When you think of manufacturing, you might picture massive factories churning out thousands of identical products—waiting in warehouses for someone to buy them. But that’s changing fast. On-demand manufacturing (also called custom manufacturing or cloud manufacturing) is rewriting the rules: it makes products only when there’s a real order, cutting waste, lowering costs, and letting businesses of all sizes create custom parts. This guide breaks down what on-demand manufacturing is, why it’s growing, its biggest advantages over traditional methods, and how to use it for your project.

What Is On-Demand Manufacturing?

At its core, on-demand manufacturing is a “make-to-order” system. Unlike traditional manufacturing (which produces large batches and stores inventory), it starts production only after receiving a specific customer request. This could be a single prototype, 50 custom parts, or 500 specialized components—whatever the customer needs, when they need it.

Think of it like ordering a custom cake: you don’t buy a pre-made cake off the shelf. You tell the baker your flavor, size, and design, and they make it just for you. On-demand manufacturing works the same way—but for everything from medical devices to automotive parts.

Key terms to know:

- Customization: Tailors products to a customer’s exact specs (size, material, design).

- No Inventory: No need to store finished goods—products go straight from production to the customer.

- Digital Integration: Relies on online platforms to connect customers (who upload designs) with manufacturers (who fulfill orders).

What’s Driving the Growth of On-Demand Manufacturing?

On-demand manufacturing isn’t just a trend—it’s a response to three big shifts in technology and consumer needs. Here’s what’s pushing its rapid growth:

1. Digital Tools (Internet + Cloud Tech)

The internet and cloud technology are the backbone of on-demand manufacturing. They let customers and manufacturers work together seamlessly, no matter where they are.

- Online Design & Quoting: Customers upload CAD (computer-aided design) models to platforms, and AI-powered tools give instant quotes. For example, Xometry’s real-time quoting engine lets users get a price for a part in minutes—just by uploading a 3D model.

- Global Manufacturer Networks: Platforms connect customers to thousands of manufacturers worldwide. If one factory is busy, another can take the order—ensuring fast turnaround.

- Transparency: Customers track their order’s progress online (e.g., “printing in progress” or “shipped”)—no more guessing where their part is.

Why it matters: These tools eliminate the “middleman” and speed up the process. What once took weeks (finding a manufacturer, negotiating quotes) now takes days.

2. Affordable, Flexible Production Tech

On-demand manufacturing relies on tools that are smaller, cheaper, and more versatile than traditional factory machines. The two biggest game-changers are:

| Technology | Key Advantage for On-Demand Manufacturing | Example Use Case |

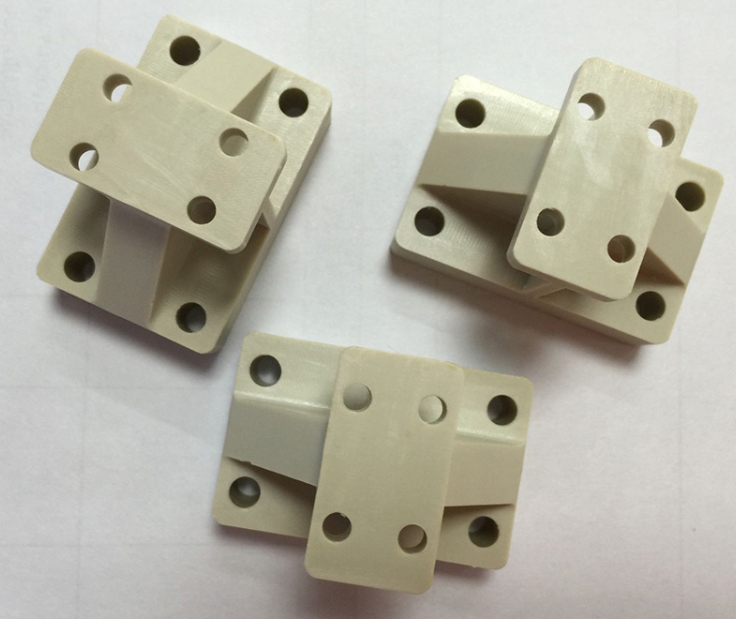

| CNC Machining | Can make custom parts from metal/plastic quickly—no expensive molds needed. | A startup orders 20 custom aluminum brackets for a drone. |

| 3D Printing (MJF/SLS) | Builds parts layer by layer—great for complex designs and small batches. | A medical clinic orders 5 custom surgical guides (nylon PA11). |

Cost Comparison: Traditional manufacturing machines (like injection molding presses) can cost \(1 million+. CNC mills or 3D printers cost \)10,000–$50,000—making it easy for small factories to join the on-demand network.

