If you’ve ever wondered how complex parts like engine blocks, surgical instruments, or even smartphone housings are made, the answer often lies in process milling. As one of the most versatile subtractive machining methods, milling plays a critical role in nearly every manufacturing industry—from automotive to aerospace, medical to electronics. But what exactly is process milling, how does it work, and why is it so indispensable? In this guide, we’ll break down everything you need to know, from the basics of the process to advanced techniques, real-world applications, and how to choose the right tools for the job. Whether you’re a manufacturing student, a small business owner looking to invest in milling equipment, or simply curious about how everyday products are made, this article will give you the knowledge you need to understand and appreciate process milling.

1. What Is Process Milling, and Why Does It Matter?

At its core, process milling is a subtractive manufacturing technique that uses a rotating, multi-edged cutting tool to remove material from a solid workpiece. Unlike other machining methods (such as turning, which spins the workpiece instead of the tool), milling allows for precise control over the shape, depth, and detail of the final part. But what makes it stand out? Let’s start with the basics.

1.1 The Definition of Process Milling

Process milling isn’t just a single step—it’s a series of controlled operations designed to transform a raw material (like a metal block or plastic sheet) into a finished part with specific dimensions and features. The key elements of the process include:

- A workpiece: The raw material being shaped (e.g., aluminum, steel, wood, or plastic).

- A rotary cutting tool: Typically a drill bit, end mill, or face mill with multiple sharp edges that spin at high speeds.

- A milling machine: The equipment that holds and moves the workpiece (or the tool) to control material removal.

- Cutting parameters: Variables like speed (how fast the tool spins), feed rate (how quickly the tool or workpiece moves), and depth of cut (how much material is removed per pass).

What makes milling unique is its ability to create both simple features (like flat surfaces or slots) and complex ones (like 3D contours, gear teeth, or internal threads) in a single setup. This versatility is why it’s used in everything from prototyping small parts to mass-producing components for airplanes.

1.2 Why Process Milling Is Essential in Manufacturing

Milling isn’t just “another machining method”—it’s a backbone of modern manufacturing. Here’s why it matters:

- Versatility: It works with nearly every material, from soft plastics to hard metals like titanium. For example, a medical device manufacturer might use milling to create plastic housings for inhalers and stainless steel surgical forceps—all on the same type of machine (with different tools).

- Precision: Modern milling machines (especially CNC models) can achieve tolerances as tight as ±0.0001 inches (0.0025 mm). This level of accuracy is critical for parts like aerospace components, where even a tiny error could lead to catastrophic failure.

- Efficiency: For batch production, milling is cost-effective because it can quickly repeat the same process across hundreds or thousands of parts. A car manufacturer, for instance, might use a CNC milling machine to produce 10,000 identical engine brackets in a week—with consistent quality every time.

- Flexibility: Unlike specialized machines that only do one task, milling machines can be adapted to create new parts by changing the tool, adjusting parameters, or updating digital instructions (for CNC models). This makes it ideal for prototyping, where designs often change rapidly.

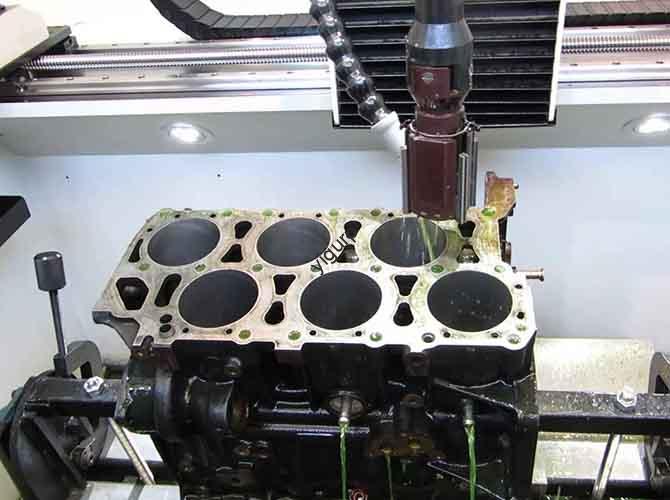

Real-World Example: In the automotive industry, process milling is used to make transmission housings. A raw aluminum block is loaded into a CNC milling machine, which uses a series of cutting tools to carve out the internal chambers (for gears), drill holes (for bolts), and smooth the outer surfaces. Without milling, creating these complex, precise parts would be slow, expensive, and prone to errors.

