1. Bolt processing basics and definitions: the core concepts that beginners must understand

For engineers or procurement personnel who are new to the fastener industry, clarifying the definition and core logic of bolt processing can avoid pitfalls in subsequent production or selection. In simple terms, bolt processing is the process of transforming raw materials into standardized fasteners with connecting and fixing functions through a series of mechanical processing methods, and its essence is a combination of “material shaping + precision control”.

Tracing the historical development of bolt processing, from early manual forging to machining after the Industrial Revolution, and then to today’s automated production lines, the processing efficiency of bolts has increased by nearly 100 times – at the beginning of the 19th century, a single equipment processed less than 100 pieces per day, while modern cold heading machines can exceed 100,000 pieces per day. Behind this evolution is the improvement of basic machining theories and the progress of material technology.

In actual work, you will frequently encounter these processing terms: for example, “fastener” is a broad concept that includes bolts, screws, and nuts, while “bolt” specifically refers to cylindrical fasteners with heads and male threads; The “nominal diameter” is the core parameter of the bolt specification, directly determining its load-bearing capacity. Only by mastering these foundations can we smoothly connect with the production link.

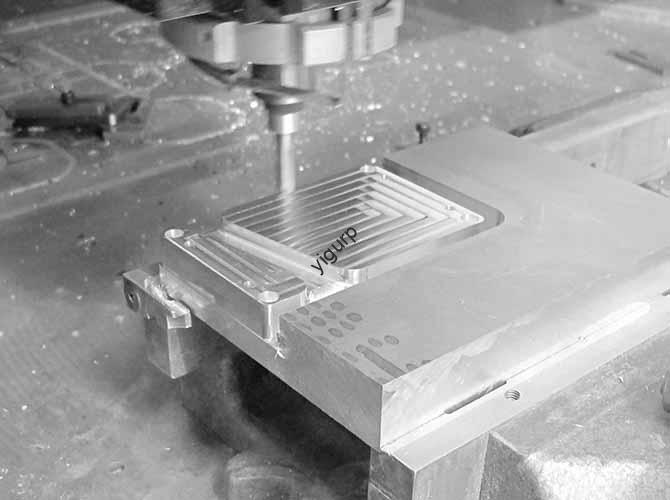

2. Bolt processing technology and technology: practical analysis from traditional to precise

The core of bolt processing lies in the combination of processes, and different scenarios need to match differentiated solutions. The following is a detailed explanation of the most commonly used processes in the industry, with practical points:

(1) Comparison of core processing technology

| Process name | Applicable scenarios | advantage | Critical control points | Practical cases |

| Turning processing | Non-standard bolts, large diameter bolts | High precision and adaptation to complex shapes | Spindle speed, tool wear | When machining M50 non-standard bolts, a heavy machinery company uses CNC turning to control the rotation speed of 800r/min and achieve a tolerance of ±0.02mm |

| Cold heading process | Standardized bolts, mass production | High efficiency and high material utilization | Mold accuracy, cold heading force | M8-M16 bolts are produced by cold heading process commonly used in the automotive industry, with a single-die production capacity of 300 pieces per minute, and a material utilization rate of over 95% |

| Thread forming | All with threaded bolts | High thread strength | Tooth profile accuracy and pitch consistency | Aerospace bolts are rolled thread with a thread surface roughness of Ra≤0.8μm and a 30% increase in fatigue strength |

| Heat treatment technology | High-strength bolts (grade 8.8 and above) | Improves hardness and toughness | Quenching temperature, cooling speed | Grade 10.9 bolts in the wind power industry, quenched at 860°C + tempered at 580°C, with a tensile strength of more than 1040MPa |

(2) Key auxiliary processes

- Surface treatment: According to the use environment – hot-dip galvanizing is preferred for outdoor scenes (corrosion resistance up to 15 years), phosphating treatment is selected for precision equipment (reducing assembly friction), and passivation treatment is required for food machinery (meeting hygiene standards).

