Our POM Vacuum Casting Services

POM Vacuum Casting combines precision and efficiency to deliver high-quality, durable components for diverse industries. Whether you need tight-tolerance parts, custom surface finishes, or cost-effective prototyping, our expertise in POM Vacuum Casting ensures your projects meet the highest standards—turning your ideas into reliable, production-ready products with speed and accuracy.

What is POM Vacuum Casting?

POM Vacuum Casting, also known as Polyoxymethylene Vacuum Casting, is a specialized manufacturing process designed to produce high-precision parts using POM (a thermoplastic polymer with excellent mechanical properties). This section breaks down its definition, meaning, concept, and provides a clear overview and introduction to how it works.

At its core, the process uses a vacuum to eliminate air bubbles from the molten POM material, ensuring uniform density and minimal defects in the final part. Unlike traditional casting methods, the vacuum environment allows for tighter control over the material flow, making it ideal for parts requiring consistent performance. Table 1 below summarizes key details of POM Vacuum Casting.

| Aspect | Details |

| Core Concept | Use of vacuum to remove air from molten POM, ensuring high part quality |

| Key Material | POM (Polyoxymethylene) – rigid, low-friction, chemical-resistant polymer |

| Primary Goal | Produce precision parts with tight tolerances and minimal defects |

| Common Use Cases | Prototyping, small-batch production, complex geometric parts |

Our Capabilities in POM Vacuum Casting

At Yigu Technology, our capabilities in POM Vacuum Casting are backed by years of experience and a team of skilled engineers. We bring unmatched expertise, skills, competence, and proficiency to every project, ensuring we meet and exceed client expectations. Our abilities extend across various stages, from design optimization to final production.

Table 2 highlights our key capabilities and how they benefit your projects:

| Capability | Description | Client Benefit |

| Design for Manufacturability (DFM) | Optimize part designs to fit POM Vacuum Casting processes | Reduces production time and costs; improves part performance |

| Material Selection | Advise on POM grades (e.g., homopolymer vs. copolymer) for specific needs | Ensures parts match required mechanical properties (strength, flexibility) |

| Quality Control | In-line inspections using advanced measurement tools (e.g., CMM) | Guarantees parts meet tight tolerances and industry standards |

| Customization | Adapt processes for unique part geometries or surface finishes | Delivers tailor-made solutions for niche applications |

The POM Vacuum Casting Process

The POM Vacuum Casting process follows a structured procedure with clear steps, a defined workflow, and a logical sequence of operations to ensure consistency. Below is a step-by-step breakdown of the process, along with a workflow diagram description.

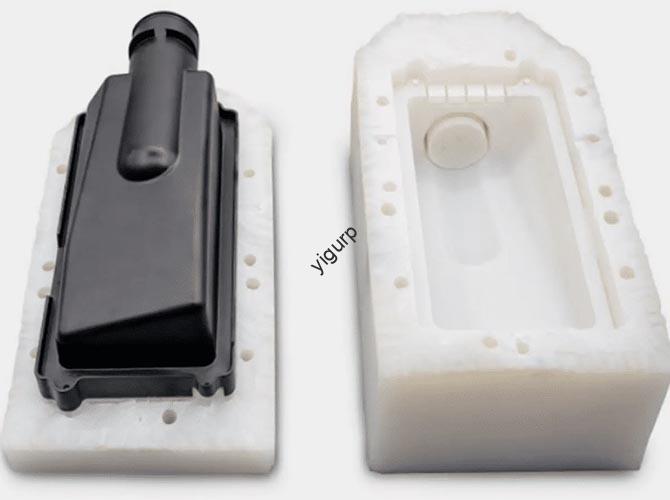

Step 1: Mold Preparation

First, a mold (typically made of silicone or metal for durability) is cleaned and prepped. The mold cavity is designed to match the final part’s geometry, with vents to allow air escape during the vacuum phase.

