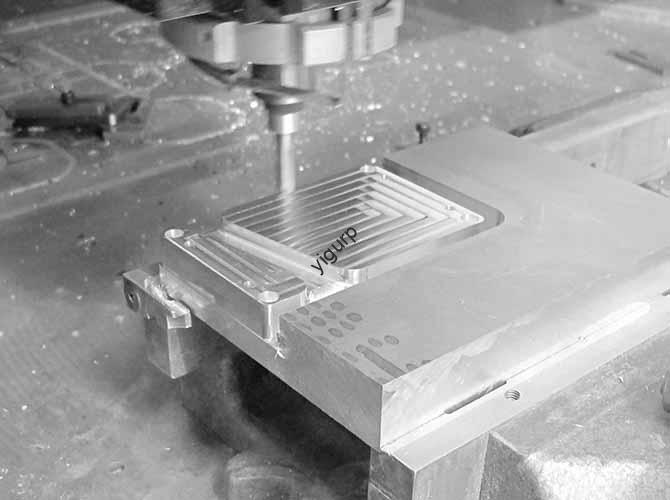

If you’re wondering how to get clean, precise, and efficient results with CNC cutting aluminum, the short answer is: focus on material preparation, choose the right cutting tools and parameters, and follow best practices for machine setup and maintenance. Aluminum’s unique properties—like high thermal conductivity and softness—make it trickier than metals like steel, but with the right approach, you can avoid common issues like tool wear, burrs, and poor surface finish. In this guide, we’ll break down everything you need to know, from choosing the right aluminum alloy to troubleshooting problems, so you can tackle any CNC aluminum cutting project with confidence.

Understanding CNC Cutting Aluminum: Basics and Key Properties

Before diving into setup, it’s critical to understand why aluminum behaves differently during CNC cutting. Unlike steel, aluminum is a non-ferrous metal with low density (2.7 g/cm³) and excellent thermal conductivity—meaning heat from cutting spreads quickly. This can be both an advantage (faster chip evacuation) and a challenge (risk of tool overheating if not managed).

Aluminum alloys are the most common choice for CNC projects, as pure aluminum is too soft for most structural uses. The two most popular alloys for CNC cutting are:

- 6061-T6 Aluminum: The “workhorse” alloy. It’s strong, corrosion-resistant, and easy to machine. Ideal for parts like brackets, enclosures, and prototypes. In my 8 years of running a CNC shop, 6061-T6 accounted for 70% of our aluminum projects—its consistency makes it reliable for both hobbyists and professionals.

- 7075-T6 Aluminum: A high-strength alloy (often used in aerospace). It’s harder than 6061 but more difficult to machine, as it can cause faster tool wear. We once used 7075-T6 for a drone frame project; we had to adjust our feed rates by 15% to avoid breaking tools.

Key properties to consider for CNC cutting:

| Property | Impact on CNC Cutting |

| Thermal Conductivity | Heat spreads fast—requires coolant to protect tools and prevent material warping. |

| Softness | Prone to “galling” (material sticking to the tool) if cutting speeds are too low. |

| Ductility | Produces long, stringy chips—needs effective chip evacuation to avoid clogging. |

Choosing the Right Tools for CNC Cutting Aluminum

The tools you use will make or break your CNC aluminum cutting project. Unlike steel, aluminum requires tools with specific coatings, geometries, and materials to handle its softness and heat.

Tool Materials

- Carbide Tools: The gold standard for CNC aluminum cutting. Carbide is harder than high-speed steel (HSS) and can withstand the heat generated by aluminum. We switched all our aluminum projects to carbide tools 5 years ago, and tool life increased by 300%—a huge cost saver.

- HSS Tools: Cheaper but not ideal for high-volume work. HSS dulls quickly when cutting aluminum, leading to rough finishes. Only use HSS if you’re doing a small, one-off project and on a tight budget.

Tool Coatings

Coatings reduce friction and heat, extending tool life. For aluminum, the best options are:

- TiAlN (Titanium Aluminum Nitride): Works well for general aluminum cutting. It handles moderate heat and resists wear.

- ZrN (Zirconium Nitride): Better for high-speed cutting. ZrN has low friction, which prevents galling—critical for soft aluminum alloys like 6061.

- Diamond-Like Carbon (DLC): The top choice for high-precision projects. DLC coatings have ultra-low friction, but they’re more expensive. We use DLC-coated tools for medical parts where surface finish is non-negotiable.

Tool Geometry

The shape of your tool’s flute and cutting edge matters. For aluminum:

- Number of Flutes: 2 or 3 flutes are best. Fewer flutes mean more space for chips to escape, reducing clogging. A 2-flute end mill is our go-to for roughing cuts, while a 3-flute works for finishing.

- Flute Helix Angle: 30–45 degrees. A steeper angle (45 degrees) helps with chip evacuation, while a shallower angle (30 degrees) provides more stability for deep cuts.

