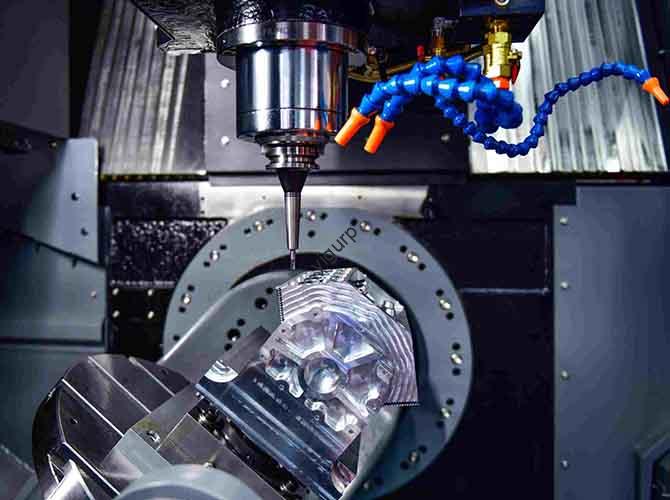

If you’re running a manufacturing shop, you know how crucial your CNC machines are—they’re the backbone of your production. But when they slow down, break down, or lose accuracy, it can throw a wrench in your entire operation. That’s where CNC machine service comes in. This guide isn’t just a list of services; it’s a practical roadmap to help you prevent issues, fix problems fast, and get the most out of your CNC equipment. We’ll walk you through everything from routine checks to major overhauls, with real-world examples and actionable steps to keep your machines in top shape.

1. Preventive & Predictive Maintenance: Stop Problems Before They Start

The biggest mistake many shops make is waiting for a CNC machine to break before servicing it. Preventive & Predictive Maintenance is all about staying ahead of issues—and it can save you thousands in downtime and repairs. Let’s break down the key tasks and why they matter.

Key Practices & Real-World Impact

- Scheduled Inspections: Set a regular schedule (we recommend monthly for high-use machines) to check for loose parts, worn belts, or unusual noises. A client of ours skipped these inspections for six months; they ended up with a broken spindle that cost $8,000 to replace—something a 15-minute monthly check could have caught.

- Lubrication Management: Use the manufacturer’s recommended lubricant and track when you apply it. Dry ball screws can increase friction by 30%, leading to faster wear and reduced accuracy. We once helped a shop cut their ball screw replacement costs by 50% just by fixing their lubrication schedule.

- Condition Monitoring: Tools like vibration sensors or thermal imaging cameras let you spot issues early. For example, Vibration Analysis can detect bearing wear before it causes a breakdown. One automotive shop used this to avoid a 48-hour production delay—saving them over $20,000 in lost orders.

- Maintenance Logging: Keep a detailed log of every service, repair, or part replacement. This helps you track Component Lifespan Tracking (e.g., “When did we last replace the coolant filter?”) and predict when parts will need to be swapped out. A metal fabrication shop we worked with used their logs to reduce unexpected downtime by 40%.

Quick Reference Table: Preventive Tasks & Frequencies

| Task | Frequency for High-Use Machines | Frequency for Low-Use Machines |

| Scheduled Inspections | Monthly | Quarterly |

| Lubrication | Every 2 Weeks | Monthly |

| Vibration Analysis | Every 3 Months | Every 6 Months |

| Fluid Analysis | Every Month (Coolant) | Every 3 Months (Coolant) |

2. Mechanical Systems Repair: Fixing the “Moving Parts” of Your CNC Machine

Even with great preventive maintenance, mechanical parts will wear out over time. The Mechanical Systems Repair category covers the most common (and critical) fixes—from spindle rebuilds to coolant system repairs. Let’s dive into what you need to know, including how to spot issues early and what to expect from repairs.

Common Repairs & Expert Insights

- Spindle Rebuild: The spindle is the “heart” of your CNC machine—if it’s not working, you can’t cut anything. Signs of a failing spindle include loud grinding noises or inconsistent cuts. A full rebuild typically takes 3–5 days and costs \(3,000–\)10,000, depending on the machine size. We recently rebuilt a spindle for a woodworking shop that was producing uneven cuts; after the repair, their part accuracy improved by 90%.

- Ball Screw & Linear Guide Replacement: These parts help your machine’s axes move smoothly. If you notice jerky movements or increased backlash, it’s time to check them. Replacing a ball screw takes 1–2 days, and we always recommend using OEM parts—aftermarket parts can be 20% cheaper upfront but often fail twice as fast.

- Coolant System Repair: A dirty or broken coolant system can lead to overheating tools and poor part quality. Common issues include clogged filters or leaky hoses. We once fixed a coolant leak for a plastics shop that was wasting 5 gallons of coolant a week—after the repair, they saved $600 a month on coolant costs.

- Automatic Tool Changer (ATC) Repair: If your ATC is dropping tools or taking too long to change them, it’s a sign of wear. A faulty ATC can slow down production by 25%—we repaired one for a aerospace parts shop that was losing 10 hours of production a week; the fix took 8 hours and got them back on track.

3. Control & Electrical Systems Troubleshooting: Solving the “Brain” of Your Machine

Your CNC machine’s control and electrical systems are like its brain—they keep everything running in sync. When these systems fail, it can be confusing (and frustrating) to diagnose. Control & Electrical Systems Troubleshooting covers the most common issues, how to fix them, and when to call a pro.

Common Issues & Step-by-Step Fixes

- CNC Controller Diagnostics: If your controller is showing error codes (e.g., “E024: Servo Drive Fault”), start by checking the user manual for code explanations. For example, a “Servo Drive & Motor Repair” issue often stems from a loose wire or a faulty encoder. We once helped a shop fix a controller error in 30 minutes—they were about to call a technician for a $500 service call.

- Parameter Backup & Restoration: Always back up your machine’s parameters (settings) before making changes. If parameters get corrupted (e.g., from a power surge), you can restore them in minutes. A medical device shop we worked with lost all their parameters after a storm—since they didn’t have a backup, it took 2 days to reconfigure everything, costing them $15,000 in lost production.

- Electrical Cabinet Cleaning: Dust and debris in the electrical cabinet can cause short circuits. Clean the cabinet every 3 months with compressed air (make sure the machine is turned off!). We once fixed a Short Circuit Diagnosis for a metal shop that was caused by dust buildup—after cleaning, their machine ran without issues for over a year.

When to DIY vs. Call a Pro

| Issue | DIY-Friendly? | When to Call a Pro |

| Parameter Backup | Yes | If backup fails |

| Electrical Cabinet Cleaning | