In modern manufacturing, precision machining suppliers are much more than “part producers” – they are the guardians of product quality, boosters of production efficiency, and even partners in technological innovation. Whether it’s the micron-level requirements for component accuracy in the aerospace sector or the stringent standards for biocompatibility in the medical device industry, choosing a reliable supplier directly determines the competitiveness of the end product.

However, in reality, many companies face such a dilemma: either they cannot find a supplier that can meet complex processing needs, or they have problems such as unstable quality, delivery delays, and cost overruns after cooperation. This article will help you systematically solve the core problems of “how to choose, how to judge, and how to cooperate” from the five core dimensions of technical capabilities, quality control, material application, supply chain services, and industry adaptation, combined with real cases and practical tools, so that you can avoid detours.

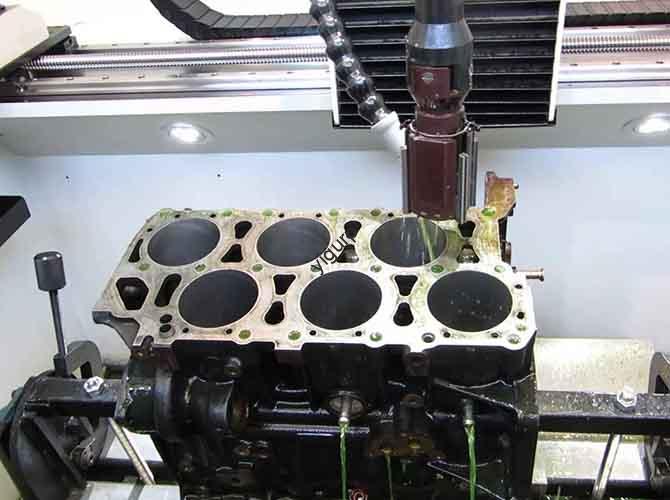

1. Processing capabilities and technical expertise: What do you think of the “hard power” of suppliers?

1.1 Adaptability of core processing technology: not the more advanced the better, but the more matching the better

When choosing suppliers, enterprises are prone to fall into the “cult of technology” – thinking that high-end technologies such as five-axis machining and automated production will definitely bring better results. But practical cases prove that adaptability is the key.

Case sharing: A new energy company needed to mass-produce automotive motor shafts and initially chose a supplier with a five-axis machining center, but due to the complex debugging of five-axis equipment and the high cost of replacement, the cost of the small-batch trial production stage was 30% higher than expected. Later, it was changed to a supplier focusing on turning, milling and CNC machining, and not only met the accuracy requirement of ±0.005mm but also reduced the unit cost by 18% through customized chemical fixtures and optimized machining processes.

Clear comparison of applicable scenarios for different processing technologies:

| Processing technology | Core strengths | Applicable scenarios | Accuracy range |

| CNC machining | Stable batch and strong flexibility | General precision parts | ±0.005-0.01mm |

| 5-axis machining | Complex surfaces, one-time forming | aerospace components | ±0.002-0.005mm |

| EDM EDM | Hard materials, fine structures | Mold cavities, micro holes | ±0.001-0.003mm |

| Microfabrication technology | Micron-level structure and high integration | electronic components, medical microdevices | ±0.0005-0.001mm |

| Rapid prototyping | Short cycle and low cost | Product development proofing | ±0.01-0.02mm |

1.2 Three core criteria for judging technical strength

In addition to the type of technology, the actual capabilities of the supplier need to be verified from the following 3 points:

- Equipment configuration: whether it has imported high-precision equipment (such as Japanese Mazak and German Demagi machine tools), whether the number of equipment can support the order volume, and whether there are equipment calibration and maintenance records;

- Process optimization capabilities: whether it can provide process improvement suggestions (such as reducing processing processes and improving material utilization) according to part drawings, and whether there are successful cases for complex parts;

- Technical team: The engineer team’s years of experience, whether they have industry certifications (such as CNC senior technician certificates), and whether they can provide technical docking and problem solutions.

2. Quality control and certification standards: How to ensure that each batch of products is qualified?

2.1 Basic certification is the threshold, and process control is the core

ISO 9001 certification is a fundamental threshold for precision machining suppliers, but certification alone is not enough to guarantee quality. A truly reliable supplier will establish a full-process quality control system.

