In high-tech industries like aerospace and medical devices, why is PEEK Polyetheretherketone becoming a go-to material? And how do manufacturers overcome its unique challenges during machining? The answer lies in optimized CNC machining PEEK Polyetheretherketone—a process that turns this high-performance thermoplastic into precise, durable parts. This article breaks down PEEK’s key properties, critical CNC machining tips, step-by-step workflows, and real-world applications, helping you avoid common issues like thermal deformation and poor surface finish.

What Makes PEEK Polyetheretherketone Special?

PEEK Polyetheretherketone is a high-performance thermoplastic with properties that bridge the gap between plastics and metals. Its unique characteristics make it ideal for demanding environments—but also create challenges for machining. Here’s a clear breakdown:

| Property | Key Advantage | Machining Challenge |

| High Strength & Hardness | Rivals metal strength (tensile strength: 90 MPa), suitable for load-bearing parts. | Hardness causes fast tool wear; dull tools lead to rough surfaces. |

| Heat Resistance | Maintains stability at temperatures up to 260°C (continuous use); melts at 343°C. | Prone to thermal deformation if cutting heat isn’t controlled. |

| Chemical Resistance | Resists oils, acids, and solvents—ideal for harsh chemical environments. | No major chemical-related machining issues, but requires compatible coolants. |

| Wear & Toughness | Withstands long-term compression and friction; tough enough to avoid brittle breakage. | Toughness increases cutting force, risking tool chatter or part displacement. |

Critical Tips for CNC Machining PEEK Polyetheretherketone

Machining PEEK isn’t the same as machining standard plastics like ABS. To achieve precision and quality, focus on these 4 key areas—each solving a common pain point:

1. Tool Selection: Avoid Wear and Tear

- Material: Use carbide tools (not HSS). Carbide’s hardness (HV 1500–2000) resists wear from PEEK’s toughness, doubling tool life compared to HSS.

- Design: Choose tools with sharp cutting edges and positive rake angles (10–15°). This reduces cutting force, minimizing thermal buildup and part deformation.

- Example: A medical parts manufacturer switched from HSS to carbide end mills and cut tool replacement costs by 40%.

2. Cutting Parameter Optimization: Control Heat

PEEK softens when overheated—so getting parameters right is critical. Use this tested range for best results:

| Parameter | Recommended Range for PEEK | Why It Works |

| Cutting Speed | 50–80 m/min (for turning); 30–50 m/min (for milling) | Slower than standard plastics to reduce friction-induced heat. |

| Feed Rate | 0.1–0.2 mm/rev (turning); 0.05–0.1 mm/tooth (milling) | Balances efficiency and surface quality—too fast causes rough finishes. |

| Depth of Cut | 0.5–1 mm per pass (avoid >1 mm). | Shallow cuts prevent excessive force and heat; multiple passes ensure accuracy. |

3. Cooling & Lubrication: Prevent Softening

- Method: Use compressed air cooling (not water-soluble coolants). Water can seep into PEEK’s microstructures, weakening the part. Compressed air (flow rate > 8 L/min) removes heat without damaging the material.

- Pro Tip: Direct the air nozzle 2–3 mm from the cutting area to maximize heat dissipation.

4. Clamping & Support: Stop Deformation

PEEK parts—especially thin-walled ones—deform easily under clamping force. Fix this with:

- Non-contact clamping: Use vacuum chucks for flat parts to distribute pressure evenly.

- Internal support: For hollow parts (e.g., medical catheters), insert a temporary polymer mandrel to maintain shape during machining.

- Case Study: An aerospace supplier used vacuum clamping for PEEK sensor housings and reduced deformation from 0.15mm to 0.02mm.

Step-by-Step Workflow for CNC Machining PEEK Parts

Follow this linear process to ensure consistency—each step builds on the last to avoid mistakes:

- Pre-Machining Preparation:

- Dry the PEEK material (80°C for 4 hours). PEEK absorbs moisture, which causes bubbles during machining.

- Import the CAD design into CNC software (e.g., Mastercam) and set the cutting path to avoid sharp turns (reduces tool chatter).

