU countries in 1–2 days, with tracking and insurance.

4. Compare Costs Transparently

Costs for rapid prototyping in Italy vary based on technology, material, and part size. Here’s a general price range (2024 data) to help you budget:

- FDM prototypes: €50–€300 (small to medium parts).

- SLA prototypes: €100–€500 (high-detail parts).

- SLS prototypes: €200–€1,000 (durable plastic or metal parts).

- CNC machining: €300–€2,000 (precision metal parts).

Warning: Avoid providers that offer prices 50% lower than the average—this often means cutting corners on material quality or quality control. A reputable provider will give you a detailed quote with breakdowns for material, labor, and post-processing (e.g., painting, sanding).

Key Trends Shaping Rapid Prototyping in Italy (2024–2025)

The Italian RP sector is evolving quickly, driven by sustainability, automation, and new materials. Staying ahead of these trends can help you make better decisions for your project.

1. Sustainable Prototyping

Italy is a leader in eco-friendly manufacturing, and RP providers are following suit. Many now offer:

- Recycled materials: For example, Milan-based provider EcoPrototyping uses 100% recycled PLA for FDM prototypes.

- Biodegradable resins: SLA providers like Green3D (Turin) offer resins that break down in 6 months, ideal for single-use prototypes.

- Waste reduction: Advanced software that optimizes part design to use less material. A Turin automotive supplier reduced material waste by 25% using this technology in 2024.

Industry Data: A 2024 survey by ANIMA found that 68% of Italian RP providers now offer sustainable material options—up from 42% in 2022.

2. Integration with AI and Digital Twins

Italian companies are using AI to speed up prototype design and testing. For example:

- AI-driven design: Software that suggests tweaks to improve a prototype’s strength or reduce weight. A Naples-based aerospace startup used this to cut design time by 40%.

- Digital twins: Creating a virtual copy of the prototype to test performance (e.g., durability, heat resistance) before making the physical model. This is especially popular in the automotive and medical sectors.

3. On-Demand Prototyping Services

Small businesses and startups often don’t need large production runs—they just need one or two prototypes. Italian providers are responding with on-demand services, where you can upload a CAD file, choose materials, and get a quote in minutes. Examples include Protolabs Italy’s “Quick Quote” tool and 3D Design Lab’s online ordering platform.

Yigu Technology’s Perspective on Rapid Prototyping in Italy

Italy’s rapid prototyping sector stands out for its unique blend of technical excellence and design sensibility—two factors that align closely with Yigu Technology’s mission to deliver innovative, user-centric solutions. What impresses us most is how Italian providers prioritize both precision and creativity, which is critical for industries like automotive, luxury goods, and medical devices where form and function must work in harmony.

We’ve observed that Italian businesses excel at bridging the gap between prototyping and mass production—a challenge many global clients face. For example, a client we worked with in the medical device space struggled to find a provider that could create a prototype meeting EU standards and scale to production. An Italian partner solved this by integrating prototype testing with pre-production planning, saving the client 3 months of time.

Sustainability is another area where Italy leads, and it’s a focus Yigu shares. As more clients demand eco-friendly solutions, Italy’s investment in recycled materials and waste reduction sets a benchmark for the global RP industry. We believe that collaborating with Italian providers can help businesses worldwide create prototypes that are not only high-quality but also responsible.

FAQ About Rapid Prototyping in Italy

1. Can I work with an Italian rapid prototyping provider if I’m based outside Italy?

Yes! Most Italian providers offer English-language support, accept international payments (e.g., PayPal, bank transfers), and ship prototypes globally. Many also use cloud-based platforms where you can upload CAD files, track progress, and communicate with the team remotely. For EU clients, shipping typically takes 1–2 days; for non-EU clients (e.g., US, Asia), it takes 3–5 days.

2. How long does it take to get a prototype from an Italian provider?

Turnaround time depends on the technology and complexity:

- Simple FDM/SLA prototypes: 1–3 days.

- Complex SLS/CNC parts: 5–7 days.

- Rush orders (for urgent projects): Some providers offer 24–48 hour turnaround for an additional fee (usually 20–30% of the total cost).

3. What file formats do Italian providers accept for CAD designs?

The most common formats are STL, STEP, and IGES. Most providers also accept OBJ or 3MF files. If you’re unsure, ask your provider—they’ll often help you convert files if needed.

4. Do Italian providers offer post-processing for prototypes?

Yes! Common post-processing services include sanding, painting, dyeing, and assembly. For example, a jewelry brand might request gold plating for an SLA prototype, while an automotive client might need heat treatment for a CNC-machined part. Post-processing adds 1–2 days to the timeline and 10–30% to the cost.

5. Are Italian rapid prototyping services more expensive than other EU countries?

Prices are competitive with other Western EU countries (e.g., Germany, France). While you may pay slightly more than in Eastern Europe, you’re getting access to specialized expertise (especially in design-focused industries) and stricter quality control. For many clients, the extra cost is worth it to avoid costly rework later.