If you’re in search of a material that delivers exceptional hardness, durability, and performance for heavy-duty tools or components, Hard Steel is a top contender. Used across mining, automotive, aerospace, and manufacturing sectors, it’s the go-to choice for parts that need to withstand wear, impact, and high stress. In this guide, we’ll break down its key properties, real-world uses, production methods, and how it compares to other materials—so you can make informed decisions for your projects.

1. Material Properties of Hard Steel

Hard Steel is an umbrella term for high-hardness steel alloys, engineered to balance strength, toughness, and wear resistance. Its properties are defined by its chemical makeup and processing. Below’s a detailed breakdown.

Chemical Composition

The hardness and performance of Hard Steel come from a precise mix of elements, tailored to specific applications. Typical components (by weight) include:

- Carbon (C): 0.60 – 1.50% – The core hardening agent; higher carbon content boosts hardness and wear resistance (critical for cutting tools).

- Manganese (Mn): 0.50 – 1.50% – Improves hardenability and reduces brittleness, making the steel easier to shape during manufacturing.

- Silicon (Si): 0.15 – 0.50% – Enhances strength and heat resistance, protecting the steel from deformation at high temperatures.

- Chromium (Cr): 0.50 – 12.00% – Boosts corrosion resistance and wear resistance; higher levels (e.g., in stainless steel variants) prevent rust.

- Vanadium (V): 0.10 – 1.00% – Refines grain structure, increasing toughness and red hardness (ability to retain hardness at high temperatures).

- Molybdenum (Mo): 0.20 – 1.00% – Enhances strength and fatigue resistance, ideal for parts like automotive components that endure repeated stress.

- Tungsten (W): 0.50 – 18.00% – Critical for red hardness; high tungsten content (e.g., in high-speed steel variants) suits cutting tools that generate heat.

- Nickel (Ni): 0.50 – 5.00% – Improves toughness and impact resistance, making the steel suitable for mining equipment or aerospace parts.

Physical Properties

These traits determine how Hard Steel behaves under physical stress (e.g., heat, pressure) and guide tool/component design:

| Property | Typical Value | Why It Matters |

| Density | ~7.80 – 7.85 g/cm³ | Consistent with most steels, simplifying weight calculations for parts like drill bits or gears. |

| Melting Point | ~1400 – 1550°C | High enough to withstand machining, heat treatment, and high-temperature applications (e.g., engine components). |

| Thermal Conductivity | ~30 – 40 W/(m·K) | Efficiently dissipates heat, preventing overheating in cutting tools (e.g., milling cutters) or automotive parts. |

| Coefficient of Thermal Expansion | ~10 – 13 x 10⁻⁶/°C | Low expansion ensures parts retain their shape when heated—critical for precision tools like punches and dies. |

| Magnetic Properties | Ferromagnetic (most variants) | Easy to handle with magnetic fixtures during manufacturing, simplifying processes like grinding or assembly. |

Mechanical Properties

After proper heat treatment (e.g., hardening + tempering), Hard Steel delivers exceptional strength and durability. Key metrics include:

- Hardness: 55 – 70 HRC (Rockwell C scale) or 500 – 800 HV (Vickers) – Varies by grade; higher hardness (e.g., 65 – 70 HRC) suits wear-resistant parts like mining equipment, while lower hardness (55 – 60 HRC) balances toughness for automotive components.

- Tensile Strength: ~1800 – 3000 MPa – Resists breaking under tension, so parts like stamping tools don’t snap during use.

- Yield Strength: ~1500 – 2500 MPa – Prevents permanent deformation, ensuring tools hold their shape after repeated stress.

- Elongation: ~5 – 15% – Lower elongation (5 – 8%) for high-hardness variants (e.g., cutting tools); higher elongation (10 – 15%) for tougher grades (e.g., aerospace components).

- Reduction of Area: ~10 – 25% – Indicates ductility; higher values mean the steel can deform slightly before breaking (useful for parts that need to absorb impact).

- Impact Toughness: ~10 – 50 J/cm² – Varies by grade; higher toughness (30 – 50 J/cm²) suits mining equipment or automotive parts, while lower toughness (10 – 20 J/cm²) is acceptable for rigid cutting tools.

Other Key Properties

- Wear Resistance: Excellent – Stands up to abrasion from rocks (mining equipment) or metal workpieces (cutting tools), extending part life.

- Abrasion Resistance: High – Resists damage from friction (e.g., drill bits drilling through concrete or metal).

- Fatigue Resistance: Good to Excellent – Endures repeated stress (e.g., automotive components under vibration) without failing.

- Corrosion Resistance: Moderate to Excellent – Depends on chromium content; low-chromium grades (0.50 – 2.00% Cr) need oiling to prevent rust, while high-chromium grades (10 – 12% Cr) are rust-resistant (suitable for outdoor or humid environments).

- Red Hardness: Good to Excellent – Retains hardness at temperatures up to 600°C (high-tungsten variants), ideal for high-speed cutting tools.

2. Applications of Hard Steel

Hard Steel’s versatility makes it suitable for applications that demand hardness, durability, or wear resistance. Below are its most common uses.