Step 2: Material Melting

POM pellets are heated to their melting point (160–175°C for most grades) in an extruder. The molten POM is then transferred to a holding chamber, where its temperature is maintained for optimal flow.

Step 3: Vacuum Application

The mold is placed in a vacuum chamber, and air is removed (vacuum level: 0.02–0.05 MPa). This step is critical to prevent air bubbles from forming in the molten POM, which would weaken the final part.

Step 4: Casting and Cooling

Molten POM is injected into the vacuum-sealed mold under low pressure. The mold is then cooled (using water or air) to solidify the POM. Cooling time varies by part thickness (typically 5–15 minutes).

Step 5: Demolding and Post-Processing

Once cooled, the mold is opened, and the part is removed. Post-processing steps (e.g., trimming excess material, surface treatment) are performed to meet final specifications.

Table 3 summarizes the process timeline for a standard POM part (50mm x 30mm x 5mm):

| Process Step | Time Required |

| Mold Preparation | 10–15 minutes |

| Material Melting | 5–8 minutes |

| Vacuum Application & Casting | 3–5 minutes |

| Cooling | 8–12 minutes |

| Demolding & Post-Processing | 10–15 minutes |

| Total Cycle Time | 36–55 minutes |

Materials Used in POM Vacuum Casting

POM Vacuum Casting relies on high-quality materials, including POM polymers and additional substances or components to enhance part properties. Understanding the raw materials (such as POM grades) and how they interact with other polymers, composites, or alloys is key to achieving desired part performance.

Primary Material: POM

POM (Polyoxymethylene) is a thermoplastic known for its high stiffness, low friction, and excellent dimensional stability. Two common grades used in vacuum casting are:

- POM Homopolymer: Higher tensile strength and heat resistance (suitable for high-stress parts).

- POM Copolymer: Better impact resistance and chemical stability (ideal for parts exposed to oils or solvents).

Secondary Materials

To improve specific properties, we may add:

- Reinforcements: Glass fibers or carbon fibers (increase strength and rigidity).

- Additives: UV stabilizers (prevent degradation from sunlight) or lubricants (reduce friction).

- Composites/Alloys: Blends with other polymers (e.g., nylon) for enhanced flexibility.

Table 4 compares the properties of common POM grades used in our processes:

| POM Grade | Tensile Strength (MPa) | Impact Strength (kJ/m²) | Heat Resistance (°C) | Ideal Application |

| POM Homopolymer (Delrin 100) | 60–65 | 5–7 | 100–110 | Gear components, fasteners |

| POM Copolymer (Celcon M90) | 50–55 | 8–10 | 90–100 | Medical devices, automotive parts |

| Glass-Filled POM (30% glass) | 85–90 | 4–6 | 110–120 | Structural brackets |

Surface Treatment for POM Vacuum Casting Parts

Surface treatment is a critical step in POM Vacuum Casting, as it enhances part appearance, durability, and functionality. Our range of surface treatment options includes various finishing, coating, painting, plating, polishing, and texturing techniques to meet your specific needs.

Table 5 outlines common surface treatments, their processes, and benefits:

| Surface Treatment | Process Description | Benefits |

| Polishing | Abrasive materials (e.g., sandpaper, buffing wheels) to smooth surfaces | Improves aesthetics; reduces friction; easier cleaning |

| Painting | Application of solvent-based or water-based paints (custom colors) | Enhances appearance; provides corrosion resistance |

| Plating | Electroplating with metals (e.g., nickel, chrome) onto POM surfaces | Increases wear resistance; adds conductivity; improves aesthetics |

| Texturing | Mold-based patterns (e.g., matte, ribbed) or laser etching | Enhances grip; hides minor defects; custom branding |

| Coating | Application of protective coatings (e.g., PTFE) | Reduces chemical exposure; improves heat resistance |

For example, a POM gear used in automotive applications may undergo nickel plating to increase wear resistance, while a consumer product part may be polished for a sleek, high-end look.

