If you’re working with carbon fiber—whether for aerospace components, high-performance automotive parts, or advanced sports equipment—you’ve probably asked: What makes carbon fiber machining different, and how do I do it right? The short answer is: carbon fiber’s unique properties (high strength-to-weight ratio, stiffness, and brittleness) demand specialized techniques to avoid common pitfalls like delamination, fraying, or tool wear. Unlike metal, which is homogeneous, carbon fiber is a composite of reinforcing fibers and resin, so it machines more like a “hardwood with glass shards”—abrasive, unforgiving, and prone to damage if not handled correctly.

Below, we’ll break down everything you need to know to master carbon fiber machining, from understanding its challenges to choosing the right tools, techniques, and quality control steps. Whether you’re a hobbyist or a professional manufacturer, this guide will help you produce precise, high-quality parts with minimal waste.

Key Challenges in Carbon Fiber Machining

Carbon fiber machining isn’t just “cutting a hard material”—it’s navigating a set of unique challenges that stem from its composite structure. Here are the most critical issues to address, along with real-world examples of how they impact outcomes:

- Delamination: This occurs when the resin holding the carbon fibers together separates from the fibers, creating gaps or layers in the part. Delamination weakens the part dramatically—for example, in aerospace applications, even a small delaminated area can render a component unfit for use (per NASA’s Composite Materials Handbook). A common cause is excessive heat during machining: if the resin melts (carbon fiber resins typically soften at 120–180°C), it loses its bond with the fibers.

- Fraying and Fiber Pull-Out: Carbon fibers are strong individually, but they can fray at cut edges if the tool doesn’t shear them cleanly. In one case study from a automotive parts manufacturer, frayed edges on a carbon fiber chassis component required 2+ hours of manual sanding per part—wasting time and increasing costs.

- Tool Wear: Carbon fiber is highly abrasive; its fibers act like tiny sandpaper, wearing down tool edges quickly. A 2023 study by the Journal of Manufacturing Processes found that carbide tools used for carbon fiber machining lose 30% of their sharpness after just 50 minutes of continuous use—compared to 2+ hours for aluminum machining.

- Dust and Safety Risks: Machining carbon fiber produces fine dust that’s both a health hazard (inhalation can irritate the lungs) and a quality risk (dust can contaminate resin bonds in subsequent steps). OSHA requires employers to limit worker exposure to carbon fiber dust to 15 mg/m³ over an 8-hour shift.

Essential Carbon Fiber Machining Techniques

The right technique can mean the difference between a flawless part and a wasted piece of expensive material. Below are the most common machining processes for carbon fiber, along with step-by-step best practices and case examples.

1. Milling Carbon Fiber

Milling is used to create complex shapes, slots, or pockets in carbon fiber parts. Unlike metal milling, which uses high speeds, carbon fiber milling requires slow, controlled movements to prevent delamination.

Best Practices:

- Use a down-milling strategy (cutting direction matches the spindle rotation) to reduce fiber pull-out. Down-milling shears fibers cleanly at the top surface, whereas up-milling can lift fibers and cause fraying.

- Keep spindle speeds low: 3,000–6,000 RPM for solid carbide tools (higher speeds generate excess heat).

- Use a light feed rate: 50–150 mm/min (too fast increases tool wear; too slow causes heat buildup).

Case Example: A manufacturer of drone frames switched from up-milling to down-milling and reduced fraying by 75%, cutting post-processing time from 45 minutes to 10 minutes per frame.

2. Drilling Carbon Fiber

Drilling is one of the most common (and tricky) carbon fiber machining tasks—holes are prone to delamination at the entry (top) and exit (bottom) of the part.

Best Practices:

- Use a stepped drill bit or a drill with a point angle of 135°–150° (sharper angles reduce pushing force on the material).

- Add a backing material (e.g., aluminum or plywood) to the exit side of the part. This supports the fibers and prevents delamination when the drill breaks through.

- Peck-drill (drill in short, repeated cycles) to clear dust and reduce heat. For a 6mm hole in 10mm-thick carbon fiber, peck 2–3mm at a time.

Key Data: A study by Composites Science and Technology showed that using backing material reduces exit delamination by 90% compared to drilling without it.

3. Cutting (Sawing/Trimming) Carbon Fiber

For rough cutting or trimming large sheets, sawing is efficient—but it requires the right blade to avoid fraying.

