1. Machining and casting: basic concepts and process principles

For those in the manufacturing industry, understanding the machining and foundry definitions is the first step to getting started. In simple terms, casting is an additive manufacturing process in which metal is melted and injected into a mold, cooled and solidified to form a blank; Machining, on the other hand, is subtractive manufacturing that achieves precision molding by removing excess parts of the material, and the two constitute the core “forming + finishing” closed loop of the manufacturing industry.

The essential difference between these two processes can be understood through a simple case: the production of an automobile engine block first prepares a preliminary shape of the blank (which belongs to the blank preparation link) through the casting process, and then completes the precision processing through turning, grinding and other material removal processes, and finally forms a product that meets the requirements of use. It is worth noting that subtractive manufacturing vs additive manufacturing are not antagonistic relationships, but complementary collaborations – casting solves the problem of “molding efficiency” and machining solves the problem of “precision standards”, which together form a complete overview of the manufacturing process.

From the principle point of view, the core of the casting process principle is to use the fluidity and solidification characteristics of metal to control the final shape through the mold; The principle of machining is based on mechanical actions such as cutting and grinding to gradually remove the blank allowance and improve dimensional accuracy and surface quality. The combination of the two lies in the connection between molding and finishing, which is also a key link that affects product quality and production efficiency.

2. Core process methods and technologies: selection guidelines and practical skills

(1) Casting process classification and applicable scenarios

| Casting process | Core features: | Applicable scenarios | Typical case |

| Sand casting | Low cost and high flexibility | Small and medium-sized batches, complex structural parts | Agricultural machinery gearbox housing |

| Die casting | High efficiency and high precision | Large quantities of thin-walled aluminum alloy parts | The middle frame of the mobile phone, the steering knuckle of the car |

| Investment casting | Extremely high precision and smooth surface | High-end precision parts | aero engine blades |

| Metal mold casting | Long life and good consistency | Medium batch non-ferrous metal parts | Motorcycle crankcase |

| Centrifugal casting | Uniform wall thickness and high strength | Tubular parts | Water pipes, boiler pipes |

| Low pressure casting | Stable filling and few defects | High quality castings | Car wheels |

| Lost foam casting | No parting surface, flexible design | Complex structural parts | Heavy machinery base |

In the actual selection, it is necessary to comprehensively consider the requirements of batch, material and precision: for example, for large-scale production of aluminum alloy mobile phone parts, die casting is preferred; while superalloy precision parts in the aerospace field must be investment casting.

(2) Core technology of machining technology

Machining technology covers a variety of subdivision technologies, and the application scenarios and effects of different processes vary significantly:

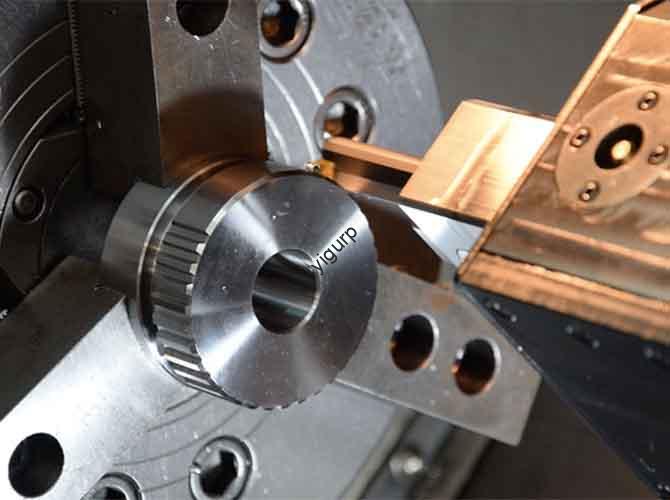

- Turning: mainly used for the outer and inner hole processing of shaft and disc parts, such as the turning of motor shafts, which can achieve IT6-IT8 level accuracy;

- Milling: suitable for flat, grooved, and complex surface processing, such as milling machine tool tables, with a surface roughness of Ra1.6-6.3μm;

- Drilling/boring: For hole feature processing, the boring accuracy is higher, and it is often used for engine cylinder hole finishing;

- Grinding: The core process of precision machining, which can achieve the accuracy of IT5 or above, such as the grinding of bearing rings;

- EDM / Laser Cutting: For high-hardness, complex-shaped parts, such as mold cavities and stainless steel precision parts.