- Automated processing technology: At present, the mainstream production line adopts “cold heading + thread rolling + heat treatment” automatic connection, reducing manual intervention, and the defective rate is reduced from 3% to less than 0.5% of the traditional process.

- Quality control process: Introduce online testing equipment to conduct 100% full inspection of bolt diameter, length, and thread accuracy to avoid unqualified products flowing downstream.

3. Bolt processing materials and selection: the core guide for accurately matching according to needs

Material is the key to determining bolt performance, and choosing the wrong material can lead to equipment failure or even safety accidents. The following is a breakdown of the material selection logic from the perspective of practical application:

(1) Mainstream material types and characteristics

| Material category | Representative material | Strength grade | Applicable environment | Notes: |

| Ordinary steel | Q235, 45 steel | Level 4.8, Grade 6.8 | General machinery, construction field | It is not corrosion-resistant, and outdoor surface treatment is required |

| stainless steel | 304、316L | Level 6.8, Level 8.8 | Food machinery, marine environment | 316L has better corrosion resistance than 304, making it suitable for high salt spray scenarios |

| Alloy material | 40Cr、35CrMoA | Grade 8.8, Grade 10.9, Grade 12.9 | Automotive, wind power, aerospace | It needs to be combined with heat treatment to achieve high strength |

| Special materials | Superalloy (Inconel 718) | Level 12.9 or above | High-temperature equipment (above 500°C) | It is difficult to process and requires special tools and processes |

(2) Three-step method of material selection

- Clarify the use environment: Is it exposed to high temperatures, corrosion, and moisture? For example, offshore platform bolts must be made of 316L stainless steel or Hastelloy.

- Determine the bearing requirements: Calculate the required strength level according to the equipment load – 4.8-6.8 for general machinery, 8.8-10.9 for critical structures, and 12.9 for extreme working conditions.

- Consider cost balance: Prioritize cost-effective materials while meeting performance. For example, for construction scaffolding bolts, 45-gauge steel can meet the requirements after heat treatment, without the need for alloy materials.

(3) Industry trend: application of environmentally friendly materials

With the advancement of the “dual carbon” policy, the trend of environmentally friendly materials is becoming increasingly obvious. The mechanical properties of recycled steel bolts currently being promoted in the industry are comparable to those of virgin steel, but carbon emissions are reduced by 40%; Biodegradable coating materials are also gradually being used in single-use scenarios to reduce environmental pollution.

4. Bolt processing equipment and tools: a complete guide to selection, use and maintenance

The right equipment is the basis for ensuring the quality and efficiency of processing, and the following practical suggestions are provided from selection to maintenance:

(1) Core equipment selection guide

- CNC machine tool / machining center: suitable for high-precision, small-batch production, it is recommended to choose equipment with a spindle speed ≥3000r/min and a positioning accuracy of ±0.005mm, such as Japanese Mazak and German Demagi brands, although the initial investment is higher, but the long-term stability is better.

- Cold heading machine: the first choice for mass production, choose according to the bolt specification – M3-M12 bolt multi-station cold heading machine (3-5 stations), M14 and above double-click cold heading machine, it is recommended to choose the model with automatic feeding and fault alarm function, which can reduce labor costs.

- Thread machine tool: the thread rolling machine is suitable for standardized threads, the tapping machine is suitable for non-standard threads, and the adaptability of the thread roller/tap should be paid attention to when selecting to avoid the thread accuracy not up to standard.

- Inspection tools: Essential tools include thread pass gauges, outside micrometers, hardness testers, and high-end needs can be equipped with coordinate measuring instruments to ensure controllable dimensional accuracy.

(2) Key points of equipment maintenance

- Daily maintenance: clean the equipment guide rail every day, lubricate key points, check the wear of the tool, and replace it in time;

- Regular maintenance: check the pressure of the hydraulic system every week, calibrate the testing tools every month, and change the lubricating oil every quarter;

- Intelligent manufacturing system: Introduce equipment network monitoring to predict faults through data analysis, such as an auto parts company adopting an MES system to reduce equipment downtime by 20%.

