In the field of plastic manufacturing, PE (Polyethylene) blow molding prototype parts are widely used in industries such as packaging, automotive, and medical due to their excellent performance and cost – effectiveness. However, the processing of these prototypes is not a simple task. It requires a precise combination of material selection, blow molding technology, prototype development, and processing techniques. Many manufacturers often encounter problems such as unstable product quality, low production efficiency, or failure to meet design requirements during the processing process. This article will break down the entire processing process of PE blow molding prototype parts, helping you solve practical difficulties and achieve high – quality prototype production.

1. Material Selection: The Foundation of High – Quality PE Blow Molding Prototypes

The performance of PE blow molding prototype parts largely depends on the selection of Polyethylene (PE) materials. Choosing the right PE material is the first step to ensure the success of prototype processing. There are various factors to consider in material selection, and each factor directly affects the subsequent processing and the final performance of the prototype.

1.1 Key Factors in PE Material Selection

| Factor | Description | Impact on Prototype |

| Grade Specifications | PE is divided into different grades such as low – density polyethylene (LDPE), high – density polyethylene (HDPE), and linear low – density polyethylene (LLDPE) according to molecular structure and performance. | LDPE has good flexibility and transparency, suitable for flexible packaging prototypes; HDPE has high strength and rigidity, suitable for automotive parts and chemical container prototypes; LLDPE has excellent impact resistance, suitable for prototypes that need to withstand external impacts. |

| Density Variations | The density of PE ranges from 0.910 to 0.970 g/cm³. Generally, the higher the density, the better the mechanical properties such as hardness and strength. | For prototypes that require high load – bearing capacity, such as small plastic pallets, high – density PE should be selected; for prototypes that require good flexibility, such as plastic hoses, low – density PE is more appropriate. |

| Additives | Common additives include antioxidants, UV stabilizers, colorants, and lubricants. | Antioxidants can prevent PE from aging during processing and use; UV stabilizers are essential for prototypes used outdoors to resist UV damage; colorants meet the appearance requirements of prototypes; lubricants can improve the fluidity of PE during molding and reduce mold sticking. |

| Recyclability | PE is a recyclable material, and the content of recycled materials in the raw material will affect the performance of the prototype. | For prototypes with high performance requirements, such as medical device accessories, it is recommended to use 100% new PE materials; for non – critical prototypes such as ordinary packaging boxes, an appropriate amount of recycled materials can be added to reduce costs. |

A common question here is: Can different grades of PE be mixed to achieve a balance of performance? The answer is yes, but it needs to be cautious. Mixing different grades of PE can adjust the performance of the material, but it may also lead to uneven material properties, affecting the stability of the prototype. If mixing is necessary, it is recommended to conduct small – batch tests first to verify the feasibility.

2. Blow Molding Technology: The Core of PE Prototype Shaping

Blow molding technology is the core link in the processing of PE blow molding prototype parts. Different blow molding methods have their own characteristics and applicable scenarios. Choosing the right technology is crucial to ensure the quality and efficiency of the prototype.

2.1 Comparison of Common Blow Molding Technologies

| Blow Molding Technology | Working Principle | Advantages | Disadvantages | Applicable Prototype Types |

| Extrusion Blow Molding | Melt PE raw material into a tube – shaped parison through an extruder, then put the parison into a mold, blow compressed air into the parison to make it expand and adhere to the inner wall of the mold, and finally cool and demold. | Simple process, low equipment investment, suitable for large – size and irregularly shaped prototypes. | The wall thickness of the prototype is not easy to control, and the precision is relatively low. | Large plastic barrels, automotive fuel tanks, and large – size packaging boxes. |

| Injection Blow Molding | First, inject PE melt into a preform mold to form a preform with a bottom, then transfer the preform to a blow mold, blow compressed air to expand the preform into the shape of the blow mold, and cool and demold. | High precision of the prototype, uniform wall thickness, good surface finish. | Complex equipment, high investment cost, not suitable for large – size prototypes. | Small – size and high – precision prototypes such as medicine bottles, cosmetic bottles, and small instrument casings. |

2.2 Key Parameters in Blow Molding Process

- Parison Formation: The parison is the blank of the prototype, and its quality directly affects the final prototype. The key to parison formation is to control the diameter, wall thickness, and uniformity of the parison. For extrusion blow molding, the extrusion speed and die gap should be adjusted; for injection blow molding, the injection pressure and temperature of the preform mold need to be controlled.