This means more manufacturers can offer custom services, creating competition that lowers prices for customers.

3. Changing Customer Needs

Today’s businesses and consumers want customization and speed—two things traditional manufacturing struggles with.

- Small Businesses & Startups: They can’t afford to make 1,000 parts upfront. On-demand lets them order 10 prototypes to test their idea, then scale up only if it works.

- Consumers: They want products that fit their lifestyle (e.g., a phone case with their logo, or a wheelchair with custom armrests). On-demand makes this affordable.

- Fast-Paced Industries: In healthcare or tech, products change quickly. On-demand lets companies respond to new needs (like a COVID test kit part) in days, not months.

On-Demand Manufacturing vs. Traditional Manufacturing: Key Differences

To understand why on-demand is better for many projects, let’s compare it to traditional manufacturing side by side:

| Factor | On-Demand Manufacturing | Traditional Manufacturing |

| Production Trigger | Starts after an order is placed (make-to-order) | Makes large batches first, stores inventory (make-to-stock) |

| Batch Size | Ideal for small batches (1–1,000 parts) | Ideal for large batches (1,000+ parts) |

| Customization | Easy—changes specs for each order | Hard—needs new tooling (costly) for changes |

| Inventory Cost | $0 (no storage needed) | High (warehouses, insurance, waste from unsold parts) |

| Lead Time | Fast (3–10 days for most parts) | Slow (4–8 weeks for tooling + production) |

| Risk of Waste | Low (every part has a buyer) | High (overproduction leads to unsold, expired, or damaged parts) |

Real-World Example: A small electronics brand needed 200 custom battery housings.

- Traditional manufacturing: \(5,000 for injection molding tooling + \)2 per housing = $5,400 total (and they’d have to wait 6 weeks).

- On-Demand (CNC machining): \(10 per housing = \)2,000 total (delivered in 5 days).

The brand saved $3,400 and got their parts 5 weeks faster—critical for launching their product on time.

The Biggest Advantages of On-Demand Manufacturing

On-demand manufacturing isn’t just “different”—it solves real problems for manufacturers and customers. Here are its four most impactful benefits:

1. Perfect for Customization & Small Batches

Traditional manufacturing is built for “one-size-fits-all” parts. If you want a custom design, you need to pay for new molds or tooling—often $10,000+—which is impossible for small batches.

On-demand manufacturing eliminates this barrier. For example:

- A dental lab can order 3 custom denture bases (each tailored to a patient’s mouth) using 3D printing (nylon PA12). No tooling needed—just upload the patient’s 3D scan.

- A car repair shop can order 2 custom metal brackets for a vintage 1970s truck. CNC machining makes them in 3 days, instead of waiting 4 weeks for a traditional factory to make a batch of 100.

Why it matters: This lets businesses serve niche markets (like vintage car parts or custom medical devices) that traditional manufacturing ignores.

2. Cuts Inventory & Logistics Costs

Traditional manufacturers spend thousands on warehouses to store parts. They also pay for shipping, insurance, and labor to manage inventory. Worse, if parts don’t sell, they’re thrown away—wasting money and harming the environment.

On-demand manufacturing removes all this:

- No warehouses: Parts go from factory to customer directly.

- No unsold parts: Every part is made for a specific order (100% sales rate).

- Lower logistics: Less shipping (no inventory transfers between warehouses).

Data Point: A 2023 study found that on-demand manufacturers save 30–40% on costs related to inventory and logistics compared to traditional manufacturers.

Example: A furniture brand used to make 500 wooden chair legs upfront, storing them in a warehouse. 100 legs would get damaged or become obsolete each year (wasting \(2,000). Switching to on-demand CNC machining let them order 50 legs at a time—no storage, no waste, and \)2,000 in annual savings.

3. Reduces Risk & Waste

Traditional manufacturing relies on “guessing” demand. If a company makes 1,000 units but only sells 600, the 400 unsold units are waste. This is even worse for perishable or fast-changing products (like tech accessories or seasonal items).

On-demand manufacturing eliminates this risk:

- No overproduction: You only make what customers order.

- No obsolete parts: If your design changes, you don’t have old inventory to get rid of.

- Less material waste: Technologies like 3D printing (MJF/SLS) reuse 50%+ of unused powder, unlike traditional machining (which wastes 50–70% of raw material).

