Yes, plastics can absolutely be machined—and CNC machining is the best method for producing plastic components. Unlike alternatives like injection molding (which lacks precision) or 3D printing (limited to heat-moldable plastics), CNC plastics machining delivers unmatched accuracy, speed, and consistency. Whether you’re making tiny insulin pen parts or large aerospace components, this process works for nearly every plastic type, from common polyethylene to high-performance PEEK.

What Exactly Is Plastics Machining?

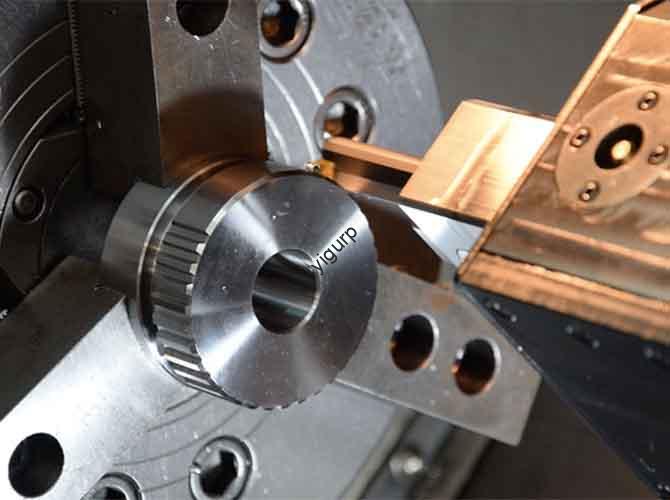

Plastics machining refers to the process of shaping plastic materials into precise parts using automated tools guided by computer numerical control (CNC) technology. Unlike manual machining, CNC systems follow pre-programmed instructions to cut, drill, mill, or turn plastic stock—ensuring every part matches exact specifications.

While CNC technology works with metals, glass, and wood, plastics machining has unique advantages. Plastics vary widely in hardness, flexibility, and heat resistance, but CNC tools adapt easily: mills handle complex 3D shapes, lathes create cylindrical parts, drills make precise holes, and waterjet cutters tackle delicate or thick materials without causing damage.

A key distinction from other methods: CNC machining is subtractive—it removes material from a solid block—rather than additive (like 3D printing) or formative (like injection molding). This makes it ideal for low-to-medium production runs and prototypes where precision is non-negotiable.

Common Plastics for Machining: A Practical Breakdown

Not all plastics perform the same in machining. Below is a curated table of the most widely used options, with critical details to guide your choice:

| Plastic Type | Key Advantages | Critical Limitations | Typical Uses | Key Data Point |

|---|---|---|---|---|

| Acetal (Delrin) | High strength, wear resistance, dimensional stability | Poor acid resistance, hard to bond | Gear, insulin pens, water meters | Most commonly used plastic for CNC machining |

| ABS | Easy to machine, impact-resistant, rigid | Low melting point, UV-sensitive | Helmets, printer parts, kitchen utensils | Easiest plastic to CNC machine |

| Polyethylene (PE) | Cheap, lightweight, water-resistant | Environmentally harmful, fossil fuel-based | Food packaging, pipes, toys | Cheapest plastic for CNC machining |

| Polycarbonate (PC) | High toughness, transparency, shatter-resistant | Prone to scratches, costly | Safety glass, bulletproof barriers | 1+ billion kg machined annually worldwide |

| PEEK | High heat resistance (up to 250°C), chemical resistance | Expensive, UV-degradable | Aerospace parts, medical implants | Hardest plastic to CNC machine |

| Polyamideimide | Extreme strength, machinability | Limited color options | High-stress industrial parts | Tensile strength over 21,000 psi |

Real-World Example: Choosing Plastic for Medical Devices

A medical equipment manufacturer needed parts for insulin pens—components that require precision, chemical resistance (to insulin), and smooth finishes. Acetal (Delrin) was the clear choice: its wear resistance prevents friction-related damage, and its dimensional stability ensures the pen’s mechanism works reliably. In contrast, PE would lack the necessary rigidity, while PEEK was too costly for high-volume production.

Key Plastics Machining Processes & When to Use Them

All CNC processes work for plastics, but selecting the right one depends on your part’s shape, size, and complexity. Here’s how to decide:

CNC Milling

Ideal for: Complex 3D shapes, parts with slots, holes, or custom contours.How it works: Rotating cutting tools remove material from a fixed plastic block. Mills handle everything from small electronic housings to large automotive dash panels.Best for: Acetal, ABS, and PC. These plastics hold their shape during the multi-axis cutting process.

CNC Turning

Ideal for: Cylindrical parts like rods, bushings, or bottle caps.How it works: The plastic stock spins while a stationary cutter shapes it. Turning is faster than milling for round components.Best for: PE, PP, and Nylon. Their flexibility won’t cause warping during spinning.

CNC Drilling

Ideal for: Creating precise holes in plastic sheets or blocks.How it works: Specialized drill bits (often with sharp, low-friction edges) prevent cracking in brittle plastics.Best for: PVC and CPVC. These rigid plastics need clean holes for plumbing applications.