5. Bolt processing applications and industries: targeted solution sharing

The requirements for bolts vary significantly across industries, and the following are solutions for typical application scenarios:

(1) Application cases in key industries

- Automotive industry application: Engine block bolts need to withstand high temperature and pressure, using 10.9 grade 35CrMoA material, using cold heading + thread rolling + nitriding process to ensure the consistency of tightening torque, a car company reduced the bolt failure rate from 0.8% to 0.1% through this scheme.

- Aerospace bolts: Requiring lightweight and high strength, titanium alloy materials are selected, precision machining using a five-axis machining center, thread accuracy reaches 6H level, and must pass NASA’s strength test certification.

- Building fasteners: Seismic construction bolts need to have good toughness, selected 8.8 grade 40Cr material, hot-dip galvanized surface, can withstand 150% rated load in seismic simulation tests without breaking.

- Electronic equipment screws: miniaturization and anti-loosening are the core requirements, using stainless steel 304 material, using precision turning technology, thread specification M1-M3, with anti-loosening rubber coating, to avoid vibration loosening.

(2) Precautions for customized processing

If you need to customize special bolts, you need to specify the following parameters in advance: the operating environment (temperature, humidity, media), load-bearing requirements (tension, shear force), installation space (size limit), and assembly method (manual/automatic tightening) to help the processing plant accurately match the process and material.

6. Quality control and standards for bolt processing: compliance and reliability guarantee

Quality control is the lifeline of bolt machining, and it is essential to strictly adhere to industry standards and specifications:

(1) Core standard system

| Standard category | Key standard number | Core requirements | Applicable Areas: |

| International standards | ISO 898-1 | Strength grade division and dimensional tolerance | Worldwide |

| European standard | EN 14399 | Technical requirements for steel structure bolts | EU countries |

| American standard | ASTM A325 | Specification for high-strength structural bolts | North American countries |

| Chinese standard | GB/T 3098.1 | ISO 898-1 equivalent, suitable for domestic production | China and Southeast Asia |

(2) Key links in quality control

- Dimensional inspection: focus on controlling the nominal diameter, length, thread pitch, 100% inspection by pass-stop gauge, and calibration with coordinate measuring instrument for sampling;

- Strength test: Tensile strength and yield strength test are carried out for each batch of sampling, the tensile strength of grade 10.9 bolts needs to be ≥ 1040MPa, and the yield strength is ≥940MPa;

- Surface quality inspection: no cracks, burrs, rust, uniform coating thickness (hot-dip galvanized thickness ≥ 85μm);

- Certification requirements: Exports to the EU need to pass CE certification, and the electronics industry must comply with RoHS standards (lead and cadmium and other hazardous substances ≤0.1%).

(3) Failure analysis and improvement

When the bolt has failure problems such as fracture and loosening, the following steps can be used to troubleshoot: (1) Check whether the material composition meets the standard; (2) Analyze the processing process parameters (such as heat treatment temperature); (3) Simulated use environment test; (4) Optimize the design (e.g., increase the number of threads, improve the surface treatment). A wind power company once stopped due to bolt breakage, and after failure analysis, it was found that the heat treatment cooling speed was too fast, and the problem was completely solved after adjusting the process.

7. Bolt processing innovation and trend: interpretation of future development direction

With the transformation and upgrading of the manufacturing industry, the bolt processing industry is ushering in three major changes:

(1) Deep penetration of intelligent manufacturing

At present, leading enterprises have achieved “digital transformation”, through the ERP+MES+PLM system to open up the whole process of design, production and testing, real-time visualization of production data, and shorten the order delivery cycle from 15 days to 7 days. For example, the smart factory of the Würth Group in Germany has a robot utilization rate of 80%, and the per capita production capacity has increased by 3 times.

