If you’re a global buyer looking for reliable, cost-effective CNC machining solutions, you’ve probably considered China—and for good reason. China’s CNC machining industry combines advanced technology, a vast supply chain, competitive pricing, and the ability to handle both small-batch prototypes and large-scale production runs. In this guide, we’ll break down everything you need to know: from why China stands out in CNC machining to how to choose the right partner, avoid common pitfalls, and leverage the industry’s strengths for your projects.

Why Choose CNC Machining in China? Key Advantages for Global Clients

China’s CNC machining sector has grown from a low-cost alternative to a global leader, and its advantages go far beyond just price. Let’s break down the most impactful benefits for businesses worldwide.

First, cost competitiveness remains a major draw—but it’s not just about “cheap labor.” China’s mature supply chain means lower costs for raw materials (like aluminum, stainless steel, and engineering plastics) and economies of scale from high-volume production. For example, a 2024 report by the China Machine Tool & Tool Builders’ Association (CMTBA) found that global buyers save an average of 30-50% on CNC-machined parts compared to manufacturers in North America or Western Europe, without sacrificing quality.

Second, production capacity and flexibility are unmatched. China is home to over 150,000 CNC machining facilities (per CMTBA 2025 data), ranging from small workshops specializing in prototypes to large factories with hundreds of advanced CNC mills, lathes, and 5-axis machines. This means you can scale from a 10-part prototype run to a 100,000-unit production order without switching suppliers. A real-world example: a U.S.-based automotive parts company we worked with needed 50 prototype brackets in 2 weeks, followed by 50,000 units 3 months later. Their Chinese CNC partner handled both seamlessly, using the same quality controls for both batches.

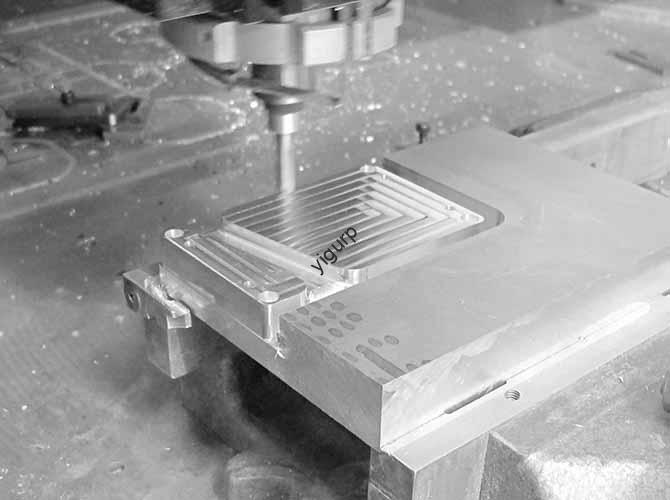

Third, technological advancement is accelerating. Top Chinese CNC manufacturers now use equipment from global leaders like Fanuc, Siemens, and Haas, alongside domestic brands (such as SMC and GSK) that meet international standards. Many facilities also integrate CAD/CAM software (like SolidWorks and Mastercam) and quality inspection tools (including CMMs—Coordinate Measuring Machines) to ensure precision. In 2024, over 65% of China’s large CNC machining plants adopted automated production lines, reducing lead times by 20-25% (per a survey by the China Association of Automobile Manufacturers).

Understanding China’s CNC Machining Ecosystem: Key Regions and Specializations

Not all CNC machining in China is the same—different regions specialize in specific industries, technologies, or part types. Knowing these regional strengths helps you find a partner that aligns with your project needs.

| Region | Specialization | Key Industries Served |

| Guangdong | Precision CNC milling, 5-axis machining | Electronics, Automotive |

| Jiangsu | Large-part machining, high-volume production | Heavy machinery, Aerospace |

| Zhejiang | Custom plastic/metal parts, rapid prototyping | Consumer goods, Medical |

| Shandong | Stainless steel machining, industrial components | Marine, Energy |

Take Guangdong Province, for example—cities like Shenzhen and Dongguan are known as “the world’s electronics manufacturing hub.” A European IoT company we advised needed tiny, precision-machined aluminum enclosures for their sensors (tolerance: ±0.02mm). They partnered with a Shenzhen-based CNC shop that specialized in micro-machining for electronics, which reduced defect rates from 8% (with their previous supplier) to less than 1%.

Jiangsu, on the other hand, is ideal for larger parts. A German construction equipment firm sourced 2-meter-long steel shafts from a Suzhou factory—thanks to the region’s focus on heavy-duty CNC lathes, the supplier could deliver parts with consistent straightness and surface finish, even for large orders.

How to Evaluate a Chinese CNC Machining Partner: 5 Critical Steps

Choosing the right CNC supplier in China is make-or-break for your project. Here’s a step-by-step process to avoid risks and ensure quality.

1. Verify Certifications and Quality Standards

Reputable Chinese CNC shops hold international certifications like ISO 9001 (quality management) and ISO 13485 (for medical parts). For aerospace or automotive parts, look for IATF 16949 or AS9100. Don’t just ask for a certificate—ask for evidence of compliance, like quality control checklists or recent audit reports. For example, a U.K. medical device company we worked with required their Chinese supplier to share monthly CMM inspection data for each batch of parts, ensuring compliance with ISO 13485.