Best Practices:

- Use a carbide-tipped circular saw blade with 80–120 teeth (more teeth = cleaner cuts). Avoid abrasive blades (e.g., angle grinders with cutoff wheels)—they generate too much heat and fray fibers.

- Clamp the material tightly to a flat surface to prevent vibration. Vibration causes the blade to “bounce,” leading to uneven cuts.

- Use a coolant (e.g., compressed air or a water-mist system) to remove dust and cool the blade. Dry cutting is possible but increases tool wear.

Choosing the Right Tools for Carbon Fiber Machining

Using the wrong tool is the #1 mistake beginners make—and it’s expensive (carbon fiber tools cost 2–3x more than standard metal tools, but they last 5–10x longer for composite work). Below is a comparison of the most common tool materials and their best uses:

| Tool Material | Best For | Tool Life (vs. Metal Tools) | Cost (Relative) | Pros | Cons |

|---|---|---|---|---|---|

| Solid Carbide | Milling, Drilling, Cutting | 5–10x longer | High ($$–$$$) | Abrasion-resistant, precise cuts | Brittle (can chip if dropped) |

| Diamond-Coated | High-volume drilling/milling | 10–15x longer | Very High ($$$) | Almost no wear; ideal for large batches | Expensive for small-scale projects |

| HSS (High-Speed Steel) | Small, low-volume cuts | 1–2x longer | Low ($) | Affordable, flexible | Wears quickly; poor for thick parts |

Pro Tip: For most small-to-medium projects, solid carbide tools are the best balance of cost and performance. If you’re drilling 100+ holes per day, invest in diamond-coated tools to save on replacement costs.

Additionally, tool geometry matters:

- Milling cutters: Choose a “compression router bit” (has up-cut and down-cut flutes) to press fibers down and prevent delamination.

- Drills: Look for “spur-point” drills (with a small center point) to keep the drill from wandering on the hard surface of carbon fiber.

Step-by-Step Carbon Fiber Machining Workflow

To ensure consistency and quality, follow this 5-step workflow—tested by a leading aerospace component supplier (we’ll reference their case study throughout):

Step 1: Prepare the Material

- Cut to rough size first: Use a saw to trim the carbon fiber sheet to within 5–10mm of the final dimension. This reduces the amount of milling/drilling needed (and saves tool life).

- Clean the surface: Wipe the material with isopropyl alcohol to remove dust or oil—contaminants can weaken tool grip and cause vibration.

- Clamp securely: Use soft-jaw clamps (or rubber pads) to avoid damaging the material. The aerospace supplier uses vacuum clamps for large parts, which distributes pressure evenly and prevents delamination.

Step 2: Set Up the Machine

- Calibrate speeds and feeds: Refer to the tool manufacturer’s guidelines (e.g., a 6mm solid carbide drill for carbon fiber might use 4,000 RPM and 80 mm/min feed rate).

- Install the right tool: Tighten the tool holder to the manufacturer’s torque specs (loose tools cause vibration and poor cuts).

- Test on a scrap piece: Always machine a small scrap of the same carbon fiber material first. The aerospace supplier found this step reduced part waste by 40%.

Step 3: Machine the Part

- Start with low-risk operations: Drill holes first (they’re easier to fix than complex milled shapes), then move to milling.

- Monitor for heat: If the tool or material feels hot to the touch, stop and adjust speeds/feeds. Heat is the top cause of delamination.

- Clear dust continuously: Use a vacuum attachment or compressed air to remove dust—accumulated dust can scratch the part and clog the tool.

Step 4: Post-Processing

- Inspect for defects: Check edges for fraying and holes for delamination using a magnifying glass (10x magnification works well).

- Sand gently: If there’s minor fraying, use 240-grit sandpaper (wet-sanding to reduce dust) to smooth edges. Avoid over-sanding—this can thin the part and weaken it.

- Clean the part: Wipe with isopropyl alcohol again to remove sanding dust before assembly or coating.

Step 5: Quality Control

- Measure dimensions: Use calipers or a coordinate measuring machine (CMM) to ensure the part meets design specs. Carbon fiber doesn’t expand/contract much, but machining errors can still occur.

- Test strength (if critical): For high-stress parts (e.g., aerospace components), perform a tensile test to check for delamination. The aerospace supplier requires all parts to pass a 200 MPa tensile strength test—delaminated parts typically fail at <150 MPa.