Cutting Tools

Hard Steel’s high hardness and wear resistance make it perfect for tools that cut or shape materials:

- Drill Bits: Drill holes in metal, wood, or concrete. Hard Steel bits retain sharp edges longer than standard carbon steel bits.

- Milling Cutters: Shape metal parts (e.g., aerospace components) by removing material. The steel’s red hardness prevents dulling during high-speed milling.

- Other Cutting Tools: Chisels, saw blades, and reamers – All benefit from Hard Steel’s ability to stay sharp and resist wear.

Forming Tools

Tools that shape metal (without cutting) rely on Hard Steel’s strength and toughness:

- Punches and Dies: Create holes or shapes in metal sheets (e.g., automotive body panels). The steel’s low thermal expansion ensures consistent results.

- Stamping Tools: Press flat parts (e.g., washers or electronics components). Hard Steel’s wear resistance ensures thousands of precise stamps.

- Molds and Dies: Mold plastic or metal parts (e.g., toy components or bolts). The steel’s durability prevents mold wear, ensuring part consistency.

Wear-Resistant Parts

Parts that endure constant abrasion or impact use Hard Steel:

- Mining Equipment: Crusher jaws, conveyor belts, and drill rods – Resist damage from rocks and dirt, reducing maintenance costs.

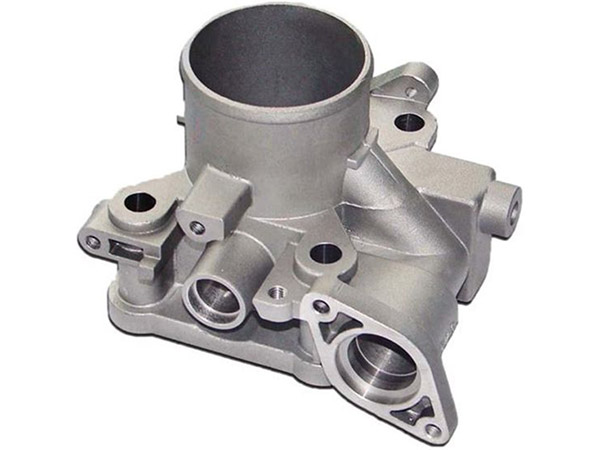

- Automotive Components: Brake rotors, gears, and axle shafts – Withstand friction and stress, extending vehicle life.

- Aerospace Components: Engine parts (e.g., turbine blades) and landing gear – Need high strength and fatigue resistance to ensure safety.

3. Manufacturing Techniques for Hard Steel

Producing high-quality Hard Steel parts requires precise control of each step, from melting the alloy to finishing the product. Below’s a step-by-step overview.

Melting and Casting

- Process: Hard Steel is typically melted in an electric arc furnace (EAF) or basic oxygen furnace (BOF). Scrap steel and pure elements (e.g., chromium, vanadium) are mixed to achieve the desired chemical composition. The molten steel is then cast into ingots (large blocks) or billets (smaller bars) for further processing.

- Key Goal: Ensure uniform mixing of elements to avoid weak spots (e.g., sulfur clusters that cause cracking).

Hot Working (Forging + Rolling)

- Forging: Ingots are heated to 1100 – 1300°C (red-hot) and hammered or pressed into rough shapes (e.g., die blanks or gear blanks). This aligns the steel’s grain structure, boosting strength and toughness.

- Rolling: For flat parts (e.g., stamping tools) or long parts (e.g., drill bits), the steel is passed through hot rollers to reduce thickness or create a uniform shape. Hot rolling softens the steel for 后续加工.

Cold Working (Drawing + Extrusion)

- Drawing: For small, precise parts (e.g., thin drill bits), the steel is pulled through a die at room temperature. This reduces diameter and improves surface finish (Ra ≤ 0.4 μm).

- Extrusion: For complex shapes (e.g., automotive gears), the steel is pushed through a die at room temperature. Cold extrusion creates tight tolerances (±0.02 mm) and enhances hardness.

Heat Treatment

Heat treatment is critical to unlock Hard Steel’s full potential. Common processes include:

- Annealing: Heated to 800 – 900°C, held for 2 – 4 hours, then cooled slowly. Softens the steel for machining (hardness drops to 20 – 30 HRC) and reduces internal stress.

- Hardening: Heated to 850 – 1050°C (depending on grade), held until uniform, then quenched in oil or water. This hardens the steel to 60 – 70 HRC but makes it brittle.

- Tempering: Reheated to 150 – 600°C, held for 1 – 3 hours, then cooled. Reduces brittleness while retaining hardness (55 – 65 HRC) – critical for preventing part breakage.

Machining

- Pre-Heat Treatment: Annealed Hard Steel (20 – 30 HRC) is soft enough to machine with standard high-speed steel (HSS) or carbide tools. Common processes include:

- Turning: Shapes cylindrical parts (e.g., drill bit shafts) on a lathe.

- Milling: Creates complex cavities (e.g., mold interiors) with a milling machine.

- Grinding: Refines surface finish and dimensions (e.g., sharpening cutting tool edges) using abrasive wheels.

