In CNC machining, a great design starts with a great technical drawing. Even the most detailed 3D CAD model can’t replace a clear, accurate 2D technical drawing—it’s the bridge between your design ideas and the machinist who builds your part. Whether you’re creating a simple bracket or a complex engine component, knowing how to draw technical drawings ensures your part is made right, on time, and without costly reworks. This guide breaks down why technical drawings matter, what they include, a step-by-step drawing process, and pro tips to avoid common mistakes.

Why You Can’t Skip Technical Drawings in CNC Machining

You might think a 3D CAD file is enough—but technical drawings solve critical gaps that 3D models can’t. Here’s why they’re non-negotiable:

1. They Clarify Details 3D Models Miss

3D CAD models are great for visualizing parts, but they struggle to show key manufacturing details. Technical drawings fill this gap by highlighting:

- Internal/external threads: 3D models often simplify threads, but technical drawings specify thread size (e.g., M6x1.0), depth, and type (coarse/fine).

- Hidden features: Things like internal holes or grooves that aren’t visible in 3D previews—technical drawings use hidden lines to make these clear.

- Tolerances beyond standards: If a part needs tighter precision than the default ISO-2768 grade (e.g., ±0.02mm for a gear), technical drawings spell this out.

Example: A startup sent a 3D model of a threaded bolt to a CNC shop. The model didn’t specify thread depth, so the machinist made it 5mm deep—too short for the part’s intended use. A technical drawing would have avoided this $200 rework.

2. They Ensure Clear Communication with Machinists

Machinists don’t just “read” 3D models—they need specific instructions to avoid guesswork. Technical drawings act as a universal language, covering:

- Surface finish: Whether a part needs sanding (Ra 1.6 μm) or a polished finish (Ra 0.8 μm).

- Deburring requirements: If sharp edges need to be rounded (e.g., 0.5mm chamfer) to prevent injury.

- Assembly notes: How the part fits with other components (e.g., “align with hole A in part B”).

Case Study: A medical device company forgot to note “all sharp edges deburred” on their technical drawing. The first 10 surgical tools had sharp corners that risked patient injury—costing $500 to rework and delaying production by a week. Adding the note to the drawing fixed the issue.

3. They Speed Up Cost Estimation

CNC shops use technical drawings to quote accurately. Without them, shops might overestimate (to cover unknowns) or underestimate (leading to cost surprises later). Drawings let shops quickly identify:

- Complex features (e.g., deep holes, tight tolerances) that add machining time.

- Surface treatments (e.g., anodizing) that increase costs.

- Material specs (e.g., 6061 aluminum vs. stainless steel) that affect pricing.

Data Point: CNC shops with clear technical drawings provide quotes 30% faster and have 40% fewer cost adjustments than those relying only on 3D models.

What a Good Technical Drawing Includes (Key Components)

A professional technical drawing has 7 core components—each serving a specific purpose. Use this table to make sure you don’t miss anything:

| Component | Purpose | Key Details to Include |

| Title Bar | Identifies the part and project | Part name, designer name, company name, material (e.g., 6061 aluminum), scale (e.g., 1:1), measurement system (metric/imperial), projection angle (first/third angle). |

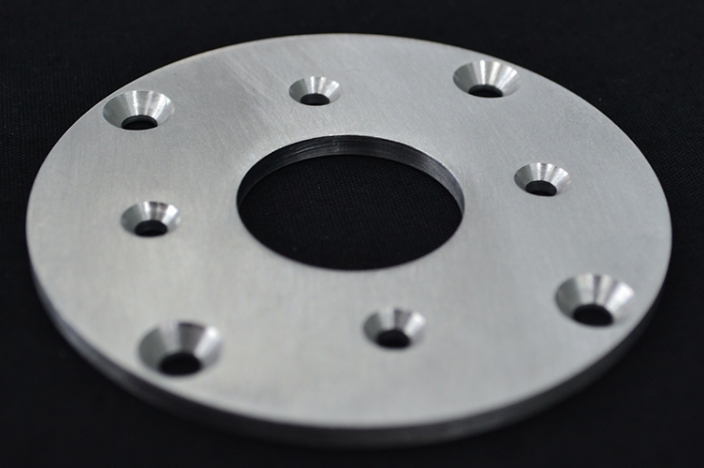

| Front View | Shows the part’s main geometry | Most dimensions (length, width, height), visible features (holes, slots), and hidden lines (for internal features like blind holes). |

