Introduction: From Computer Design to Real Parts

The journey from a computer CAD model to a real, working part is the most important phase in product development. Success depends on speed and accuracy. Getting real prototype parts in your hands quickly allows for faster design testing, function checking, and feedback from others. This guide provides a clear path to navigate the complex world of rapid manufacturing. We will explore the main technologies that turn your designs into reality, from cutting away material to adding material layer by layer.

The Prototyping Challenge

Engineers and designers constantly balance speed, cost, material properties, and precision. Choosing the wrong process can lead to expensive delays, parts that break during testing, or prototypes that don’t accurately represent the final product. The challenge is not just to make a part, but to make the right part for the current stage of development.

Your Manufacturing Roadmap

We have organized this guide to help you make smart decisions. We will cover the essential technologies and processes for creating high-quality prototype parts efficiently.

- Decision-Making Chart: A direct comparison of technologies based on key project needs.

- CNC Machining: For precise parts from production-grade metals and plastics.

- 3D Printing (Additive Manufacturing): For complex shapes and speed, covering SLA, SLS, and MJF.

- Sheet Metal Manufacturing: For enclosures, brackets, and structural panels.

- Urethane Casting: For small batches of pre-production parts.

- Finishing & Quality Control: The important final steps to ensure your part is perfect.

- Expert Problem-Solving: Solutions to common prototyping problems we see every day.

Choosing the Right Technology

No single manufacturing technology is the best choice for all prototype parts. The best method depends entirely on your specific needs. A part designed for a visual model has very different needs than one intended for a high-stress function test. Making the right choice upfront saves time, reduces cost, and gives more valuable feedback.

Key Decision Factors

Your decision should be guided by four main factors: speed (lead time), cost (per part), complexity (geometric freedom), and scale (quantity of parts). A cosmetic prototype for a trade show prioritizes speed and surface finish over material strength. A functional engine component, however, demands high-strength, production-intent materials and tight tolerances above all else.

Prototyping Technology Chart

To simplify this decision, we use a comparison chart. Use this table to quickly identify the technologies that best align with your project’s most critical needs.

| Technology | Best For | Lead Time | Typical Tolerance | Material Strength | Relative Cost per Part |

| CNC Machining | High-precision functional parts, production-intent materials | 1-5 days | +/- 0.125mm | Excellent | High (for 1), Medium (for 10+) |

| SLA 3D Printing | High-detail cosmetic models, fit checks, master patterns | 1-3 days | +/- 0.1mm | Low to Medium | Medium |

| SLS 3D Printing | Durable functional parts, complex geometries, snap-fits | 1-3 days | +/- 0.25mm | Good | Medium |

| MJF 3D Printing | Fast, functional nylon parts with good consistent properties | 1-3 days | +/- 0.25mm | Very Good | Medium |

| Sheet Metal | Enclosures, brackets, panels, flat or bent components | 2-5 days | +/- 0.2mm | Excellent | Low to Medium |

| Urethane Casting | Small series (10-50) of high-quality parts | 7-15 days | +/- 0.3mm | Good to Very Good | Low (for 10+) |

CNC Machining for Prototypes

CNC (Computer Numerical Control) machining is the standard for precision. It is a subtractive manufacturing process, meaning it starts with a solid block of material (a “blank”) and selectively removes material using cutting tools to achieve the final shape. This method produces parts with excellent mechanical properties and tight tolerances.

What is CNC Machining?

A computer program, created from your CAD file, controls the movements of the cutting tools. Multi-axis machines (3-axis, 4-axis, and 5-axis) can create highly complex shapes by rotating the workpiece or the tool head. The result is a part that is precisely carved from a production-grade material, making it ideal for rigorous functional testing.

When to Choose CNC

We recommend CNC machining for prototype parts when your priorities include:

- High-precision requirements: When critical dimensions, flatness, or hole positions must be exact.

- Testing with production-intent materials: To validate a design using the exact same metal or plastic that will be used in mass production (e.g., Aluminum 6061, Stainless Steel 304).

- Superior strength and durability: When the prototype will be subjected to significant mechanical stress, loads, or thermal cycles.

Materials and Tolerances

CNC machining offers the widest range of engineering materials.

