In CNC machining, why do two identical-looking parts—one made of aluminum alloy, one of stainless steel—perform drastically differently in real-world use? The answer lies in CNC machining materials—the foundation of every precision part. Selecting the wrong material can lead to premature failure, wasted costs, or missed performance goals. This article breaks down the most common CNC machining materials, their key properties, industry applications, selection criteria, and future trends, helping you pick the perfect material for your project.

What Are CNC Machining Materials?

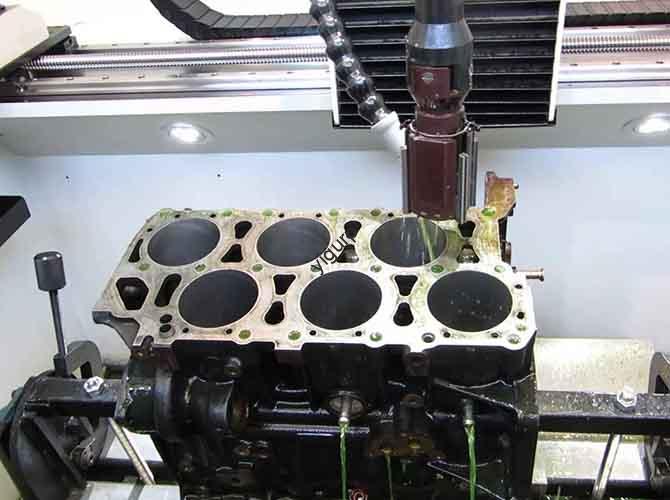

CNC machining materials refer to the diverse range of substances used in Computer Numerical Control (CNC) manufacturing to create precision parts. These materials are chosen based on the final product’s needs—whether it requires strength (for aerospace components), corrosion resistance (for medical devices), or lightweight design (for automotive parts).

Think of them as “building blocks with unique superpowers”: each material has a set of properties that make it ideal for specific tasks. For example, titanium alloys are “strong yet light” (perfect for aircraft parts), while ceramics are “heat-resistant warriors” (great for high-temperature industrial tools).

A Complete Guide to Common CNC Machining Materials

CNC machining materials fall into four main categories: metallic, non-metallic, special, and composite. Below is a detailed breakdown of each category, with key properties and real-world uses:

1. Metallic Materials (Most Widely Used)

Metals dominate CNC machining due to their strength and durability. The table below highlights the top options:

| Material | Key Properties | Industry Applications | Machinability Tips |

| Aluminum Alloys (6061, 7075) | – Lightweight (density: 2.7 g/cm³) – Good machinability – Moderate strength (6061: 276 MPa tensile strength) | – Automotive: Wheel rims, engine parts – Consumer Electronics: Phone cases, laptop frames – Aerospace: Interior components | – Use high cutting speeds (150–200 m/min) – Avoid excessive force (causes deformation) |

| Stainless Steel (304, 316) | – Excellent corrosion resistance – High strength (304: 515 MPa tensile strength) – Heat-resistant (up to 870°C) | – Medical: Surgical instruments, implantable parts – Food Industry: Equipment tanks, conveyors – Marine: Ship hull components | – Use carbide tools (resists wear) – Apply coolant to reduce heat buildup |

| Titanium Alloys | – Ultra-high strength-to-weight ratio – Corrosion-resistant (even in saltwater) – Biocompatible | – Aerospace: Aircraft wings, rocket engine parts – Medical: Hip replacements, dental implants – Defense: Military vehicle armor | – Slow cutting speeds (50–80 m/min) – Use cermet tools (handles high heat) |

| Superalloys (Inconel, Hastelloy) | – Maintain strength at extreme temperatures (up to 1,200°C) – Resist oxidation and chemical corrosion | – Aerospace: Gas turbine blades – Energy: Nuclear reactor components – Chemical: High-temperature reaction vessels | – Use diamond-coated tools – Low feed rates (0.05–0.1 mm/rev) to prevent tool chipping |

2. Non-Metallic Materials (For Lightweight & Special Needs)

Non-metals are ideal for parts that don’t require heavy strength but need other properties (e.g., insulation, flexibility). Here are the top choices:

- Engineering Plastics (ABS, PC, POM):

- Properties: ABS is tough and impact-resistant; PC has high heat resistance (up to 130°C); POM is wear-resistant (like metal but lighter).

- Applications: ABS for automotive dashboards; PC for safety goggles; POM for gears and bearings.

