Whether it’s precision parts in aerospace, core components in the automotive industry, or even microstructures in medical devices, CNC fabrication plays an irreplaceable role. It uses computer programs to control machine tools to complete automated machining, breaking through the precision limitations of manual operations and achieving the stability of mass production. Whether you are an engineer new to CNC technology or a manufacturing practitioner seeking process optimization, mastering the complete knowledge system of CNC machining can significantly improve production efficiency and product quality. This article will take you from basic principles to cutting-edge applications, and will take you to unlock the core technology and practical skills of CNC machining.

1. CNC machining basics and principles: understand the underlying logic of CNC machining

1.1 Core principles and technical framework

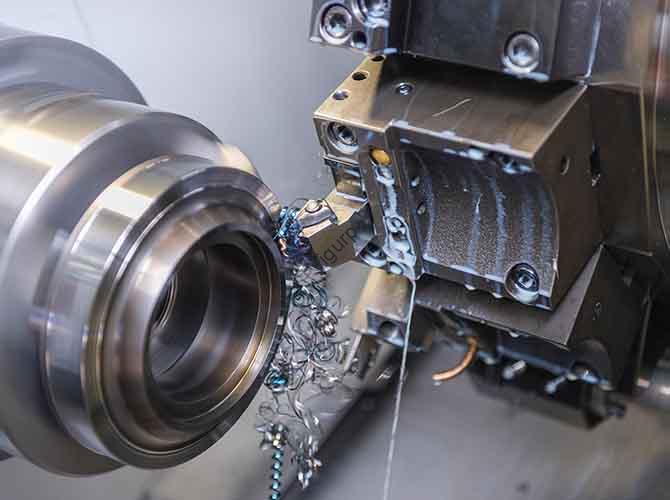

The core of CNC machining principle is “digital instructions drive mechanical movement”: the design drawings are converted into G-code programming through the computer, the computer numerical control system parses the instructions, and the servo control system is controlled to drive the coordinate axis movement of the machine tool, and finally the material cutting is completed. Among them, the principle of interpolation is the key to ensuring machining accuracy – the machine tool generates a smooth motion trajectory between specified coordinate points through algorithms such as linear interpolation and arc interpolation to avoid glitches or errors on the machining surface.

1.2 Standard machining process and precision control

A complete CNC machining process consists of 6 key steps: (1) drawing design and process analysis→ (2) CNC program writing (manual or automatic programming) → (3) machine tool coordinate system setting (establishing the association between the origin of the workpiece and the origin of the machine tool) → (4) tool and fixture installation → (5) trial cutting verification (single or small batch trial machining) → (6) mass production and quality inspection. Among them, the machining accuracy control needs to focus on three points: first, the repeatability of the machine tool coordinate system (usually required ≤0.005mm); second, the response speed of the servo system (affecting the trajectory follow-up during high-speed machining); and third, the rationality of program writing (avoiding overcut and undercutting problems).

Practical case: When processing aluminum alloy shells, a precision parts processing factory once caused a batch part size deviation of 0.02mm due to not calibrating the machine tool coordinate system. By resetting the origin of the workpiece, optimizing the servo parameters, and adding tool radius compensation instructions to the program, the machining accuracy was finally stabilized within ±0.003mm, meeting the customer’s aviation-grade requirements.

2. CNC machine type and equipment: Choosing the right equipment is half the battle

2.1 Mainstream machine tool types and applicable scenarios

Different types of CNC machines are designed for different machining needs, taking into account the shape, material, and precision requirements of the workpiece:

| Machine type | Core features: | Typical applications: | Accuracy range |

| Vertical machining centers | Three-axis linkage, vertical layout | Flat and box parts | ±0.005~0.01mm |

| 5-axis CNC machine | Five-axis linkage, can be processed from multiple angles | Complex surfaces, special-shaped parts (e.g., impellers, molds) | ±0.002~0.005mm |

| Turning-milling compound machine tools | Turning + milling in one | Shaft and disc parts (e.g., motor shafts, gears) | ±0.003~0.008mm |

| CNC engraving machine | High-speed light cutting | Non-metallic materials, thin-walled parts engraving | ±0.01~0.02mm |

| Gantry machining center | Large stroke, heavy cutting | Large machine tool beds, construction machinery parts | ±0.01~0.03mm |

