In the field of modern high-end manufacturing, gantry machining has become an indispensable key processing technology in aerospace, heavy machinery, energy equipment and other industries with its core advantages of large stroke, high rigidity, and high precision. This article will start from basic cognition, take you to gradually gain an in-depth understanding of the core concepts, key components, working principles, type division, practical application scenarios, advantages and disadvantages analysis, selection skills, and finally share practical suggestions and FAQs based on industry experience to help you fully grasp the core knowledge of gantry machining and solve the confusion of selection and application in actual production.

1. What is a gantry milling machine? ——Basic cognition of gantry machining

Gantry milling machine is one of the core equipment of gantry machining, which belongs to a kind of large milling machine, and its structure is characterized by a “gantry” frame composed of beams and columns on both sides, and the worktable is usually located under the gantry frame, which can realize the multi-process processing of large and heavy workpieces such as planes, bevels, grooves, and hole systems. Compared with ordinary milling machines, gantry milling machines can effectively reduce vibration during machining and ensure machining accuracy due to the high rigidity of frame structure, especially suitable for the overall processing of large-sized workpieces.

From the perspective of industry development, with the popularization of CNC technology, traditional gantry milling machines have been gradually upgraded to CNC gantry machining centers, realizing automation and multi-axis linkage machining, and becoming the mainstream direction of gantry machining technology development. According to industry data, the global CNC gantry machining center market size will reach US$8.6 billion in 2024, a year-on-year increase of 7.2%, of which the aerospace and new energy industries contribute more than 40% of the demand.

2. The core component of gantry machining, the key component of gantry milling machine

The performance of a gantry milling machine depends on the design and manufacturing precision of its key components. The following is a breakdown of the key components and functions of the core equipment of gantry machining, clearly presented in the form of a table:

| Key components | Core features: | Influencing factors | Industry quality standards |

|---|---|---|---|

| beam | The headstock is installed to bear the machining cutting force and realize the lateral feed | Material strength, cross-sectional design, heat treatment process | It adopts high-strength cast iron or welded steel structure, and the aging treatment eliminates internal stress, and the deformation ≤ 0.02mm/m |

| Columns | Support beams to ensure the stability of the gantry frame | Height to section ratio, connection accuracy with base | The column and base are cast or rigidly connected, and the verticality error ≤ 0.015mm/m |

| Workbench | Position the workpiece to achieve longitudinal feed movement | Table size, load-bearing capacity, guide rail accuracy | It adopts rectangular guide rail or line rail, with a load-bearing capacity of ≥ 5t/m² and a positioning accuracy of ≤0.01mm |

| Headstock | Install the spindle to realize the rotation of the spindle and the up and down feeding | Spindle speed, power, rigidity | The spindle speed range is 50-8000rpm, the power ≥ 15kW, and the radial runout ≤ 0.005mm |

| CNC system | Control the movement of each axis of the equipment to realize automatic processing | System responsiveness, ease of programming, compatibility | The mainstream uses high-end systems such as FANUC 31i and Siemens 840D, which support five-axis linkage control |

Case sharing: The double-column gantry milling machine used by a heavy machinery manufacturing enterprise, its beam is made of welded steel structure and after two aging treatments, the column and the base are cast as one, and the processing accuracy error is controlled within 0.03mm when processing a large machine tool bed weighing up to 20t, which is 30% higher than that of traditional equipment.

3. The working principle of gantry milling machine – the operating logic of gantry machining

The core working logic of gantry machining is to achieve precise machining of the workpiece through the rigid support of the gantry frame, with the synergy of multi-axis feed movement and spindle cutting movement. The specific workflow can be divided into the following 5 steps, clearly presented in an ordered list:

- Workpiece clamping: According to the size and shape of the workpiece, use pressure plates, fixtures, etc. to fix the workpiece on the workbench to ensure that the clamping is firm and avoid displacement during the processing process. When clamping, it is necessary to pay attention to the alignment of the positioning reference of the workpiece with the coordinate system of the machine tool, and the positioning error is controlled within 0.02mm.

- Program preparation: Write the machining program through the CNC system to clarify the processing path and cutting parameters (rotational speed, feed, cutting depth), etc. For complex surface processing, CAD/CAM software can be used for automatic programming and program simulation verification to avoid interference collisions.

