If you’ve ever wondered how complex aerospace parts or precise medical components get made, the answer often lies in a machining center. These versatile machines are the backbone of modern manufacturing, but with so many types and specs, it’s easy to feel overwhelmed. Let’s break this down step by step—whether you’re buying one, training your team, or just curious, this guide has you covered.

1. Types of Machining Centers: Which Fits Your Work?

Not all machining centers are the same. The right choice depends on your parts, materials, and production volume. Here’s a breakdown of the most common types with real-world context:

Vertical vs. Horizontal Machining Centers (VMC vs. HMC)

These two are the most widely used, but their strengths differ dramatically. Let’s compare them:

| Feature | Vertical Machining Center (VMC) | Horizontal Machining Center (HMC) |

|---|---|---|

| Spindle Orientation | Vertical (perpendicular to the ground) | Horizontal (parallel to the ground) |

| Best For | Top-surface work (plates, small casings) | Multi-sided parts (engine blocks, gearboxes) |

| Chip Removal | Needs frequent cleaning (chips pile on the table) | Gravity-aided (chips fall naturally) |

| Cost & Footprint | Compact, budget-friendly (small workshops) | Larger, pricier (high-volume production) |

Real Case Example: A medical device maker uses a VMC to machine small titanium casings (30mm x 20mm). The accessible table makes loading/unloading easy, and the coolant system directly targets the cutting area—critical for precision. Meanwhile, an automotive plant relies on HMCs for engine blocks, cutting 4 sides in one setup and slashing production time by 35% .

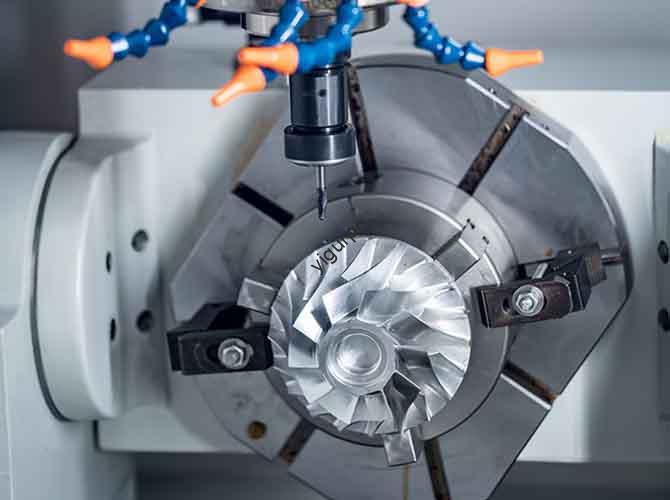

5-Axis Machining Center: Complex Geometry Made Easy

Unlike 3-axis models, 5-Axis Machining Centers move along X, Y, Z axes plus two rotary axes (A/B/C), letting you machine from almost any angle in one setup. This eliminates repositioning errors and speeds up work.

Case Study: An aerospace supplier needed aluminum housings (180mm x 120mm x 60mm) with ±0.008mm tolerance for avionics. Using a 5-axis machine, they cut setup from 4 operations to 1, achieved defect-free parts, and hit their 8,000 units/year target . Another example: A tool maker used a 5-axis center for U-drill bodies (Φ40mm x 278mm), boosting 良率 from 90-95% to 98% by avoiding tool interference .

Other Common Types

- 3-Axis Mill: Basic, affordable—great for simple 2.5D work like drilling and face milling.

- Turn-Mill Center: Combines milling and turning in one machine (ideal for parts needing both, like shafts).

- Gantry Machining Center: Large, heavy-duty—handles 巨型 parts (e.g., 5m+ mold plates) with high stability.

2. Key Components: What Makes a Machining Center Work?

Every part of a machining center plays a role in precision and speed. Let’s break down the critical components:

Core “Brains & Muscles”

- CNC Control System: The “brain” (e.g., Fanuc, Siemens). It runs programs and controls all movements. A good system has vibration suppression and speed optimization—key for smooth cuts .

- Spindle: The “cutting heart”. Spindle Speed (RPM) and Power matter: High speeds (12,000+ RPM) work for aluminum; high torque (300+ N·m) is for steel .