The popularity of CNC machining has greatly improved machining efficiency and precision, and automated production is achieved through CAD/CAM programming, especially suitable for machining multi-variety and high-precision parts. Near-net molding technology (such as precision casting + low-volume finishing) has become a key direction for cost reduction – an auto parts company has reduced the machining allowance of engine pistons by 30% and production costs by 15% through near-net molding technology.

In addition, heat treatment and post-treatment are important links in improving product performance: stress relief annealing after casting reduces deformation, quenching after machining improves hardness, and surface treatments (such as electroplating and spraying) enhance wear resistance and corrosion.

3. Material science and selection: match process and performance requirements

(1) Mainstream casting alloys and their characteristics

The choice of casting alloy directly affects product performance and process feasibility, and common materials include:

- Cast iron: low cost, good wear resistance, suitable for machine tool bed, engine block, tensile strength up to 200-900MPa;

- Cast steel: high strength and good toughness, used for heavy-duty structural parts, such as crane hooks, bridge bearings;

- Aluminum alloy: lightweight, good thermal conductivity, the first choice in the automotive and aviation fields, density only 2.7g/cm³;

- Magnesium alloy: high specific strength, used in high-end lightweight products, such as drone frames;

- Copper alloy: excellent electrical and thermal conductivity, suitable for valves and pipeline fittings.

(2) Core considerations for material selection

- Machinability: The cutting difficulty of different materials varies greatly, for example, aluminum alloys are easy to machine, while superalloys are 5-10 times more difficult to process than ordinary steel, requiring special tools and process parameters.

- Material properties: match strength, hardness, toughness, wear resistance and other indicators according to the usage scenario – such as construction machinery parts need high toughness, molds need high hardness;

- Relationship between casting defects and materials: cast iron is prone to graphite floating defects, aluminum alloy is prone to porosity, which needs to be avoided by adjusting composition and process parameters;

- Effect of heat treatment on materials: For example, 45 gauge cast steel can be increased from HB200 to HB280-320 after quenching and tempering, and the toughness is significantly improved.

Practical advice: When selecting materials, you can refer to the material selection guide, combined with the stress of the product, the working environment, and the cost budget. For example, for bracket parts working at room temperature, gray cast iron can be selected; For parts in high-temperature environments, heat-resistant steel or superalloys need to be selected.

4. Design and engineering considerations: optimization solutions for manufacturing

(1) Key points of casting structure design

- Draft slope: This is the basic requirement of casting design, generally 1-3°, if the slope is too small, it is easy to lead to casting sticking, strain, an agricultural machinery enterprise has caused a casting scrap rate of up to 8% due to insufficient draft slope;

- Processing allowance: It needs to be determined according to the casting accuracy and processing technology, the processing allowance of sand casting is usually 3-5mm, and die casting can be reduced to 0.5-2mm.

- Wall thickness uniformity: avoid sudden changes in wall thickness, otherwise it is easy to produce defects such as shrinkage and porosity, and gradual transition should be used in design.

(2) Precision and tooling design

- Tolerance and fit: According to the product use requirements, the tolerance level of machining is generally IT6-IT10, and the type of mating needs to be selected according to assembly requirements (such as gap fit, transition fit);

- Surface roughness: The surface roughness of castings is usually Ra12.5-100μm, and it can reach Ra0.8-6.3μm after machining, which needs to be matched according to the usage scenario – the moving mating surface needs a higher finish, and the non-mating surface can reduce the requirements;

- Tooling fixture design: reasonable fixtures can improve machining efficiency and accuracy, such as using double top clamps when processing shaft parts, and two pins on one side when processing box parts;

- DFM (Design for Manufacturing): The core is to consider manufacturing feasibility during the design phase, such as simplifying complex structures and avoiding closed cavities, and an electronics company optimized the life of die casting molds from 50,000 to 80,000 molds.

