Yigu will focus on the core keyword flange machining, starting from the basic definition, characteristics and connection principles of flanges, gradually delve into various flange types, connection surface forms, and size standards, and then dismantle the key points of the whole process of flange machining in detail, and answer common questions in the industry. Whether you are an experienced practitioner in mechanical engineering, pipeline engineering, or someone who needs to understand flange machining technology, you will gain systematic and practical expertise to help solve practical problems in flange machining.

1. Unveil the mystery of flanges

Before delving into flange machining, we must first clarify the core basic attributes of flanges – they are not only the key components connecting pipes and equipment, but also their own characteristics and connection principles directly determine the design direction of subsequent machining processes.

(1) What is a flange?

Flange, commonly known as flange or nosing, is a ring-shaped part with bolt holes at the end of the pipe, at the interface of the equipment, for connection. Its core role is to realize the detachable sealed connection between pipelines and pipelines, pipelines and equipment, and equipment and equipment, which is indispensable in petrochemical, aerospace, water conservancy and power, municipal engineering and other fields. Flange machining refers to the whole process of processing raw materials into flange products that meet design requirements through a series of mechanical processing processes, and its accuracy directly affects the tightness and stability of the connection.

(2) Characteristics of flanges

The characteristics of flanges are mainly determined by the material and structure, which is also the core basis for material selection and process design in flange machining: 1. Structural characteristics: It has a stable ring structure and evenly distributed bolt holes to ensure the balanced force during connection; 2. Material characteristics: According to different working conditions, carbon steel, stainless steel, alloy steel, non-ferrous metals, etc. can be selected, which have the characteristics of high pressure resistance, corrosion resistance, high temperature resistance, etc.; 3. Sealing characteristics: By coordinating with the gasket, the sealing is achieved by relying on the bolt fastening force, and the sealing performance directly depends on the processing accuracy.

(3) The working principle of flange connection

The core logic of flange connection is “clamping sealing”: first fix the two flanges to be connected to the pipe or equipment port respectively, and place a gasket between the sealing surfaces of the two flanges; Then fasten through the bolt through the bolt hole, the preload of the bolt will press the two flanges tightly against the gasket, so that the gasket will be elastic or plastic deformed, fill the small bumps on the sealing surface of the flange, so as to block the leakage of the medium and achieve a sealing connection. The processing accuracy of the sealing surface and the position accuracy of the bolt hole in flange machining directly determine the uniformity of the bolt preload and the sealing effect of the gasket.

2. Various types and unique uses of flanges

Different types of flanges correspond to different working conditions, and their structural differences directly determine the process focus of flange machining. Only by understanding the characteristics of various types of flanges can we accurately control the key dimensions in processing.

(1) Common flange types

| Flange type | Structural features: | Applicable working conditions | flange machining focus |

|---|---|---|---|

| Socket-Weld Flanges | With socket, the pipe is welded and fixed after insertion, and the structure is compact | Small diameter (DN10-DN100), high-pressure, and high-temperature pipelines, and scenarios with high sealing requirements | Accurately control the size tolerance of the socket to ensure the fit of pipe insertion and smooth welding surface |

| Lap Joint Flanges | The flange can slide along the pipe and work with the flanging section for flexible disassembly | Frequent disassembly and a certain flexible connection required, corrosive media pipes (different materials can be used for flanging) | Ensure the fitting accuracy of the flange inner hole and the flanging short section, and control the flatness of the sealing surface |

| Blind Flanges | Annular structure without center hole for closed pipe ports | Scenarios at the end of the pipeline system, equipment maintenance isolation, and temporary closure | Ensure the accuracy of the sealing surface, control the uniformity of the thickness of the plate, and the position of the bolt hole is accurate |

| Weld Neck Flanges | With a long neck structure, it is welded with the pipe butt and is evenly forced | High temperature, high pressure, high vibration working conditions, large diameter pipeline (DN100 or above) | The transition arc between the long neck and the flange body is smooth, the welding bevel angle is accurate, and the overall dimensional tolerance is tight |

| Slip-On Flanges | The structure is simple, and the pipe is welded on both sides after inserting the flange, and the cost is low | Low-pressure, ambient temperature piping systems, civil or general industrial scenarios with low connection strength requirements | Control the mating gap between the inner hole and the pipe, and the welding surface can be flat |

