When it comes to making plastic parts—whether for prototypes, small batches, or mass production—two processes dominate: Injection Molding and 3D Printing. Injection Molding uses molds to pour molten plastic into shapes, while 3D Printing builds parts layer by layer from filaments or resin. Both have strengths, but the wrong choice can waste time, money, or ruin your project. This guide breaks down their differences, explains when to use each, shares real-world examples, and helps you make an informed decision.

First: What Are Injection Molding and 3D Printing? (Core Principles)

To compare them, you need to understand how each process works—their basic steps explain why they excel at different tasks.

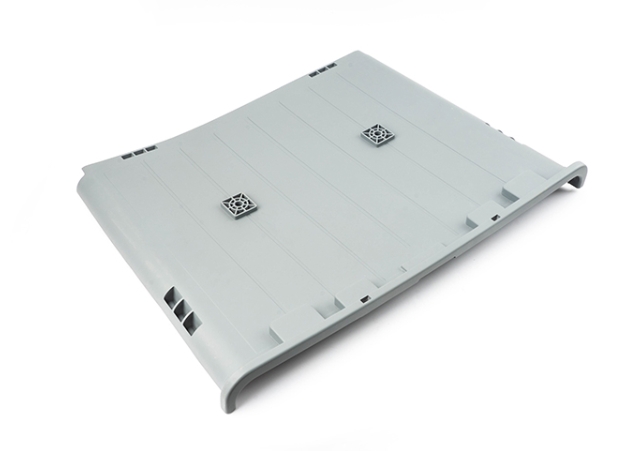

Injection Molding: Mold-Based, High-Volume Production

Injection Molding is a “mold-and-pour” process, ideal for making hundreds or thousands of identical parts. Here’s how it works in 5 simple steps:

- Make the Mold: A mold (usually aluminum or tool steel) is machined to match the part’s shape—this is the most time-consuming and costly step (molds can take 10–20 days to make).

- Melt the Plastic: Thermoplastic pellets (e.g., ABS, PC, Nylon) are heated to 200–300°C until they melt into a liquid.

- Inject into the Mold: The molten plastic is forced into the mold under high pressure (10–100 MPa) to fill every detail.

- Cool and Harden: The plastic cools inside the mold (usually 1–5 minutes) and hardens into the part’s shape.

- Remove and Finish: The mold opens, the part is removed, and any excess plastic (called “flash”) is trimmed off.

Key Trait: Relies on molds—great for high volume, but expensive to set up for small batches.

3D Printing: Layer-Based, Low-Volume Flexibility

3D Printing (Additive Manufacturing) builds parts from the bottom up, no mold needed. The two most common 3D Printing processes for plastics are:

FDM (Fused Deposition Modeling) – Filament-Based

- A spool of thermoplastic filament (e.g., PLA, ABS) feeds into a heated nozzle.

- The nozzle melts the filament (180–260°C) and deposits it onto a build plate in thin layers (0.05–0.3 mm thick).

- Layers cool and bond together, and the build plate lowers to add the next layer—repeat until the part is done.

SLA (Stereolithography) – Resin-Based

- A vat holds liquid resin (sensitive to UV light).

- A UV laser traces the part’s first layer onto the resin, curing it into a solid.

- The build plate lifts, fresh resin flows over the cured layer, and the laser repeats—layers stack until the part is complete.

- The part is rinsed to remove excess resin and cured again for strength.

Key Trait: No molds—perfect for small batches, prototypes, or complex designs that molds can’t make.

Injection Molding vs. 3D Printing: Key Comparison (Data & Details)

The table below compares the two processes across 8 critical factors—cost, speed, design flexibility, and more—using real-world data from manufacturers like Xometry and industry studies.

| Factor | Injection Molding | 3D Printing (FDM/SLA) |

| Upfront Cost | High (\(1,000–\)100,000+ for molds) | Low (\(150–\)2,000 for desktop printers) |

| Per-Part Cost | Low (\(0.10–\)5 for high volume) | High (\(5–\)50 for small batches) |

| Production Speed (1,000 parts) | Fast (1–2 days) | Slow (1–2 weeks) |

| Production Speed (10 parts) | Slow (10–20 days for mold + 1 day for parts) | Fast (3–5 days) |

| Design Complexity | Limited (molds can’t make lattices/hollow interiors easily) | High (can make complex shapes with no extra cost) |

| Part Strength | Strong (no layer lines—uniform plastic) | Weaker (layer lines cause weak points; FDM is stronger than SLA) |

| Surface Finish | Smooth (no layer lines—ready to use) | Rough (FDM has visible layers; SLA is smoother but needs rinsing) |

| Material Options | Wide (thermoplastics like ABS, PC, Nylon) | Moderate (FDM: PLA/ABS/PETG; SLA: resins) |

| Batch Size Sweet Spot | 1,000+ parts | 1–100 parts |

| Material Waste | Low (uses only the plastic needed for the part) | Moderate (FDM: 10–20% waste from supports; SLA: 20–30% resin waste) |

Real-World Cases: When to Choose Injection Molding vs. 3D Printing

Numbers tell part of the story—but real projects show how these processes perform in practice. Here are 3 examples where the choice made a big difference.

Case 1: Mass-Produced Phone Cases (Injection Molding Wins)

A consumer brand needed 10,000 plastic phone cases (ABS material) for a new product launch.

- 3D Printing (FDM) Option: Each case took 2 hours to print. 10,000 cases would take 20,000 hours (833 days) and cost \(10 per case (\)100,000 total). The cases had visible layer lines and needed sanding.