- Blow Ratio: The blow ratio refers to the ratio of the diameter of the prototype after blow molding to the diameter of the parison. Generally, the blow ratio of PE is between 2:1 and 4:1. A too – large blow ratio will lead to insufficient material in the prototype wall, reducing strength; a too – small blow ratio will cause material waste and uneven wall thickness.

- Cooling Systems: The cooling speed and uniformity of the prototype affect its shape stability and production efficiency. Common cooling methods include water cooling and air cooling. For thick – walled prototypes, water cooling is more efficient, which can quickly cool the prototype and prevent deformation; for thin – walled prototypes, air cooling can avoid excessive cooling rate leading to brittle prototype.

3. Prototype Development: From Design to Mock – up

Prototype development is a process from design concept to physical mock – up, which includes design, modeling, simulation, and testing. A scientific prototype development process can reduce the number of iterations and improve the success rate of the prototype.

3.1 Step – by – Step Prototype Development Process

- Design with Software: Use professional design software such as AutoCAD, SolidWorks, or Pro/E to carry out the structural design of the prototype. During the design process, it is necessary to consider the characteristics of PE material and blow molding technology. For example, avoid sharp corners in the design to prevent stress concentration during blow molding; set reasonable draft angles to facilitate demolding.

- CAD Modeling: Convert the 2D design drawing into a 3D CAD model. The 3D model should accurately reflect the size, shape, and structural details of the prototype. It is recommended to use parametric modeling, which is convenient for subsequent modifications and adjustments.

- Simulation Analysis: Use simulation software such as Moldflow to simulate the blow molding process of the prototype. The simulation can predict problems such as uneven wall thickness, air trapping, and deformation during the molding process. According to the simulation results, optimize the design of the prototype and the parameters of the blow molding process. For example, if the simulation shows that the wall thickness of a certain part of the prototype is too thin, the shape of the parison or the blow ratio can be adjusted.

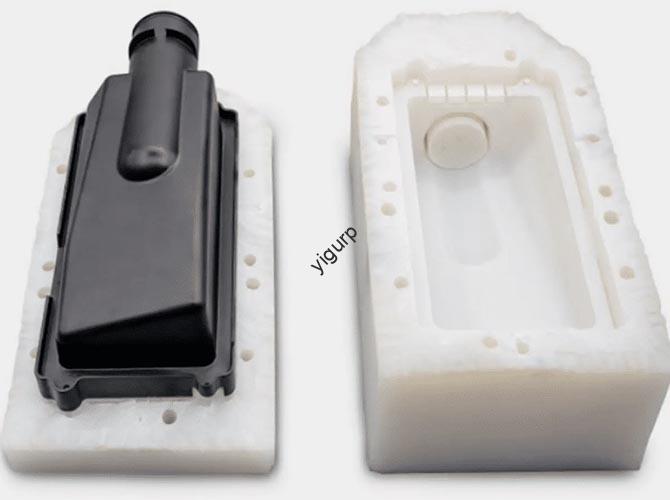

- Mock – up Creation: Based on the optimized 3D model, create a physical mock – up. For simple prototypes, 3D printing can be used to make a mock – up quickly; for prototypes that need to test the blow molding effect, a small – size blow molding machine can be used to produce a small batch of prototypes.

- Iterative Testing: Test the performance and appearance of the mock – up, including dimensional accuracy, mechanical properties (such as tensile strength and impact strength), and appearance quality (such as surface smoothness and color uniformity). According to the test results, modify the design or adjust the processing parameters, and repeat the process of mock – up creation and testing until the prototype meets the requirements.