Tolerances in POM Vacuum Casting

Tolerances are a cornerstone of POM Vacuum Casting, as they ensure parts fit and function as intended. Our process delivers exceptional tolerances, precision, and accuracy in dimensions and measurements, adhering to strict limits and minimizing variations.

Table 6 shows typical tolerances we achieve for different part dimensions, compared to industry standards:

| Part Dimension (mm) | Our Tolerance (±mm) | Industry Standard Tolerance (±mm) | Improvement Over Industry (%) |

| <10 | 0.02–0.03 | 0.05–0.07 | 40–71 |

| 10–50 | 0.03–0.05 | 0.08–0.10 | 38–50 |

| 50–100 | 0.05–0.08 | 0.12–0.15 | 33–67 |

| >100 | 0.08–0.12 | 0.18–0.22 | 33–64 |

We use advanced measurement tools, such as Coordinate Measuring Machines (CMM) with a precision of ±0.001mm, to verify tolerances at every production stage. This ensures even complex parts (e.g., those with intricate holes or slots) meet your exact specifications.

Advantages of POM Vacuum Casting

POM Vacuum Casting offers numerous advantages and benefits over other manufacturing methods. Its pros and merits make it a top choice for many industries, with positive aspects that add significant value to your projects.

Key Advantages:

- High Precision: The vacuum environment eliminates air bubbles, resulting in parts with tight tolerances and consistent dimensions.

- Cost-Effective for Small Batches: Unlike injection molding (which requires expensive tooling), vacuum casting uses low-cost molds, making it ideal for prototyping or small-batch production (10–1,000 parts).

- Material Versatility: Works with various POM grades and additives, allowing customization of part properties (strength, flexibility, heat resistance).

- Fast Turnaround: Shorter cycle times (as shown in Table 3) compared to traditional casting, enabling quick iteration and faster time-to-market.

- Complex Geometries: Can produce parts with undercuts, thin walls, or intricate details that are difficult to achieve with machining.

Table 7 compares POM Vacuum Casting to other manufacturing methods:

| Method | Cost (Small Batch) | Precision | Lead Time | Ideal for Complex Geometries? |

| POM Vacuum Casting | Low | High | Short | Yes |

| Injection Molding | High (tooling) | High | Long | Yes |

| Machining | Medium | High | Medium | No (limited by tool access) |

| 3D Printing | Medium | Medium | Short | Yes |

Applications of POM Vacuum Casting by Industry

POM Vacuum Casting has wide-ranging applications across various industries, sectors, markets, and fields. Its versatility and precision make it suitable for diverse uses and segments, from automotive to medical.

Table 8 highlights key industries and their common POM Vacuum Casting applications:

| Industry | Common Applications | Required Properties |

| Automotive | Gearshift components, sensor housings, interior trim parts | Wear resistance, chemical stability (oils/solvents) |

| Medical | Surgical instrument handles, diagnostic device parts | Biocompatibility, easy cleaning |

| Electronics | Connector housings, switch components, cable management parts | Dimensional stability, electrical insulation |

| Consumer Goods | Toy parts, appliance knobs, zipper components | Durability, low friction, aesthetic finish |

| Aerospace | Small structural parts, valve components (non-critical systems) | High strength, heat resistance |

For example, in the automotive industry, we produced 500 POM sensor housings for a leading manufacturer, achieving a tolerance of ±0.03mm and reducing production time by 30% compared to their previous supplier.

Manufacturing Techniques Related to POM Vacuum Casting

POM Vacuum Casting is part of a broader set of manufacturing techniques used to produce high-quality parts. Understanding how it integrates with other production methods, fabrication processes, assembly steps, machining, tooling, and prototyping is key to optimizing your production workflow.

Complementary Techniques:

- Tooling: Silicone molds are commonly used for POM Vacuum Casting, as they are flexible (easy demolding) and cost-effective for small batches. For high-volume production, we can transition to metal molds.