- Parameter setting: Input tool compensation parameters, workpiece coordinate system parameters, etc. into the CNC system, start the equipment for origin regression, and ensure that the movement reference of each axis is accurate.

- Machining execution: The equipment drives the worktable, beam, headstock and other components to move together according to the program instructions, and the spindle drives the tool to rotate to cut the workpiece. During the processing process, the CNC system monitors the motion status and cutting force of each axis in real time, and automatically alarms and stops the machine when there is an abnormality.

- Finished product testing: After the processing is completed, the workpiece is unloaded, and precision testing equipment such as coordinate measuring instruments is used to test the size, shape and position tolerance of the workpiece to confirm whether it meets the processing requirements. If there are errors, they are corrected by adjusting the program parameters or tool compensation.

Core principle supplement: The key to the high-precision machining of the gantry milling machine lies in its “static indefinite structure” design – the rigid connection between the beam and the column forms a stable force system, which can effectively disperse the cutting force and reduce equipment deformation during the cutting process; At the same time, high-precision guide rails and ball screw transmission are used to ensure the smoothness and positioning accuracy of the feed movement of each axis.

4. Types of gantry milling machines – adapt to different gantry machining needs

According to the differences in structural design and processing function, gantry milling machines can be divided into various types, and different types are suitable for different workpiece sizes, machining accuracy and industry needs. Here’s a breakdown of the mainstream types:

4.1 Fixed bridge gantry milling machine

Structural features: The beam is fixed on the column, immovable, and is processed through the longitudinal movement of the worktable and the lateral and vertical movement of the headstock. Its core advantages are simple structure, strong rigidity, and relatively low manufacturing costs.

Applicable scenarios: suitable for machining workpieces with long lengths and small widths, such as large machine tool beds, guide rails, etc. Case: A machine tool factory uses a fixed bridge gantry milling machine to process machine tool bed guide rails with a length of 12m and a width of 1.5m, with a machining accuracy of H7 level to meet the needs of mass production.

4.2 Mobile bridge gantry milling machine

Structural characteristics: The beam can move up and down along the column guide, and at the same time, it can drive the headstock to move laterally along the beam, and the worktable can be fixed or moved longitudinally. Its advantage is that it has a wide processing range and can adapt to workpieces of different heights and widths.

Applicable scenarios: Suitable for processing large and complex shaped workpieces, such as fuselage frames and large molds in the aerospace field. Industry data: Mobile bridge gantry milling machines account for 65% of the application in the aerospace industry, mainly used for processing large aluminum alloy structural parts.

4.3 Mobile table gantry milling machine

Structural features: The beam is fixed with the column, the worktable can move longitudinally along the bed, and the headstock can move horizontally and vertically along the beam. Its advantage is that the worktable has a strong load-bearing capacity and is suitable for processing workpieces with large weights.

Applicable scenarios: heavy machinery manufacturing, shipbuilding and other industries, used to process large gearbox shells, hull structural parts, etc. For example, a shipyard uses a mobile gantry milling machine to process hull ribs weighing 30 tons, and the processing efficiency is 25% higher than that of traditional equipment.

4.4 Gantry machining center

Structural features: On the basis of the gantry milling machine, an automatic tool change system and tool magazine are added, which can realize multi-process automatic machining, and support various processing methods such as milling, drilling, boring, and tapping.

Applicable scenarios: high-precision, multi-process complex workpiece processing, such as automobile molds, aero engine receivers, etc. Core advantages: reduce the number of workpiece clamping, reduce clamping errors, and improve processing efficiency and accuracy. According to statistics, gantry machining centers can shorten the processing cycle of complex workpieces by more than 40%.

4.5 Other special types

- Hybrid gantry milling machine: combines the advantages of traditional gantry milling machine with high-speed machining center, which not only has large-stroke machining capabilities, but also can achieve high-speed cutting, suitable for machining precision large workpieces.

- Double column gantry milling machine: adopts a double column symmetrical structure, with stronger rigidity and higher processing accuracy, suitable for the processing of ultra-large and high-precision workpieces, such as large hydraulic turbine rotors, nuclear power plant equipment components, etc.

