In modern manufacturing, why do industries like automotive and electronics rely on CNC sheet metal stamping instead of traditional manual stamping? The answer lies in its ability to solve critical pain points—such as low accuracy, slow batch switching, and high scrap rates—that plague conventional methods. This article breaks down its core processing methods, key advantages, real-world applications, development trends, and practical tips, helping you leverage this technology to boost production efficiency and part quality.

What Is CNC Sheet Metal Stamping?

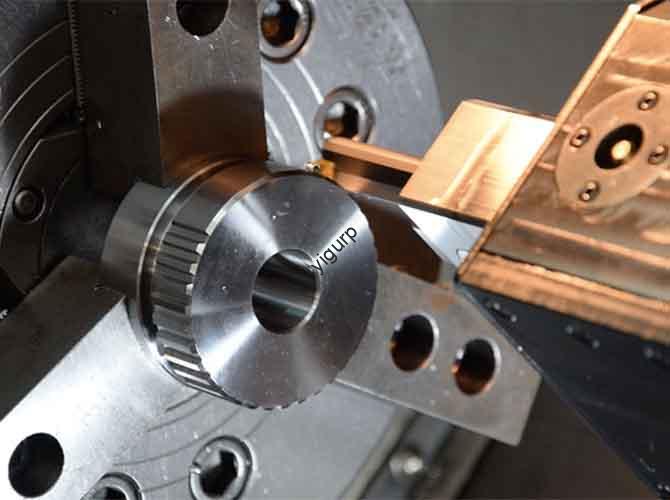

CNC Sheet Metal Stamping is an automated manufacturing process that uses Computer Numerical Control (CNC) systems to punch, form, and shape thin metal sheets (typically 0.1–6mm thick) into custom parts. Unlike manual stamping—where operators adjust molds and pressure manually—CNC systems follow pre-programmed code to control every step, ensuring consistent precision (up to ±0.1mm) across high-volume or small-batch production.

Think of it as a “digital metal craftsman”: it transforms flat metal sheets into complex components (e.g., car body panels, electronic device housings) with minimal human intervention, balancing speed, accuracy, and flexibility.

Core Processing Methods of CNC Sheet Metal Stamping

CNC sheet metal stamping offers 7 specialized methods to handle diverse part shapes and requirements. The table below details each method, its workflow, and ideal use cases—helping you select the right approach for your project:

| Processing Method | Workflow Description | Key Advantages | Ideal Applications |

|---|---|---|---|

| Single-Time Punching | Completes all punching tasks (e.g., holes) in one operation; supports circumferential, arc, straight-line, or grid hole patterns. | Fast (1–2 seconds per part); minimal setup time for simple hole patterns. | – Electronic enclosures (grid ventilation holes)- Metal brackets (mounting holes) |

| Multi-Directional Continuous Punching | Uses small molds to machine large holes by punching in multiple directions sequentially. | Eliminates the need for large, expensive molds; reduces tooling costs by 40%. | – Industrial machine panels (large access holes)- HVAC ductwork (circular airflow holes) |

| Single Molding | Shapes metal into shallow or deep forms (e.g., cups, trays) using a single mold that matches the final part shape. | High forming consistency; no need for multiple mold passes. | – Automotive interior parts (cup holders)- Kitchenware (stainless steel trays) |

| Same-Direction Continuous Punching | Uses partially overlapping rectangular molds to cut edges, long holes, or slots by moving the mold in one direction. | Creates long, uniform features (e.g., 1m+ slots) without mold size limits. | – Metal shelving (long adjustment slots)- Server racks (ventilation slits) |

| Ennibalization (Arc Punching) | Uses a small circular die to punch arcs in tiny steps, forming large curved shapes. | Precise arc control (radius tolerance ±0.2mm); ideal for irregular curves. | – Aerospace components (curved brackets)- Furniture frames (rounded edges) |

| Array Forming | Processes multiple identical or different workpieces on a single large metal sheet using arrayed mold positions. | Boosts productivity by 50% vs. single-part processing; reduces material waste. | – Electronic components (batch-produced sensor housings)- Hardware (multiple small fastener plates) |

| Continuous Forming | Creates features larger than the mold (e.g., rolling steps, large blinds) by moving the sheet past the mold repeatedly. | Handles oversized parts without custom large molds; flexible for variable sizes. | – Construction materials (metal roof panels with rolling steps)- Automotive body panels (large blind holes) |

Key Process Characteristics: CNC vs. Traditional Sheet Metal Stamping

To understand why CNC is a game-changer, compare its strengths to traditional manual stamping with this table:

| Aspect | CNC Sheet Metal Stamping | Traditional Manual Stamping |

|---|---|---|

| Automation Level | High—fully automated punching/forming; 1 operator manages 2–3 machines. | Low—requires manual mold adjustment and pressure control; 1 operator per machine. |

| Processing Accuracy | Stable (punching accuracy ±0.1mm); small burrs (<0.05mm); high workpiece flatness. | Variable (accuracy ±0.5mm); large burrs; frequent flatness issues. |

| Production Preparation Time | Short—switching parts only needs CNC program updates (10–30 minutes). | Long—requires mold disassembly/assembly (2–4 hours per part change). |

| Scrap Rate | Low (<2%)—precise control reduces material waste. | High (8–12%)—human error and mold misalignment cause defective parts. |

| Operator Skill Requirement | Moderate—needs basic CNC programming knowledge; no advanced manual skills. | High—depends on operator’s experience for mold setup and quality control. |

Real-World Applications: Solving Industry Challenges

CNC sheet metal stamping addresses unique pain points across key industries. Here are 4 practical case studies:

1. Automotive Industry: Body Panel Production

- Problem: A car manufacturer needed 10,000 aluminum door panels monthly—traditional stamping required 3 custom molds ($50k each) and 4 hours to switch batches.