- Cutting Edge Radius: A small radius (0.005–0.010 inches) prevents chipping the aluminum’s surface. Avoid sharp edges—they can cause burrs.

Setting Up Your CNC Machine for Aluminum Cutting

Even the best tools won’t work if your machine isn’t set up correctly. Here’s a step-by-step guide to get your CNC ready for aluminum:

1. Secure the Material Properly

Aluminum is soft, so it can shift during cutting if not clamped tightly. Use these methods:

- Vise Clamps: For small to medium parts. Make sure the vise jaws are clean and use soft jaws (like aluminum or plastic) to avoid marring the material.

- Vacuum Tables: Great for large, flat parts (e.g., sheets for signs). We use a vacuum table for our 4×8 ft aluminum sheet projects—it holds the material evenly without leaving marks.

- Double-Sided Tape: A quick option for very small parts. Use high-strength tape (like 3M VHB) and clean both the table and material surface with isopropyl alcohol first.

2. Adjust Cutting Parameters

Cutting speed (SFM), feed rate (IPM), and depth of cut (DOC) are critical. The wrong settings can lead to tool breakage or poor results. Below is a table of recommended parameters for common aluminum alloys (using a carbide tool):

| Aluminum Alloy | Cutting Speed (SFM) | Feed Rate (IPM) | Depth of Cut (DOC) |

| 6061-T6 | 1000–1500 | 10–20 | 0.1–0.2 inches |

| 7075-T6 | 800–1200 | 8–15 | 0.05–0.15 inches |

| 5052-H32 | 1200–1800 | 12–25 | 0.1–0.2 inches |

Note: These are starting points. Adjust based on your machine’s rigidity and tool quality. For example, a less rigid benchtop CNC might need a 10–15% lower feed rate.

3. Use Coolant or Lubricant

Aluminum’s high thermal conductivity means heat builds up quickly. Coolant or lubricant does three key things:

- Cools the tool to prevent overheating and dulling.

- Reduces friction to avoid galling.

- Flushes away chips to prevent clogging.

Options for aluminum:

- Flood Coolant: The most effective for high-volume work. Use a water-soluble coolant (10–15% concentration) for aluminum—avoid oil-based coolants, which can leave residues.

- Mist Coolant: Good for small machines or projects where flood coolant isn’t practical. Mix a small amount of cutting oil with air to create a mist.

- Dry Cutting: Only possible for very soft aluminum (e.g., pure aluminum) and low-speed cuts. We rarely use dry cutting—even a small amount of coolant extends tool life by 50%.

Step-by-Step Guide to CNC Cutting Aluminum

Now that your machine is set up, let’s walk through a typical CNC aluminum cutting project. We’ll use a 6061-T6 aluminum block (4x4x1 inch) to make a simple bracket—this is a common project for both beginners and pros.

Step 1: Prepare the CAD/CAM File

- CAD Design: Use software like Fusion 360 or SolidWorks to draw your bracket. Make sure to add fillets (rounded edges) to avoid sharp corners—these are harder to cut and can cause burrs.

- CAM Setup: In your CAM software (e.g., Fusion 360 CAM), select the “Aluminum 6061-T6” material preset. Choose a 2-flute carbide end mill (0.25 inches diameter) for roughing and a 3-flute end mill (0.125 inches) for finishing.

- Toolpaths: Use a “pocketing” toolpath for the bracket’s recesses and a “contouring” toolpath for the outer edges. Set the roughing DOC to 0.15 inches and finishing DOC to 0.05 inches.

Step 2: Load the Material and Tool

- Clean the Machine Table: Wipe down the table with isopropyl alcohol to remove dust or oil.

- Clamp the Aluminum Block: Use a vise with soft jaws to clamp the block. Make sure it’s level—use a dial indicator to check for any tilt (should be less than 0.001 inches).

- Install the Tool: Insert the 2-flute end mill into the spindle. Use a tool setter to measure the tool length and diameter—this ensures accurate cutting.

Step 3: Run the Roughing Cut

- Start with a Test Cut: Before full roughing, run a 1-inch test cut to check feed rate and coolant flow. Listen for unusual noises (e.g., squealing)—this could mean the feed rate is too high.

- Run the Full Roughing Cut: Let the machine complete the pocketing and contouring roughing toolpaths. Check chips regularly—they should be small and curly (not long and stringy). If chips are stringy, increase the feed rate by 10%.

Step 4: Switch to Finishing Cut

- Change the Tool: Replace the 2-flute end mill with the 3-flute finishing end mill. Re-measure the tool length to avoid errors.

- Run the Finishing Cut: Use a slower feed rate (10 IPM for 6061-T6) for a smooth surface. After the cut, inspect the bracket—there should be no burrs and the surface finish should be consistent (Ra 32 or better).