Case sharing: When choosing an orthopedic implant processing supplier, a medical device company eliminated a number of companies with only ISO 9001 certification, and finally chose a supplier that also passed the ISO 13485 medical industry special certification. The supplier’s quality control system includes: material composition analysis at the time of raw material entry (detected by spectrometer), SPC statistical process control during processing (sampling to detect dimensions every 2 hours), non-destructive testing (X-ray flaw testing) and surface roughness testing before the finished product leaves the factory (Ra≤0.8μm) to ensure that the product meets the biocompatibility and mechanical properties requirements of the medical industry.

2.2 Key links and testing methods of quality control

| Control link | Core testing items | Commonly used testing equipment | Industry standard requirements |

| Raw material inspection | Composition analysis, hardness test | Spectrometer, hardness tester | Comply with material grade standards (e.g. GB/T 3190-2022) |

| Process inspection | dimensional accuracy, shape and position tolerance | CMM, projector | Execute according to the tolerance marked on the drawing |

| Finished product inspection | Surface quality, non-destructive testing | Roughness meter, X-ray flaw detector | No surface defects, no internal defects |

| Compliance checks | environmental protection indicators, biocompatibility | Gas chromatograph, cytotoxicity tester | Compliant with RoHS/REACH, ISO 10993 standards |

2.3 2 practical tips to avoid quality risks

- Require suppliers to provide quality control plans (QCP): clarify the testing standards, sampling ratios, and non-conforming product handling processes in each link;

- On-site inspection of quality laboratories: Verify the advancement and calibration of testing equipment, and check past quality inspection reports and customer complaint handling records.

3. Material selection and application scope: choosing the right material is more important than processing?

3.1 Matching logic between material properties and processing technology

The processing difficulty, cost and applicable scenarios of different materials vary greatly, and whether suppliers can recommend suitable materials according to product needs and master the corresponding processing technology is one of the core competitiveness.

Professional interpretation: Taking aerospace parts as an example, commonly used titanium alloys have the advantages of high strength and corrosion resistance, but they are difficult to process (poor thermal conductivity, easy sticking knives), requiring suppliers to have special tools, low-speed cutting processes, and cooling systems; while aluminum alloys are less difficult to process and have controllable costs, but their strength is low, making them suitable for structural parts rather than load-bearing components. If the supplier selects the wrong material or the processing process is improper, even if the accuracy is up to standard, it will lead to product failure during use.

3.2 Application scenarios and processing points of mainstream processing materials

| Material type | Core features | Typical applications: | Processing precautions |

| stainless steel | Corrosion resistance and high strength | Medical equipment, food machinery | Avoid cutting temperatures that are too high and prevent knives from sticking |

| Titanium alloy | High strength and light weight | aerospace, orthopedic implants | Adopt special tools for low-speed cutting |

| Engineering plastics | Low cost and good insulation | Electronic housings, car interiors | Control the processing deformation and avoid melting at high temperatures |

| Superalloys | High temperature resistance and fatigue resistance | engine blades, gas turbines | Carbide tools are used for optimized cooling |

| Composites | Lightweight and high strength | New energy vehicles, drones | Prevents delamination and fiber damage |

3.3 Three decision steps for material selection

- Clarify the use environment (temperature, humidity, medium) and performance requirements (strength, hardness, corrosion resistance) of the product;

- Communicate with suppliers about material selection suggestions and compare the cost and processing feasibility of different materials.

- Suppliers are required to provide material samples and performance test reports to verify compliance with requirements.

4. Supply chain management and service model: the key factor in the smoothness of cooperation

4.1 On-time delivery rate: A more important metric than price

In manufacturing, the loss of “downtime” often far exceeds the cost of parts. Therefore, on-time delivery rates of suppliers are a core indicator of supply chain management. According to industry data, quality precision machining suppliers should have an on-time delivery rate of more than 98%, compared to the industry average of only around 85%.

Case study: A robot company once cooperated with a supplier with a lower quotation, but the supplier experienced multiple delivery delays due to the lack of flexible production planning and order tracking systems, resulting in the shutdown of the robot assembly line. Later, it was replaced by a supplier with global logistics support and supplier collaboration system, and the on-time delivery rate increased to 99.2% and the assembly line efficiency increased by 20% by sharing production plans and tracking order status in real time.

4.2 The core value of the service model: from “passive response” to “active service”

Quality suppliers not only meet basic needs, but also provide value-added services:

- One-stop service: from design optimization, material procurement, processing and production to finished product delivery, the whole process service reduces the communication cost of enterprises;

- After-sales technical support: when there is a problem during the use of the product, it can quickly provide solutions, and even door-to-door service;

- Cost optimization suggestions: help enterprises reduce production costs through process improvement, material substitution, etc.