- Solution: Used CNC same-direction continuous punching for edge trimming and array forming for mounting holes. Program updates took 20 minutes, and no new molds were needed.

- Result: Batch switching time cut by 92%; mold costs eliminated; scrap rate dropped from 10% to 1.5%.

2. Electronics Industry: Precision Enclosures

- Problem: A smartphone maker needed small, complex sensor housings (0.5mm thick stainless steel) with 10+ tiny holes—manual stamping couldn’t achieve consistent hole positioning.

- Solution: Applied CNC single-time punching with a micro-die (0.3mm diameter). The CNC system’s ±0.05mm positioning accuracy ensured hole alignment.

- Outcome: 99.8% of housings met quality standards; production time per unit fell from 2 minutes to 30 seconds.

3. HVAC Industry: Ductwork Components

- Problem: An HVAC firm needed large, curved ductwork covers (1.2m long) — traditional stamping required a $100k custom mold, unfeasible for small batches (50 units).

- Solution: Used CNC ennibalization for curved edges and continuous forming for rolling steps. Small dies ($5k total) handled the large part.

- Impact: Mold costs reduced by 95%; batch production time cut from 1 week to 2 days.

4. Medical Device Industry: Stainless Steel Trays

- Problem: A medical supplier needed sterile stainless steel instrument trays with deep, smooth forming—traditional stamping caused surface scratches and uneven depth.

- Solution: Implemented CNC single molding with a polished die and real-time pressure control. The process ensured scratch-free surfaces and uniform depth (±0.1mm).

- Result: Trays met medical sterilization standards; no post-processing (e.g., sanding) was needed—saving 2 hours per batch.

Development Trends of CNC Sheet Metal Stamping

The technology is evolving to meet demands for faster, smarter, and more flexible manufacturing. Here are 4 key trends:

- High-Speed, High-Finish Equipment

- Manufacturers are developing CNC stamping machines with punching speeds up to 1,200 hits per minute (vs. 600 hits for older models) and polished dies that reduce workpiece burrs to <0.03mm. This cuts production time by 30% while improving surface quality.

- 5-Axis Parallel & Compound Machining

- 5-axis CNC stamping machines add rotational axes to handle complex 3D shapes (e.g., curved aerospace components) that were once impossible. Compound machines integrate punching, cutting, and bending in one setup—eliminating workpiece repositioning and reducing errors.

- Intelligent, Open, Networked CNC Systems

- Modern CNC systems use AI to monitor real-time data (e.g., punch force, die temperature) and auto-adjust parameters to prevent defects. They also support network integration—allowing remote monitoring, program sharing, and factory-wide production scheduling (Industry 4.0 compliance).

- New Technical Standards & Specifications

- Industry bodies (e.g., ISO, ASTM) are updating standards for CNC sheet metal stamping—covering material compatibility, accuracy metrics, and safety protocols. This ensures consistent quality across suppliers and reduces market confusion.

Yigu Technology’s Perspective

At Yigu Technology, we see CNC sheet metal stamping as a cornerstone of efficient manufacturing. Our CNC stamping machines integrate smart features: AI-driven real-time defect detection (reduces scrap rate by 15%), high-speed punch heads (1,000 hits/min), and open CNC systems that sync with factory MES software. We’ve helped automotive clients cut production time by 40% and electronics firms reduce setup time for small batches to 10 minutes. As trends like 5-axis machining grow, we’ll keep optimizing hardware/software to make CNC stamping more accessible—empowering manufacturers to handle complex parts with ease.

FAQ

- Q: What types of sheet metal materials are suitable for CNC stamping?A: Most thin metals work, including cold-rolled steel (1–6mm thick), aluminum alloys (0.5–4mm), stainless steel (0.3–5mm), and copper (0.2–3mm). For high-strength parts (e.g., automotive), use galvanized steel; for lightweight parts (e.g., electronics), choose aluminum alloy 6061.

- Q: What’s the maximum part size CNC sheet metal stamping can handle?A: Standard machines handle sheets up to 1,500mm×3,000mm. For larger parts (e.g., 2m×4m construction panels), custom CNC stamping lines with extended worktables are available—these use continuous feeding to process oversized sheets.

- Q: How long does it take to switch from one part design to another?A: It depends on complexity—simple parts (e.g., basic brackets) only need CNC program updates (10–30 minutes). Complex parts (e.g., 3D curved components) may require die changes, but modern quick-change die systems reduce this to 1–2 hours (vs. 4–6 hours for traditional setups).