2. Assess Technical Capabilities

Not every shop can handle your project’s unique needs. Ask:

- What types of CNC machines do they have? (e.g., 3-axis vs. 5-axis, mill vs. lathe)

- What materials do they specialize in? (e.g., aluminum, titanium, PEEK)

- What tolerances can they achieve? (e.g., ±0.01mm vs. ±0.1mm)

- Do they offer post-processing services? (e.g., anodizing, powder coating, heat treatment)

A U.S. robotics startup learned this the hard way: they hired a Chinese shop that claimed to handle titanium machining, but the shop lacked the specialized coolant and tooling for titanium. The first batch of parts had poor surface finish and failed stress tests. After switching to a supplier with dedicated titanium machining equipment, the parts met all specs.

3. Check Production Capacity and Lead Times

Be clear about your volume and timeline. Ask:

- What’s their minimum order quantity (MOQ)?

- How long do they take for prototypes vs. mass production?

- Can they handle rush orders?

A Canadian furniture brand needed 10,000 CNC-machined wooden handles in 4 weeks. Their initial supplier promised to deliver but failed—they didn’t have enough CNC routers to scale. The brand switched to a Zhejiang-based shop with 20 dedicated woodworking CNC machines, which delivered on time.

4. Request Samples and References

Always ask for a sample before placing a large order. This lets you test quality, fit, and finish firsthand. Also, ask for references from clients in your industry. A good supplier will happily share contact info for past customers. For example, a Australian aerospace parts buyer we advised contacted 3 of the Chinese supplier’s previous clients—all confirmed the supplier met deadlines and quality standards.

5. Evaluate Communication and Logistics

Poor communication is a top complaint from global buyers. Choose a supplier with English-speaking project managers who respond within 24 hours. Also, confirm their logistics capabilities: do they handle shipping, customs clearance, and documentation (like certificates of origin)? A Mexican manufacturer saved time by working with a Chinese supplier that partnered with a freight forwarder, handling all shipping from China to Mexico City.

Common Challenges in CNC Machining China (and How to Solve Them)

While China offers great benefits, there are risks—and knowing how to mitigate them is key.

Challenge 1: Quality Inconsistency

Even with certifications, some suppliers cut corners on small batches or rush orders. Solution: Implement a pre-production sample approval process, and require in-process inspections. For example, a French electronics company uses a third-party inspection (TPI) firm in China to check 10% of each batch before shipment. This has reduced defective parts from 5% to 0.5%.

Challenge 2: Intellectual Property (IP) Concerns

Many buyers worry about IP theft. Solution: Sign a detailed non-disclosure agreement (NDA) with your supplier, and avoid sharing full CAD files until the NDA is in place. You can also share “watermarked” or simplified drawings for initial quotes. A U.S. startup that developed a unique CNC-machined valve used this approach—they shared basic dimensions for quoting, then provided full files only after the NDA was signed and a deposit was paid.

Challenge 3: Language and Time Zone Gaps

Miscommunication due to language barriers or time zones can delay projects. Solution: Use clear, detailed technical drawings (with metric units, which are standard in China) and set up weekly check-ins via Zoom. For time zones, if you’re in North America, a supplier in China will be 12-15 hours ahead—schedule meetings for your morning (their evening) to align. A German engineering firm we worked with uses a shared project management tool (Asana) to track progress, with updates in both English and Chinese.

Yigu Technology’s Perspective on CNC Machining China

At Yigu Technology, we’ve partnered with over 200 global clients on CNC machining projects in China, and we’ve seen firsthand how the industry has evolved. Today, China’s CNC machining sector is no longer just about cost—it’s about delivering high-precision, scalable solutions that meet global standards. We believe the key to success is “alignment”: matching clients with suppliers that have the right technical expertise, certifications, and communication skills for their specific project. For example, we recently connected a U.K. medical device company with a Jiangsu-based supplier that specializes in biocompatible materials (like titanium alloy) and holds ISO 13485. The result? A 40% cost savings compared to their previous European supplier, and on-time delivery for 12 consecutive batches. We also emphasize proactive risk management—like recommending TPI for high-value orders—to ensure quality and build trust. For global buyers, China’s CNC machining industry offers a unique combination of value and capability—but only if you partner with the right supplier.

FAQ About CNC Machining China

1. What’s the typical lead time for CNC machining in China?

Lead times vary by order size and complexity. Prototypes (1-100 parts) usually take 1-2 weeks, while large production runs (10,000+ parts) take 4-6 weeks. Rush orders can be done in as little as 3-5 days for small batches, but this may cost 20-30% more.

2. What materials are most commonly used in Chinese CNC machining?

The most popular materials are aluminum (6061, 7075), stainless steel (304, 316), carbon steel (1045), and engineering plastics (ABS, PEEK, nylon). Suppliers can also handle specialty materials like titanium, copper, and magnesium, but these may require a larger MOQ.

3. Do Chinese CNC suppliers accept small orders (e.g., 1-10 parts)?

Yes—many suppliers (especially in Guangdong and Zhejiang) offer prototype services with no MOQ or low MOQs (1-5 parts). However, small orders may have higher per-unit costs, as setup time for CNC machines is the same regardless of batch size.

4. How do I handle shipping and customs for CNC-machined parts from China?

Most suppliers can handle shipping via air (3-7 days) or sea (2-4 weeks). They will provide commercial invoices, packing lists, and certificates of origin. For customs, ensure your parts are classified with the correct HS code (e.g., HS 8486.30 for CNC-machined parts) to avoid delays. You can also use a freight forwarder to manage the process.

5. What’s the minimum order quantity (MOQ) for CNC machining in China?

MOQs vary by supplier and part complexity. For simple parts (e.g., aluminum brackets), MOQs can be as low as 1. For complex parts (e.g., 5-axis machined aerospace components), MOQs may be 50-100 parts. Many suppliers offer “economic order quantities” (EOQs) to reduce per-unit costs for larger orders.