2. Key Factors That Influence Process Milling Success

Not all milling operations are the same—success depends on understanding and optimizing several critical factors. Whether you’re milling a small plastic part or a large steel component, these variables will determine the quality of your final product, the speed of production, and the lifespan of your tools.

2.1 Material Properties: The Foundation of Milling

The material you’re working with dictates nearly every other decision in the milling process. Harder materials require more robust tools and slower speeds, while softer materials need careful handling to avoid melting or warping. Here’s a breakdown of common materials and their milling considerations:

| Material Type | Examples | Key Milling Considerations |

| Metals | Steel, aluminum, brass, titanium | – Steel: Use high-speed steel (HSS) or carbide tools; slower cutting speeds to prevent tool wear.- Aluminum: Faster speeds (since it’s soft); carbide tools for precision.- Titanium: Extremely hard—use carbide tools with coolant to reduce heat. |

| Plastics | Acrylic, nylon, polyethylene | – Soft plastics (e.g., polyethylene): Use sharp tools to avoid melting; lower feed rates.- Rigid plastics (e.g., acrylic): Faster speeds possible, but avoid excessive heat (can cause cracking). |

| Wood | Pine, oak, maple | – Use HSS tools (cost-effective); faster speeds.- Avoid tear-out (rough edges) by using tools with fine teeth and cutting with the grain. |

Professional Tip: Always check the material’s “machinability rating” before starting. For example, 1018 steel (a common low-carbon steel) has a machinability rating of 70 (vs. 100 for 1112 steel, which is more easily machined), meaning you’ll need to adjust speeds and feeds accordingly.

2.2 Cutting Tool Selection: Choosing the Right Tool for the Job

The cutting tool is the “engine” of process milling—choose the wrong one, and you’ll get poor results, damaged tools, or even ruined workpieces. Here’s what to consider when selecting a tool:

- Tool Material:

- High-Speed Steel (HSS): Affordable, versatile, and good for soft materials (wood, aluminum, low-carbon steel). Ideal for small shops or prototyping.

- Carbide: Harder, more heat-resistant than HSS. Perfect for hard metals (titanium, stainless steel) and high-volume production. More expensive, but longer-lasting.

- Ceramic: Even harder than carbide, used for ultra-hard materials (e.g., tool steel) or high-temperature applications. Brittle, so requires careful handling.

- Tool Geometry:

- End Mills: Used for cutting slots, pockets, and contours. Available in 2-flute (for aluminum) or 4-flute (for steel) designs.

- Face Mills: Flat, disc-shaped tools used for creating flat surfaces (e.g., the top of a metal block). Have multiple teeth for fast material removal.

- Ball Nose End Mills: Rounded tips for creating 3D contours or curved surfaces (e.g., the handle of a tool).

Case Study: A aerospace manufacturer needed to mill titanium turbine blades. Initially, they used HSS tools, but the tools wore out after just 5 parts, leading to delays and increased costs. Switching to carbide tools with a titanium nitride (TiN) coating reduced tool wear by 80%, allowing them to produce 40 blades per tool—saving time and money.

2.3 Cutting Speed and Feed Rate: Balancing Speed and Quality

Cutting speed (how fast the tool spins, measured in surface feet per minute, SFM) and feed rate (how fast the tool moves across the workpiece, measured in inches per minute, IPM) are two of the most critical parameters in process milling. Get them wrong, and you’ll face:

- Too fast: Tool overheating, poor surface finish, or tool breakage.

- Too slow: Slow production, wasted time, and “rubbing” (which can damage the workpiece).

The right speed and feed rate depend on the material and tool. Here are general guidelines for common combinations:

| Material | Tool Type | Cutting Speed (SFM) | Feed Rate (IPM) |

| Aluminum | Carbide End Mill (4-flute) | 1000–2000 | 50–200 |

| Steel (1018) | HSS End Mill (4-flute) | 100–200 | 10–50 |

| Titanium | Carbide End Mill (4-flute) | 50–150 | 5–20 |

| Acrylic | HSS End Mill (2-flute) | 300–500 | 20–80 |

Pro Insight: Use a “speed and feed calculator” (available online or as apps) to get precise values for your specific setup. These calculators factor in tool diameter, material, and depth of cut to avoid guesswork.