| Threaded Flanges | The flange bore is threaded and connects directly to the threaded pipe without welding | Scenarios that are not suitable for welding (such as flammable and explosive environments), low-pressure, and non-violent vibration pipes | Precise machining of internal threads ensures the tightness of thread fitting and controls thread depth |

| Long Neck Welding Flanges | The long neck length is longer than ordinary butt weld flanges, with better stiffness and more uniform stress distribution | Extreme high temperature and high pressure working conditions, large equipment interfaces, high-stress piping systems | The straightness control of the long neck part, the heat treatment process of the transition area, and the overall dimensional accuracy are strictly controlled |

| Orifice Flanges | With special pressure take-off port for mounting orifice flow meters, symmetrical structure | Pipeline systems that need to measure the flow of media, such as metering pipelines for petroleum and chemical industries | The position of the pressure intake port is accurate, and the sealing surface accuracy is high to ensure the coaxiality after the orifice plate is installed |

(2) Special flange type

In addition to the above common types, customized special flanges are also used under special working conditions, which are more difficult to flange machining and have stronger requirements for the pertinence of the process. For example: 1. Special-shaped flanges: non-circular or irregularly shaped flanges designed according to the special interface of the equipment, which require customized machining molds and fixtures; 2. Special material flanges: such as titanium alloy, Hastel alloy and other corrosion-resistant high-temperature material flanges, special tools need to be selected during processing to control cutting parameters to prevent material deformation; 3. High-pressure deep-sea flanges: used in deep-sea oil and gas exploitation, they need to withstand extremely high water pressure, and the ultra-precise accuracy of the sealing surface and the compressive strength of the overall structure need to be ensured during processing.

3. The different faces of the flange: the mystery of the connecting surface

The connection surface of the flange (sealing surface) is the core part of the sealing, and its form design is directly adapted to different sealing requirements, and it is also one of the most critical processes in flange machining. The processing accuracy requirements and process difficulties of different connection surfaces vary greatly.

(1) Raised Face (RF)

The most widely used type of protrusion flange is a sealing surface that is a certain height above the flange body (usually 1.6mm or 3.2mm in height). The advantage of this construction is that it is relatively simple to process and is compatible with most gasket types. In flange machining, the focus is on ensuring the flatness of the protruding surface (tolerance should be controlled within 0.02mm/m) and surface roughness (generally required Ra3.2-Ra6.3), and at the same time ensuring the coaxiality of the protrusion face and the flange body. Case: In the municipal water pipeline system, more than 90% of the flat welded flanges are designed with protruding surfaces, which can meet the processing requirements through ordinary turning technology, and the cost is controllable and the seal is reliable.

(2) Male and Female Face (M&F)

The concave and convex flange is paired with the “convex flange” and “concave flange”, and the raised part of the convex surface is precisely matched with the groove of the concave surface to form a positioning sealing structure. This design has better sealing performance than protruding surfaces and can effectively prevent gasket displacement under pressure. The focus of flange machining is to control the mating gap of the concave and convex surfaces (generally require a gap of ≤ 0.1mm), to ensure the dimensional accuracy of the groove depth and the height of the convex surface, and to ensure the coaxiality of the two. It is suitable for medium and high pressure piping systems, such as steam transmission pipelines in the chemical industry.

(3) Tongue and groove surface (T&G)

The sealing surface of the tongue and groove flange is divided into “tenon surface” (raised bar structure) and “groove surface” (corresponding bar groove), and the gasket is fully embedded in the groove after pairing, and will not be scoured by the medium or extruded by pressure. This structure has excellent sealing performance, especially suitable for pipelines with toxic, flammable, explosive and other hazardous media. In flange machining, it is necessary to accurately control the width and height of the tenon surface and the depth and width of the groove surface to ensure the fit between the two, and strictly control the surface roughness (Ra1.6-Ra3.2). Example: In the petrochemical industry, the use rate of tongue and groove face flanges is as high as 60%, and their sealing reliability has been verified under long-term working conditions.

(4) Flat Face

The sealing surface of the flat flange is in the same plane as the flange body, and the structure is the simplest. However, its sealing performance is poor, and it is only suitable for low-pressure, non-toxic, and non-hazardous media scenarios, such as water supply and drainage pipes in civil buildings. In flange machining, it is only necessary to ensure that the flatness and surface roughness of the plane meet the standards, and the process is the least difficult and can usually be completed in a single turning process.