(3) CAD/CAM integrated application

The integration of CAD/CAM technology realizes the seamless connection between design and manufacturing: after completing the 3D modeling through CAD, the CAM software is directly imported for machining path planning, tool selection, parameter setting, and NC programs are generated and transferred to the CNC machine tool for automated machining. This model not only shortens production cycles, but also reduces human error, and a mold company shortened product development cycles by 40% through CAD/CAM integration.

5. Quality control and testing: defect prevention and control in the whole process

(1) Application of non-destructive testing technology

NDT is a core means of quality control for castings, allowing internal defects to be found without destroying the product:

- X-ray inspection: It can detect internal porosity and shrinkage, and the detection accuracy can reach 0.1mm, which is suitable for precision castings;

- Ultrasonic testing: for internal cracks and inclusions, the detection depth can reach several meters, often used for thick-walled parts;

- Magnetic particle detection: suitable for surface crack detection of ferromagnetic materials, such as gears and shaft parts.

(2) Whole process quality inspection system

- Raw material testing: Ensure that raw materials meet the requirements through material chemical composition analysis, such as the carbon content of cast iron should be controlled at 2.5-3.5%;

- Process testing: including sand performance testing in the casting process, temperature detection of metal liquid, and size sampling inspection in machining;

- Finished product inspection:

- Dimensional inspection: use coordinate measuring instruments, calipers, and other tools to ensure that the dimensions meet the requirements of the drawings;

- Mechanical property test: through tensile test, impact test to detect strength, toughness and other indicators;

- Surface quality inspection: Visually or with the help of a magnifying glass to check for surface porosity, sand holes, strain and other defects.

(3) Analysis and solution of common defects

| Casting defects | Causes | Solution |

| stoma | The metal liquid has high gas content and the mold exhaust is not smooth | Refine degassing and increase exhaust holes |

| Shrink loose | The solidification sequence is unreasonable and the shrinkage is insufficient | Set up risers and optimize the gating system |

| Cold isolation | The metal liquid temperature is low and the filling speed is slow | Increase the pouring temperature and optimize the sprue |

Monitoring key parameters in the production process through statistical process control (SPC) can effectively reduce defect rates. After the introduction of SPC by an automobile casting company, the scrap rate dropped from 5% to less than 2%.

6. Cost, efficiency and supply chain: optimization strategy and decision-making basis

(1) Cost composition and control

- Mold cost: It is the main fixed cost of the casting process, the cost of sand mold is low (about tens of thousands of yuan), and the cost of die-casting mold is high (hundreds of thousands of yuan to millions of yuan), which needs to be distributed in batches;

- Machining cost calculation: including equipment depreciation, tool consumption, labor costs, etc., for example, the hourly cost of CNC machining is about 100-300 yuan, and the machining path needs to be optimized to reduce man-hours;

- Cost optimization tips: Use near-net molding technology to reduce processing allowances, select cost-effective materials, and optimize the supply chain to reduce procurement costs.

(2) Production efficiency and batch considerations

- Production cycle: The production cycle of sand casting is shorter (hours to days) and the investment casting is longer (days to weeks); The machining cycle depends on the complexity and precision requirements of the part;

- Batch size considerations: small batch production is suitable for sand casting + general processing, mass production is suitable for die casting + CNC automatic processing, a home appliance company changed sand casting to die casting after the batch reached 100,000 pieces, reducing the unit cost by 20%;

- Rapid prototyping: For new product development, 3D printing can be used to make molds or direct molding to shorten the R&D cycle, and a medical device company uses rapid prototyping to advance the time to market for new products by 6 months.

