If you work in product development or manufacturing, understanding how prototype parts differ from machined parts is key to avoiding costly mistakes. These two manufacturing outputs serve entirely distinct stages of production—one focuses on testing ideas, while the other delivers consistent, production-ready components. Below, we break down their differences with clear data, examples, and actionable insights to help you choose the right option for your project.

1. Core Production Goal: Testing Ideas vs. Mass Supply

The biggest divide between prototype parts and machined parts lies in their purpose. Prototype parts are built to validate designs, while machined parts are made to meet industrial production needs.

| Aspect | Prototype Parts | Machined Parts |

| Primary Objective | Verify design feasibility; fix flaws early | Produce consistent parts for assembly or sale |

| Target Stage | Product development (pre-production) | Mass production (post-design finalization) |

| End-User | Design teams, investors, testing departments | Manufacturers, assembly lines, end customers |

| Typical Output | 1–10 pieces per design (small, iterative batches) | 100–10,000+ pieces per order (large, uniform runs) |

For instance, if you’re developing a new laptop hinge, you’d first create 3–5 prototype parts to check if the hinge opens smoothly and holds the screen securely. Once the design works, you’d make 5,000 machined parts to install in production laptops.

2. Manufacturing Technologies: Flexibility vs. Precision

Prototype parts use diverse, fast methods to test designs, while machined parts rely on specialized techniques for consistent quality.

Prototype Part Technologies (Fast, Adaptable)

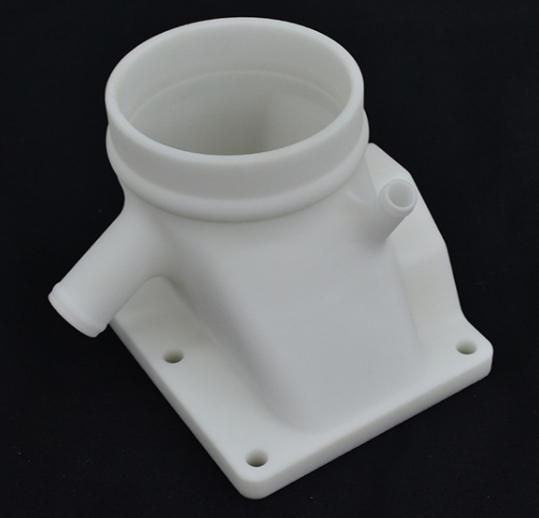

- 3D Printing: Turns digital designs into physical parts in 4–24 hours; ideal for complex shapes (e.g., custom smartphone cases).

- CNC Machining: Uses computer-controlled tools to carve parts from solid materials; great for testing strength (e.g., metal brackets).

- Handcrafting: Manual work with tools like drills or sanders; perfect for quick tweaks (e.g., adjusting the size of a plastic prototype).

- Key benefit: These methods let you modify designs in days—no need for expensive setup changes. For example, a 3D printed prototype can be revised and reprinted in under 12 hours.

Machined Part Technologies (Precise, Scalable)

- Turning: Spins materials while cutting tools shape them; used for cylindrical parts (e.g., bolts, pipes).

- Milling: Uses rotating cutters to remove material from a workpiece; makes flat or complex 3D shapes (e.g., laptop chassis).

- Grinding: Uses abrasive wheels to smooth surfaces; ensures ultra-tight tolerances (e.g., medical device components).

- Key benefit: These techniques achieve precision within ±0.001 inches—critical for parts that need to fit together perfectly (like engine components). Over 70% of industrial machined parts use turning or milling for consistency.

3. Key Characteristics: Uniqueness vs. Consistency

Prototype parts are designed to be one-of-a-kind for testing, while machined parts must meet strict, uniform standards for mass production.

Prototype Part Characteristics

- Diversity: Each prototype can be different. For example, you might make one plastic prototype and one metal prototype of a tool handle to test weight and grip.

- Iterativity: They’re meant to be modified. 85% of product teams revise prototypes 2–4 times to fix issues like poor fit or weak spots.

- Non-Production Focus: They don’t need to meet long-term durability standards. A prototype of a water bottle might only be tested for shape—no need to check if it resists cracking after 100 uses.

Machined Part Characteristics

- Precision: Every part must match exact specs. A batch of machined bolts, for example, must all have the same thread size (e.g., M8 x 1.25mm) to fit into nuts.

- Consistency: 99% of machined parts in a batch are identical. This is vital for assembly lines—if one part is too big, it can stop production.

- Production Readiness: They’re built to last. Machined parts for cars, for instance, must withstand heat, vibration, and wear for years.

4. Cost Comparison: Short-Term Investment vs. Long-Term Value

Costs differ because prototype parts prioritize speed over scale, while machined parts leverage volume to lower per-unit costs.

Cost Breakdown (for 50 Pieces of a Small Metal Part)

| Cost Type | Prototype Parts (3D Printed + CNC) | Machined Parts (Milling + Turning) |

| Setup Cost | \(100–\)300 (no specialized tooling) | \(500–\)1,200 (tooling and programming) |

| Per-Piece Cost | \(15–\)40 | \(3–\)8 |

| Total Cost for 50pcs | \(750–\)2,000 + \(100–\)300 = \(850–\)2,300 | \(150–\)400 + \(500–\)1,200 = \(650–\)1,600 |

- When prototypes are cheaper: For 1–20 pieces. If you need 10 parts, prototypes cost \(150–\)400 total—far less than machined parts (\(500–\)1,200 setup + \(30–\)80 parts).

- When machined parts are cheaper: For 100+ pieces. For 200 parts, machined parts cost \(600–\)1,600 + \(500–\)1,200 = \(1,100–\)2,800, while prototypes cost \(3,000–\)8,000.

Yigu Technology’s Perspective

At Yigu Technology, we view prototype parts as the “design safety net” and machined parts as the “production backbone.” For prototypes, we use 3D printing and CNC machining to deliver iterations in 3–5 days, helping clients catch flaws early (like a poorly fitting gear) before investing in tooling. For machined parts, our precision turning and milling processes ensure 99.5% consistency—critical for clients in automotive and electronics. By combining these two, we help teams move from idea to mass production faster and more affordably.

FAQ

- Can machined parts be used as prototypes?

Yes, but it’s costly. Machined parts require tooling, so making 1–5 as prototypes would cost \(500–\)1,200 in setup fees—far more than 3D printed prototypes (\(100–\)300). Save machined parts for after design finalization.

- How do I know if I need a prototype or a machined part?

If you’re still testing design changes (e.g., adjusting a part’s size), use a prototype. If your design is fixed and you need 50+ identical parts for production, use a machined part.

- Are prototype parts less durable than machined parts?

Not always, but they’re not built for long-term use. A CNC machined prototype can be as durable as a production machined part, but a 3D printed prototype (made of PLA plastic) may break easily—choose prototype materials based on your test needs.