2.2 Key equipment selection skills

- Machining complex surfaces (such as aero engine blades): Prefer five-axis CNC machines to avoid positioning errors caused by multiple clamping;

- Mass production of shaft parts: It is recommended to turn and mill composite machine tools, which can complete turning, milling, drilling and other processes at one time, shortening the machining cycle by more than 30%;

- Small precision parts (such as electronic connectors): choose a high-speed machining center (spindle speed ≥20000rpm) and use precision fixtures to improve surface quality;

- Large structural parts (such as machine tool bases): Gantry machining centers are used to ensure rigidity and stability during large-stroke machining.

3. CNC Machining Materials and Applications: Material properties determine the process scheme

3.1 Common processing materials and process points

The cutting performance of different materials varies significantly, and it is necessary to optimize the tools and cutting parameters:

- Metal CNC Machining:

- Aluminum alloy: easy to cut, suitable for high-speed machining (spindle speed 10000~20000rpm), commonly used coating tools, coolant selection emulsion;

- Stainless steel: high hardness and high viscosity, need to use carbide tools to reduce the cutting speed (30~50m/min) and strengthen chip evacuation;

- Titanium alloy: high temperature resistance, high strength, using special titanium alloy tools, oil-based coolant to avoid too fast wear of the tools.

- Non-Metallic CNC Machining:

- Plastics (such as POM, PC): easy to deform, need to control the cutting temperature (spindle speed 5000~8000rpm), use vacuum adsorption fixtures;

- Composite materials (such as carbon fiber): high hardness, easy to chip, diamond-coated tools, using a trim milling process.

3.2 Application cases in key industries

- Aerospace parts: An aircraft manufacturing company used a five-axis CNC machine tool to process titanium alloy landing gear components, and by optimizing the cutting parameters (cutting speed 40m/min, feed rate 0.1mm/r), the machining cycle was reduced from 8 hours to 5 hours, and the scrap rate was controlled below 0.5%.

- Medical device processing: A company uses a precision CNC lathe to process 316L stainless steel implants, using high-speed cutting technology and three-coordinate inspection to ensure a surface roughness of Ra≤0.8μm to meet biocompatibility requirements;

- Auto parts processing: A car company uses turning-milling composite machine tools to mass-produce engine crankshafts, integrating turning, milling, and grinding processes, achieving a single processing time of ≤ 3 minutes and an annual output of up to 500,000 pieces.

4. CNC Programming and Software: Efficient programming is a prerequisite for precision

4.1 Mainstream programming software and its characteristics

CAD/CAM software is the core tool of CNC programming, and different software focuses on different scenarios:

| Software name | Core strengths | Applicable scenarios | Difficulty of operation |

| MasterCAM programming | Strong tool path optimization function, supporting 2~5 axis machining | Mold processing, parts processing | medium |

| UG/NX programming | 3D modeling and programming are integrated, and the simulation function is powerful | Complex surface machining, aerospace field | Higher |

| SolidWorks integration | Seamless integration with design software, easy to learn and use | Small and medium-sized enterprises, simple parts processing | Lower |

4.2 Efficient programming skills

- Automatic programming takes precedence over manual programming: For complex parts, automatic programming technology saves 80% of programming time with fewer errors;

- Pay attention to post-processing configuration: customize the post-processing configuration according to the machine tool model to avoid machine tool alarms caused by incompatible instructions;

- Simulation verification before programming: Use the simulation machining verification function of the software to check whether the tool path is overcut or collided to reduce trial cut loss;

- DNC transmission: For large programs (exceeding the machine memory), instructions are sent in real time through DNC transmission to avoid program loss or error.

