If you’re searching for reliable CNC machining services or looking to partner with manufacturers in Europe, Slovakia stands out as a top choice. With its strategic location in Central Europe, skilled workforce, competitive costs, and strong industrial heritage, Slovakia has become a hub for high-precision CNC machining—serving industries like automotive, aerospace, medical devices, and electronics. Whether you need prototype development, small-batch production, or large-scale manufacturing, Slovakia’s CNC machining sector offers the technical expertise and infrastructure to meet strict quality standards, such as ISO 9001 and IATF 16949.

Why Choose CNC Machining in Slovakia? Key Advantages for Businesses

Slovakia’s CNC machining industry isn’t just growing—it’s thriving, thanks to a unique combination of factors that solve common pain points for global buyers, like long lead times, high costs, or inconsistent quality. Here’s why it’s a smart choice:

Strategic Geographical Location

Slovakia sits at the crossroads of Central Europe, bordering Germany, Austria, Hungary, Poland, and the Czech Republic. This proximity to major European markets (like Germany’s automotive industry) means faster shipping times and lower logistics costs. For example, a CNC part manufactured in Bratislava (Slovakia’s capital) can reach Munich (Germany) in just 4 hours by truck, cutting delivery times by 30–50% compared to suppliers in Eastern Europe or Asia. This is critical for industries like automotive, where just-in-time (JIT) production is essential.

Skilled Workforce and Technical Expertise

Slovakia has a long history of engineering excellence, dating back to its days as part of the Austro-Hungarian Empire’s industrial heartland. Today, the country invests heavily in technical education—with vocational schools and universities (like the Slovak University of Technology in Bratislava) offering specialized programs in CNC programming, mechanical engineering, and precision manufacturing. According to the Slovak Automotive Industry Association (ZAP) , over 60% of CNC machinists in Slovakia have at least 5 years of experience, and 40% hold advanced certifications in CAD/CAM software (e.g., SolidWorks, Mastercam) or CNC machine operation (e.g., Haas, DMG MORI).

A real-world example: A German aerospace supplier recently partnered with a Slovak CNC shop to produce complex turbine components. The Slovak team’s expertise in 5-axis machining and ability to work with titanium alloys helped reduce production errors by 25% compared to their previous supplier in Eastern Europe.

Competitive Costs Without Sacrificing Quality

While Western European countries (like Germany or Switzerland) offer top-tier CNC machining, their costs can be 20–35% higher than Slovakia’s. Slovakia’s lower labor and operational costs (combined with access to affordable raw materials from neighboring countries) mean businesses can get high-precision parts at a more budget-friendly price. For instance, a custom aluminum CNC part with tight tolerances (±0.005 mm) might cost €15–€20 in Slovakia, compared to €22–€28 in Germany—without compromising on quality (as most Slovak shops adhere to ISO 9001 and IATF 16949 standards).

Strong Industrial Ecosystem

Slovakia’s manufacturing sector is well-integrated, with a network of CNC shops, raw material suppliers, and quality testing labs. This means businesses don’t have to source components from multiple countries—they can find everything they need locally. For example, if you need a CNC-machined plastic part, you can work with a Slovak shop that partners with local polymer suppliers (like Slovnaft) and uses in-house CMM (Coordinate Measuring Machine) testing to ensure accuracy. This reduces supply chain complexity and minimizes delays.

How to Select the Right CNC Machining Partner in Slovakia

Choosing the right CNC machining supplier is critical to your project’s success. With so many options available, it’s important to focus on factors that align with your specific needs—whether you’re producing automotive parts, medical devices, or aerospace components. Here’s a step-by-step guide:

1. Define Your Project Requirements Clearly

Before reaching out to suppliers, outline key details like:

- Material (e.g., aluminum, steel, titanium, plastic)

- Machining processes needed (e.g., 3-axis, 5-axis, milling, turning)

- Tolerances (e.g., ±0.001 mm for precision parts)

- Production volume (prototype, small batch <100 units, large batch >1,000 units)

- Quality standards (e.g., ISO 9001, IATF 16949, AS9100 for aerospace)

- Lead time (e.g., 2 weeks for prototypes, 6 weeks for large batches)

For example, if you’re developing a medical device component, you’ll need a supplier with ISO 13485 certification (for medical devices) and experience machining biocompatible materials like stainless steel 316L.