5. The application field of gantry machining – the industry value of gantry machining

Gantry machining is widely used in many high-end manufacturing industries due to its large-scale processing capabilities, high precision, and high rigidity. The following is a detailed breakdown of the main application areas, combined with specific cases and data explanations:

5.1 Aerospace Industry

Application scenarios: Processing key components such as large aircraft fuselage frames, wing girders, engine receivers, and landing gear. These components usually have the characteristics of large size, high precision requirements, and special materials (such as titanium alloy and aluminum alloy), which require extremely high rigidity and precision of processing equipment.

Case: An aviation manufacturing enterprise uses a five-axis gantry machining center to process aircraft wing girders, the length of the component is 8m, the thickness is 0.8m, and the processing accuracy is ±0.02mm. Through the high rigidity of gantry processing and the multi-axis linkage function, the precise machining of complex curved surfaces has been successfully realized, and the pass rate has reached 99.5%.

Industry data: The aerospace industry is the core demand area for gantry machining, and about 30% of the world’s high-end gantry processing equipment is used in this industry, and the demand growth rate is expected to remain above 8% in the next five years.

5.2 Automotive industry

Application scenarios: processing large automotive molds (such as body covering molds, bumper molds), engine blocks, gearbox housings, etc. Gantry processing can realize the overall processing of molds, reduce splicing errors, and improve mold accuracy and service life.

Case: A large auto parts enterprise uses a gantry machining center to process automobile body covering molds, with a mold size of 3.5m×2.2m, and a surface roughness of 0.8μm Ra≤8μm after processing, which increases the mold life by 50% compared with the traditional processing method and shortens the mold development cycle.

5.3 Shipbuilding

Application scenarios: processing large structural parts such as hull ribs, decks, and marine engine bases. These components are large in size and heavy, which requires high travel and load-bearing capacity of processing equipment.

Advantages: Gantry machining can realize the overall processing of large hull components, reduce the on-site splicing workload, and improve the stability and safety of the hull structure. According to shipbuilding industry data, the assembly accuracy of hull components processed by gantries is increased by 35% and the assembly efficiency is increased by 20%.

5.4 Energy sector

Application scenarios: processing hubs, bases, and blade molds of wind power equipment, pressure vessels and steam turbine blades of nuclear power equipment, hydraulic turbine rotors of hydropower equipment, etc. These components are often subjected to harsh operating conditions and require extremely high machining accuracy and reliability.

Case: A wind power equipment manufacturer uses a double-column gantry milling machine to process wind turbine hubs, with a diameter of 4.2m and a processing accuracy of ≤ flatness of the flange surface. Through the high rigidity and high-precision control of gantry processing, it successfully meets the stringent requirements of wind power equipment, and the operation stability of the product is increased by 40%.

5.5 Heavy machinery and other fields

Heavy machinery manufacturing: processing large machine tool beds, gearboxes, crane main beams, etc.; Tool and mold manufacturing: processing large plastic molds, die-casting molds, etc. In addition, gantry processing also plays an important role in rail transit, construction machinery and other fields.

6. Advantages and potential disadvantages of gantry machining – a comprehensive evaluation of gantry machining

6.1 Core Advantages

The advantages of gantry machining are mainly reflected in processing capacity, precision, efficiency and other aspects, the following is a detailed analysis:

- Large machining area and large workpiece capacity: The gantry structure design allows it to have a large travel range and can process large workpieces with a length of tens of meters and a weight of hundreds of tons, which is a core advantage that ordinary processing equipment cannot match.

- High rigidity and stability: The gantry frame composed of beams and columns has strong rigidity and low vibration during the cutting process, which can effectively ensure machining accuracy. The experimental data show that the cutting vibration amplitude of the gantry milling machine is reduced by more than 60% compared with the ordinary milling machine.

- High-precision machining: With high-precision guide rails, ball screws, and high-end CNC systems, gantry machining can achieve positioning accuracy of ±0.01mm, meeting the precision machining needs of high-end manufacturing industries.

- Heavy cutting capacity: Due to its strong rigidity, the gantry milling machine can use a large cutting depth and feed to achieve heavy cutting and improve material removal efficiency. For example, when processing 45 steel, the cutting efficiency of the gantry milling machine is 50%-80% higher than that of ordinary milling machines.

