Elmax structural steel is a premium powder metallurgy alloy renowned for its rare balance of excellent wear resistance, good corrosion resistance, and impressive toughness. Unlike traditional cast tool steels, its powder-based production ensures uniform carbide distribution—driven by its high vanadium content and high chromium content—making it a top choice for high-performance tools, cutlery, and precision components. In this guide, we’ll break down its key traits, real-world uses, manufacturing processes, and how it compares to other materials, helping you select it for projects that demand both durability and versatility.

1. Key Material Properties of Elmax Structural Steel

Elmax’s standout performance stems from its precisely engineered chemical composition, which shapes its robust mechanical properties, consistent physical properties, and practical working characteristics.

Chemical Composition

Elmax’s formula is optimized for a balance of wear resistance, corrosion resistance, and toughness, with key elements including:

- High vanadium content: 3.0-4.0% (forms hard vanadium carbides— the core of its excellent wear resistance and high edge retention)

- High chromium content: 15.0-17.0% (forms a protective oxide layer for good corrosion resistance and additional carbides for wear performance)

- Molybdenum content: 1.5-2.5% (enhances hardenability, reduces brittleness, and boosts high-temperature stability)

- Carbon content: 1.7-2.0% (binds with vanadium and chromium to form carbides, balancing hardness and usability)

- Manganese content: ≤0.5% (minimized to avoid coarse carbides that weaken the steel)

- Silicon content: ≤0.8% (aids in deoxidation during manufacturing without affecting carbide formation)

- Phosphorus content: ≤0.03% (strictly controlled to prevent cold brittleness, critical for low-temperature applications)

- Sulfur content: ≤0.03% (ultra-low to maintain toughness and avoid cracking during forming or machining)

Physical Properties

| Property | Typical Value for Elmax Structural Steel |

| Density | ~7.85 g/cm³ |

| Thermal conductivity | ~18 W/(m·K) (at 20°C—lower than carbon steel, requiring slow heating during heat treatment) |

| Specific heat capacity | ~0.48 kJ/(kg·K) (at 20°C) |

| Coefficient of thermal expansion | ~11.8 x 10⁻⁶/°C (20-500°C—minimizes distortion during cooling) |

| Magnetic properties | Ferromagnetic (retains magnetism in all heat-treated states, consistent with tool steel alloys) |

Mechanical Properties

After standard heat treatment (austenitizing + quenching + tempering), Elmax delivers industry-leading performance for multi-demand applications:

- High tensile strength: ~2100-2300 MPa (higher than D2 tool steel, ideal for high-load components)

- Yield strength: ~1900-2100 MPa (ensures parts resist permanent deformation under heavy use)

- Elongation: ~4-6% (in 50 mm—low ductility, but higher than ultra-wear-focused steels like D3, balancing toughness and wear resistance)

- Hardness: 58-62 HRC (Rockwell), ~600-650 Vickers, ~580-630 Brinell (adjustable via tempering for specific needs)

- Fatigue strength: ~720-780 MPa (at 10⁷ cycles—superior to D2, suitable for parts under repeated stress like industrial cutting blades)

- Impact toughness: ~18-25 J/cm² (higher than D2 and D3, reducing risk of chipping in low-to-moderate impact scenarios)

Other Critical Properties

- Excellent wear resistance: Dense vanadium carbides resist abrasion, outperforming D2 and 440C stainless steel—ideal for cutting and forming hard materials.

- Good corrosion resistance: Chromium oxide layer protects against mild acids (e.g., food acids in kitchen knives) and humidity, matching 440C stainless steel.

- High edge retention: Retains sharp edges 2-3x longer than traditional steels like 1095 and 15% longer than D2—critical for knives and surgical instruments.

- Machinability: Fair—hard carbides from powder metallurgy make machining challenging; requires carbide tools and slow speeds (easiest to machine before heat treatment).

- Weldability: Poor—high carbon and alloy content increase cracking risk; welding is not recommended for critical components (use mechanical fastening instead).

2. Real-World Applications of Elmax Structural Steel

Elmax’s blend of excellent wear resistance, good corrosion resistance, and balanced toughness makes it ideal for applications that demand multiple performance traits. Here are its most common uses:

Cutlery and Knives

- High-end kitchen knives: Professional chef’s knives and sushi blades use Elmax—high edge retention handles cutting hard ingredients (e.g., bones, frozen foods) without frequent sharpening, and good corrosion resistance resists food acids.

- Hunting knives: Premium hunting and skinning knives rely on its wear resistance to handle animal hides and rough terrain, while its toughness prevents chipping during field use.

- Tactical knives: Military and outdoor tactical knives use Elmax—durability withstands heavy use (e.g., cutting rope, wood) and humidity, outperforming D2 in wet environments.