2. Verify Certifications and Quality Control Processes

Reputable Slovak CNC shops will hold industry-specific certifications to prove their commitment to quality. Look for:

- ISO 9001: General quality management (required for most industries)

- IATF 16949: Specific to automotive manufacturing (critical for parts like engine components)

- AS9100: For aerospace parts (e.g., turbine blades, aircraft brackets)

- ISO 13485: For medical devices (e.g., surgical instruments, implant components)

Additionally, ask about their quality control (QC) processes. Do they use CMMs for dimensional testing? Do they perform 100% inspection on critical parts, or statistical sampling? A good example is Slovak CNC Solutions (a leading shop in Košice), which uses automated CMMs to check every part before shipping and provides a detailed QC report to clients—giving them peace of mind about accuracy.

3. Evaluate Experience and Specializations

Not all CNC shops are the same—some specialize in specific industries or processes. For instance:

- A shop focused on automotive may excel at high-volume production of simple parts (e.g., bolts, brackets) using 3-axis machines.

- A shop focused on aerospace may specialize in low-volume, complex parts (e.g., 5-axis machined turbine housings) using advanced materials like Inconel.

Ask for case studies or references from clients in your industry. For example, if you’re in the electronics sector, a shop that has worked with companies like Samsung or Siemens (which have operations in Slovakia) will understand your need for miniaturized parts with tight tolerances.

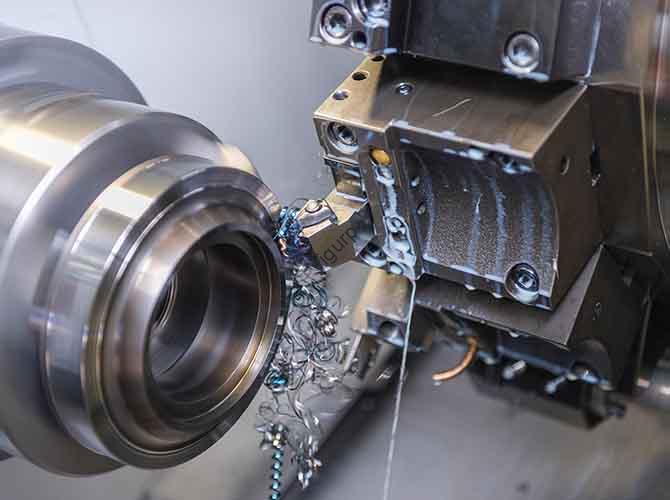

4. Assess Technology and Equipment

The quality of a CNC shop’s equipment directly impacts the quality of your parts. Look for shops that invest in modern machinery, such as:

- 5-axis CNC mills (for complex, 3D-shaped parts)

- CNC lathes with live tooling (for turning and milling in one setup)

- CAD/CAM software (e.g., Mastercam, Fusion 360) for precise programming

- Automation tools (e.g., robotic loaders) for high-volume production

A shop with outdated equipment may struggle to meet tight tolerances or fast lead times. For example, a shop using a 10-year-old 3-axis mill may not be able to produce a part with a ±0.002 mm tolerance, whereas a shop with a new DMG MORI 5-axis mill can handle it easily.

5. Compare Costs and Lead Times

While cost shouldn’t be the only factor, it’s important to get detailed quotes from 2–3 suppliers. Make sure quotes include:

- Material costs

- Machining labor costs

- Setup fees (for prototypes or small batches)

- Quality testing fees

- Shipping costs (if applicable)

Also, confirm lead times upfront. Most Slovak shops can deliver prototypes in 1–2 weeks and large batches in 4–6 weeks, but this can vary based on complexity. For example, a 5-axis machined part with a complex geometry may take 3 weeks to produce, while a simple turned part can be ready in 5 days.