3. The Two Fundamental Milling Processes: Face Milling vs. Peripheral Milling

While there are many specialized milling techniques, nearly all operations fall into two main categories: face milling and peripheral milling. Understanding the difference between these two is key to choosing the right method for your project. Let’s compare them side by side.

3.1 What Is Face Milling?

Face milling is used to create flat, smooth surfaces on the face of a workpiece (e.g., the top of a metal block or the base of a plastic part). Here’s how it works:

- A flat, disc-shaped face mill with multiple teeth is mounted on a vertical or horizontal spindle.

- The tool rotates, and the workpiece is fed into the tool (or the tool is fed into the workpiece).

- The entire face of the tool engages the workpiece, removing material in a single pass (or multiple passes for deeper cuts).

Key Characteristics:

- High material removal rate (fast at removing large amounts of material).

- Excellent surface finish (ideal for parts that need a smooth, flat surface for assembly).

- Works best for large, flat areas.

Applications:

- Creating the reference surface for a part (e.g., the bottom of an engine block, which needs to be flat to mount other components).

- Finishing the top of a metal plate for a machine frame.

- Smoothing the surface of a wooden tabletop (in woodworking milling).

Real-World Example: A furniture manufacturer uses a face milling machine to smooth the top of oak table blanks. The face mill removes any unevenness from the raw wood, creating a flat surface that’s ready for sanding and finishing. Without face milling, the tables would have rough, uneven tops that are hard to use.

3.2 What Is Peripheral Milling?

Peripheral milling (also called “end milling”) is used to create features like slots, pockets, grooves, or contours on the sides or edges of a workpiece. Here’s how it works:

- A cylindrical end mill with teeth along its circumference (and sometimes its end) is used.

- Only the periphery (sides) of the tool engages the workpiece (not the entire face).

- The tool can move in multiple directions (up/down, left/right, forward/backward) to create complex shapes.

Key Characteristics:

- Moderate material removal rate (slower than face milling but more precise for details).

- Versatile for creating complex features (e.g., slots for bolts, curved edges on a smartphone case).

- Can be used with multi-axis machines to create 3D shapes.

Applications:

- Cutting slots in a metal bracket for screws.

- Creating the teeth on a gear or sprocket.

- Machining the contour of a prosthetic limb (to match the shape of a patient’s body).

Real-World Example: A medical device company uses peripheral milling to create the slots in a surgical bone plate. The end mill cuts precise, narrow slots where screws will be inserted to attach the plate to a patient’s bone. The accuracy of peripheral milling ensures the slots align perfectly with the screws, preventing the plate from shifting during surgery.

3.3 Face Milling vs. Peripheral Milling: A Side-by-Side Comparison

To help you choose the right process, here’s a detailed comparison:

| Feature | Face Milling | Peripheral Milling |

| Tool Engagement | Entire face of the tool | Only the periphery (sides) of the tool |

| Primary Function | Creating flat, smooth surfaces | Creating slots, pockets, grooves, or contours |

| Material Removal Rate | High (fast at removing large amounts of material) | Moderate (slower but more precise) |

| Surface Finish | Excellent (smooth, flat surfaces) | Varies (depends on tool diameter and feed rate; can be smooth for fine cuts) |

| Tool Type Used | Face mill (disc-shaped with multiple teeth) | End mill (cylindrical with teeth on circumference/end) |

| Best For | Large, flat areas; reference surfaces | Complex features; details; 3D shapes |

| Common Applications | Engine block faces, table tops, metal plate finishing | Gear teeth, surgical instrument slots, smartphone case contours |

4. Types of Milling Machines: Which One Should You Use?

The success of your milling process also depends on choosing the right machine. There are four main types of milling machines, each with unique characteristics and applications. Let’s break them down, so you can decide which is best for your needs.