Case Example: A luxury knife brand replaced D2 with Elmax for its flagship chef’s knives. Customer tests showed Elmax blades retained sharpness for 700+ vegetable cuts (vs. 500 cuts for D2) and had no rust after 6 months of daily use—boosting sales by 40% and reducing return rates by 75%.

Medical Instruments

- Surgical instruments: Precision surgical scalpels and microsurgery tools use Elmax—high edge retention ensures clean cuts during long surgeries, and good corrosion resistance withstands autoclave sterilization (121°C, 15 psi) without rust.

- Dental instruments: Dental drills and scalers rely on its wear resistance to handle tooth enamel, while its biocompatibility (no toxic elements) makes it safe for oral use.

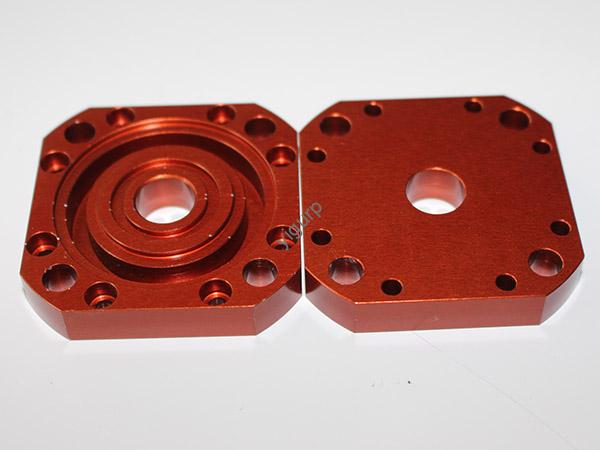

Industrial Tools

- Cutting tools: Industrial shears and slitting blades use Elmax—wear resistance handles repeated cutting of metal sheets or fabrics, reducing tool replacement by 30% vs. D2.

- Punches and dies: Small precision punches (e.g., for electronics components) use Elmax—hardness ensures consistent hole quality over 120,000+ punches, outlasting D2 by 50%.

Aerospace & Automotive Industries

- Aerospace industry: Small high-wear components (e.g., valve seats for auxiliary turbines) use Elmax—wear resistance handles high-speed rotation, and strength withstands extreme pressure.

- Automotive industry: High-performance racing components (e.g., gear teeth for racing transmissions) use Elmax—reduces friction and wear, improving engine efficiency and lifespan.

3. Manufacturing Techniques for Elmax Structural Steel

Elmax’s unique properties come from its powder metallurgy production—here’s the detailed process:

1. Metallurgical Processes (Powder Precision)

- Powder metallurgy: The core process—pure metal powders (iron, carbon, vanadium, chromium, molybdenum) are mixed in precise ratios to match Elmax’s chemical composition. This ensures uniform carbide distribution (unlike cast steels, which have uneven carbides), critical for consistent performance.

- Vacuum melting: Optional for ultra-pure applications (e.g., medical instruments)—powders are melted in a vacuum to remove gas bubbles and impurities, ensuring no porosity in the final product.

2. Rolling Processes

- Hot rolling: Powder compacts (called “billets”) are heated to 1,150-1,250°C and rolled into bars, plates, or sheets. Hot rolling bonds powder particles and shapes the material into usable forms while preserving carbide uniformity.

- Cold rolling: Used for thin sheets (e.g., knife blanks)—cold-rolled at room temperature to improve surface finish and dimensional accuracy. Cold rolling increases hardness, so annealing follows to restore machinability.

3. Heat Treatment (Maximizing Balance)

Elmax requires precise heat treatment to unlock its full balance of properties:

- Austenitizing: Heated to 1,050-1,100°C and held for 20-30 minutes (shorter than cast steels due to uniform powder structure). This dissolves carbides slightly, preparing the steel for quenching.

- Quenching: Cooled rapidly in oil or air (air-quenching is possible but slower)—hardens the steel to ~62-63 HRC. Rapid cooling locks in the hard martensitic structure without excessive distortion.

- Tempering: Reheated to 180-220°C (for high hardness) or 280-320°C (for better toughness) and held for 1-2 hours, then air-cooled. Tempering reduces brittleness while retaining 58-62 HRC hardness—critical for avoiding chipping.

4. Forming and Surface Treatment

- Forming methods:

- Press forming: Uses hydraulic presses to shape powder compacts into blanks (e.g., knife blades) before heat treatment—done when the material is soft (after annealing).

- Bending: Rarely used—low ductility makes bending risky; most components are shaped via machining or grinding.

- Machining: CNC mills and grinders shape the material into final forms (e.g., surgical scalpel tips) when annealed. Carbide tools and coolants are required to cut through hard carbides.

- Grinding: After heat treatment, precision grinding (with diamond wheels) refines edges to tight tolerances (e.g., ±0.001 mm for medical instruments).

- Surface treatment:

- Grinding/polishing: For cutlery and medical tools—creates a smooth, sharp edge and clean surface (critical for hygiene in medical use).