- Metals: Aluminum (6061, 7075), Stainless Steel (304, 316), Mild Steel, Titanium, Brass.

- Plastics: ABS, Polycarbonate (PC), Nylon, Delrin (POM), PEEK.

For tolerances, a standard CNC process can reliably hold dimensions to +/- 0.125mm (+/- 0.005″). This is sufficient for most prototyping applications. Tighter tolerances, such as +/- 0.025mm, are achievable but require more precise setups, specialized tooling, and slower machining speeds, which increases cost. Always specify only the critical tolerances on your drawing to manage expense.

Additive Manufacturing (3D Printing)

Additive manufacturing, commonly known as 3D printing, builds parts layer by layer from a digital file. This approach offers unmatched geometric freedom and speed, making it a cornerstone of modern rapid prototyping. Instead of removing material, it adds it, allowing for the creation of intricate internal channels, complex organic shapes, and consolidated assemblies that are impossible to machine. We will focus on the three most relevant professional technologies: SLA, SLS, and MJF.

Stereolithography (SLA)

SLA works by using an ultraviolet (UV) laser to selectively cure a liquid photopolymer resin in a vat, layer by layer.

- Best for: High-detail cosmetic prototypes, presentation models, and master patterns for urethane casting. Its ability to produce extremely fine features makes it perfect for fit and form checks where appearance is most important.

- Key Characteristics: SLA is known for its excellent, smooth surface finish, often resembling injection-molded plastic. It achieves high resolution with typical layer heights between 25 and 100 microns. However, standard resins can be brittle and are not ideal for functional parts requiring high impact strength.

Selective Laser Sintering (SLS)

SLS uses a high-powered laser to fuse or sinter powdered polymer particles, typically nylon (PA11, PA12), together.

- Best for: Durable, functional prototypes with complex shapes. Because the unfused powder supports the part during printing, SLS requires no dedicated support structures. This allows for intricate internal features, living hinges, and snap-fit assemblies.

- Key Characteristics: SLS parts are strong, temperature-resistant, and suitable for real-world functional testing. The surface finish is slightly grainy or matte. They offer a good balance of strength and flexibility.

Multi Jet Fusion (MJF)

MJF is another powder-bed fusion technology, similar to SLS, but with a different process. It deposits a fusing agent onto a layer of polymer powder, which is then fused by an infrared heating element.

- Best for: Rapid production of functional nylon prototypes where speed and mechanical consistency are key. It is often faster than SLS for full builds.

- Key Characteristics: MJF parts, typically made from PA12, have a more uniform grey or black finish and exhibit more consistent mechanical properties (strength is more consistent in all directions) than SLS. The tensile strength of MJF PA12 is often slightly higher than standard SLS PA12, making it an excellent choice for parts that need to withstand force. The process is extremely fast, allowing for next-day delivery of parts.

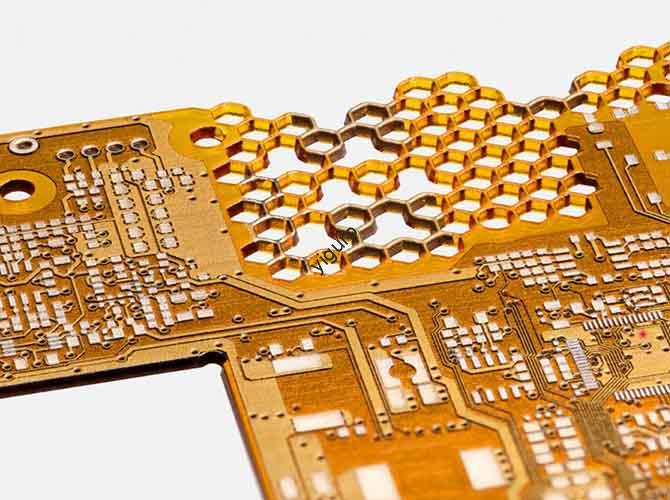

Sheet Metal Manufacturing

For many products, especially in electronics, robotics, and industrial equipment, the housing is just as important as the internal components. Sheet metal forming and laser cutting are the go-to processes for creating robust, cost-effective prototype parts like enclosures, brackets, and panels.