- Versatility and High Productivity: Gantry machining centers can realize multi-process automation, equipped with tool magazines and automatic tool change systems, reducing the number of workpiece clamping times and assistance time, and greatly improving production efficiency. At the same time, the multi-axis linkage function can realize the processing of complex curved surfaces and spatial structures, and adapt to diverse processing needs.

- Cost-effectiveness and labor reduction: Automated machining reduces manual intervention and reduces labor costs; At the same time, the overall processing reduces the number of workpiece transfers and clamping, reduces machining errors and scrap rates, and significantly improves cost-effectiveness in the long run.

6.2 Potential Drawbacks

- High equipment cost and maintenance cost: Gantry processing equipment has a complex structure, high manufacturing accuracy, and high initial purchase cost; At the same time, key components such as the guide rail, spindle, and CNC system of the equipment require regular maintenance and maintenance, and the maintenance cost is relatively high. For example, the annual maintenance cost of a high-end gantry machining center is about 3%-5% of the equipment acquisition cost.

- Complexity and steep learning curve: Gantry machining equipment is difficult to operate and program, requiring operators to have solid CNC machining knowledge and rich practical experience. New operators usually need to undergo 3-6 months of professional training to operate independently, and the learning cost is high.

- High time and energy consumption: Due to the large size and heavy weight of the equipment, the energy consumption during start-up and operation is large; at the same time, when processing large workpieces, the single processing cycle is long, and the arrangement of production planning is high.

- Large footprint: The size of the gantry processing equipment is large, which needs to occupy a large production site, and has certain requirements for the plant area and floor height, which increases the cost of site leasing or construction.

7. In-depth analysis of gantry machining center – the high-end form of gantry machining

Gantry machining center is a high-end development form of gantry machining, integrating CNC technology, automation technology and precision machining technology, with more powerful machining capabilities and higher machining accuracy. The following is an analysis of its core features:

7.1 Core structural characteristics

The structure of the gantry machining center has been optimized and upgraded on the basis of the traditional gantry milling machine, and the core includes: (1) The more rigid gantry frame, usually using one-piece casting or welded steel structure, after multiple aging treatments to eliminate internal stress; (2) High-precision linear guide rail and ball screw transmission to ensure the smoothness and positioning accuracy of each axis movement; (3) High-power spindle system, supporting high-speed cutting and heavy cutting; (4) Automatic tool change system and tool magazine, the tool magazine capacity is usually 24-60, which can realize the rapid switching of multiple tools.

7.2 Multi-axis machining capabilities

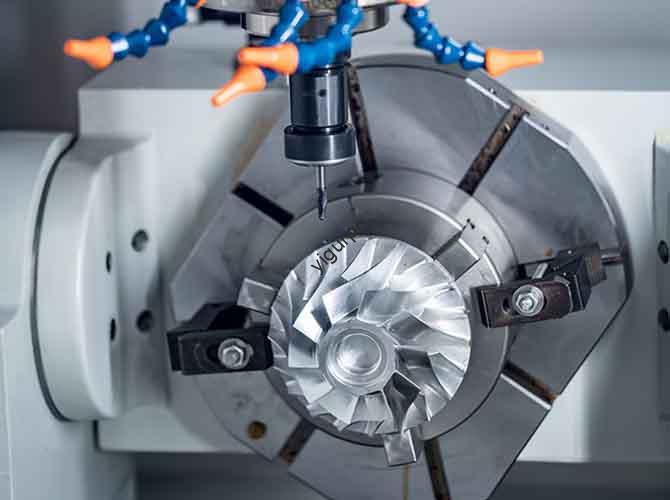

High-end gantry machining centers generally have five-axis linkage machining capabilities, which can realize the coordinated movement of three linear axes of X, Y, and Z and two rotary axes of A and C, and can process complex spatial surfaces and special-shaped structures. For example, the blades, impellers and other components of aero engines can be completed through the five-axis gantry machining center in one clamping, greatly improving the machining accuracy and efficiency.

Industry trend: With the development of intelligent manufacturing technology, multi-axis gantry machining centers are gradually developing in the direction of “intelligence”, integrating functions such as online detection, adaptive machining, and remote monitoring, further improving the level of processing stability and intelligence.