Practical skills: When machining complex molds, you can use UG/NX for 3D modeling and tool path planning, then optimize the milling path through MasterCAM, and finally use simulation software to verify it, which can reduce the programming error rate by more than 90%.

5. Tools and cutting technology: tools are the “teeth” of processing

5.1 Tool selection and life management

- Tool material matching materials: high-speed steel tools for steel parts, diamond tools for cemented carbide, and cubic boron nitride (CBN) tools for superalloys;

- Coating tool application: TiN coating tool is suitable for steel processing, AlTiN coating tool is suitable for superalloy processing, which can improve tool life by 3~5 times;

- Tool life management: By setting the tool wear threshold (such as replacing when the rear tool surface wear is ≥ 0.2mm), combined with tool wear detection equipment, to avoid the degradation of machining accuracy due to tool wear;

- Coolant strategy: Select the coolant type (emulsion for steel, cutting oil for aluminum alloys) according to the material, and control the coolant flow rate (≥20L/min) to reduce the cutting temperature.

5.2 Application of key cutting technologies

- High-speed cutting technology: suitable for aluminum alloy, plastic and other materials, the cutting speed is 3~5 times higher than traditional machining, which can improve the machining efficiency by more than 40%, but it is necessary to ensure the rigidity of the machine tool and the quality of the tool;

- Deep hole drilling: When machining holes with a hole diameter of ≤ 10mm and a depth-diameter ratio of ≥ 10, use gun drills or BTA deep hole drills with high-pressure coolant to evacuate chips to avoid roughness or deflection of the hole wall;

- Thread processing tools: Preferential taps are preferred for machining internal threads, and die teeth or thread mills are selected for external threads, and thread milling cutters are more efficient and more accurate for large diameter threads.

6. Precision and Quality Control: Details make the difference

6.1 Core accuracy indicators and detection methods

- Machining accuracy standards: According to ISO standards, precision machining accuracy levels are divided into IT01~IT18, and commonly used in CNC machining IT5~IT7 levels (tolerance range 0.005~0.03mm);

- Surface roughness measurement: Using a roughness meter for testing, precision parts usually require Ra≤1.6μm, ultra-precision parts Ra≤0.4μm;

- CMM Inspection: For complex parts, CMM is used for 3D dimensional inspection, and the repeated measurement accuracy can reach ±0.002mm;

- Online monitoring system: Install force sensors and temperature sensors on the machine tool to monitor abnormalities in the processing process in real time and adjust parameters in time.

6.2 Error compensation and quality improvement

- Error compensation technology: Correcting machine tool geometric errors (such as verticality, straightness errors) and thermal deformation errors through software, the machining accuracy can be improved by 20~30%;

- Implement SPC statistical analysis: Monitor fluctuations in the machining process through SPC statistical analysis to detect systemic issues (such as tool wear, loose fixtures) in a timely manner;

- Establish a quality inspection process: During mass production, implement “first article inspection→ inspection (every 50 pieces) →last part inspection” to ensure product consistency.

7. Automation and Smart Manufacturing: Future Trends in CNC Machining

7.1 Automated processing system

- Automatic loading and unloading system: with truss manipulator or gantry manipulator, it realizes automatic clamping and disassembly of workpieces, suitable for mass production, and can reduce labor costs by more than 50%;

- Robot integration: Industrial robots work together with CNC machine tools to complete multi-machine tool linkage and workpiece transfer, improving the flexibility of production lines.

- Flexible Manufacturing Unit (FMC): Integrates multiple CNC machines, robots, and testing equipment to automate multi-mix, small-batch production, with a changeover time of ≤ 30 minutes.

7.2 Application of intelligent manufacturing technology

- Internet of Things monitoring: collect machine tool operation data (spindle speed, cutting force, temperature) through sensors, monitor equipment status in real time, and predict maintenance needs;

- Intelligent tool management: Track tool position and wear status through RFID technology, automatically schedule tools, and avoid downtime due to tool problems.