(5) Ring Joint Face (RTJ)

The sealing side of the ring connection face flange is an annular groove for placing the metal ring gasket. Through the bolt fastening force, the metal ring gasket is plastically deformed, and the groove is filled to achieve sealing, and the sealing performance is extremely strong, which is suitable for extreme working conditions such as high temperature (up to 600 °C), high pressure (up to 100 MPa or more), flammable and explosive, etc. At the heart of flange machining is the control of the dimensional accuracy (groove width, groove depth tolerance ≤0.01mm) and surface hardness (generally required HRC28-32) of the annular groove, which requires precision turning or grinding processes. According to industry data, in the high-temperature and high-pressure steam pipelines of the thermal power industry, the sealing pass rate of RTJ flanges has reached more than 99.5%.

4. Precise control: key points of flange size and standard

Dimensional accuracy and standard compliance of flanges are prerequisites for ensuring connection versatility and safety, and are core requirements that must be strictly adhered to in flange machining. Different countries and industries have different flange standards, and they need to be accurately matched during processing.

(1) The importance and consideration of flange size

The size deviation of the flange will directly lead to the failure of the connection: if the position of the bolt hole deviates by more than 0.5mm, the bolt will not be installed smoothly or the force will be uneven; if the diameter of the sealing surface is too large, the gasket will not fit; if the thickness of the flange is insufficient, it will affect the overall compressive strength. In flange machining, the following size factors need to be considered: 1. Nominal diameter (DN): matches the pipe diameter and determines the overall size of the flange; 2. Nominal pressure (PN): determined according to the pressure under working conditions, determine the thickness, number of bolts and specifications of the flange; 3. Sealing surface size: such as protrusion height, groove depth, etc., directly affect the sealing effect; 4. Bolt hole parameters: quantity, hole diameter, center distance, need to ensure that it is completely consistent with the mating flange.

(2) Flange standards and marking interpretation

At present, there are three major systems of global mainstream flange standards, and the dimensional parameters of different standards are different, and flange machining needs to be strictly implemented in accordance with the corresponding standards: 1. National standard (GB): such as GB/T 9112-2010 “Types and parameters of steel pipe flanges”, which is applicable to most domestic industrial fields; 2. American Standard (ASME): such as ASME B16.5, suitable for high-end fields such as petroleum, chemical, aerospace, etc., with higher requirements for dimensional accuracy; 3. European Standard (EN): such as EN 1092-1, which is applicable to Europe and related trade cooperation fields. The markings on the finished flange usually contain the standard code, nominal diameter, nominal pressure, material and other information, such as “GB/T 9119-2010 PN16 DN200 304”, indicating compliance with the national standard GB/T 9119-2010, nominal pressure 16MPa, nominal diameter 200mm, and material of 304 stainless steel. During processing, it is necessary to accurately control the dimensional parameters according to the marking information.

5. From Raw Materials to Finished Products: The Journey of Precision Machining of Flanges

Flange machining is a complex process with multiple processes, and the process control of each link directly affects the quality of the final product. The following is the standard process of flange processing and the core points of each link, combined with actual cases to illustrate the process design ideas.

(1) Material selection

The choice of material is the basis of flange machining, which needs to be perfectly matched to the requirements of the working conditions. Common materials and applicable scenarios: 1. Carbon steel (such as Q235, 20#): suitable for low pressure, room temperature, non-corrosive media, low cost, widely used in civil pipelines; 2. Stainless steel (such as 304, 316L): It has good corrosion resistance and is suitable for chemical, food, and pharmaceutical industries, of which 316L can withstand strong acids and alkalis; 3. Alloy steel (such as 16Mn, Cr5Mo): It has high strength, high temperature and high pressure resistance, and is suitable for extreme working conditions such as thermal power and oil extraction; 4. Non-ferrous metals (such as copper and aluminum): suitable for low temperature and weak current fields, with good processing performance. Case: The hydrochloric acid conveying pipeline flange of a chemical enterprise uses 316L stainless steel material, and the material needs to be spectrally analyzed before processing to ensure that the composition meets the standards and avoid insufficient corrosion resistance.

