Polycarbonate (PC) injection molding remains a critical manufacturing process for producing high-performance plastic components, yet engineers frequently encounter hurdles like material degradation, surface imperfections, and inconsistent dimensional accuracy. This expanded guide incorporates industry best practices and technical insights to address these challenges while exploring advanced techniques and material considerations for successful PC injection outcomes.

The Unique Advantages of PC Injection Molding

Polycarbonate’s exceptional combination of optical clarity (86% light transmittance), impact resistance (12.0-16.0 Izod), and thermal stability (270-280°F heat deflection) makes it indispensable across diverse sectors. Unlike alternative materials, PC maintains its mechanical properties across a broad temperature range, offering distinct advantages:

| Key Property | Advantage | Critical Applications |

| High Impact Strength | Withstands sudden force without shattering | Safety equipment, automotive components |

| Optical Transparency | Clear visibility with minimal haze (<1%) | Lenses, medical devices, display covers |

| Thermal Resistance | Performs in extreme temperature environments | LED lighting, industrial enclosures |

| Dimensional Stability | Maintains tolerances (±0.1mm) under stress | Precision mechanical parts |

PC injection molding outperforms processes like machining and thermoforming in high-volume production, delivering lower unit costs while maintaining complex geometries and tight tolerances.

Essential Material Preparation for PC Injection

Proper material handling is foundational to successful PC injection. Polycarbonate pellets absorb up to 0.3% moisture within 24 hours, which can cause silver streaks, splay marks, and mechanical property degradation. Follow these critical steps:

- Drying Parameters: 100-120°C for 3-4 hours in a dehumidifying dryer

- Moisture Verification: Use a dew point meter to confirm <0.02% moisture content

- Storage: Keep dried material in sealed containers with desiccant to prevent reabsorption

- Contamination Control: Ensure material handling equipment is clean and dedicated to PC grades

For enhanced processing, consider glass-filled PC grades for improved stiffness or UV-stabilized formulations for outdoor applications, adjusting drying times accordingly for modified grades.

Advanced Process Parameters for Optimal PC Injection

Precise control of PC injection molding parameters directly impacts part quality and production efficiency. The following optimized settings balance flowability and material integrity:

| Parameter | Optimal Range | Impact on Part Quality |

| Melt Temperature | 300-350°C (572-662°F) | Lower temperatures (300-320°C) for high MFR grades; higher (340-350°C) for low flow formulations |

| Injection Pressure | 70-100 MPa | Prevents short shots in thin-walled sections (<1mm) |

| Mold Temperature | 150-174°C (302-345°F) | Reduces internal stress and improves surface finish |

| Screw Speed | 50-80 rpm | Moderate speeds prevent shear-induced degradation |

| Back Pressure | 5-15 bar | Enhances melt uniformity without excessive heating |

Tip: For complex geometries, implement sequential valve gating to control flow fronts and minimize weld lines, particularly critical for optical components.

Troubleshooting Common PC Injection Defects

Even with precise controls, challenges may arise. This expanded troubleshooting guide addresses additional common issues:

| Defect | Root Cause | Solution |

| Silver Streaks | Moisture or trapped air | Increase drying time; add venting; reduce injection speed |

| Weld Lines | Poor flow front integration | Raise melt temperature; optimize gate location with mold flow analysis |

| Sink Marks | Uneven cooling in thick sections | Implement compression molding; extend holding time |

| Yellowing | Thermal degradation | Reduce barrel temperature; shorten residence time |

| Flash | Excessive pressure or mold mismatch | Increase clamp force; inspect mold for wear; reduce injection pressure |

| Warping | Non-uniform cooling or residual stress | Improve mold cooling channels; implement annealing post-process |

Pro Insight: Use statistical process control (SPC) to monitor critical parameters and detect variations before they affect part quality.