The Manufacturing Process

The workflow is straightforward and efficient, moving a design from a flat pattern to a three-dimensional object.

1. Design: The 3D model is “unfolded” into a 2D flat pattern in CAD software.

2. Laser Cut: A high-powered laser cuts the 2D pattern from a sheet of metal (e.g., aluminum, steel, stainless steel) with high precision.

3. Bend/Form: The cut sheet is placed in a press brake, where it is bent along predefined lines to form the final 3D shape.

4. Finish: Secondary operations like inserting hardware (PEM inserts), welding, or applying a finish (powder coating, anodizing) complete the part.

Ideal Sheet Metal Applications

Sheet metal is ideal when you need strong, lightweight parts with a uniform wall thickness. It is the primary method for prototyping:

- Electronic enclosures and chassis.

- Mounting brackets and support structures.

- Faceplates and control panels.

- Server racks and housing components.

Key Design Considerations

To ensure a successful sheet metal prototype, we advise following a few best practices:

- Maintain a uniform wall thickness throughout the part.

- Specify bend radii that are at least equal to the material thickness to prevent cracking.

- Place holes and cutouts a safe distance away from bends to avoid distortion. A good rule of thumb is at least 2.5x the material thickness plus the bend radius.

- Consider the grain direction of the material for bends to maximize strength.

Urethane Casting for Prototypes

What happens when you need more than one or two prototype parts for beta testing, market research, or a small pre-production run? Machining 15 identical parts can be prohibitively expensive, and injection molding tooling is not yet justified. This is where urethane casting provides an elegant solution. It is a process that bridges the gap between single prototypes and low-volume production.

How Urethane Casting Works

The process uses a soft silicone mold to create high-quality copies of a master pattern.

1. Create a Master Pattern: A perfect, highly-finished master pattern is created, typically using SLA 3D printing or CNC machining.

2. Create a Silicone Mold: The master pattern is suspended in a box, and liquid silicone is poured around it. Once cured, the mold is cut in half, and the master is removed, leaving a precise cavity.

3. Cast Urethane Parts: The two halves of the mold are reassembled, and a two-part liquid urethane is poured into the cavity. The urethane cures, forming a plastic part that is an exact replica of the master.

When to Use Casting

Urethane casting is the ideal choice when you need a small series of parts (typically 10-50 units per mold) with properties that mimic production plastics. It is perfect for:

- Beta testing units for early customer feedback.

- Marketing samples and trade show models.

- First assembly line setup and testing.

Advantages and Limitations

The primary advantage is cost-effectiveness at low volumes; the cost per part drops significantly after the first few units. It also allows for a wide range of material properties, from rigid plastics to rubber-like elastomers, and parts can be overmolded or colored. The main limitation is the mold life; a single silicone mold typically lasts for about 20-25 shots before it starts to degrade, affecting dimensional accuracy.

Post-Processing and Finishes

A raw part directly from a machine is rarely the final product. Post-processing and finishing are critical steps that transform a raw part into a functional, aesthetically pleasing prototype that accurately represents your design intent. These operations can improve surface quality, enhance mechanical properties, and provide the look and feel of a final product.

Why Finishing Matters

For a cosmetic prototype, the finish is everything. For a functional part, a finish like anodizing can provide crucial corrosion resistance and surface hardness. Understanding the available options ensures your prototype not only works correctly but also looks the part, which is essential for stakeholder buy-in and user testing.

Finishes for Machined Parts

- As-Machined: The standard finish with visible tool marks. Cost-effective and suitable for many functional parts.

- Bead Blasting: Creates a uniform, non-reflective matte or satin surface finish by bombarding the part with fine glass beads.

- Anodizing (Type II & Type III): An electrochemical process for aluminum parts that creates a hard, durable, corrosion-resistant outer layer. Type II allows for clear or colored finishes, while Type III (hardcoat) provides superior wear resistance.

- Powder Coating: A durable, paint-like finish applied as a dry powder and cured with heat. Offers excellent protection and a wide range of colors.

Finishes for 3D Prints

- Sanding: Manual or automated sanding to remove layer lines and prepare the surface for painting.