4.3 Evaluation dimension of supply chain capability

| Evaluate the dimension | Key indicators | Verification method |

| Deliverability | On-time delivery rate, order response cycle | View past delivery records and communicate delivery safeguards |

| Logistics support | Logistics network coverage and transportation mode selection | Meet logistics partners and validate global delivery capabilities |

| Order management | Order tracking system, information transparency | Test the order inquiry function to assess communication efficiency |

| Flexible production | Small-batch customization capabilities, urgent order response | Ask about urgent order processing cases and cycles |

5. Industry applications and customized solutions: The degree of matching determines the depth of cooperation

5.1 Industry experience: an important guarantee to reduce cooperation risks

The processing requirements vary greatly across industries, and the supplier’s industry experience directly affects the success rate of cooperation. For example, the aerospace industry has extremely high requirements for the reliability and traceability of parts, requiring suppliers to have AS9100 certification and a complete batch traceability system; while the automotive industry pays more attention to cost control and efficiency in mass production.

Case Study: When selecting an engine blade supplier, an aerospace company prioritized companies with more than 10 years of experience in processing aviation parts. This supplier is not only familiar with the OEM/ODM cooperation model in the aviation industry but also provides customized solutions that meet aviation standards, improving the service life of blades by 30% by optimizing blade structure design and processing technology.

5.2 Core processes for customized solutions

- Demand communication: Gain an in-depth understanding of product usage scenarios, performance requirements, and batch requirements.

- Scheme design: Combine its own technical advantages to provide design optimization and process solutions;

- Sample trial production: make samples and conduct performance tests, and adjust the scheme according to the test results;

- Mass production: Formulate detailed production plans to ensure product quality and delivery cycles;

- Continuous Optimization: Continuously improve products and services based on customer feedback and market changes.

5.3 Focus on customized needs in different industries

| Industry Sectors | Core requirements | Customization focus |

| Aerospace | High precision and high reliability | Material selection, process optimization, batch traceability |

| Medical devices | Biocompatible, miniaturized | Microfabrication technology, aseptic production |

| Automotive manufacturing | Stable batch and controllable cost | Flexible production and process standardization |

| Electronic communication | Lightweight and integrated | Precision injection molding, surface treatment |

6. Yigu Technology’s views

Choosing a precision machining supplier is essentially choosing a long-term partner. Enterprises should not only focus on price, but should comprehensively evaluate from four dimensions: technical strength, quality control, supply chain capabilities and industry adaptability. High-quality suppliers can help enterprises reduce costs, improve efficiency, and enhance product competitiveness through technological innovation and service optimization. In the context of the transformation and upgrading of the manufacturing industry, the professional ability and innovation awareness of suppliers will become an important part of the core competitiveness of enterprises, so investing enough time and energy to choose the right precision machining supplier is a key decision for the sustainable development of enterprises.

7. FAQ FAQ

- Q: What is the MOQ of precision machining suppliers in general?

A: The MOQ varies greatly from supplier, usually the MOQ for CNC machining is 10-50 pieces, and rapid prototyping can support a minimum order of 1 piece. It is recommended to communicate with suppliers according to their own needs, and some suppliers can reduce the MOQ by optimizing the process.

- Q: How to verify whether the supplier’s machining accuracy is up to standard?

A: Suppliers can be asked to provide samples and conduct precision tests through third-party testing institutions; You can also inspect the supplier’s testing equipment and quality control process on the spot, and check past test reports.

- Q: How long is the general cycle of customized processing?

A: Customized processing cycles depend on product complexity, batch size, and supplier production capacity. It usually takes 3-7 days for small batches of samples and 15-30 days for mass production. It is recommended to confirm the delivery cycle with the supplier in advance and allow a certain buffer time.

- Q: What are the costs included in the supplier’s quotation?

A: The quotation usually includes material cost, processing fee, testing fee, packaging fee and logistics fee. It is recommended to clarify the details of various fees at the quotation stage to avoid additional charges in the future.

- Q: What is the supplier’s handling process if there is a quality problem with the product?

A: Quality suppliers will first confirm the cause of the problem and then provide rework, restocking or refund plans. Before cooperation, the handling process and responsibility division of quality problems should be clarified to avoid disputes.