4. Processing Techniques: Improve the Quality and Functionality of Prototypes

Processing techniques after blow molding are essential to improve the quality and functionality of PE blow molding prototype parts. These techniques include trimming, finishing, assembly, and surface treatment.

4.1 Key Post – Molding Processing Techniques

- Trim and Finish: After blow molding, the prototype often has excess material such as flash and burrs, which need to be trimmed. Common trimming methods include manual trimming, mechanical trimming, and laser trimming. Manual trimming is suitable for small – batch prototypes, but the efficiency is low and the quality is unstable; mechanical trimming is suitable for large – batch prototypes, with high efficiency and good consistency; laser trimming has high precision, suitable for prototypes with complex shapes and high trimming requirements. After trimming, the prototype can be polished to improve the surface smoothness.

- Assembly Methods: If the prototype is composed of multiple components, assembly is required. Common assembly methods for PE prototypes include thermal welding, adhesive bonding, and mechanical connection. Thermal welding uses heat to melt the PE at the joint of the components to achieve bonding, which has high bonding strength and is suitable for airtight prototypes such as plastic water tanks; adhesive bonding is simple and convenient, but the bonding strength is affected by the type of adhesive and the surface condition of the components; mechanical connection such as screws and clips is easy to disassemble, suitable for prototypes that need to be maintained or replaced.

- Surface Treatment: Surface treatment can improve the appearance and functionality of the prototype. Common surface treatments include printing, coating, and electroplating. Printing can print patterns, logos, and text on the prototype surface to meet the marketing and identification needs; coating can improve the wear resistance, chemical resistance, and barrier properties of the prototype, such as coating a layer of fluorine – containing material on the inner surface of the chemical container prototype to enhance corrosion resistance; electroplating is suitable for prototypes that need to have a metallic appearance, such as decorative parts of household appliances.

5. Yigu Technology’s View on PE Blow Molding Prototype Parts Processing

At Yigu Technology, we think PE blow molding prototype processing needs to balance material, technology and development. We select PE grades by matching prototype use scenarios, like HDPE for auto parts. For tech, we combine extrusion and injection blow molding, using simulation to optimize parison and blow ratio, ensuring ±0.1mm wall thickness tolerance. In development, we iterate fast with 3D printing and small – batch tests. Post – processing uses laser trimming and thermal welding for quality. The core is integrating each link to make prototypes meet performance and cost needs.

FAQ

1. What should I do if the wall thickness of the PE blow molding prototype is uneven?

First, check the parison formation. For extrusion blow molding, adjust the extruder speed and die gap to ensure uniform parison diameter and wall thickness; for injection blow molding, optimize the injection parameters of the preform mold. Second, adjust the blow ratio. Ensure that the blow ratio is within the reasonable range of 2:1 – 4:1, and avoid excessive or insufficient blow ratio. Finally, check the cooling system to ensure that the cooling is uniform, and adjust the cooling time and cooling medium flow rate if necessary.

2. How to choose between extrusion blow molding and injection blow molding for PE prototypes?

It depends on the size, precision, and production batch of the prototype. If the prototype is large – sized (such as a plastic barrel with a volume of more than 50L) or has an irregular shape, and the precision requirement is not high, extrusion blow molding is more suitable due to its low equipment investment and simple process. If the prototype is small – sized (such as a medicine bottle with a volume of less than 1L), has high precision requirements (such as uniform wall thickness and good surface finish), and the production batch is large, injection blow molding is a better choice.

3. Can PE blow molding prototypes be used directly in practical applications?

It depends on the purpose of the prototype. If the prototype is used for functional testing or market research, and its performance meets the requirements of practical applications, it can be used directly. However, if the prototype is used in key fields such as medical treatment and automotive safety, it needs to go through strict performance testing and certification (such as ISO certification, FDA certification) to ensure that it meets the relevant industry standards before it can be used in practical applications. In addition, the production process of the prototype may be different from that of mass – produced products, so it is necessary to adjust the process parameters when converting to mass production.