- Vapor Smoothing: Exposing certain polymer parts (like ABS or Polycarbonate) to a chemical vapor that melts the outer surface, resulting in a smooth, glossy, injection-mold-like finish. It also seals the part, making it watertight.

- Painting: Applying primer and paint to achieve specific colors and finishes, essential for high-fidelity cosmetic models.

Quality Checks and Testing

Once your prototype part is made and finished, one final, critical phase remains: verification and validation. This step ensures that what was made matches what was designed. Skipping quality checks can lead to discovering fitment or functional issues late in the assembly process, causing frustrating delays and rework.

The Importance of Verification

A prototype’s purpose is to provide data. That data is only reliable if the part is dimensionally accurate and meets all design specifications. Verification confirms that the part you are holding is a true physical representation of your CAD model, allowing you to trust the results of your fit and functional tests.

A 3-Step Quality Check

We recommend a systematic, three-step process for every prototype part you receive.

1. Dimensional Inspection: Use digital calipers or micrometers to measure critical dimensions noted on your engineering drawing. For highly complex parts, a Coordinate Measuring Machine (CMM) or a 3D scanner can be used to compare the entire part geometry against the original CAD file.

2. Visual Inspection: Carefully check the part for any cosmetic defects, such as scratches, dents, or blemishes. Verify that the correct material was used and that the specified surface finish has been applied correctly.

3. Fit Testing: This is the ultimate test. Assemble the prototype part with its mating components in the final assembly. Check for proper fit, alignment, and clearance. Actuate any moving parts to ensure they function smoothly without interference.

Common Problems & Problem-Solving

Over years of making millions of prototype parts, our engineers have seen nearly every possible issue. Many frustrating problems have straightforward solutions if you know where to look. Here is our expert guidance on troubleshooting some of the most common prototyping problems.

Problem: Part Warped/Cracked

A common issue we encounter, especially with 3D printing, is a part that comes off the build plate warped, or a CNC part that cracks during or after machining.

- Likely Causes: For 3D prints, this is often due to thermal stress from uneven cooling, poor orientation on the build plate, or excessively thin walls. For CNC parts, it can be internal stress within the material being released during machining.

- Solutions:

1. Reorient the 3D printed part on the build plate to minimize large, flat surfaces parallel to the plate.

2. Add generous fillets to sharp internal corners in your design to distribute stress.

3. Increase wall thickness in critical areas. For CNC, discuss a post-machining stress relief heat treatment with your machinist for certain materials.

Problem: Features Out of Tolerance

You receive your machined part, but a critical hole diameter or feature location is just outside the specified tolerance.

- Likely Causes: This can result from tool deflection during cutting, improper workholding (fixturing) that allows the part to shift slightly, or vibrations in the machine.

- Solutions: Here’s how our engineers typically solve this:

1. Clearly call out only the most critical dimensions on your 2D drawing. This tells the machinist where to focus their attention.

2. For complex or thin-walled parts, discuss the fixturing strategy with the manufacturing partner beforehand.

3. For very tight tolerances, a final finishing pass with a sharp tool at a lower speed can be specified.

Problem: Parts Don’t Fit Together

You have all your prototype parts, but they don’t assemble as intended. Holes are misaligned, or there is an unexpected interference.

- Likely Causes: The most common culprit is tolerance stack-up, where the acceptable variation in several parts accumulates to cause a mismatch. Other causes include using materials with different thermal expansion rates or a simple design oversight.

- Solutions:

1. Perform a tolerance stack-up analysis in your CAD software before finalizing designs.

2. When possible, have all mating parts made using the same process and at the same time for better consistency.

3. For a quick sanity check, 3D print a low-cost version of the entire assembly for a preliminary fit test before committing to more expensive CNC or cast parts.

Conclusion: Your Next Project

The path from digital design to a successful physical prototype is paved with informed decisions. There is no single “best” technology, only the right technology for your specific application. By understanding the core strengths of each process—the precision of CNC machining, the speed and complexity of 3D printing, the robustness of sheet metal, and the scalability of urethane casting—you empower yourself to make the optimal choice.

The key is to align the manufacturing method with your project’s goals. Choose the process that delivers the speed, material properties, and accuracy you need to validate your design and move forward with confidence. With this knowledge, you are well-equipped to turn your next great idea into a tangible reality.