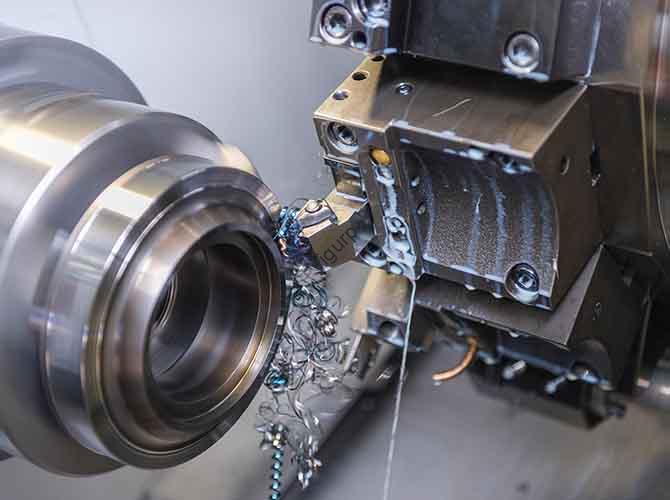

CNC machining right-angle is a core requirement in manufacturing, especially for parts like structural brackets, mold cavities, and mechanical components. However, achieving sharp, accurate right angles (with minimal residual R-values) demands a mix of process optimization, tool selection, and equipment control. This article breaks down proven technical paths, key tips, and real-world comparisons to help you solve right-angle machining challenges.

1. Core Technical Paths for CNC Machining Right-Angle

There are three mainstream solutions for CNC machining right-angle, each tailored to specific scenarios. Below is a detailed breakdown of their workflows, advantages, and ideal uses:

1.1 Patented Technology-Based Standardized Process

This path relies on standardized steps and conventional equipment, making it cost-effective for universal right-angle structures.

Linear Workflow (4 Key Steps)

- Roughing Pretreatment: Use high-feed cutters to quickly remove 80–90% of excess material, creating a preliminary profile with 0.3–0.5 mm machining allowance for finishing.

- Chamfering Tool Selection & Layout: Choose a dedicated chamfering tool (e.g., 90° indexable chamfer mills) to identify two critical features: the first cutting wall, the second cutting wall, and the fillet between them.

- Tool Attitude Adjustment: Align the chamfer tool’s axis perpendicular to the first cutting wall, then tilt it by 3–5° away from the right-angle vertex. This ensures one side of the tool’s cutting edge stays perpendicular to the first wall, avoiding overcutting.

- Fixed Axis Machining Execution: Lock the adjusted tool axis direction via CNC program (e.g., G-code G54 for work offset) and control the tool path with 0.01 mm step increments to minimize residual marks.

Advantages

- No need for special equipment—works with standard 3-axis CNC machines.

- Low process risk and cost, suitable for mass production of exposed right-angle parts (e.g., aluminum structural frames).

1.2 Spindle Orientation Technology for High-Precision Needs

This path is designed for complex structures like deep cavities or internal right angles, where standard processes struggle to reach tight tolerances.

Key Technologies & 5-Step Strategy

| Step | Action | Technical Details |

| 1 | Roughing | Use end mills to remove bulk material, leaving 0.2 mm allowance for finishing. |

| 2 | Finishing | Use ball-end mills to smooth the cavity walls, reducing initial surface roughness (Ra <1.6 μm). |

| 3 | Right-Angle Groove Roughing | Adopt custom spool mills to pre-cut the right-angle groove, avoiding tool chipping in hard materials. |

| 4 | Spindle Directional Insert Milling | Use the machine spindle’s arbitrary angle positioning function (e.g., FANUC system’s secondary development code M88/M89) to adjust the spindle angle dynamically. This ensures the tool cuts along the right-angle vertex without leaving residual R-values. |

| 5 | Finished Product Separation | Use low-feed, high-speed cutting (spindle speed: 4,000–6,000 RPM) to separate the part, preventing edge deformation. |

Tool & Equipment Requirements

- Custom Tools: Moderately thick alloy steel slotted knives with small rounded edges (R <0.1 mm) to resist chipping—ideal for hard metals like stainless steel (HRC 30–45).

- Rigidity Enhancement: Use shrink-fit tool holders to improve clamping rigidity, reducing vibration in deep cavity machining (depth-to-diameter ratio >5:1).

1.3 EDM-Assisted Processing (for Extreme Precision)

Electrical Discharge Machining (EDM) is a supplementary method for scenarios requiring ultimate right-angle accuracy (tolerance <±0.005 mm).

