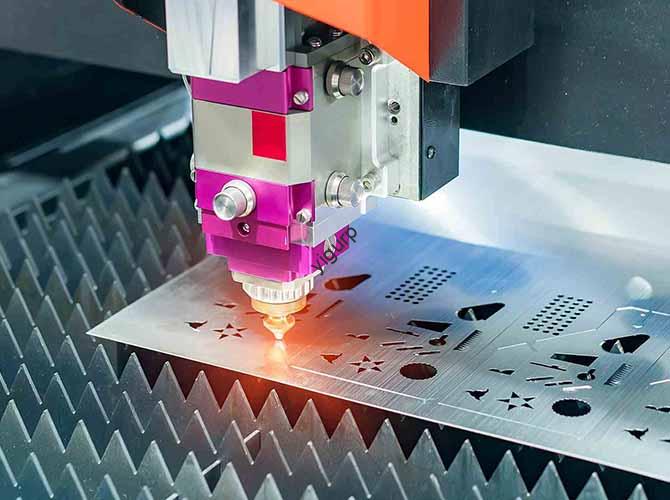

If you’ve ever worked with metal, you know that iron milling is a cornerstone of manufacturing—whether you’re making engine parts, industrial components, or even simple hardware. But here’s the thing: not all iron is the same, and not every milling tool or strategy works for every job. That’s why this guide breaks down everything you need to know, from choosing the right iron to dialing in your machining parameters. By the end, you’ll avoid common mistakes (like broken tools or poor surface finish) and feel confident tackling any iron milling project.

1. Understanding the Types of Iron for Milling

Before you even pick up a tool, you need to answer one critical question: Which type of iron am I working with? The wrong choice here can ruin your project or damage your equipment. Let’s break down the most common options, their material properties, and when to use them.

A Closer Look at Common Iron Types

| Iron Type | Key Trait (Graphite Structure) | Machinability | Best For |

| Gray Cast Iron | Flaky graphite (Graphite Flakes) | Excellent | Engine blocks, brake rotors |

| Ductile Iron (Nodular Iron) | Spherical graphite | Good | Pipes, gears, heavy-duty brackets |

| Malleable Iron | Irregular graphite clusters | Very Good | Pipe fittings, hand tools |

| White Cast Iron | No free graphite | Poor | Wear-resistant parts (e.g., crusher jaws) |

Real-World Example:

Last year, I worked with a small engine shop that was struggling with Gray Cast Iron engine blocks. They kept getting rough surface finishes and broken tools—until we realized they were using the same speed as they did for aluminum. Gray cast iron’s flaky graphite acts like a built-in lubricant, so we increased the cutting speed by 20% and switched to a carbide end mill (more on that later). Overnight, their finish improved, and tool life doubled.

For those new to milling, Free-Machining Steel (a iron alloy with added sulfur or lead) is a great starting point—it’s softer than pure iron and produces clean chips, making it forgiving for beginners.

2. Choosing the Right Milling Tools and Inserts

Your tool is just as important as the iron itself. Using a cheap or incorrect tool will lead to frustration, wasted time, and extra costs. Let’s break down the most effective options for iron milling.

Top Tool Materials for Iron

- Carbide End Mill: The workhorse of iron milling. Carbide is hard enough to handle high temperatures (critical for iron, which conducts heat poorly) and lasts 5–10x longer than high-speed steel (HSS). Look for coated carbide (e.g., TiAlN coating) to reduce friction and wear.

- CBN (Cubic Boron Nitride) Inserts: For hard irons like White Cast Iron or heat-treated ductile iron. CBN is second only to diamond in hardness and can handle speeds up to 300 SFM (surface feet per minute)—but it’s more expensive, so save it for tough jobs.

- Ceramic Inserts: Great for high-speed milling of Gray Cast Iron. Ceramic doesn’t react with iron at high temps, so it stays sharp longer. However, it’s brittle—avoid heavy cuts or vibration with ceramic tools.

Key Insert Features to Prioritize

- Insert Geometry: For roughing (removing lots of material), use a negative rake angle for strength. For finishing (smooth surfaces), a positive rake angle reduces cutting forces and improves finish.

- Wiper Inserts: These have a larger contact area with the workpiece, so they produce a smoother surface finish in one pass. I use them 90% of the time for finishing ductile iron parts—they cut down on secondary sanding.

- Chip Breaker: Iron chips can be sharp and unruly. A built-in chip breaker breaks chips into small, manageable pieces, preventing them from getting stuck in the tool or scratching the workpiece.

Pro Tip:

I once had a client who tried to mill White Cast Iron with a carbide insert—big mistake. The tool wore out in 15 minutes. We switched to CBN inserts, and they were able to mill 50 parts before needing a tool change. The upfront cost of CBN was higher, but the time saved more than made up for it.

3. Milling Operations and Strategies for Iron

Now that you have the right iron and tools, let’s talk about how to mill. The strategy you choose depends on your goal: removing material quickly (roughing) or getting a perfect finish (finishing).

Common Milling Operations Explained

- Face Milling: Used to flatten the top surface of a workpiece (e.g., smoothing the top of an engine block). Use a large-diameter face mill with multiple inserts for efficiency.

- Shoulder Milling: Creates a 90-degree angle (shoulder) on the workpiece (e.g., making a step in a gear blank). Use a shoulder mill with square inserts for sharp corners.