Key Industries Served by Slovakia’s CNC Machining Sector

Slovakia’s CNC machining industry caters to a wide range of sectors, thanks to its versatility and technical expertise. Here are the top industries that rely on Slovak CNC services, along with examples of parts produced:

Automotive Industry

The automotive sector is Slovakia’s largest industrial employer, with major manufacturers like Volkswagen, Peugeot, and Kia operating factories in the country. CNC machining plays a critical role in producing parts like:

- Engine components (e.g., cylinder heads, crankshafts)

- Transmission parts (e.g., gears, shafts)

- Chassis components (e.g., brackets, control arms)

According to ZAP , over 70% of CNC machining revenue in Slovakia comes from the automotive industry. A notable example is Continental Slovakia , a supplier of automotive electronics, which partners with local CNC shops to produce precision sensor housings—requiring tolerances of ±0.003 mm to ensure accurate data collection.

Aerospace and Defense

Slovakia’s aerospace sector is growing rapidly, with companies like UTC Aerospace Systems (now Collins Aerospace) having a presence in the country. CNC shops in this sector produce high-strength, lightweight parts like:

- Turbine blades (using titanium or Inconel)

- Aircraft brackets (using aluminum alloy 7075)

- Avionics enclosures (using magnesium for weight reduction)

These parts require strict adherence to AS9100 standards and often involve 5-axis machining. For example, a Slovak shop in Žilina recently produced 500 turbine blades for a European aircraft manufacturer, using 5-axis mills to achieve the complex airfoil shape and CMM testing to ensure compliance with aerospace regulations.

Medical Devices

The medical device industry demands precision and biocompatibility, and Slovak CNC shops meet these needs with ISO 13485 certification. Common parts produced include:

- Surgical instruments (e.g., scalpel handles, forceps)

- Implant components (e.g., hip implant stems, dental abutments)

- Diagnostic device parts (e.g., MRI machine brackets)

A case study: A Slovak CNC shop in Bratislava partnered with a German medical device company to produce custom dental abutments. Using 5-axis machining and biocompatible titanium, the shop delivered 1,000 abutments with a tolerance of ±0.002 mm—meeting the strict requirements for dental implants.

Electronics and Telecommunications

With the rise of 5G and IoT devices, the electronics sector needs miniaturized, high-precision CNC parts. Slovak shops produce:

- Circuit board housings (using plastic or aluminum)

- Connector components (using brass or copper)

- Heat sinks (using aluminum for thermal conductivity)

For example, a Slovak shop in Banská Bystrica supplies CNC-machined heat sinks to a European 5G equipment manufacturer. The heat sinks, which require precise fin spacing to maximize cooling, are produced using 3-axis mills and undergo 100% inspection to ensure consistency.

Latest Trends Shaping Slovakia’s CNC Machining Industry

Like the global CNC sector, Slovakia’s industry is evolving to keep up with technological advancements and changing market demands. Here are the key trends to watch:

1. Automation and Industry 4.0 Integration

Slovak CNC shops are increasingly adopting automation to improve efficiency and reduce errors. This includes:

- Robotic loaders: These load and unload parts from CNC machines, allowing 24/7 operation without human intervention. For example, a shop in Nitra installed robotic loaders on 10 of its CNC lathes, increasing production capacity by 40% and reducing labor costs by 25%.

- IoT-connected machines: CNC machines equipped with sensors collect real-time data on performance (e.g., spindle speed, tool wear). This data is analyzed to predict maintenance needs and optimize production. A survey by the Slovak Chamber of Commerce found that 60% of mid-sized CNC shops in Slovakia now use IoT-connected machines.

- Digital twins: Some advanced shops use digital twins (virtual replicas of CNC machines) to test machining programs before running them on physical equipment. This reduces setup time and minimizes material waste.

2. 5-Axis Machining for Complex Parts

While 3-axis machining is still common for simple parts, 5-axis machining is becoming the standard for complex components (e.g., aerospace turbine blades, medical implants). 5-axis machines can move a part in five different directions, allowing for the production of intricate geometries in a single setup—reducing lead time and improving accuracy. According to industry data, the number of 5-axis CNC machines in Slovakia has increased by 35% in the past 5 years, as shops look to meet the demands of high-tech industries.