- Injection Molding Option: The mold cost \(5,000 and took 15 days to make. Once the mold was ready, 10,000 cases were made in 1 day at \)1 per case ($10,000 total). The cases were smooth, strong, and ready to ship.

Result: The brand chose Injection Molding—saved $85,000 and met their launch deadline.

Case 2: Custom Dental Prototypes (3D Printing Wins)

A dental lab needed 5 custom crown prototypes (to test fit for patients) made from biocompatible material.

- Injection Molding Option: A mold for 5 small crowns would cost \(2,000 and take 10 days to make. The prototypes would cost \)0.50 each, but the total ($2,002.50) was overkill for 5 parts.

- 3D Printing (SLA) Option: Using biocompatible resin, the lab printed 5 crowns in 2 days. Each crown cost \(8, total \)40. The prototypes had tight tolerance (±0.1 mm) and fit patients perfectly.

Result: The lab chose 3D Printing—saved $1,962.50 and got prototypes fast enough to treat patients on time.

Case 3: Complex Drone Frame (3D Printing Wins)

A startup needed 20 drone frames with a hollow lattice design (to reduce weight) made from Nylon PA12.

- Injection Molding Option: A mold for the lattice design was impossible—molds can’t create internal hollow structures without extra parts. Even if a mold was made, it would cost $10,000 and take 20 days.

- 3D Printing (MJF) Option: The startup used MJF (a 3D Printing process for Nylon) to print 20 frames in 3 days. Each frame cost \(30, total \)600. The lattice design reduced weight by 40%—critical for drone flight.

Result: The startup chose 3D Printing—avoided impossible mold costs and got the lightweight design they needed.

How to Choose Between Injection Molding and 3D Printing (Step-by-Step)

Follow these 4 steps to pick the right process—no guesswork needed.

Step 1: Define Your Batch Size

Batch size is the biggest factor—here’s the rule of thumb:

- 1–100 parts: Choose 3D Printing (no mold costs, fast setup).

- 100–1,000 parts: Choose 3D Printing (MJF/SLS) or Injection Molding—calculate total cost (mold + parts vs. 3D Printing per-part cost).

- 1,000+ parts: Choose Injection Molding (mold costs are spread over many parts, per-part cost is low).

Example: 500 parts: Injection Molding (mold \(3,000 + \)1 per part = \(3,500) vs. 3D Printing (MJF: \)5 per part = $2,500). 3D Printing is cheaper here.

Step 2: Check Your Design Complexity

- Simple, uniform shapes (e.g., phone cases, cups): Injection Molding works.

- Complex shapes (lattices, hollow interiors, organic curves): 3D Printing is the only option—molds can’t make these.

Pro Tip: If your design has undercuts (parts that stick out and block mold removal), Injection Molding needs expensive “complex molds.” 3D Printing handles undercuts for free.

Step 3: Prioritize Strength and Surface Finish

- Need strong, smooth parts (e.g., engine components, medical devices): Injection Molding—parts have no layer lines and uniform strength.

- Strength is less critical (e.g., prototypes, display models): 3D Printing (FDM for functional parts, SLA for smooth details).

Step 4: Calculate Total Cost (Upfront + Per-Part)

Total cost = upfront cost + (per-part cost × number of parts). Use this to compare:

| Batch Size | Injection Molding Total Cost | 3D Printing (FDM) Total Cost |

| 10 parts | \(5,000 (mold) + \)5 (parts) = $5,005 | \(50 (parts) = \)50 |

| 100 parts | \(5,000 (mold) + \)50 (parts) = $5,050 | \(500 (parts) = \)500 |

| 1,000 parts | \(5,000 (mold) + \)500 (parts) = $5,500 | \(5,000 (parts) = \)5,000 |

| 5,000 parts | \(5,000 (mold) + \)2,500 (parts) = $7,500 | \(25,000 (parts) = \)25,000 |

Key Takeaway: Injection Molding becomes cheaper than 3D Printing at around 1,000 parts for most projects.

Yigu Technology’s Perspective on Injection Molding vs. 3D Printing

At Yigu Technology, we don’t pick sides—we pick what fits your project. For clients needing mass production (1,000+ parts) like consumer goods or automotive components, we recommend Injection Molding for its low per-part cost and strong parts. For startups prototyping complex designs or small batches (1–100 parts) like medical guides or drone frames, 3D Printing (FDM/MJF) is faster and more cost-effective. We also help with hybrid approaches: use 3D Printing for prototypes to test designs, then switch to Injection Molding for production. Our team provides cost quotes and sample parts for both processes, so you’re never guessing. The best process is the one that meets your budget, timeline, and part needs.

FAQ About Injection Molding vs. 3D Printing

1. Can 3D Printing replace Injection Molding for mass production?

No—3D Printing is too slow and expensive for large batches (1,000+ parts). Injection Molding’s per-part cost is 10–100x lower, and it can make parts 50x faster. 3D Printing is great for prototypes or small batches, but Injection Molding is still the best for mass production.

2. Is Injection Molding worth it for small batches (under 100 parts)?

Rarely—unless you need ultra-strong, smooth parts and have a big budget. For 100 parts, Injection Molding’s mold cost (\(1,000–\)5,000) will make your total cost 10–50x higher than 3D Printing. Only choose Injection Molding for small batches if no other process can meet your strength/finish needs.

3. Which process is better for complex designs (e.g., lattices, hollow parts)?

3D Printing is the only practical option. Injection Molding molds can’t create internal hollow structures or lattices without adding expensive, complex features (like sliding cores). 3D Printing builds parts layer by layer, so complex designs cost the same as simple ones—no extra setup needed.