7.3 Quick tool change system

The quick tool change system is one of the core components of the gantry machining center to achieve automated machining, and its tool change time is usually 3-8 seconds, which greatly reduces the auxiliary time of tool change. The tool changing system adopts a cam mechanism or manipulator structure, and the tool change action is precise and fast, ensuring the continuity of the machining process. For example, the manipulator tool change system of a brand gantry machining center has a tool change time of only 4.5 seconds, which is more than 90% higher than the traditional manual tool change efficiency.

7.4 The difference between gantry and bridge machining center

In the field of gantry machining, gantry machining centers and bridge machining centers are often confused, and the core differences between the two are mainly reflected in the structural design and application scenarios, as shown in the following table:

| Contrast dimensions | Gantry machining center | Bridge machining center |

|---|---|---|

| Structural features | The columns are located on both sides of the workbench, forming a gantry frame and the beams can be moved along the columns | The beam is a bridge structure, and both ends are supported on the bed guide rail, which can be moved along the guide rail |

| Rigidity | Stronger rigidity for heavy cutting and large workpiece machining | The rigidity is relatively weak, making it suitable for high-precision machining of medium and light workpieces |

| Processing range | Large stroke range for larger workpiece sizes | The stroke range is relatively small, making it suitable for small and medium-sized workpiece processing |

| Application scenarios | Processing of large workpieces in aerospace, heavy machinery, shipbuilding and other industries | Medium and light high-precision machining scenarios such as mold manufacturing and precision parts processing |

| Cost | The purchase and maintenance costs are high | The cost is relatively low |

8. Gantry milling machine selection guide – accurately match gantry machining needs

Choosing the right gantry milling machine is key to ensuring efficient and precise gantry machining. The following are the key points of selection based on industry experience to provide you with practical advice from multiple dimensions:

8.1 Clarify the specifications of the workpiece

Core considerations: maximum dimensions (length, width, height), weight, material properties of the workpiece. (1) Size matching: ensure that the travel range of the equipment is greater than the maximum size of the workpiece, it is usually recommended that the travel of the equipment is 10%-20% larger than the maximum size of the workpiece, and reserve the clamping and processing allowance; (2) Weight matching: The load-bearing capacity of the equipment worktable should be greater than the weight of the workpiece to avoid the deformation of the worktable affecting the machining accuracy; (3) Material adaptation: high-power and high-rigidity equipment should be selected for processing hard materials (such as steel and titanium alloy); For processing soft materials such as aluminum alloys, high-speed processing equipment can be selected.

8.2 Clarify the processing requirements

Core considerations: machining accuracy, surface roughness, type of machining process. (1) Accuracy requirements: According to the dimensional tolerance and shape tolerance requirements of the workpiece, select the equipment with corresponding positioning accuracy and repeatable positioning accuracy. For example, for workpieces with machining accuracy requiring ± 0.01mm, a high-end gantry machining center with a positioning accuracy ≤ 0.008mm should be selected; (2) Surface roughness: For workpieces that require higher surface roughness (such as Ra≤0.8μm), equipment with high-speed spindle and high-precision guide rails should be selected, and high-quality tools should be selected; (3) Process type: If you need to realize multi-process processing such as milling, drilling, boring, and tapping, you should choose a gantry machining center with a tool magazine and automatic tool change system.

8.3 Selection of spindle and number of axes

(1) Spindle specifications: choose the spindle power and rotation speed according to the processing material and cutting needs. For heavy workpieces, a high-power spindle (≥22kW) needs to be selected; For processing precision workpieces, a high-speed spindle (rotation speed ≥ 8000rpm) should be selected; (2) Axis number selection: simple plane and groove machining can choose three-axis equipment; For the processing of complex curved surfaces and spatial structures, five-axis linkage equipment should be selected.

8.4 Rigidity and structural design of equipment

Priority should be given to equipment with integrated casting or welded steel structure and aging treatment to ensure the rigidity and stability of the equipment. The linear guide rail is preferentially selected, and its positioning accuracy and motion stability are better than that of the rectangular guide rail. At the same time, pay attention to the cooling system and lubrication system of the equipment to ensure the stability of long-term operation of the equipment.