- Post-Heat Treatment: Hardened Hard Steel (60 – 70 HRC) requires carbide or diamond tools for machining. Grinding is the most common method, used to correct small errors or achieve tight tolerances.

Surface Treatment

Optional treatments to enhance performance:

- Coating: PVD (Physical Vapor Deposition) or CVD (Chemical Vapor Deposition) coatings (e.g., TiN, TiAlN) add a hard, low-friction layer. This extends tool life by 50 – 100% (e.g., milling cutters with TiAlN coatings last twice as long).

- Nitriding: Heated in ammonia gas to 500 – 550°C, creating a hard surface layer (~20 – 50 μm thick). Boosts wear resistance for punches, dies, and automotive gears.

- Carburizing: Heated in a carbon-rich atmosphere to 850 – 950°C, increasing surface carbon content. Hardens the surface (65 – 70 HRC) while keeping the core tough (50 – 55 HRC) – ideal for parts like gears that need a hard surface and strong core.

Quality Control and Inspection

To ensure Hard Steel parts meet standards, manufacturers perform:

- Hardness Testing: Use Rockwell or Vickers testers to confirm hardness (e.g., 60 – 65 HRC for cutting tools).

- Mechanical Testing: Tensile tests (measure strength) and impact tests (measure toughness) to verify performance.

- Dimensional Inspection: Use calipers, laser scanners, or coordinate measuring machines (CMMs) to check part size against design specs (tolerances ±0.005 mm for precision tools).

- Microstructure Analysis: Examine the steel under a microscope to check for defects (e.g., cracks, uneven grain structure) that weaken parts.

4. Case Studies: Hard Steel in Action

Real-world examples show how Hard Steel solves industry challenges. Below are three practical cases.

Case Study 1: Hard Steel Drill Bits for Construction

A construction company struggled with frequent drill bit replacements—their standard carbon steel bits dulled after drilling 20 concrete holes, causing downtime and extra costs.

Solution: They switched to Hard Steel drill bits (62 HRC) with a TiAlN coating.

Results:

- Drill bit life increased to 120 holes (a 500% improvement).

- Reduced downtime by 80% (fewer bit changes).

- Lower cost: Despite being 30% more expensive upfront, the Hard Steel bits saved $2,000/month in replacement costs.

Why it worked: The Hard Steel’s wear resistance stood up to concrete’s abrasion, while the TiAlN coating reduced friction and heat buildup.

Case Study 2: Hard Steel Mining Crusher Jaws

A mining operation had crusher jaws (made from standard alloy steel) that wore out after 3 months, requiring costly replacements and downtime.

Solution: They installed Hard Steel crusher jaws (65 HRC) with a nitrided surface.

Results:

- Jaw life extended to 12 months (a 300% improvement).

- Reduced maintenance costs by $50,000/year.

- No unplanned downtime—jaws maintained performance consistently.

Why it worked: The Hard Steel’s abrasion resistance resisted damage from rocks, while nitriding added a hard surface layer to slow wear.

Case Study 3: Failure Analysis of Hard Steel Automotive Gears

An automotive manufacturer had Hard Steel gears that failed after 50,000 miles—gears showed signs of fatigue cracking, leading to transmission issues.

Investigation: Testing revealed the gears were tempered at too high a temperature (550°C), reducing hardness to 50 HRC (below the required 58 – 62 HRC). The lower hardness made the gears prone to wear and fatigue.

Fix: The manufacturer adjusted tempering to 250°C, achieving 60 HRC. They also added a carburizing step to harden the gear surface.

Results:

- Gear life increased to 150,000 miles (a 200% improvement).

- No more fatigue cracking—transmissions performed reliably.

5. Hard Steel vs. Other Materials

How does Hard Steel compare to other common materials used in tooling and manufacturing? Below’s a side-by-side breakdown to help you choose.

Hard Steel vs. High-Speed Steel (HSS)

| Factor | Hard Steel (High-Hardness Grade) | HSS (e.g., M2) |

| Hardness | 60 – 70 HRC | 60 – 65 HRC |

| Red Hardness | Good (up to 550°C) | Excellent (up to 600°C) |

| Wear Resistance | Excellent | Good |

| Toughness | Moderate (10 – 30 J/cm²) | Good (20 – 40 J/cm²) |

| Cost | Moderate (\(15 – \)30/kg) | Higher (\(20 – \)40/kg) |

| Best For | Wear-resistant parts (mining equipment), high-hardness tools | High-speed cutting tools (milling cutters), hot work tools |

When to choose Hard Steel: For applications where wear resistance and high hardness matter more than extreme red hardness (e.g., mining crusher jaws, drill bits).

Hard Steel vs. Carbide

| Factor | Hard Steel (High-Hardness Grade) | Carbide (e.g., WC-Co) |

| Hardness | 60 – 70 HRC | 85 – 90 HRA (much harder) |

| Wear Resistance | Excellent | Superior |

| Toughness | Moderate (resists chipping) | Poor (brittle) |

| Cost | Moderate (\(15 – \)30/kg) | Very High (\(80 – \)150/kg) |

| Best For | Impact-resistant parts (automotive gears), general tools | High-speed cutting of hard metals (stainless steel), precision tools |