If you’re in product development, you’ve likely heard about replica prototypes—but do you know why they’ve become such a valuable tool for manufacturers and designers? Unlike traditional manufacturing methods that rely on expensive steel molds, replica prototypes use silicone molds to create multiple copies of a master model. This approach offers unique benefits that make it ideal for certain production scenarios. In this guide, we’ll explore the core advantages of replica prototypes, helping you determine if they’re the right choice for your next project.

Understanding Replica Prototypes: What Makes Them Different

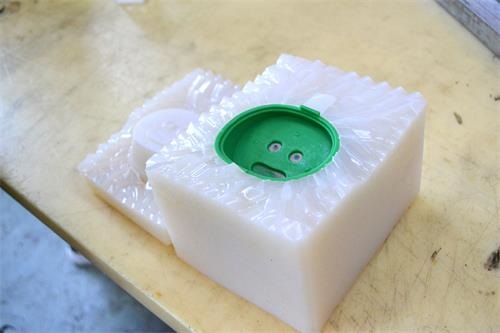

Before diving into advantages, let’s clarify what replica prototypes actually are. Also known as silicone mold prototypes or batch 复制 prototypes, this process involves creating a master model (often using 3D printing or CNC machining) and then making silicone molds from that master. These silicone molds are then used to produce multiple copies of the prototype, typically using materials like polyurethane resins that mimic the properties of production plastics.

This method sits between one-off rapid prototypes and mass production using steel molds. It’s designed for small to medium batch sizes, filling a critical gap in the product development cycle where you need more than a single prototype but not enough to justify the cost of expensive tooling.

Advantage 1: Cost-Effectiveness for Small to Medium Batches

One of the most compelling advantages of replica prototypes is their cost efficiency—especially when compared to traditional steel mold production. Let’s break down how this cost advantage works in real-world scenarios.

Dramatic Cost Reduction at Scale

While a single custom prototype might cost around 1,000 yuan, replica prototypes become significantly cheaper as you produce more units. Here’s how the numbers typically work out:

- First unit (master model + initial mold): Approximately 1,000 yuan

- Batch 复制 pricing: Generally 500 yuan or less per unit

- Dozens of units: Costs can drop to 200 yuan per unit or lower

This cost structure creates a clear financial advantage for small production runs. For example, if you need 50 prototypes, replica manufacturing would cost around 10,000-15,000 yuan (50 units × 200-300 yuan each) plus the initial mold cost. In contrast, producing 50 units using CNC machining would likely cost around 50,000 yuan (50 units × 1,000 yuan each), representing a cost savings of up to 70%.

Avoiding the High Cost of Steel Molds

Traditional steel molds for mass production can cost tens of thousands of yuan—sometimes hundreds of thousands—depending on complexity. This makes them impractical for small batches. Replica prototypes use silicone molds instead, which are far less expensive to create. Even if you need multiple silicone molds to meet your production needs, the total investment remains a fraction of what you’d spend on steel tooling.

Cost Comparison Table

| Production Method | Initial Setup Cost | Cost per Unit (50 units) | Total Cost for 50 Units |

| CNC Machining (one-off) | Low (no mold cost) | 1,000 yuan | 50,000 yuan |

| Replica Prototypes | Medium (silicone mold) | 200-300 yuan | 10,000-15,000 yuan |

| Steel Mold Production | High (steel tooling) | 50-100 yuan | 50,000+ yuan (setup dominates) |

This table clearly shows that replica prototypes offer the best value for small to medium production runs, where steel molds haven’t yet become cost-effective.

Advantage 2: Flexible Production Scalability

Replica prototypes offer impressive flexibility when it comes to scaling your production needs—without the rigidity of traditional manufacturing methods.

Ideal Batch Size Range

While you can technically produce any number of replica prototypes, they’re most cost-effective for batches ranging from just a few units up to 100-200 units. This sweet spot perfectly matches the needs of many product development stages:

- Market testing with limited samples

- Trade show displays requiring multiple identical units

- Initial product launches with low-volume production

- Internal testing across different departments or teams

Scaling with Multiple Molds

When you need more units than a single silicone mold can produce, you can simply create additional molds. This modular approach to scaling means you don’t have to invest in a single large (and expensive) mold upfront. Instead, you can produce molds as needed, matching your production volume to demand.

For example, if a single silicone mold can produce 50 units before needing replacement, and you need 150 units, you can create three separate molds. This not only allows you to meet your production target but also enables parallel production—using multiple molds simultaneously to speed up delivery.

Handling Larger Volumes When Needed

While replica prototypes are optimized for 100-200 units, they can handle larger volumes when necessary. The trade-off is that you’ll need to create additional silicone molds as existing ones wear out. This flexibility lets you bridge the gap between prototype and mass production without committing to expensive steel tooling until you’re certain of your design and market demand.