(2) Promotion of green processing technology

- Energy-saving process: using frequency conversion motor and waste heat recovery system, production energy consumption is reduced by 25%;

- Environmentally friendly materials: The application rate of recycled steel and degradable coatings has increased year by year, and the utilization rate of recycled materials in an enterprise has reached 30%;

- Wastewater treatment: Zero-discharge technology is introduced in the surface treatment process, and the recycling rate of water resources reaches 95%.

(3) Application of new technologies

- 3D printing applications: For customized, low-volume bolt production, especially for complex shape bolts, the production cycle is shortened by 50%, but the current cost is high, suitable for high-end scenarios;

- New material research and development: ceramic matrix composites and carbon fiber reinforced polymer bolts are gradually used in the aerospace field, with 40% lighter weight and 20% higher strength than traditional steel bolts;

- Smart bolts: “Smart bolts” with integrated sensors can monitor the tightening torque and working status in real time, and have been piloted in the high-speed rail and nuclear power industries.

8. Bolt processing problems and solutions: a guide to practical pit avoidance

(1) Common processing defects and countermeasures

| Defect type | Causes | solution |

| The thread accuracy is not up to standard | Tool wear, machine vibration | Regularly change tools (recommended for every 100,000 pieces) to strengthen the machine foundation |

| Bolt breakage | There are many impurities in the material and improper heat treatment | Selection of high-quality raw materials (purity ≥99.5%) and optimization of heat treatment parameters (quenching temperature ±10°C) |

| Surface rust | The surface treatment is not thorough and the storage environment is humid | Increase degreasing and pickling processes, and maintain ambient humidity ≤ 60% during storage |

| The size deviation is large | Mold wear and low feeding accuracy | Calibrate the mold regularly (once a month) with a servo feeding system |

(2) Efficiency and cost optimization

- Efficiency improvement method: use multi-station equipment, automatic wiring, reduce mold change time (fast mold change technology can shorten the mold change time from 30 minutes to 5 minutes);

- Cost control strategy: Bulk purchase of raw materials (10%-15% reduction in procurement costs), optimization of process combination (such as cold heading + wire rolling instead of turning, increase material utilization by 20%);

- Supply Chain Management Optimization: Establish long-term cooperation with raw material suppliers to ensure a stable supply of materials while establishing safety stock (recommended 30% of monthly sales).

(3) Respond to environmental challenges

For the problem of exhaust gas and wastewater in the surface treatment process, RTO incinerators can be introduced to treat waste gas (standard discharge), and membrane separation technology can be used to treat wastewater (to achieve water resource recycling). After investing 5 million yuan in renovating environmental protection equipment, a company not only meets environmental protection requirements, but also saves 800,000 yuan per year due to water resource recycling.

9. FAQ: Frequently Asked Questions

- Q: How do I choose the strength rating of a bolt?

Answer: choose according to the bearing needs – 4.8 level for ordinary scenes (such as furniture, light fixation); 6.8-8.8 grade for machinery and equipment; Grade 10.9-12.9 for critical structures (e.g. engines, bridges).

- Q: What is the difference in service life between stainless steel bolts and carbon steel bolts?

A: In outdoor environments, stainless steel 304 bolts have a lifespan of about 10-15 years, carbon steel bolts (without surface treatment) only 1-2 years, and hot-dip galvanized carbon steel bolts about 5-8 years.

- Q: What is the cost difference between automated machining and traditional machining?

A: The initial investment of automated production lines is 30%-50% higher than that of traditional equipment, but in mass production (daily production capacity ≥ 10,000 pieces), the unit cost can be reduced by 20%-30%, which is suitable for large-scale production.

- Q: What tests do I need to do after bolt processing?

Answer: The mandatory inspection items include dimensional accuracy (pass-stop gauge, micrometer), strength test (tensile force, hardness), surface quality (appearance, coating thickness); Special scenarios need to add corrosion resistance test (salt spray test) and fatigue strength test.

- Q: What are the current application limitations of 3D printed bolts?

A: High cost (3-5 times that of traditional processes), low mass production efficiency, limited material selection (currently mainly suitable for resin and titanium alloy), suitable for customized, small-batch high-end scenarios.