- Tool Magazine & ATC: The Tool Magazine stores tools (capacity ranges from 10-100+), and the ATC (Automatic Tool Changer) swaps them fast. For complex parts, a 20+ tool magazine cuts downtime by 40% .

Structural Backbone

- Machine Bed & Column: Made of rigid cast iron to reduce vibration. A stable bed ensures long-term precision.

- Ball Screw & Linear Guideways: These drive axis movement. Pre-stretched ball screws eliminate backlash, while linear guideways boost Rapid Traverse Rate (up to 60m/min with linear motors) .

Support Systems

- Chip Conveyor: Removes chips to keep the workspace clean (critical for HMCs with high chip volume).

- Coolant System: Prevents overheating. HMCs need more robust systems to flush chips from internal cavities .

3. Critical Technical Specs: How to Compare Machines

When shopping for a machining center, specs aren’t just numbers—they determine if the machine can do your job. Here’s what to focus on:

Precision Metrics

- Positioning Accuracy: How close the spindle gets to the target (aim for ±0.005mm or better for precision work).

- Repeatability: How consistently it hits the same target (±0.003mm or less is ideal for batch production) .

Performance Specs

| Spec | What It Means For You |

|---|---|

| Spindle Speed (RPM) | 12,000+ RPM = Fast aluminum milling; 6,000 RPM = Steel cutting |

| Feed Rate | Higher rates (20-50mm/min) = Faster material removal |

| Table Load Capacity | Must match your heaviest part (e.g., 5 tons for large molds) |

| Pallet Changer | Automated (swaps workpieces in seconds) = Less downtime |

Pro Tip: Don’t chase “big numbers”. A machine with 24,000 RPM is overkill if you only cut steel. Balance specs with your needs .

4. Common Machining Operations: What Can You Do?

Machining centers handle a range of tasks—here are the most frequent, with when to use them:

- Milling: Shapes material with rotating cutters (used for flat surfaces or slots).

- Drilling: Creates holes (pair with tapping for threaded holes).

- Contouring & 3D Profiling: Makes curved surfaces (critical for molds or aerospace parts).

- Pocketing: Cuts hollow areas (e.g., cavities in engine parts).

Case Example: A toy maker used 3D Profiling on a VMC to machine S136H mold parts for a popular action figure. The machine ran a 0.15mm small cutter for 10.5 hours straight, hitting ±10μm accuracy—no post-machining polishing needed .

Yigu Technology’s Perspective

Machining centers are evolving from “tools” to “smart production hubs”. We see three key trends: 5-axis machines are becoming standard for mid-sized shops (thanks to falling costs), CNC Control Systems are integrating AI for predictive maintenance (reducing downtime by 25%), and sustainability features (energy-efficient spindles, coolant recycling) are no longer optional. For businesses, the goal isn’t just buying a machine—it’s choosing one that scales with your needs, whether that’s prototyping or high-volume production. Prioritize rigidity, user-friendly controls, and reliable support over flashy specs.

FAQ: Your Top Machining Center Questions Answered

Q1: VMC or HMC—Which Should I Buy for Small-Batch Production?

A: Go with a VMC. It’s cheaper, easier to maintain, and fits in small spaces. HMCs only make sense if you need multi-sided machining for 500+ parts/month.

Q2: How Important Is Spindle Power for My Work?

A: Very—if you cut hard materials (steel, titanium), aim for 15+ kW. For aluminum or plastics, 5-10 kW is enough. Low power leads to slow cuts and tool wear.

Q3: Can a 5-Axis Machine Replace My 3-Axis Mill?

A: It depends. If you only do simple work (drilling, face milling), a 3-axis is more cost-effective. But if you’re moving to complex parts (e.g., medical implants), 5-axis saves time and improves accuracy.

Q4: What’s the Minimum Maintenance Needed?

A: Daily: Clean chips and check coolant level. Weekly: Lubricate ball screws and linear guideways. Monthly: Inspect spindle vibration. Neglecting maintenance cuts machine life by 30% .