4.1 Vertical Milling Machine (VMC)

The Vertical Milling Machine (VMC) is the most common type, especially in small shops, prototyping facilities, and general manufacturing. Here’s what you need to know:

- How it works: The cutting tool is mounted on a vertical spindle (it spins straight up and down), and the workpiece is placed on a table that moves horizontally (X-axis) and vertically (Y-axis). Some VMCs also have a rotating table (Z-axis) for 3D work.

- Key Characteristics:

- Versatile: Can handle both face milling and peripheral milling.

- Good visibility: Since the tool is above the workpiece, you can easily see the cutting process (helpful for setup and quality checks).

- Compact: Smaller than horizontal milling machines, making it ideal for shops with limited space.

- Applications:

- General-purpose machining (e.g., making brackets, washers, or small parts).

- Prototype creation (since it’s easy to adjust for new designs).

- 3D shaping (with multi-axis VMCs, like those used to make custom jewelry or dental crowns).

Case Study: A startup that designs custom drone parts uses a VMC to prototype their propeller housings. They start with a block of lightweight aluminum, load it into the VMC, and use a ball nose end mill to cut the curved shape of the housing. The VMC’s visibility allows them to check the shape as it’s being cut, and they can quickly adjust the digital design if needed—saving weeks of development time.

4.2 Horizontal Milling Machine (HMC)

The Horizontal Milling Machine (HMC) is designed for heavy-duty work and large workpieces. Here’s the breakdown:

- How it works: The cutting tool is mounted on a horizontal spindle (it spins side to side), and the workpiece is held on a table that moves vertically and horizontally. Many HMCs have a “pallet changer”—a feature that allows you to load a new workpiece while the machine is cutting, reducing downtime.

- Key Characteristics:

- Ideal for large parts: Can handle workpieces that weigh hundreds or thousands of pounds (e.g., engine blocks, construction equipment components).

- Long cuts: Perfect for machining parts that need long, continuous cuts along their length (e.g., a steel beam with a slot cut down its entire length).

- High productivity: Pallet changers and fast spindle speeds make HMCs great for high-volume production.

- Applications:

- Aerospace manufacturing (e.g., machining fuselage panels or landing gear parts).

- Automotive production (e.g., making large transmission cases).

- Construction equipment (e.g., machining parts for bulldozers or cranes).

4.3 Bed Mills

Bed mills are the “workhorses” of milling—large, powerful machines designed for heavy-duty operations. Here’s what you need to know:

- How it works: The workpiece is mounted on a fixed bed (instead of a moving table), and the cutting tool moves over the workpiece. Bed mills have a large, rigid frame that can handle heavy loads.

- Key Characteristics:

- Large and powerful: Can machine workpieces up to several feet long and weighing thousands of pounds.

- High stability: The fixed bed reduces vibration, which improves precision for large cuts.

- Slow but precise: Not as fast as VMCs or HMCs, but ideal for jobs that require extreme accuracy.

- Applications:

- Power generation (e.g., machining turbine casings for power plants).

- Oil and gas industry (e.g., making large valves or pipeline components).

- Heavy equipment manufacturing (e.g., machining engine blocks for ships or locomotives).

4.4 CNC Milling Machines

CNC (Computer Numerical Control) Milling Machines are the most advanced type—they use digital instructions (from a CAD/CAM file) to automate the milling process. Here’s why they’re game-changers:

- How it works: Instead of a operator manually moving the table or tool, the CNC machine follows a pre-programmed code. The code tells the machine exactly where to move the tool, how fast to spin it, and how much material to remove.

- Key Characteristics:

- Precision: Can achieve

- tolerances as tight as ±0.0001 inches (0.0025 mm)—far more precise than manual machines.

- Consistency: Every part produced is identical, even across thousands of units. This is critical for industries like automotive, where parts must fit together perfectly.

- Automation: Once programmed, CNC machines can run 24/7 with minimal human intervention. This reduces labor costs and increases production efficiency.

- Flexibility: Changing the part design only requires updating the CAD/CAM file—no need to reconfigure the entire machine. This is ideal for prototyping or small-batch production of custom parts.

- Applications:

- Medical device manufacturing (e.g., machining custom knee implants with precise 3D contours).

- Electronics (e.g., making the aluminum housings for laptops or smartphones with tight tolerances).