Waterjet Cutting

Ideal for: Delicate or heat-sensitive plastics (like PET or PMMA).How it works: High-pressure water mixed with abrasive particles cuts through plastic without generating heat—avoiding melting or warping.Best for: Acrylic (PMMA) used in display cases. Waterjet cutting preserves its optical clarity.

Industries Relying on Plastics Machining: Applications & Insights

Plastics machining serves nearly every sector, thanks to its versatility. Below are the most common use cases:

Automotive

Plastics are everywhere in cars: interior linings, dashboards, engine covers, and exterior bumpers. CNC machining ensures parts fit perfectly—critical for safety and aesthetics. For example, ABS is used for bumpers because its impact resistance absorbs collisions, while Nylon makes durable seatbelt components.

Healthcare

Precision is life-or-death here. CNC-machined plastics create medical implants (like PEEK hip components), pacemaker housings, and sterilization trays. PPSU is a favorite for baby bottles and medical equipment because it’s sterile, heat-resistant, and easy to clean.

Aerospace

Aerospace demands lightweight, high-strength parts that withstand extreme conditions. Carbon Fiber Reinforced Polymers (CFRP) are machined into robotic arms and power shafts—their strength-to-weight ratio outperforms many metals. Kapton, which handles temperatures from -269°C to 400°C, is used for flexible PCBs in spacecraft.

Food Processing

Food-grade plastics like PET and HDPE are machined into containers and trays. These parts must be non-toxic, easy to sanitize, and impact-resistant (to protect food during shipping). CNC machining ensures no sharp edges or crevices trap bacteria.

How to Choose the Right Plastic for Your Project: A Step-by-Step Guide

Selecting plastic starts with answering five key questions. Follow this framework to avoid costly mistakes:

- What physical stress will the part face?

- High impact? Choose ABS or PC.

- Heavy loads? Opt for PEEK or polyamideimide.

- Wear and friction? Go with Acetal or UHMW.

- Will it encounter chemicals or moisture?

- Acids or solvents? Use PTFE (Teflon) or PVDF.

- Water or humidity? HDPE or Celcon work best.

- Food or medical fluids? PET or PPSU (both food-grade).

- What temperature range will it operate in?

- High heat (over 200°C)? PEEK or PSU.

- Extreme cold? Kapton or PTFE.

- Room temperature only? PE or ABS.

- Does appearance matter?

- Transparency? PMMA (acrylic) or PC.

- Smooth finish? Acetal or ABS.

- Color retention? Nylon.

- What’s your budget?

- Low-cost projects: PE or Nylon.

- Mid-range: Acetal or PVC.

- High-performance needs: PEEK or CFRP.

Pro Tip: Test First

Always order a small sample before full production. A manufacturer once chose PVC for outdoor electrical enclosures without testing—only to find it cracked in cold temperatures. Switching to CPVC (which resists temperature damage) solved the problem, but the initial mistake cost time and money.

Optimizing Plastics Machining: Tips for Better Results

Even the right plastic and process can fail without proper optimization. Here are actionable strategies to improve quality and efficiency:

- Use the right cutting tools: Carbide tools work best for hard plastics like PEEK, while high-speed steel (HSS) tools are fine for softer PE or ABS. Dull tools cause melting and rough finishes.

- Control temperature: Thermoplastics like ABS melt easily—use coolant or compressed air to keep parts cool during machining.

- Optimize feed rates: Slow rates for brittle plastics (like PMMA) prevent cracking; faster rates for flexible PE save time.

- Automate where possible: Automated material handling (like robotic arms) reduces downtime—critical for high-volume runs. This aligns with industry trends toward reducing 停机时间 through automation.

- Maintain equipment: Regularly clean and lubricate machines. A dirty spindle can cause uneven cuts, ruining parts.

Yigu Technology’s Perspective

Plastics machining is evolving from a “one-size-fits-all” process to a precision-driven craft, and material selection remains the foundation of success. We’ve seen clients achieve 30% higher part durability by switching from generic PE to application-specific HDPE for plumbing parts. The key is balancing performance needs with cost—over-specifying (e.g., using PEEK for a simple tray) wastes budget, while under-specifying leads to failures. As automation and tooling advance, we’re also seeing faster turnaround times without sacrificing quality—making CNC machining more accessible than ever for small businesses and startups.

Frequently Asked Questions (FAQs)

- Is CNC machining better than injection molding for plastics?It depends on your needs. CNC machining is better for low-to-medium runs, prototypes, and precise parts. Injection molding is cheaper for high-volume production but lacks CNC’s precision.

- Can recycled plastics be machined?Yes, but quality varies. Recycled PE and PP work well for non-critical parts (like packaging), but avoid them for high-stress applications (like medical devices) due to inconsistent strength.

- How accurate is plastics machining?CNC machining typically achieves tolerances of ±0.005 inches (0.127 mm)—more than precise enough for most industrial and consumer parts.

- What’s the most environmentally friendly plastic for machining?Recyclable PET or biodegradable PLA (polylactic acid) are better options, though PLA has lower heat resistance. Avoid non-recyclable plastics like PVC when possible.

- How long does plastics machining take?Simple parts (like a PE washer) can be made in minutes, while complex aerospace components (like CFRP shafts) may take hours. Most projects are completed within 1–5 business days.