(3) Supply chain management decision-making

- Supplier selection: Priority is given to suppliers with process capabilities and complete quality control systems, which can be evaluated through on-site audits and sample testing;

- Manufacturing outsourcing decisions: Non-core processes can be considered outsourcing, such as outsourcing casting to a professional foundry, the company focuses on precision machining and assembly, and a machinery company reduces fixed asset investment by 30% by outsourcing the casting link.

7. Industry applications and case studies: practical experience sharing

(1) Application scenarios in key industries

- Auto parts manufacturing: the engine block and gearbox housing are sand casting, the wheel hub is made of low-pressure casting, and the drive shaft is processed by turning and grinding, and the core requirements are lightweight and reliability.

- Aerospace applications: Engine blades are investment casting (superalloy), fuselage structural parts are CNC machining (aluminum alloy, titanium alloy), and the precision requirements are above IT5 level;

- Medical device processing and casting: surgical instruments are cast in stainless steel + precision grinding, and implants are processed with titanium alloy, which must meet biocompatibility and sterility requirements;

- Energy equipment castings: wind turbine hubs are made of sand casting (ductile iron), and nuclear power pipelines are made of centrifugal casting (heat-resistant steel), which requires high strength and corrosion resistance;

- Mold manufacturing: The injection mold cavity adopts EDM + grinding, and the mold base adopts casting + milling processing, which needs to meet the requirements of high hardness and precision.

(2) Typical case analysis

Case 1: Optimization of automotive wheel production process

An automobile company originally used sand casting to produce wheels, with a scrap rate of 8% and a long production cycle. Later, it was changed to low-pressure casting + CNC machining, and by optimizing the mold design (adding exhaust holes) and adjusting the aluminum alloy composition (adding refiner), the scrap rate was reduced to 2%, the production efficiency was increased by 30%, and the unit cost was reduced by 15%.

Case 2: Aero engine blade manufacturing

An aviation company that produced superalloy blades using an investment casting process faced a core problem with internal shrinkage defects. By employing directional solidification technology, optimizing the pouring temperature and speed, combined with X-ray non-destructive testing, the defect rate was reduced from 12% to 3%, meeting the stringent requirements of the aerospace sector.

8. Yigu Technology’s view

As the core basic process of the manufacturing industry, machining and casting are the key trends in the development of the industry. At present, digital and intelligent technologies are promoting two major process upgrades – CAD/CAM integration, AI-driven process parameter optimization, and the application of automated testing equipment, which not only improves product accuracy and consistency, but also shortens the R&D and production cycles. For enterprises, it is necessary to balance process selection, cost control and quality requirements to maximize value through DFM design and supply chain collaboration. In the future, the application of lightweight materials and breakthroughs in near-net molding technology will further promote the development of the machining and foundry industry in the direction of high efficiency, energy saving and precision, and provide stronger support for high-end manufacturing.

9. FAQ FAQ

- Q: How is the order of casting and machining determined?

A: Usually the blank is prepared by casting first, and then machined and finished; If the precision of the parts is low and the structure is simple, it can also be molded only by casting (such as some agricultural machinery parts).

- Q: How to choose the right casting process?

A: Core considerations include: batch size (large batch die casting, small batch sand casting), material type (aluminum alloy die casting/low-pressure casting, superalloy investment casting), precision requirements (high-precision investment casting, ordinary precision sand casting).

- Q: How to improve surface roughness in machining?

A: Finishing processes such as grinding and polishing can be used to optimize cutting parameters (reduce cutting speed, reduce feed), select sharp tools, and ensure sufficient cutting fluid.

- Q: How to effectively prevent and control casting defects?

A: Starting from the four links of raw materials (refining and degassing), mold design (optimizing the gating system, adding exhaust holes), process parameters (controlling the pouring temperature, solidification speed), and testing (non-destructive testing of the whole process), a closed-loop control system is established.

- Q: How to control costs when producing small batches?

A: Choose sand casting, general machining technology, use general tooling fixtures, simplify the structure through DFM design, reduce processing allowance, and consider process outsourcing to reduce fixed asset investment.