- Aerospace (e.g., producing complex turbine blades with intricate internal channels).

Key Statistic: According to a 2024 report by the Association for Manufacturing Technology, over 75% of all precision machining operations in North America now use CNC milling machines—up from 50% in 2010. This growth highlights the shift toward automation and precision in modern manufacturing.

5. Advanced Milling Techniques: Taking Process Milling to the Next Level

For complex or high-precision parts, basic milling techniques may not be enough. Advanced methods have been developed to tackle challenging designs, improve efficiency, and reduce costs. Let’s explore three of the most important advanced milling techniques.

5.1 3-Axis vs. 5-Axis Milling: What’s the Difference?

Most milling machines operate on 3 axes (X, Y, Z), which allow the tool to move left/right, forward/backward, and up/down. However, 5-axis milling adds two more rotational axes (A and B, or A and C), which let the workpiece or tool tilt and rotate. Here’s how they compare:

| Feature | 3-Axis Milling | 5-Axis Milling |

| Axes of Movement | X (left/right), Y (forward/backward), Z (up/down) | X, Y, Z + 2 rotational axes (e.g., A = tilt, C = rotate) |

| Complexity of Parts | Can handle simple to moderately complex parts (e.g., flat surfaces, slots, basic 3D shapes) | Can handle highly complex parts (e.g., turbine blades, custom implants, aerospace components with curved surfaces) |

| Setup Time | Faster (fewer axes to configure) | Longer (more axes to program and calibrate) |

| Cost | Lower (less complex machinery) | Higher (more advanced technology) |

| Best For | Prototyping, small-batch production of simple parts, general manufacturing | High-precision industries (aerospace, medical), complex part designs, high-volume production of intricate components |

Real-World Example: A aerospace company needed to machine a turbine blade with a curved surface and internal cooling channels. Using a 3-axis machine would have required multiple setups (rotating the blade manually between cuts), leading to errors and longer production time. Switching to a 5-axis machine allowed them to cut the entire blade in one setup—reducing production time by 40% and improving precision by 25%.

5.2 High-Speed Milling (HSM): Faster, More Efficient Machining

High-Speed Milling (HSM) is a technique that uses extremely high cutting speeds (often 2–10 times faster than traditional milling) and high feed rates to remove material quickly. While it may seem counterintuitive (faster speeds could cause tool wear), HSM works because:

- The tool cuts material in smaller chips, reducing heat buildup (since less friction is generated).

- The high feed rate means the tool spends less time in contact with the workpiece, further reducing heat and tool wear.

Key Benefits of HSM:

- Faster production: Can reduce machining time by 30–60% compared to traditional milling.

- Better surface finish: Smaller chips and less heat lead to smoother surfaces, reducing the need for post-machining finishing (like sanding or polishing).

- Longer tool life: Despite higher speeds, HSM often extends tool life because the tool doesn’t overheat.

Applications:

- Mold and die manufacturing (e.g., making plastic injection molds with complex cavities).

- Automotive prototyping (e.g., quickly producing test parts for new car models).

- Electronics (e.g., machining small, precise parts for smartphones or wearables).

Professional Tip: HSM requires specialized tools (often carbide or ceramic) and a rigid machine (to handle high speeds without vibration). It’s also important to use a high-pressure coolant system to remove chips and cool the tool quickly.

5.3 Micro-Milling: Precision for Tiny Parts

Micro-Milling is a specialized technique used to machine extremely small parts (often with features as small as 0.001 inches, or 0.025 mm). It’s critical for industries that require miniaturized components, like electronics and medical devices.

Key Characteristics of Micro-Milling:

- Small tools: Uses end mills with diameters as small as 0.001 inches (0.025 mm)—thinner than a human hair.

- High precision: Can achieve tolerances as tight as ±0.00005 inches (0.0013 mm).

- Slow feed rates: To avoid breaking the tiny tools, feed rates are much slower than traditional milling (often 0.1–1 IPM).

Applications:

- Medical devices (e.g., machining the tiny components of a pacemaker or a micro-needle for drug delivery).

- Electronics (e.g., making the small connectors in a smartphone or the components of a microchip).

- Aerospace (e.g., machining tiny sensors for aircraft engines).