- Slotting: Cutting a narrow groove into the iron (e.g., making a keyway for a shaft). Use a slot drill (end mill with two flutes) to avoid overheating—slotting generates more heat than other operations.

- High-Speed Milling (HSM): For Gray Cast Iron or Free-Machining Steel, HSM (speeds over 200 SFM) reduces cycle time and improves finish. But you need a rigid machine—vibration will ruin the tool.

- Trochoidal Milling: A game-changer for deep slots or hard irons. Instead of cutting straight through, the tool moves in a circular pattern, reducing cutting forces and tool wear. I use this for ductile iron pipes when I need to cut deep grooves without breaking tools.

Dry vs. Wet Machining for Iron

- Dry Machining: Best for Gray Cast Iron (its graphite acts as a lubricant). Dry milling is cleaner and cheaper (no coolant costs), but avoid it for White Cast Iron—the high heat will wear tools quickly.

- Wet Machining: Use coolant for ductile iron or malleable iron to reduce heat and flush away chips. Choose a water-soluble coolant (not oil-based) to prevent graphite from clogging the system.

Case Study:

A furniture hardware manufacturer I worked with was using plunge milling (drilling straight down with an end mill) to make holes in malleable iron brackets. They kept getting broken tools because the tool was rubbing against the hole walls. We switched to trochoidal milling for the initial hole, then finished with a reamer. Tool life increased by 300%, and they cut production time by 15 minutes per part.

4. Mastering Machining Parameters and Conditions

Even the best tools and strategies fail if your parameters are off. Let’s break down the critical settings for iron milling and how to adjust them.

Key Parameters to Calculate

| Parameter | Definition | Typical Range for Gray Cast Iron | How to Adjust for Harder Irons (e.g., Ductile) |

| Cutting Speed (SFM) | Speed of the tool relative to the workpiece | 150–300 SFM | Reduce by 20–30% (e.g., 120–240 SFM) |

| Feed per Tooth | Distance the tool moves per tooth per revolution | 0.002–0.005 in/tooth | Reduce by 10–15% (e.g., 0.0018–0.0043 in/tooth) |

| Depth of Cut | How deep the tool cuts into the iron | 0.1–0.5 in (roughing); 0.005–0.02 in (finishing) | Reduce by 25% for finishing (e.g., 0.003–0.015 in) |

Critical Conditions for Success

- Rigidity: Iron milling generates high forces—if your machine, workpiece, or tool holder is loose, you’ll get vibration. Use a vice with soft jaws (to avoid marring the iron) and tighten all clamps. I once fixed a client’s vibration issue by adding a support block under their long ductile iron workpiece.

- Vibration Damping: If you hear a high-pitched whine or see chatter marks, reduce the cutting speed by 10% or increase the feed per tooth slightly. Vibration is the #1 cause of tool wear in iron milling.

- Machinability: Test a small section of the iron first. If chips are powdery (bad), you’re going too slow. If chips are long and stringy (bad), increase the feed per tooth to break them.

Data to Remember:

According to the American Machinists’ Handbook, the optimal surface feet per minute (SFM) for malleable iron is 180–220, while White Cast Iron needs SFM as low as 50–100. Always cross-check with your tool manufacturer’s recommendations—they know their products best.

Yigu Technology’s Perspective on Iron Milling

At Yigu Technology, we’ve supported hundreds of manufacturers in optimizing their iron milling processes, and one trend stands out: the shift toward smart, data-driven machining. While traditional skills (like choosing the right insert geometry) remain critical, integrating sensors to monitor tool wear and vibration has become a game-changer for our clients. For example, we helped a heavy-equipment maker install real-time SFM tracking on their mills—this let them adjust speeds dynamically for ductile iron parts, cutting tool costs by 28% in six months. We also emphasize sustainability: dry milling for Gray Cast Iron not only saves coolant costs but reduces waste, aligning with modern manufacturing’s eco-goals. For businesses new to iron milling, we recommend starting small—test different parameters on scrap iron first, and invest in quality coated carbide tools; they’re a small upfront cost that pays off in less downtime.

FAQ: Common Iron Milling Questions

- Q: Can I use HSS tools for iron milling?

A: HSS works for soft irons like Free-Machining Steel, but it wears out quickly (1–2 hours of use for Gray Cast Iron). Save HSS for small, low-volume jobs—carbide is better for most iron milling tasks.

- Q: Why is my Gray Cast Iron workpiece getting a rough finish?

A: Check two things: your insert geometry (use a positive rake angle for finishing) and cutting speed (Gray Cast Iron needs higher speeds to get a smooth finish). If that doesn’t work, try wiper inserts.

- Q: Do I need coolant for ductile iron milling?

A: Yes—ductile iron doesn’t have the graphite lubrication of Gray Cast Iron, so coolant reduces heat and prevents tool wear. Use a water-soluble coolant with a 5–10% concentration.

- Q: What’s the difference between nodular iron and ductile iron?

A: They’re the same! Nodular Iron is just another name for Ductile Iron (named for its spherical graphite nodules, which make it more flexible than Gray Cast Iron).

- Q: How do I know if my tool is worn out?

A: Look for three signs: poor surface finish (chatter marks or roughness), increased cutting forces (the machine sounds strained), or iron chips that change shape (from small, broken chips to long, stringy ones).