How It Works

EDM uses electrical sparks to erode metal, creating sharp right angles without physical tool contact. It is often used after CNC machining to eliminate residual R-values in critical areas (e.g., mold cores for injection molding).

Pros & Cons

- Pros: Achieves near-perfect right angles (theoretical R ≈0) with no mechanical stress.

- Cons: High cost (3–5x more expensive than CNC) and low efficiency (processing time 10–20x longer than spindle orientation technology).

2. Process Optimization & Programming Tips for Better Right-Angles

Even with the right technical path, small programming or parameter errors can ruin right-angle precision. Follow these actionable tips:

2.1 Toolpath Planning

- Root Cleaning Treatment: Add a corner cleaning program (e.g., G02/G03 arc interpolation) after the main machining cycle. This ensures uniform 0.05 mm allowances on both the side and bottom of the right angle, reducing residual R-values from 0.2 mm to <0.05 mm.

- Advance/Retreat Knife Strategy: Avoid vertical cutting on the contour surface—use diagonal cutting (45° angle to the right-angle vertex) for tool entry/exit. This minimizes tool marks caused by sudden direction changes.

2.2 Parameter & Equipment Configuration

- Cutting Parameter Adaptation: Adjust spindle speed and feed rate based on material hardness:

- Soft materials (aluminum, plastic): Spindle speed = 6,000–8,000 RPM; Feed rate = 0.1–0.15 mm/rev (can achieve theoretical R ≈0 directly).

- Hard materials (steel, titanium): Spindle speed = 3,000–5,000 RPM; Feed rate = 0.05–0.08 mm/rev (reduces tool wear and overcutting).

- Rigidity Boost: For deep cavity machining, use high-rigidity machine tools (e.g., 5-axis CNC with double-column structure) and shorten the tool overhang (keep it <3x the tool diameter) to reduce vibration.

2.3 Design-Manufacturing Collaboration

- Early Designer Intervention: Advise designers to avoid “over-theoretical right angles” (e.g., R=0 in 5 mm thick steel parts). Such designs force excessive tool wear and increase machining difficulty by 40–60%.

- Tolerance Allocation: Mark acceptable R-value ranges on drawings (e.g., “R 0.05–0.1 mm”) for actual processing. This balances design requirements with manufacturing feasibility.

3. Comparison of CNC Machining Right-Angle Solutions

Use this table to select the best solution for your project:

| Solution | Advantage | Limitation | Applicable Scenario |

| Patented Standardized Process | Low cost, no special equipment | Not suitable for deep cavities/internal right angles | Exposed right angles, simple structures (e.g., aluminum brackets) |

| Spindle Orientation Technology | High precision, one-clamping multi-angle machining | Requires custom tools and programming | Deep cavities, internal right angles, small-batch production (e.g., aerospace parts) |

| EDM-Assisted Processing | Ultimate accuracy (R≈0) | High cost, low efficiency | Single-piece production for extreme precision (e.g., mold cores) |

Yigu Technology’s Perspective

At Yigu Technology, we believe CNC machining right-angle success lies in matching the right technical path to project needs. For most clients (automotive, electronics), we prioritize spindle orientation technology—integrating FANUC’s M88/M89 codes with custom alloy steel tools to achieve R <0.05 mm in deep cavities. We also optimize toolpath planning: our corner cleaning program reduces residual R-values by 70% compared to standard methods. For extreme precision cases (e.g., medical molds), we combine CNC with EDM but streamline workflows to cut EDM time by 30%. Ultimately, the goal is not just “sharp right angles”—but cost-effective, stable precision that meets mass production demands.

FAQ

- What is the minimum residual R-value achievable with CNC machining right-angle?

With spindle orientation technology and optimized parameters, the minimum residual R-value can reach 0.02–0.05 mm for most metals. For R≈0, EDM-assisted processing is required.

- Can 3-axis CNC machines achieve internal right-angle machining?

Yes, but with limitations: 3-axis machines work for shallow internal right angles (depth <3x tool diameter). For deep cavities (depth >5x tool diameter), 5-axis machines with spindle orientation are better—they avoid tool overhang and vibration.

- How to reduce tool wear when machining right angles in hard materials?

Use TiAlN-coated carbide tools (resist high temperatures) and adopt a “layered cutting” strategy (cutting depth = 0.1–0.2 mm per pass). Also, use oil-based coolant to reduce friction—this extends tool life by 20–30%.