Case Study: A medical device company needed to create a micro-needle array (a patch with hundreds of tiny needles) for delivering vaccines painlessly. Using micro-milling, they were able to machine each needle (0.005 inches in diameter) with precise sharpness—ensuring the needles could penetrate the skin without causing pain. Traditional milling would have been unable to create such small, precise features.

6. Yigu Technology’s Perspective on Process Milling

At Yigu Technology, we’ve worked closely with manufacturers across industries to optimize their process milling operations—from small shops to large aerospace firms. Based on our experience, process milling is more than just a machining technique; it’s a critical enabler of innovation and efficiency in modern manufacturing.

One key trend we’ve observed is the growing adoption of 5-axis CNC milling, especially in high-precision industries like medical and aerospace. Manufacturers are no longer satisfied with “good enough” precision—they need parts that meet ultra-tight tolerances (±0.0001 inches or less) to keep up with advancing technologies (e.g., smaller medical devices, more efficient aircraft engines). 5-axis milling delivers this precision while reducing setup time, making it a game-changer for complex part production.

Another trend is the shift toward sustainability in milling. Manufacturers are increasingly looking for ways to reduce waste (e.g., using high-speed milling to minimize material scrap) and energy consumption (e.g., using efficient CNC machines that only use power when cutting). At Yigu Technology, we help our clients implement these sustainable practices—not just to reduce their environmental impact, but also to cut costs (e.g., less scrap means lower material expenses).

Finally, we believe that training is critical to maximizing the value of process milling. Even the most advanced CNC machine will underperform if operators don’t understand how to optimize cutting parameters, select the right tools, or troubleshoot issues like tool wear. We offer training programs to help manufacturers upskill their teams, ensuring they can get the most out of their milling equipment.

7. FAQ: Answers to Common Questions About Process Milling

Q1: What’s the difference between milling and turning?

A: Milling and turning are both subtractive machining methods, but they differ in how the tool and workpiece move. In milling, the cutting tool rotates, and the workpiece moves (or the tool moves over the workpiece) to remove material. This allows for complex shapes and features (e.g., slots, contours). In turning, the workpiece rotates, and a stationary cutting tool removes material from the outer or inner surface. Turning is ideal for cylindrical parts (e.g., bolts, shafts) but can’t create complex shapes like milling.

Q2: Can process milling be used for non-metallic materials?

A: Yes! Process milling works with a wide range of non-metallic materials, including plastics (acrylic, nylon), wood (pine, oak), composites (carbon fiber, fiberglass), and even ceramics (for high-temperature applications). The key is to select the right tool (e.g., HSS for wood, carbide for composites) and adjust cutting parameters (e.g., lower speeds for soft plastics to avoid melting).

Q3: How much does a milling machine cost?

A: The cost of a milling machine depends on the type, size, and complexity:

- Manual vertical milling machine: \(5,000–\)20,000 (ideal for small shops or hobbyists).

- CNC vertical milling machine (VMC): \(20,000–\)100,000 (for small to medium-sized parts).

- CNC horizontal milling machine (HMC): \(100,000–\)500,000+ (for large, heavy-duty parts).

- 5-axis CNC milling machine: \(200,000–\)1,000,000+ (for complex, high-precision parts).

Q4: How long does it take to learn process milling?

A: Learning the basics of manual milling (e.g., setting up a workpiece, using simple tools) can take 1–3 months with hands-on training. Mastering CNC milling (including programming with CAD/CAM software, optimizing parameters, and troubleshooting) typically takes 6–12 months of dedicated training and practice. Advanced techniques like 5-axis milling or micro-milling may take additional time to learn.

Q5: What’s the future of process milling?

A: The future of process milling is focused on three key areas:

- Automation: More manufacturers will adopt fully automated CNC systems (with robotics for loading/unloading workpieces) to run 24/7.

- AI and Machine Learning: AI tools will be used to optimize cutting parameters in real time (e.g., adjusting speed and feed rate to reduce tool wear) and predict maintenance needs (e.g., alerting operators when a tool is about to fail).

- Sustainability: New technologies (e.g., dry milling, which uses no coolant) and materials (e.g., recycled metals) will make milling more environmentally friendly while reducing costs.