- Tool Setting:

- Use a tool presetter to calibrate tool length and diameter. Record offsets in the CNC system to ensure cuts align with the design.

- Why it matters: A 0.01mm tool offset error can make a PEEK medical implant out of tolerance.

- Machining:

- Start with a test run on a scrap PEEK piece. Check surface finish (Ra should be < 0.8 μm) and dimensions before moving to production.

- Monitor in real time: If you see smoke (sign of overheating), slow the cutting speed by 10%.

- Post-Processing & Inspection:

- Deburring: Use a 300-grit sandpaper to remove sharp edges—critical for medical parts that touch human tissue.

- Cleaning: Wipe parts with isopropyl alcohol to remove oil or debris.

- Inspection: Use a coordinate measuring machine (CMM) to check tolerances (aim for ±0.005mm for critical parts like aerospace components).

Real-World Applications of CNC Machined PEEK Parts

Where does CNC machined PEEK shine? Here are 3 industries reaping its benefits:

- Medical Devices: Machined PEEK is used for spinal implants and dental abutments. Its biocompatibility (approved by the FDA) and strength mean implants last 10+ years. A leading medical firm produces 2,000 PEEK spinal cages monthly with CNC machining—defect rate < 0.05%.

- Aerospace: PEEK parts (e.g., sensor housings, valve seats) replace metal, cutting aircraft weight by 30%. Aeronautical engineers use CNC machining to achieve tolerances of ±0.003mm, ensuring parts fit in tight engine spaces.

- Oil & Gas: PEEK’s chemical resistance makes it ideal for downhole tool components. CNC-machined PEEK seals withstand 200°C temperatures and corrosive oils, outlasting rubber seals by 5x.

Yigu Technology’s Perspective

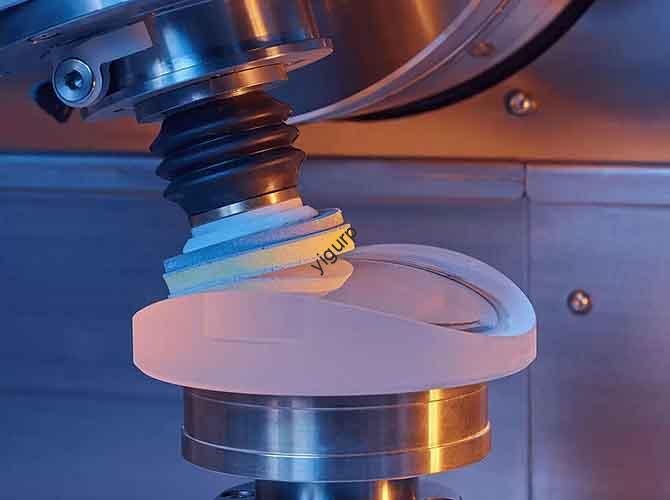

At Yigu Technology, we see CNC machining PEEK Polyetheretherketone as a game-changer for high-tech industries. Our CNC systems are optimized for PEEK: they integrate air-cooling ports, vacuum clamping options, and real-time heat sensors to prevent deformation. We’ve helped clients cut PEEK machining time by 25% while improving tolerance accuracy to ±0.004mm. As demand for lightweight, durable parts grows, we’ll keep refining our software to simplify PEEK processing—making it accessible for more manufacturers.

FAQ

- Q: Can CNC machining PEEK achieve the same tolerance as metal machining?

A: Yes. With optimized tools and parameters, CNC machining PEEK can reach tolerances of ±0.003–±0.005mm—comparable to aluminum or steel machining.

- Q: Why not use water coolant for CNC machining PEEK?

A: Water absorbs into PEEK’s microstructures, reducing its tensile strength by up to 15%. Compressed air cooling avoids this issue while still controlling heat.

- Q: How long does it take to machine a small PEEK part (e.g., a 10mm diameter medical pin)?

A: Including setup, machining, and inspection, it takes 8–10 minutes. Larger parts (e.g., 50mm aerospace housings) take 20–25 minutes.