3. Sustainable and Eco-Friendly Practices

As global demand for sustainability grows, Slovak CNC shops are adopting eco-friendly measures:

- Waste reduction: Shops are using software to optimize cutting paths, reducing material waste by 15–20%. For example, a shop in Trnava uses Mastercam’s “OptiRough” toolpath to minimize chip production when machining aluminum.

- Energy efficiency: Newer CNC machines are designed to use less energy. A modern 5-axis mill uses 30% less electricity than a machine built 10 years ago.

- Recycled materials: Many shops now offer machining services using recycled metals (e.g., recycled aluminum, steel) to reduce their carbon footprint. Some even partner with local recycling facilities to source materials.

4. Customization and Low-Volume Production

With the rise of on-demand manufacturing, Slovak CNC shops are focusing on customization and low-volume production. This is especially important for startups and small businesses that need prototypes or small batches of parts. For example, a Slovak shop in Prešov offers “rapid CNC machining” services, delivering custom prototypes in as little as 3 days—helping startups bring their products to market faster.

Cost Breakdown: What to Expect When Outsourcing CNC Machining to Slovakia

Understanding the cost structure of CNC machining in Slovakia helps you budget effectively and avoid unexpected expenses. Below is a typical cost breakdown for common projects, based on data from Slovak CNC shops and industry reports:

| Project Type | Material | Machining Process | Volume | Average Cost per Unit | Lead Time | Key Cost Drivers |

| Prototype (simple part) | Aluminum 6061 | 3-axis milling | 1–5 units | €8–€15 | 1–2 weeks | Setup fees, small volume |

| Small-batch (automotive) | Steel 1018 | CNC turning | 50–100 units | €5–€8 | 2–3 weeks | Labor, material cost |

| Large-batch (electronics) | Plastic (ABS) | 3-axis milling | 1,000+ units | €1.50–€3.00 | 4–6 weeks | Automation (robotic loaders), volume discounts |

| Complex part (aerospace) | Titanium Ti-6Al-4V | 5-axis milling | 20–50 units | €50–€80 | 3–4 weeks | Advanced material, 5-axis setup, quality testing |

Factors That Affect Cost

- Material Choice: Titanium and Inconel are more expensive than aluminum or steel. For example, titanium costs €8–€12 per kg, while aluminum costs €2–€3 per kg.

- Part Complexity: 5-axis machining costs more than 3-axis because it requires more advanced equipment and programming. A complex 5-axis part can cost 2–3 times more than a simple 3-axis part.

- Tolerances: Tighter tolerances (e.g., ±0.001 mm) require more precise machining and longer setup times, increasing cost. A part with ±0.001 mm tolerance can cost 50% more than one with ±0.01 mm tolerance.

- Volume: Larger volumes lead to lower per-unit costs, as setup fees are spread across more parts. For example, a part that costs €15 for 1 unit may cost €5 for 100 units.

Compliance and Regulations for CNC Machining in Slovakia

To ensure your project meets legal and industry standards, it’s important to understand the regulations governing CNC machining in Slovakia:

Quality Standards

As mentioned earlier, most Slovak CNC shops hold international quality certifications:

- ISO 9001: Mandatory for most B2B projects, as it ensures consistent quality management.

- IATF 16949: Required for automotive parts, as it aligns with global automotive standards (e.g., those set by Ford, General Motors, Toyota).

- AS9100: Required for aerospace parts, as it meets the strict safety and quality requirements of the aerospace industry.

- ISO 13485: Required for medical devices, as it ensures parts are safe for human use and meet regulatory requirements (e.g., EU MDR—Medical Device Regulation).

Environmental Regulations

Slovakia adheres to EU environmental laws, which govern waste disposal, emissions, and energy use. CNC shops must comply with:

- EU Waste Framework Directive: Requires shops to recycle or properly dispose of machining waste (e.g., metal chips, oil). Most shops partner with licensed waste management companies to ensure compliance.