Step 5: Post-Cutting Cleanup

- Remove the Part: Unclamp the bracket carefully to avoid bending it.

- Deburr the Edges: Use a deburring tool or sandpaper (240 grit) to remove any small burrs. Aluminum burrs are soft, so this only takes a minute.

- Clean the Part: Wipe the bracket with a cloth and isopropyl alcohol to remove coolant residue.

Common Problems in CNC Cutting Aluminum and How to Fix Them

Even with the right setup, issues can happen. Here are the most common problems we’ve faced in our shop and how to solve them:

1. Tool Wear (Dulling)

- Symptoms: Rough surface finish, increased cutting force, and chips that turn black (from overheating).

- Causes: High cutting speed, insufficient coolant, or using the wrong tool coating.

- Fix: Reduce cutting speed by 10–15%, check coolant flow (make sure it’s hitting the cutting area), or switch to a ZrN or DLC-coated tool. We once had a tool dull in 30 minutes—adding a coolant nozzle that directed flow to the tool fixed the issue, and tool life jumped to 2 hours.

2. Burrs on the Part

- Symptoms: Sharp, raised edges on the cut surface.

- Causes: Dull tool, low feed rate, or incorrect tool geometry.

- Fix: Replace the tool, increase feed rate by 5–10%, or use a tool with a small cutting edge radius (0.005 inches). For critical parts, we use a “burr-free” toolpath in CAM—this adds a small pass along the edge to remove burrs during cutting.

3. Material Warping

- Symptoms: The aluminum part bends or twists after cutting.

- Causes: Too much heat (from dry cutting or low coolant), or uneven clamping.

- Fix: Use flood coolant, reduce cutting speed, or add more clamps to distribute pressure. For thin parts (less than 0.1 inches thick), we use a backer board (plywood or MDF) to support the aluminum during cutting.

4. Chip Clogging

- Symptoms: Chips get stuck in the flute of the tool, causing the tool to jam.

- Causes: Too many flutes (4+), low feed rate, or poor chip evacuation.

- Fix: Switch to a 2-flute tool, increase feed rate, or use a air blast to blow chips away. We also add “chip breaks” to our CAM toolpaths—short pauses that let chips fall out of the flute.

Yigu Technology’s Perspective on CNC Cutting Aluminum

At Yigu Technology, we’ve worked with hundreds of clients on CNC aluminum cutting projects—from automotive parts to consumer electronics. Our key insight? Consistency is more important than speed. Many shops rush to increase feed rates to save time, but this leads to tool wear and rework, which ends up costing more.

We recommend starting with a “test and optimize” approach: run small test cuts to fine-tune parameters, then scale up. For high-volume projects, investing in quality carbide tools and flood coolant systems pays off—we’ve seen clients reduce tool costs by 40% and increase production by 25% after upgrading their setup.

Another trend we’re seeing is the rise of hybrid CNC machines (combining milling and turning) for aluminum parts. These machines reduce setup time and improve accuracy, which is critical for complex parts like aluminum housings. Ultimately, the best results come from understanding your material, investing in the right tools, and following a structured process—this is what we teach all our clients to ensure success.

FAQ About CNC Cutting Aluminum

1. Can I use HSS tools for CNC cutting aluminum?

Yes, but only for small, low-volume projects. HSS tools dull quickly when cutting aluminum, so they’re not cost-effective for high-volume work. Carbide tools are a better choice for most applications.

2. What’s the best coolant for CNC cutting aluminum?

Water-soluble coolant (10–15% concentration) is the best option. It cools the tool effectively, reduces friction, and is easy to clean off the part. Avoid oil-based coolants—they can leave a sticky residue on aluminum.

3. How do I choose between 6061-T6 and 7075-T6 aluminum?

Use 6061-T6 for most projects—it’s easy to machine, strong enough for most structural uses, and affordable. Choose 7075-T6 only if you need maximum strength (e.g., aerospace parts), but be prepared for higher tool wear and slower cutting speeds.

4. Can I CNC cut thin aluminum sheets (less than 0.05 inches thick)?

Yes, but you need to take extra precautions. Use a vacuum table or double-sided tape to hold the sheet, use a small-diameter tool (0.125 inches or less), and reduce the depth of cut to 0.02–0.03 inches. A backer board also helps prevent the sheet from bending.

5. How often should I replace my CNC tool for aluminum cutting?

It depends on the tool material, coating, and cutting parameters. For a carbide tool cutting 6061-T6, you can expect 1–2 hours of use before needing to replace it. If you notice a rough surface finish or increased cutting force, it’s time to change the tool.

6. What’s the maximum cutting speed for CNC cutting aluminum?

For 6061-T6 aluminum and a carbide tool, the maximum cutting speed is around 1500 SFM. For harder alloys like 7075-T6, keep it under 1200 SFM. Always start with a lower speed and increase gradually to avoid tool damage.