- Example: A consumer electronics firm uses PC to make laptop bezels—they withstand daily impacts and don’t warp in hot environments.

- Ceramic Materials (Zirconia, Silicon Nitride):

- Properties: High hardness (HV 1,200–1,500), heat resistance (up to 1,600°C), and electrical insulation.

- Applications: Zirconia for dental crowns; silicon nitride for industrial cutting tools.

- Case: A manufacturing plant uses silicon nitride tools to cut steel—they last 5x longer than carbide tools.

- Semiconductor Materials (Silicon):

- Properties: Semiconducting (conducts electricity under specific conditions), high purity (99.9999%).

- Applications: Electronic chips, microprocessors, solar panels.

- Fact: 90% of global semiconductors are made from CNC-machined silicon wafers.

3. Special Materials (For Advanced Technologies)

These materials have unique “smart” or specialized properties, making them critical for cutting-edge industries:

| Material | Unique Property | Applications |

| Shape Memory Alloys (Nitinol) | Restore original shape when heated to a specific temperature (e.g., 60°C). | – Medical: Stents (expand in blood vessels when heated) – Aerospace: Self-deploying satellite antennas |

| Superconducting Materials (Yttrium-Barium-Copper-Oxide) | Zero electrical resistance at extremely low temperatures (-196°C for liquid nitrogen cooling). | – Transportation: Maglev train magnets – Medical: MRI machine coils – Energy: Superconducting power cables |

| Smart Materials (Piezoelectric Ceramics) | Change shape when an electric current is applied (or generate current when squeezed). | – Sensors: Pressure detectors in industrial machines – Actuators: Precision valves in aerospace systems – Consumer Tech: Touchscreen haptic feedback |

How to Choose the Right CNC Machining Material (Step-by-Step)

Selecting a material isn’t guesswork—follow this 4-step process to match your project’s needs:

- Define Product Requirements:

Ask: What does the part need to do? For example:

- Does it need to withstand weight? (Prioritize strength: titanium, steel.)

- Will it be exposed to water or chemicals? (Prioritize corrosion resistance: stainless steel, superalloys.)

- Does it need to be lightweight? (Prioritize aluminum, engineering plastics.)

- Evaluate Machinability:

Some materials are hard to machine (e.g., titanium) and require expensive tools. Balance performance with cost:

- Example: A startup making low-cost drone frames chooses aluminum over titanium—it’s 30% cheaper to machine and light enough for the drone’s needs.

- Consider Cost-Effectiveness:

- Superalloys cost \(100–\)200 per kg; aluminum costs \(2–\)5 per kg. Only use expensive materials if the part needs their properties.

- Tip: For non-critical parts (e.g., decorative covers), use engineering plastics instead of metals to cut costs by 50%.

- Test & Validate:

Machine a small prototype with your chosen material and test it in real conditions:

- If a stainless steel part rusts in saltwater tests, switch to 316 stainless steel (more corrosion-resistant than 304).

- If an aluminum part bends under load, upgrade to 7075 aluminum (stronger than 6061).

Yigu Technology’s Perspective

At Yigu Technology, we believe CNC machining materials are the “unsung heroes” of precision manufacturing. Our CNC systems are optimized for diverse materials: we offer specialized toolpaths for titanium (reducing machining time by 25%) and real-time material monitoring for plastics (preventing overheating). We’ve helped clients—from medical device makers to aerospace firms—cut material waste by 15% by matching the right material to their needs. As new materials (like bio-based plastics and advanced composites) emerge, we’ll keep updating our software to ensure seamless machining—making high-performance parts more accessible than ever.

FAQ

- Q: What’s the most cost-effective CNC machining material for general-purpose parts?

A: 6061 aluminum alloy— it’s cheap (\(2–\)5 per kg), easy to machine, and has enough strength for most non-critical parts (e.g., brackets, enclosures).

- Q: Can CNC machining handle both metallic and non-metallic materials with the same machine?

A: Yes! Most of our CNC machines use interchangeable tools: switch to carbide tools for metals and high-speed steel (HSS) tools for plastics. Just adjust cutting parameters (speed, feed rate) for each material.

- Q: Are there eco-friendly CNC machining materials?

A: Absolutely. Options include recycled aluminum (uses 95% less energy than virgin aluminum), bio-based plastics (made from corn or sugarcane), and bamboo fiber composites. We help clients integrate these materials into their workflows to reduce carbon footprints.