- Adaptive machining technology: The machine tool automatically adjusts cutting parameters based on real-time cutting data (such as changes in cutting force) to ensure machining accuracy and efficiency;

- Industry 4.0 applications: Realize the interconnection of data for design, programming, processing, and inspection, build a digital factory, and increase production efficiency by 30~50%.

8. Process optimization and efficiency improvement: the core path of cost reduction and efficiency increase

8.1 Key optimization directions

- Shortening the machining cycle: Using high-speed cutting, multi-station machining, and optimizing the tool path (such as reducing empty stroke), the cycle cycle can be shortened by 20~40%;

- Fixture design optimization: Modular fixture and quick mold change system are used to shorten the production changeover time from 1 hour to 10 minutes;

- Material removal rate improvement: By increasing the cutting depth and increasing the feed rate, the material removal rate is improved under the premise of ensuring accuracy, but it is necessary to avoid overloading the machine tool;

- Energy Consumption Management: Optimizing machining parameters (e.g., avoiding machine idling and selecting cutting speeds wisely) can reduce energy consumption by 15~25%.

8.2 Lean Manufacturing Applications

- Establish a process parameter library: organize the optimal cutting parameters of different materials and parts into a library, which is convenient for direct call during programming;

- Implement production scheduling optimization: Reasonably arrange production plans according to order priority and machine load to reduce machine tool waiting time;

- Continuous improvement: Continuously optimize processes by analyzing production data (e.g., processing cycles, scrap rates) to identify bottleneck processes.

9. Industry applications and cases: from theory to practice

9.1 Customized parts production

A startup needs to process a batch of customized aluminum alloy housings (batch of 50 pieces) and uses a vertical machining center + SolidWorks programming to optimize the fixture design (using vacuum adsorption + dowels) to achieve a single-piece machining time of ≤ 15 minutes, reducing the cost by 30% compared to traditional machining.

9.2 Mass Production Solutions

An electronics company mass-produces mobile phone middle frames (daily output of 1,000 pieces), adopts high-speed machining center + automatic loading and unloading system, integrates milling, drilling, and chamfering processes, monitors quality through SPC statistical analysis, and controls the scrap rate below 0.3% to meet customers’ large-scale delivery requirements.

10. Yigu Technology’s view

CNC machining has been upgraded from traditional “machining” to “digital manufacturing”, and its core competitiveness lies in the balance of “precision, efficiency, and flexibility”. In the future, with the popularization of intelligent manufacturing technology, CNC machining will focus more on data-driven, automation integration, and green production. Enterprises should start from three aspects: equipment upgrades, talent training, and process optimization, and embrace technological change – small enterprises can first introduce efficient programming software and precision testing equipment, medium-sized enterprises can build flexible manufacturing units, and large enterprises should deploy digital factories. Only by continuous innovation can we gain an advantage in the fierce market competition.

FAQ: Frequently Asked Questions

- How accurate can CNC machining achieve?

Ordinary CNC machines have an accuracy of around ±0.01mm, precision five-axis machines can reach ±0.002mm, and ultra-precision machining can reach the micron level (±0.001mm), depending on the machine accuracy, tool quality, and programming level.

- Which programming software should a beginner choose?

It is recommended that beginners learn SolidWorks integrated programming (easy to learn and use, closely connected with design software), and then learn MasterCAM (suitable for mold processing) or UG/NX (suitable for complex parts) after having a certain foundation.

- How to extend tool life?

The key is to select tools and coatings that match the material, optimize cutting parameters (to avoid overloading), ensure sufficient coolant, regularly detect tool wear and replace it in a timely manner.

- Which companies are automated loading and unloading systems suitable for?

It is suitable for enterprises with mass production (daily output ≥ 100 pieces) and relatively simple parts structure, which can significantly reduce labor costs and human errors, and the turnaround time is usually 1~2 years.

- Difference Between CNC Machining and 3D Printing?

CNC machining is “subtractive manufacturing” and is suitable for high-precision mass production of metals, plastics, and other materials; 3D printing is “additive manufacturing” for complex structures, low-volume custom parts, and is less accurate and efficient than CNC machining.