- EU Emissions Trading System (ETS): Applies to large shops that emit significant amounts of CO2. Smaller shops are exempt but still need to meet local air quality standards.

- Energy Efficiency Directive: Encourages shops to use energy-efficient equipment and reduce their carbon footprint.

Import/Export Rules

If you’re importing CNC parts from Slovakia to another country, or exporting materials to Slovakia for machining, you’ll need to comply with:

- EU Customs Union: Parts shipped within the EU don’t require customs duties or additional paperwork—simplifying cross-border transactions. For example, a French automotive company can import CNC-machined engine parts from Slovakia without paying tariffs, reducing overall costs.

- Non-EU Exports: If shipping parts to countries outside the EU (e.g., the U.S., China), you’ll need to provide a Certificate of Origin to prove the parts were manufactured in Slovakia. This can help reduce or eliminate import duties in the destination country (depending on trade agreements). For instance, parts exported to the U.S. may qualify for reduced tariffs under the EU-U.S. Trade and Technology Council (TTC) initiatives.

- Restricted Materials: Some materials used in CNC machining (e.g., certain titanium alloys for aerospace) may be subject to export controls. Ensure your supplier has the necessary licenses if you’re working with restricted materials—this avoids delays or legal issues.

Yigu Technology’s Perspective on CNC Machining in Slovakia

As a company with extensive experience in global manufacturing and supply chain management, Yigu Technology recognizes Slovakia as a standout destination for CNC machining in Europe. What sets Slovakia apart is its rare balance of technical excellence and cost efficiency—two factors that are often mutually exclusive in Western or Eastern Europe.

We’ve observed that Slovak CNC shops excel at adapting to diverse industry needs, whether it’s high-volume automotive parts or low-volume, complex aerospace components. Their integration of Industry 4.0 tools (like IoT-connected machines and digital twins) also aligns with the global shift toward smart manufacturing, making them reliable long-term partners for businesses looking to scale.

Additionally, Slovakia’s commitment to sustainability resonates with our focus on eco-friendly supply chains. The adoption of recycled materials and energy-efficient machining helps reduce the carbon footprint of production—an increasingly important factor for clients worldwide. For businesses seeking to optimize their manufacturing processes, Slovakia’s CNC sector offers a practical, future-forward solution.

FAQ: Common Questions About CNC Machining in Slovakia

1. What is the average lead time for CNC machining projects in Slovakia?

Lead times vary based on project complexity and volume. For simple prototypes (1–5 units), most shops deliver in 1–2 weeks. Small batches (50–100 units) typically take 2–3 weeks, while large batches (1,000+ units) or complex 5-axis parts may require 3–6 weeks. Rush services are often available for urgent projects, with prototypes sometimes delivered in as little as 3 days (for an additional fee).

2. Do Slovak CNC shops offer design support or CAD/CAM services?

Yes, many reputable shops provide design support, including CAD modeling and CAM programming. This is especially helpful for businesses that have a concept but need help refining the design for manufacturability (DFM). For example, if you have a 2D drawing of a part, a Slovak shop can convert it to a 3D CAD model and optimize the design to reduce machining time and costs.

3. Can Slovak CNC shops handle large-scale production (10,000+ units)?

Absolutely. While some shops specialize in prototypes or small batches, many mid-sized to large Slovak CNC facilities are equipped for high-volume production. They use automation tools like robotic loaders and conveyor systems to handle 10,000+ unit orders efficiently. For example, a shop in Bratislava with 20+ CNC lathes and mills regularly fulfills large orders for automotive clients, with monthly production volumes exceeding 50,000 parts.

4. What quality documentation do Slovak CNC shops provide?

Most shops offer detailed quality documentation, including:

- First Article Inspection (FAI) Reports: For new projects, to verify the first part meets all specifications.

- Coordinate Measuring Machine (CMM) Reports: To prove dimensional accuracy (with measurements down to ±0.001 mm).

- Material Certificates (Mill Test Reports): To confirm the material used meets industry standards (e.g., ASTM, EN).

- ISO Compliance Certificates: To validate adherence to quality standards like ISO 9001 or IATF 16949.