Advantage 3: Rapid Turnaround Times

In product development, time is often as valuable as money—and replica prototypes deliver impressive speed advantages.

Fast from Concept to Sample

One of the most significant time benefits is how quickly you can go from design to physical samples. The entire process—from finalizing your design to having production-ready prototypes in hand—typically takes just one week. This rapid turnaround includes:

- Creating the master model (1-2 days)

- Producing the silicone mold (1-2 days)

- Casting and finishing the prototypes (2-3 days)

Compare this to the weeks or even months required to produce steel molds and you can see why replica prototypes are so valuable for time-sensitive projects.

Speed Advantage for Exhibition and Foreign Trade

The rapid response capability of replica prototypes is particularly valuable for:

- Trade show preparations, where last-minute design changes are common

- Foreign trade samples, where quick turnaround can mean the difference between securing an order or losing to a competitor

- Time-to-market acceleration, where getting samples in front of stakeholders faster can shorten overall development cycles

A survey of product development teams found that using replica prototypes reduced time-to-sample by an average of 75% compared to traditional mold-based methods for small batches.

Advantage 4: Design Validation and Defect Prevention

Beyond cost and speed, replica prototypes offer significant advantages in ensuring your design is correct before moving to mass production.

Intuitive Design Expression

Replica prototypes create physical models that completely and intuitively express your product’s appearance and structure. It’s like printing a three-dimensional drawing that stakeholders can hold, examine, and test. This physical representation is far more effective than digital models or 2D drawings for identifying design issues.

Early Problem Detection

By creating accurate physical prototypes, you can identify and address design flaws during the development stage—before committing to expensive production tooling. Common issues caught using replica prototypes include:

- Fit and finish problems between components

- Ergonomic issues that aren’t apparent in digital models

- Aesthetic concerns that affect marketability

- Structural weaknesses under real-world use

Every defect identified and corrected at the prototype stage saves significant time and money down the line. Changing a design before creating steel molds can save tens of thousands of yuan in rework costs and prevent costly production delays.

Avoiding Mold Modification Costs

Perhaps the most valuable aspect of this design validation is avoiding expensive mold modifications. Once steel molds are produced, making changes can cost 30-50% of the original mold cost and delay production by weeks or months. Replica prototypes let you test multiple iterations quickly and inexpensively, ensuring your design is correct before investing in mass production tooling.

Advantage 5: Material Versatility

While not explicitly mentioned in our reference material, it’s worth noting that modern replica prototype techniques offer impressive material versatility—a significant advantage for many projects.

Mimicking Production Materials

Replica prototypes can use a wide range of casting resins that mimic the properties of production materials, including:

- ABS-like resins for general-purpose testing

- Polypropylene-like materials for flexibility

- High-temperature resins for heat resistance testing

- Transparent resins for optical clarity evaluation

This material versatility means your replica prototypes can accurately simulate the performance of your final product, making them suitable for functional testing as well as visual evaluation.

Color and Finish Options

Replica prototypes also offer various color and finish options, allowing you to evaluate not just form and function but also aesthetic appeal. This includes:

- Custom color matching to brand specifications

- Different surface textures (matte, glossy, textured)

- Special effects like metallic finishes or translucency

This level of customization helps ensure that your final product meets both functional and marketing requirements.

Limitations to Consider

While replica prototypes offer many advantages, it’s important to understand their limitations to make informed decisions:

- Silicone mold lifespan: Imported materials typically last for about 100 uses, while domestic materials last for dozens of uses. This means larger batches will require multiple molds.

- Production time for large batches: While fast for small runs, producing hundreds or thousands of units will take longer as you’ll need to cycle through multiple molds.

- Material properties: While casting resins mimic production plastics, they may not perfectly match all mechanical properties, making them less suitable for certain types of performance testing.

Understanding these limitations helps you choose the right production method for your specific needs.

Yigu Technology’s Perspective

At Yigu Technology, we recognize replica prototypes as a bridge between design and production. Their cost efficiency for small batches, rapid turnaround, and design validation capabilities make them invaluable for accelerating product development. By leveraging replica prototyping, our clients reduce risk, save time, and make more informed decisions before committing to mass production tooling.

Frequently Asked Questions (FAQ)

- What’s the ideal batch size for replica prototypes?

They’re most cost-effective for 10-200 units. Beyond 200 units, you may need multiple molds, and steel tooling might become more economical for very large volumes.

- How long do silicone molds last for replica prototypes?

Imported silicone molds typically last about 100 cycles, while domestic materials last around 50 cycles. This means you’ll need new molds as you approach these numbers.

- Can replica prototypes replace functional testing?

They’re excellent for design validation and basic functional testing, but for rigorous performance testing, you may still need prototypes made from production materials.