| Isometric View | Provides a 3D-like perspective | Helps machinists visualize the part’s shape—critical for complex designs (e.g., lattice structures). Not mandatory, but highly recommended. |

| Sectional View | Reveals internal features | Cut line (on the front view) showing where the part is sliced, cross-hatching (to mark cut areas), and dimensions for internal holes/grooves. |

| Detail View | Zooms in on small/complex areas | Used for features too tiny to dimension clearly in the front view (e.g., a 1mm micro-hole). Labeled with a letter (e.g., “Detail A”) to link to the front view. |

| Dimensions & Tolerances | Specifies size and precision | Overall dimensions (e.g., 100mm length), critical feature dimensions (e.g., 8mm hole diameter), and tolerances (e.g., ±0.05mm). |

| Manufacturer Notes | Adds extra instructions | Deburring requirements, surface finish standards (e.g., Ra 3.2 μm), thread specs (e.g., M8x1.25), and assembly hints. |

Step-by-Step Guide to Draw Technical Drawings (For CNC Machining)

Drawing a technical drawing doesn’t have to be complicated—follow these 10 steps, and you’ll create a file that machinists love to work with. Most 3D CAD software (e.g., SolidWorks, Fusion 360) has built-in tools to simplify this process, but you can also use 2D software like AutoCAD if you don’t have a 3D model.

Step 1: Choose a Standard Template

Start with a template that follows industry standards (ASTM, DIN, or ISO)—this ensures consistency and avoids confusion. Templates include pre-built:

- Title bar (with placeholders for part info).

- Coordinate lines (for referencing features).

- Projection angle markers (first or third angle—stick to what your CNC shop uses).

Pro Tip: If your shop has a custom template, use it! It will align with their workflow and speed up production.

Step 2: Add the Front View (Your Main Reference)

The front view is the foundation of your drawing—it shows the part’s most important features.

- Center it: Leave 2–3cm of space around the view for dimensions and notes.

- Minimize hidden lines: Only use them for critical internal features (too many hidden lines clutter the drawing).

- Include key features: Show holes, slots, threads, or chamfers that affect how the part works.

Example: For a simple bracket, the front view should show the bracket’s length (100mm), width (50mm), and the 8mm hole in the center.

Step 3: Add Sectional/Detail Views (If Needed)

Use these views to clarify complex areas:

- Sectional views: For internal features (e.g., a blind hole 15mm deep). Draw a cut line on the front view (labeled “A-A”) and place the sectional view nearby. Add cross-hatching to mark the cut area.

- Detail views: For small features (e.g., a 2mm slot). Circle the area on the front view (labeled “Detail B”) and draw a larger version of it elsewhere on the sheet.

Case Study: An engineer designing a valve used a sectional view to show the internal flow channel—something the front view couldn’t display. The machinist said this view saved 2 hours of guesswork.

Step 4: Add an Isometric View (For Clarity)

Isometric views aren’t required, but they’re worth adding for complex parts. They:

- Help machinists visualize the part’s 3D shape at a glance.

- Clarify installation orientation (e.g., “this side faces up”).

- Reduce questions from the shop (fewer emails = faster production).

Pro Tip: Place the isometric view in the top-right corner—out of the way of dimensions but easy to find.

Step 5: Add Construction Lines

These lines guide dimensioning and ensure accuracy:

- Centerlines: Mark the center of holes, shafts, or symmetrical features (use dashed lines).

- Cut lines: Show where sectional views are taken (thick, solid lines with arrows).

- Extension lines: Connect dimensions to features (thin, solid lines—don’t overlap with other lines).

Mistake to Avoid: Skipping centerlines—this leads to misaligned holes or lopsided parts.

Step 6: Dimension Your Drawing (The Most Critical Step)

Dimensions tell the machinist how big the part should be. Follow these rules to avoid mistakes:

- Start with overall dimensions: Length, width, height (e.g., 120mm x 60mm x 10mm).

- Add critical feature dimensions: Focus on parts that affect fit (e.g., hole diameter, thread size).

- Use a common baseline: Dimension from one edge (not multiple edges) to avoid cumulative errors.

- Label repeated features: If you have 3 identical 5mm holes, write “3 x ø5.0” instead of dimensioning each one.

| Dimension Type | Example | When to Use It |

| Linear | 100mm | Length/width of flat parts |

| Radial | ø8mm | Hole diameter or shaft size |

| Thread | M6x1.0 | Internal/external threads |

| Depth | 15mm | Blind holes or grooves |

Warning: If you don’t specify dimensions, the CNC shop will use their discretion—and you won’t be able to claim errors later.