Advanced PC Injection Molding Techniques

Innovative approaches address specific challenges in PC injection:

Optical Molding for Precision Components

This ultra-precision technique produces optical parts with <1% haze without secondary polishing. Critical for lenses and light guides, it requires:

- Mirror-finish mold surfaces (Ra <0.02μm)

- Tight temperature control (±1°C)

- Slow injection speeds to prevent flow-induced birefringence

Water-Assisted Injection Molding

Ideal for hollow parts like handles and tubes, this method:

- Uses high-pressure water (10-30 MPa) to core out molten PC

- Achieves uniform wall thickness (±0.05mm)

- Reduces cycle times by 20-30% compared to conventional molding

- Improves surface finish on internal features

Two-Component Molding

Combines PC with other materials (elastomers, different polymers) to create multi-functional parts:

- Overmolding for soft-touch grips on medical devices

- Co-injection for cost-saving core materials with PC exteriors

- Bi-injection for color-matched components without assembly

Comprehensive Design Guidelines for PC Injection Molding

Effective part design minimizes defects and reduces production costs:

- Wall Thickness: Maintain 1-3.8mm (0.04-0.15 inches) with gradual transitions to prevent stress concentrations

- Rib Design: Rib thickness should be 50-60% of adjacent walls; height limited to 3x wall thickness

- Corner Radii: Minimum 3mm radius to reduce stress and improve flow

- Draft Angles: 0.5-3° per side, increasing for textured surfaces

- Gate Placement: Position gates to facilitate balanced filling; use mold flow analysis to optimize

- Undercuts: Minimize where possible; use side pulls or collapsible cores for necessary features

Design for Manufacturing (DFM) Tip: Incorporate self-mating features where possible to eliminate assembly steps and improve part consistency.

Leading PC Injection Molding Machine Brands

Selecting appropriate equipment is critical for successful PC injection. Top manufacturers include:

- Negri Bossi: Known for precision control in optical applications

- Arburg: Specialized machines for micro-molding PC components

- Toshiba: High-performance machines for large-part PC molding

- Engel: Advanced process control for consistent high-volume production

- Husky: Specialized systems for medical-grade PC molding

Yigu Technology’s Perspective on PC Injection Molding

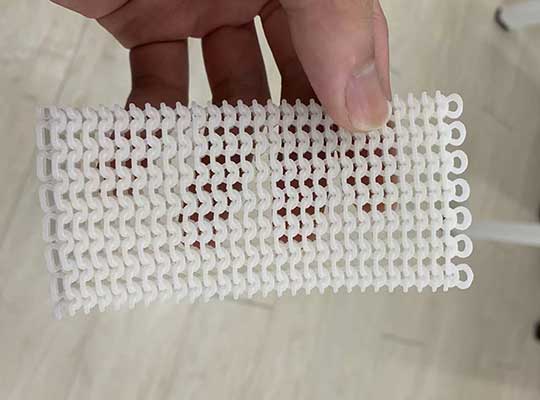

As a trusted rapid prototyping supplier, Yigu Technology emphasizes prototyping as the foundation of successful PC injection. We validate designs with 3D-printed prototypes, testing form, fit, and function before mold investment. Our expertise in material selection—from standard to high-flow PC grades—ensures optimal process parameters, reducing mold revisions and delivering high-quality PC parts efficiently from prototype to production.

Frequently Asked Questions About PC Injection Molding

- What are the key differences between PC and acrylic injection molding?

PC offers superior impact resistance and temperature range compared to acrylic but requires higher processing temperatures. PC maintains clarity under stress, making it better for load-bearing transparent parts.

- How does glass content affect PC injection molding?

Glass-filled PC improves stiffness and dimensional stability but increases viscosity, requiring higher injection pressures and potentially causing greater mold wear. Typical glass contents range from 10-40%.

- What post-processing options are available for injection molded PC parts?

PC parts can be annealed to reduce residual stress, painted with specialized coatings, bonded using ultrasonic welding, or polished to enhance optical clarity for critical applications.

By implementing these advanced techniques and best practices, manufacturers can fully leverage the capabilities of PC injection molding to produce high-quality, cost-effective components across industries.