(2) Material cutting and shaping

The purpose of this link is to cut the raw material into blanks that meet the rough processing requirements. Core process: 1. Cutting method: according to the material size selection, small blank by shearing machine, large blank by plasma cutting or flame cutting; 2. Size control: The size of the cut blank should be 5-10mm larger than the finished product, and the rough processing allowance should be reserved; 3. Surface treatment: After cutting, burrs and scales need to be removed to avoid affecting the subsequent processing accuracy. In flange machining, the key to this process is to ensure the flatness of the blank, if there is warping after cutting, it needs to be leveled. For example, after the 20# carbon steel flange blank is flame cut, it needs to be naturally cooled to room temperature, and then leveled by a leveling machine to prevent deformation due to internal stress release during subsequent processing.

(3) Heat treatment

The core role of heat treatment is to improve the mechanical properties of the material and eliminate internal stresses in processing. Common processes: 1. Normalizing treatment: suitable for carbon steel and alloy steel, which can refine grains and improve material strength and toughness; 2. Quenching and tempering treatment: that is, quenching + high-temperature tempering, suitable for high-strength flanges, which can make the material have good comprehensive mechanical properties; 3. Stress relief annealing: used to eliminate internal stress after cutting and forging, and avoid subsequent processing deformation. Case: A 16Mn alloy steel flange, used in high-temperature and high-pressure steam pipelines, needs to be quenched and tempered during processing, the quenching temperature is 850°C, the tempering temperature is 600°C, and the hardness of the material after treatment reaches HRC22-26, and the strength is increased by more than 30%.

(4) Forming and forging

For medium and high pressure flanges, forging is usually used to form them, which can significantly improve the density and mechanical properties of the material. Forging process: 1. Heating: heating the blank to 1100-1250°C to make the material in a plastic state; 2. Forging: By free forging or die forging, the blank is forged into the approximate shape of the flange; 3. Cooling: Cool slowly after forging to avoid cracks caused by rapid cooling. In flange machining, the key to the forging process is to control the forging temperature and deformation, if the temperature is too high, the material grain will be coarse, and if the temperature is too low, it will increase the difficulty of forging, and even cracks will occur. For example, when forging 304 stainless steel flanges, the heating temperature needs to be controlled at 1150-1200°C, and the deformation amount should be controlled at 30%-50% to ensure the quality of the forgings.

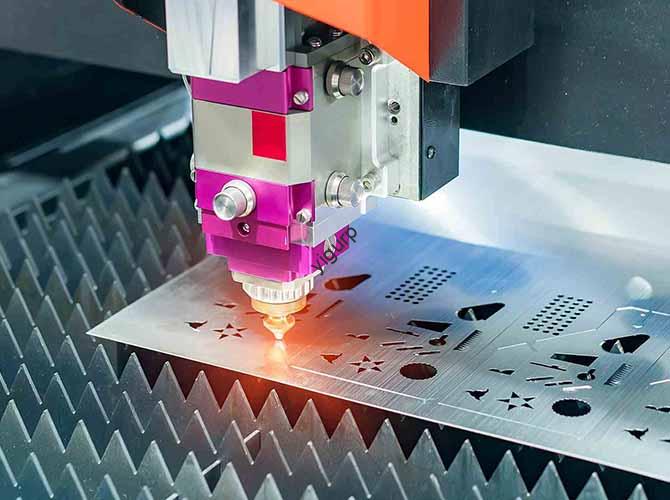

(5) Mechanical processing

This is the core part of flange machining, which processes the forged blanks into finished products that meet the design requirements through turning, milling, drilling and other processes. Core processes: 1. Rough turning: process the end face, outer circle and inner hole of the flange, remove most of the allowance, and control the dimensional tolerance at ±0.5mm; 2. Finishing turning: focus on processing the sealing surface and flange end face to ensure flatness, coaxiality and surface roughness, and the flatness tolerance of the sealing surface is ≤ 0.02mm; 3. Drilling: Processing bolt holes, using drilling machines or CNC machine tools to ensure the position accuracy of bolt holes (center distance tolerance ≤0.1mm) and hole diameter accuracy; 4. Milling: For special-shaped flanges (such as special-shaped flanges), the contour needs to be processed using the milling process. Case: A high-precision flange in the aerospace field is processed by a five-axis CNC machine tool, and PCD tools are used to seal the surface of the fine turning, and the surface roughness reaches Ra0.8, which fully meets the high sealing requirements.