- Machining: Post-casting machining (e.g., CNC milling) is used to refine critical features (e.g., threaded holes) that require ultra-tight tolerances.

- Prototyping: POM Vacuum Casting is ideal for functional prototyping, as it produces parts with material properties similar to final production parts—unlike 3D printing (which uses different materials).

- Assembly: Cast parts are often assembled with other components (e.g., screws, gaskets) using automated or manual assembly processes, which we can integrate into your project.

Table 9 shows how we combine techniques for a typical project (automotive gear component):

| Stage | Technique Used | Purpose |

| Prototyping | POM Vacuum Casting (silicone mold) | Test gear functionality and fit |

| Tooling | Metal mold fabrication (for volume production) | Increase durability for 10,000+ parts |

| Production | POM Vacuum Casting (metal mold) | Mass-produce gears with consistent quality |

| Post-Processing | CNC machining (to add threaded holes) + Nickel plating | Refine critical features and enhance wear resistance |

| Assembly | Automated screw fastening with quality checks | Attach gears to shafts; ensure proper alignment |

Case Studies: Success with POM Vacuum Casting

Our case studies and examples showcase how we’ve used POM Vacuum Casting to solve complex challenges for clients across industries. These projects and success stories (or case histories) highlight real-world applications and implementations of our process.

Case Study 1: Medical Device Handle Production

- Client: A leading medical equipment manufacturer.

- Challenge: Need 200 biocompatible POM handles for surgical instruments, with a matte texture and ±0.04mm tolerance.

- Solution: Used POM copolymer (Celcon M90) for biocompatibility, applied matte texturing via mold patterns, and verified tolerances with CMM.

- Result: Delivered parts in 2 weeks (30% faster than client’s target), with 100% passing biocompatibility tests. The client later expanded the order to 1,000 parts.

Case Study 2: Automotive Sensor Housing

- Client: A global automotive supplier.

- Challenge: Replace 3D-printed sensor housings with production-ready parts that can withstand engine heat (up to 100°C) and oil exposure.

- Solution: Used glass-filled POM (30% glass) for heat resistance, nickel-plated surfaces for corrosion protection, and vacuum casting to ensure no air bubbles (critical for sensor performance).

Result: Housings met all performance requirements, with a 50% reduction in cost per part compared to 3D printing. The client now uses our process for all their sensor housing production.

Why Choose Us for POM Vacuum Casting?

When selecting a partner for POM Vacuum Casting, there are clear reasons and motivations to choose Yigu Technology. Our selection criteria focus on delivering value, and our advantages and differentiation set us apart from competitors—all backed by a strong value proposition.

Key Reasons to Choose Us:

- Expertise: Our team has 10+ years of experience in POM Vacuum Casting, with a track record of solving complex client challenges (see Case Studies).

- Quality Assurance: We follow ISO 9001 standards, with in-line inspections and final testing to ensure parts meet your specifications.

- Flexibility: We adapt to your needs, whether you require prototyping (1–100 parts) or small-batch production (100–10,000 parts), and offer custom surface treatments and material options.

- Fast Turnaround: Our optimized processes reduce lead times—we typically deliver prototype parts in 1–2 weeks and small-batch orders in 2–4 weeks.

- Customer Support: Our team provides end-to-end support, from initial design consultation to post-delivery follow-up. We assign a dedicated project manager to every client, ensuring clear communication and timely updates.

To further illustrate our differentiation, Table 10 compares our services to a typical competitor:

| Service Aspect | Yigu Technology | Typical Competitor |

| Experience in POM Vacuum Casting | 10+ years | 2–5 years |

| Lead Time (Prototyping) | 1–2 weeks | 3–4 weeks |

| Quality Certifications | ISO 9001, FDA (for medical parts) | ISO 9001 only |

| Customization Options | Full range (materials, finishes, tolerances) | Limited (standard materials/finishes only) |

| Post-Delivery Support | 6-month warranty, technical troubleshooting | 1-month warranty, limited support |