8.5 CNC system and software compatibility

Choose mainstream and mature CNC systems (such as FANUC, Siemens, Huazhong CNC), its stability and after-sales service are more guaranteed; At the same time, ensure that the CNC system supports mainstream CAD/CAM software (such as UG, Mastercam) to facilitate program preparation and import.

8.6 Automation and Additional Features

According to production needs, choose whether to be equipped with automatic clamping system, online inspection system, chip removal system and other additional functions. For example, mass production can be equipped with automatic clamping system to improve efficiency; Precision machining can be equipped with an online inspection system to monitor the machining accuracy in real time.

8.7 Venue and Budget Considerations

Select the equipment size according to the plant area and floor height to ensure that there is enough space for operation and maintenance after the equipment is installed; In terms of budget, it is necessary to comprehensively consider equipment purchase costs, maintenance costs, energy consumption costs, etc., choose the most cost-effective equipment, and pay attention to the return on investment (ROI) of the equipment. Typically, the payback cycle for high-end gantry machining centers is 2-3 years.

8.8 Supplier Selection

Choose a supplier with rich industry experience, good reputation and perfect after-sales service. Priority is given to enterprises that have passed the ISO9001 quality system certification, and their product quality is more guaranteed; At the same time, pay attention to the technical support capabilities of suppliers to ensure that equipment installation, commissioning, training and maintenance services are in place in a timely manner.

9. Yigu Technology’s views

As the core supporting technology of high-end manufacturing, gantry machining is deeply bound to the upgrading and transformation of the manufacturing industry. At present, intelligence, high precision, and large stroke are the mainstream development trends of gantry processing, and the core of enterprise selection lies in “precise matching needs” – there is no need to blindly pursue high-end configuration, but need to combine the characteristics of the workpiece, processing requirements and budget comprehensive considerations. Yigu Technology believes that in the future, gantry processing equipment will further integrate cutting-edge technologies such as digital twins and AI adaptive machining to greatly improve processing efficiency and stability. For enterprises, choosing suppliers with technological innovation capabilities and perfect services, while strengthening operator skill training, is the key to giving full play to the value of gantry machining.

10. Frequently Asked Questions (FAQs)

What is a gantry machine? Gantry machine is a large-scale processing equipment using a “gantry” frame structure (composed of beams and columns on both sides), which is mainly used for milling, drilling, boring, tapping and other processing processes of large and heavy workpieces. Its core advantages are strong rigidity, large processing stroke, and high precision, and are widely used in high-end manufacturing industries such as aerospace, heavy machinery, and energy. According to the functional differences, it can be divided into various types such as gantry milling machines and gantry machining centers.

What is a gantry on a CNC machine? The gantry on CNC machines refers to the frame-type structure composed of beams and columns, which is the core support component of the equipment. Its role is to install key components such as headstocks and guide rails, providing stable rigid support for machining, reducing vibration during cutting, and ensuring machining accuracy. In CNC gantry machine tools, the design of the gantry structure directly affects the processing capacity, rigidity and precision of the equipment, usually made of high-strength cast iron or welded steel structure.

What is CNC VMC and HMC? CNC VMC is a Vertical Machining Center, whose spindle axis is perpendicular to the worktable, compact structure, small footprint, suitable for processing small and medium-sized workpieces of planes, hole systems, curved surfaces, etc., widely used in mold manufacturing, precision parts processing and other fields. CNC HMC is the CNC horizontal machining center (Horizontal Machining Center), its spindle axis is parallel to the worktable, equipped with a rotating worktable, which can achieve multi-faceted machining, high processing efficiency and good stability, suitable for batch processing of complex box workpieces, such as engine blocks, gearbox housings, etc.

What is tramming in machining? Tramming in machining refers to the process of adjusting the machine tool spindle or worktable to ensure that it remains accurately perpendicular or parallel to the machining datum, with the aim of eliminating machining errors and ensuring machining accuracy. For example, in gantry machining, if the spindle is not perpendicular to the worktable, it will lead to problems such as tilt of the machined plane and deviation of the hole system. Calibration is usually done with precision testing tools such as dial indicators and levels.