(6) Surface treatment

The purpose of surface treatment is to improve the corrosion resistance, wear resistance and aesthetics of the flange, and different processes are selected according to the material and working conditions: 1. Galvanizing treatment: suitable for carbon steel flanges, which can improve corrosion resistance, divided into hot-dip galvanized and electro-galvanized; 2. Pickling passivation: suitable for stainless steel flanges to remove oxide scale generated during processing and enhance corrosion resistance; 3. Spraying: Suitable for special corrosive working conditions, spraying anti-corrosion coatings (such as PTFRON). In flange machining, surface treatment is carried out after finishing to avoid damaging the sealing surface accuracy during the treatment process. For example, after finishing 304 stainless steel flanges, they are pickled and passivated, and the passivation time is controlled at 20-30 minutes, and the sealing surface forms a dense oxide film after treatment, which significantly improves corrosion resistance.

(7) Testing and quality control

Inspection is the last line of defense for flange machining, ensuring that the finished product meets the design requirements and standards. Core testing items: 1. Dimensional inspection: use calipers, micrometers, projectors, coordinate measuring instruments and other tools to detect the outer diameter, inner diameter, thickness, bolt hole position, sealing surface size, etc. of the flange; 2. Surface quality inspection: observe whether there are scratches, dents, cracks and other defects on the sealing surface through the naked eye or magnifying glass, and use a roughness meter to detect the surface roughness; 3. Mechanical property testing: Conduct tensile, impact, and hardness tests on sampled products to ensure that the mechanical properties meet the standards; 4. Sealing performance testing: Use hydrostatic test or air pressure test to test the sealing reliability of the flange. Case: A high-pressure flange manufacturer conducts coordinate measurement and hydrostatic test on each batch of flanges, the hydrostatic test pressure is 1.5 times the nominal pressure, and the pressure is held for 30 minutes without leakage to ensure that the product quality is qualified.

6. Summary and prospect

This article systematically sorts out the core knowledge related to flange machining, from the basic understanding of flanges to the whole processing process, covering key dimensions such as type, connection surface, size standards, and process points. It can be seen that flange machining is a field with extremely high requirements for precision and process control, and the slightest deviation in each link may lead to connection failure, especially in the high-end industrial field, where the precision of flange processing directly determines the operational safety of the equipment.

7. Yigu Technology’s view

As an enterprise focusing on the field of precision machining, Yigu Technology believes that the core competitiveness of flange machining lies in “precise matching” and “process innovation”. The working conditions of different industries vary greatly, and only by deeply understanding the actual needs of customers, combining material characteristics and standard requirements, and customizing the design and processing process can we produce high-quality flange products. At the same time, the application of intelligent technology is the key to improving the level of flange machining, and we are actively introducing intelligent testing equipment and automated processing production lines to improve production efficiency on the basis of ensuring accuracy and provide more reliable flange processing solutions for global customers.

8. FAQ

What is a flange in machining? In the field of machining, a flange (Flange) is a ring part with bolted holes that enables removable sealed connections between pipes and pipes and pipes and equipment. Flange machining is the process of processing raw materials into finished flanges that meet design requirements through a series of machining processes (such as turning, milling, drilling, etc.).

What is a flange in manufacturing? In the manufacturing industry, flanges are the core components of pipeline systems and equipment connections, and their production and manufacturing cover material selection, cutting, forging, heat treatment, precision machining, testing and other links. The manufacturing quality of flanges directly affects the tightness and safety of connections, and is widely used in various industries such as petrochemical, aerospace, water conservancy and power.

What flanges are machined with a flat face? Flat face flanges are usually used in low-pressure, normal temperature, and non-corrosive working conditions, and the corresponding flange types include flat welded flanges, partially threaded flanges, etc. For example, most of the Q235 carbon steel flat welded flanges used in water supply and drainage pipelines in civil buildings are processed on a flat surface, with relatively simple processing technology and low cost.

What are types of machining? Common types of machining in flange machining include: 1. Turning: machining flange end faces, outer circles, inner holes and sealing surfaces; 2. Milling: machining special-shaped flange contours or special structures; 3. Drilling: machining bolt holes; 4. Grinding: Finishing of high-precision flange sealing surfaces; 5. Forging: blank forming processing of medium and high pressure flanges.