COVID Example: During the 2020 pandemic, traditional manufacturers had warehouses full of unused parts (like hotel furniture or event equipment). On-demand manufacturers shifted overnight to make COVID supplies (mask brackets, test kit parts)—no waste, just quick response to need.

4. Fosters Innovation (For Everyone)

In the past, only big companies could afford to innovate. They’d spend millions on research, tooling, and prototyping. Small businesses or inventors had no way to test their ideas.

On-demand manufacturing changes this:

- Low-cost prototyping: A student can order 5 3D-printed prototypes of their new phone stand for \(50, instead of \)5,000.

- Fast iteration: If the first prototype is too big, they can tweak the design and order 5 more in 3 days.

- No upfront investment: You don’t need to build a factory to launch a product. Just upload your design and start selling.

Success Story: A group of engineers used on-demand manufacturing to create a portable water filter for disaster zones. They ordered 10 3D-printed prototypes (nylon PA12) for $200, tested them, and iterated 3 times. Within 2 months, they were selling 100 filters per week—all made via on-demand CNC machining. No traditional factory needed.

Manufacturing-as-a-Service (MaaS): The Next Step for On-Demand

On-demand manufacturing has evolved into a more powerful model called Manufacturing-as-a-Service (MaaS). MaaS is like a “one-stop shop”: a platform (like Xometry) connects customers to a network of manufacturers, handling everything from quoting to shipping.

Here’s why MaaS is better than working with a single on-demand manufacturer:

1. Instant Access to Production Capacity

You don’t have to search for a manufacturer that’s available. The MaaS platform finds the best fit in its network (e.g., a CNC shop for metal parts, an MJF printer for nylon parts) in minutes.

Xometry’s network has 10,000+ manufacturers—so there’s always someone available to take your order, even during busy times.

2. Guaranteed Quality & Expertise

MaaS platforms vet every manufacturer in their network. They check for certifications (like ISO for medical parts) and track past performance (on-time delivery, quality).

This means you don’t have to worry about hiring a bad manufacturer. If a part doesn’t meet your specs, the platform handles rework or refunds.

3. Less Work for You (and Manufacturers)

For customers: You upload your design, get a quote, and wait for delivery. The platform handles communication, payment, and shipping.

For manufacturers: You don’t have to spend time marketing or finding customers. The platform sends you orders, and handles delivery to the customer. You just focus on making parts.

Example: A startup needed 50 custom plastic enclosures for their new sensor. Using a MaaS platform:

- They uploaded their CAD model and got a quote in 2 minutes.

- The platform matched them with an MJF manufacturer in their region.

- The parts were made in 4 days and shipped directly to the startup.

The startup didn’t have to call 5 different manufacturers or negotiate prices—saving 10 hours of work.

Yigu Technology’s Perspective on On-Demand Manufacturing

At Yigu Technology, we see on-demand manufacturing as the key to making production fair and efficient for everyone. We help small businesses, startups, and clinics access custom parts without the high costs of traditional manufacturing—using CNC machining and 3D printing (MJF/SLS) for small batches. We also partner with MaaS platforms to connect our customers to a global network of manufacturers, ensuring fast lead times and quality. For us, on-demand isn’t just about making parts—it’s about empowering innovation: letting a student’s prototype become a product, or a clinic’s custom tool save lives. We focus on transparency and affordability, so every customer knows exactly what they’re getting and how much it will cost—no surprises.

FAQ About On-Demand Manufacturing

1. Is on-demand manufacturing more expensive than traditional manufacturing for small batches?

No—for batches under 1,000 parts, on-demand is cheaper. Traditional manufacturing requires expensive tooling (even for small batches), while on-demand has no tooling costs. For example, 100 plastic parts cost \(1,000 via on-demand (CNC) vs. \)5,000 via traditional (injection molding: \(4,000 tooling + \)10 parts).

2. What types of parts can I make with on-demand manufacturing?

Almost any part—from small plastic prototypes (3D printed) to metal automotive components (CNC machined). Common uses include: custom medical tools, drone parts, electronics housings, vintage car repairs, and consumer products (like phone cases). The only limit is size (most on-demand machines handle parts up to 1m x 1m) and material (focus on plastics, metals, and some composites).

3. How long does on-demand manufacturing take?

Most parts are ready in 3–10 days. Simple parts (like a PLA prototype) take 3–5 days. More complex parts (like a custom metal bracket) take 7–10 days. This is much faster than traditional manufacturing (4–8 weeks) because there’s no tooling or inventory wait time.