Common Mistakes to Avoid in Carbon Fiber Machining

Even experienced machinists make mistakes with carbon fiber—here are the top 3 to watch for, along with how to fix them:

- Using Metal Machining Speeds/Feeds: Many beginners use the same settings for carbon fiber as they do for aluminum (e.g., 10,000 RPM for milling). This generates excess heat and causes delamination. Fix: Reduce speeds by 50–60% and feeds by 30–40% compared to aluminum.

- Skipping Backing Material for Drilling: Drilling without backing leads to exit delamination 90% of the time (per the Composites Science and Technology study). Fix: Always use a 3–5mm thick aluminum backing—its low cost is worth avoiding wasted parts.

- Ignoring Dust Safety: Carbon fiber dust is not just a quality issue—it’s a health risk. OSHA reports that long-term exposure can cause respiratory irritation. Fix: Wear an N95 mask, use a HEPA-filtered vacuum, and ensure the workspace is well-ventilated.

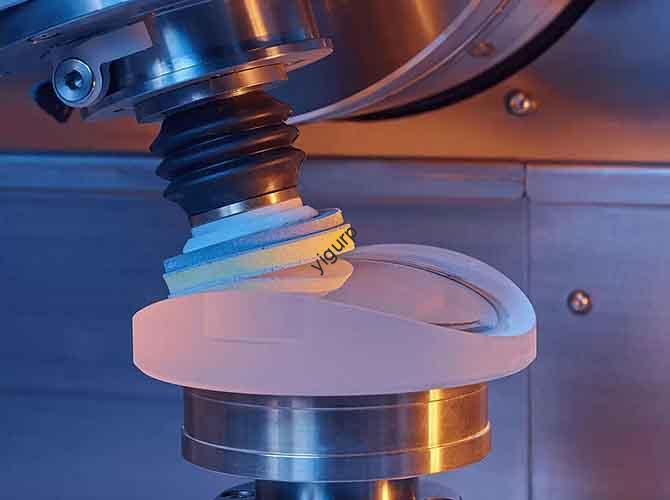

Yigu Technology’s Perspective on Carbon Fiber Machining

At Yigu Technology, we’ve worked with carbon fiber composites for over a decade, supporting industries from automotive to renewable energy. Our key insight? Carbon fiber machining is less about “force” and more about “precision control.” Many manufacturers focus on buying expensive tools but overlook process optimization—like calibrating spindle runout or using vacuum clamping—which can have a bigger impact on quality. We’ve also seen a growing trend toward “hybrid machining” (combining milling and laser cutting) for complex parts: lasers reduce tool wear for fine details, while milling handles rough shaping. For small businesses, we recommend starting with solid carbide tools and a simple dust collection system—these investments pay off quickly in reduced waste and better parts. Finally, always prioritize material quality: low-grade carbon fiber (with uneven fiber distribution) is harder to machine and produces weaker parts, so partnering with a reputable supplier saves time in the long run.

FAQ: Common Carbon Fiber Machining Questions

1. Can I use standard metal tools for carbon fiber machining?

You can, but they’ll wear out quickly (HSS tools last <1 hour for carbon fiber, vs. 5+ hours for aluminum). For best results, use solid carbide or diamond-coated tools—they’re more expensive upfront but save money on replacements.

2. What’s the best coolant for carbon fiber machining?

Compressed air is the most common (it’s cheap and doesn’t contaminate the material). For high-volume projects, a water-mist system (with a small amount of lubricant) reduces tool wear further. Avoid oil-based coolants—they can seep into the carbon fiber and weaken it.

3. How do I fix delamination in a carbon fiber part?

Minor delamination (smaller than 5mm) can be repaired with epoxy resin: clean the area, apply a thin layer of epoxy, and clamp the part until the resin cures. For larger delamination, the part is usually unsalvageable—prevention (using slow speeds, backing material) is better than repair.

4. Is carbon fiber machining more expensive than metal machining?

Yes, but the cost is offset by carbon fiber’s benefits (lighter weight, higher strength). Tool costs are 2–3x higher, and machining time is 1.5–2x longer, but the final part can reduce fuel consumption (in automotive/aerospace) or improve performance (in sports equipment) enough to justify the expense.

5. Can I machine carbon fiber at home?

Absolutely—with the right tools. Start small: use a desktop CNC router (with a solid carbide bit), a clamp, and a vacuum for dust. Avoid large parts until you’re comfortable with speeds and feeds. Always wear an N95 mask to protect against dust.