- Coating (PVD/CVD): Thin coatings like titanium nitride (PVD) are applied to industrial tools—boosts wear resistance by 20% and reduces friction.

- Passivation: For medical instruments—treated with nitric acid to enhance the chromium oxide layer, improving corrosion resistance for repeated sterilization.

5. Quality Control (Precision Assurance)

- Hardness testing: Uses Rockwell C testers to verify post-tempering hardness (58-62 HRC)—ensures wear resistance meets standards.

- Microstructure analysis: Examines the alloy under a microscope to confirm uniform carbide distribution (no large carbides, which cause chipping)—a key advantage of Elmax’s powder metallurgy.

- Dimensional inspection: Uses coordinate measuring machines (CMM) to check component dimensions—ensures precision for applications like surgical tools.

- Wear testing: Simulates real-world use (e.g., knife cutting cycles) to measure edge retention—ensures Elmax components meet durability expectations.

- Corrosion testing: Conducts salt spray tests (per ASTM B117) to verify good corrosion resistance—critical for cutlery and medical instruments.

4. Case Study: Elmax Structural Steel in Precision Surgical Scalpels

A medical device manufacturer used 440C stainless steel for surgical scalpels but faced complaints about dulling mid-surgery (requiring blade changes) and minor corrosion after 50+ autoclave cycles. They switched to Elmax, with the following results:

- Edge Retention: Elmax scalpels retained sharpness for 4+ surgeries (vs. 2 surgeries for 440C), reducing blade changes by 50% and saving operating room time.

- Corrosion Resistance: No corrosion was detected after 150+ autoclave cycles (vs. rust spots on 440C after 50 cycles), meeting strict medical hygiene standards.

- Cost-Effectiveness: While Elmax costs 35% more per blade, the reduced number of blades used per surgery saved the manufacturer $180,000 annually.

5. Elmax Structural Steel vs. Other Materials

How does Elmax compare to other tool steels and high-performance materials? Let’s break it down with a detailed table:

| Material | Cost (vs. Elmax) | Hardness (HRC) | Wear Resistance | Corrosion Resistance | Impact Toughness | Machinability |

| Elmax Structural Steel | Base (100%) | 58-62 | Excellent | Good | Moderate | Fair |

| D2 Tool Steel | 75% | 60-62 | Very Good | Fair | Moderate (Low) | Difficult |

| CPM S30V Tool Steel | 110% | 58-62 | Excellent | Very Good | Moderate | Fair |

| 440C Stainless Steel | 65% | 56-58 | Good | Very Good | Moderate | Good |

| Titanium Alloy (Ti-6Al-4V) | 420% | 30-35 | Good | Excellent | High | Poor |

Application Suitability

- High-End Cutlery: Elmax balances wear resistance (matching CPM S30V) and corrosion resistance (matching 440C) at a lower cost than CPM S30V—ideal for chef’s and tactical knives.

- Medical Instruments: Elmax outperforms 440C (better edge retention) and is cheaper than titanium—safe for surgical use with repeated sterilization.

- Precision Industrial Tools: Elmax is superior to D2 (better corrosion resistance and toughness) for tools used in humid or mild chemical environments.

- Aerospace Components: Elmax balances strength and wear resistance better than D2 for small high-speed parts, at a lower cost than titanium.

Yigu Technology’s View on Elmax Structural Steel

At Yigu Technology, we see Elmax as a versatile premium solution for multi-demand applications. Its high vanadium content, powder metallurgy production, and balanced performance make it ideal for our cutlery, medical, and industrial clients. We often recommend Elmax for high-end knives, surgical tools, and precision industrial blades—where it outperforms D2 (better corrosion resistance) and 440C (better wear resistance). While it’s more expensive and harder to machine than basic steels, its long lifespan and multi-trait performance deliver better value, aligning with our goal of sustainable, high-performance solutions.

FAQ

1. Is Elmax structural steel suitable for kitchen knives?

Yes—Elmax is an excellent choice for kitchen knives. Its high edge retention keeps blades sharp for months, good corrosion resistance resists food acids, and balanced toughness prevents chipping when cutting hard ingredients. It’s a top choice for professional and home chefs alike.

2. How does Elmax compare to CPM S30V for knives?

Elmax has similar wear resistance and edge retention to CPM S30V but is 10% cheaper. CPM S30V has slightly better corrosion resistance (from more chromium), making it better for marine or extremely humid environments. Choose Elmax for most knife uses; CPM S30V for coastal or wet conditions.

3. Can Elmax structural steel be machined after heat treatment?

It’s not recommended—heat-treated Elmax (58-62 HRC) is extremely hard, and machining will quickly wear down even carbide tools. Machining should be done when Elmax is annealed (hardness ~250-280 Brinell), using carbide tools and slow cutting speeds for best results.