Step 7: Specify Tolerances for Key Features

Tolerances define how much a dimension can vary (e.g., ±0.05mm). Use them only for features that need precision—default ISO-2768 tolerances work for most non-critical parts.

- Bilateral tolerance: ±0.03mm (variation allowed above and below the dimension).

- Unilateral tolerance: +0.02/-0mm (only variation above the dimension is allowed).

- GD&T (Geometric Dimensioning & Tolerancing): For complex parts (e.g., “parallelism ≤0.01mm”)—use this only if you’re familiar with GD&T standards.

Example: A gear that fits into a motor needs a tolerance of ±0.02mm, but a decorative bracket can use ±0.1mm.

Step 8: Fill in the Title Bar

Don’t rush this—missing info here delays production. Include:

- Part name (e.g., “CNC Bracket v2”).

- Your name, date, and company.

- Material (e.g., “Stainless Steel 304”).

- Scale (e.g., 1:1—use this for most CNC parts, as it avoids scaling errors).

- Projection angle (e.g., “Third Angle Projection”—standard in North America; “First Angle” in Europe).

Step 9: Add Manufacturer Notes

This is where you spell out “the small stuff” that affects quality:

- Deburring: “All sharp edges to 0.5mm chamfer.”

- Surface finish: “Ra 1.6 μm on all external surfaces.”

- Threads: “M8x1.25 tap to 10mm depth, full thread.”

- Assembly: “Align hole C with part D’s pin.”

Pro Tip: Keep notes short and specific—avoid vague phrases like “make it smooth.”

Step 10: Export & Review

- Export as PDF: This is the universal format for CNC shops—avoids software compatibility issues.

- Review with a machinist (if possible): A quick check can catch errors you missed (e.g., conflicting dimensions).

- Save a backup: Keep a copy of the original CAD file (not just the PDF) in case you need to make changes.

Common Mistakes to Avoid When Drawing Technical Drawings

Even experienced designers make these errors—here’s how to skip them:

1. Overcomplicating the Drawing

Adding too many views or unnecessary details (e.g., a detail view for a simple 5mm hole) clutters the drawing and confuses machinists. Stick to:

- 1–2 front views (for simple parts).

- 1 sectional view (if there are internal features).

- 1 isometric view (for complex parts).

2. Ignoring Tolerances

Assuming “standard tolerances” will work for every part is risky. For example:

- A part that fits into a tight space needs ±0.03mm tolerance.

- A part that’s just for mounting can use ±0.1mm.

Always specify tolerances for critical features—don’t leave it to chance.

3. Poor Dimension Placement

Dimensions that overlap, cross lines, or are too small to read lead to mistakes. Fix this by:

- Placing dimensions outside the part view (not on top of it).

- Using a font size of at least 2.5mm (so machinists don’t squint).

- Avoiding dimension stacking (don’t put 3 dimensions in a row—space them out).

Yigu Technology’s Perspective on Drawing Technical Drawings

At Yigu Technology, we know great technical drawings are the key to smooth CNC machining. We work with clients to refine their drawings—fixing vague notes, clarifying tolerances, and simplifying cluttered views—before production starts. Our team recommends using 3D CAD software (like Fusion 360) to generate drawings, as it links dimensions to the 3D model (no more conflicting info). We also share a template with our clients that includes all the details our machinists need—saving them time and reducing errors. For us, a good technical drawing isn’t just a document—it’s a way to ensure your part is made exactly as you imagined, with no surprises.

FAQ About Drawing Technical Drawings

1. Do I need to draw a technical drawing if I have a 3D CAD model?

Yes—3D models don’t show critical details like thread specs, tolerances, or surface finish. A CNC shop can’t make your part accurately without a technical drawing, even with a perfect 3D model. Skipping the drawing often leads to reworks or wrong parts.

2. What software should I use to draw technical drawings?

For most users, 3D CAD software (Fusion 360, SolidWorks, Inventor) is best—it automatically generates drawings from your 3D model, so dimensions stay linked (no manual updates). If you don’t have a 3D model, 2D software like AutoCAD or LibreCAD works for simple parts.

3. How long does it take to draw a technical drawing?

It depends on complexity:

- Simple part (e.g., bracket): 30–60 minutes.

- Complex part (e.g., gear with internal features): 2–3 hours.

Using a template and 3D CAD software cuts this time by 50%—don’t start from scratch!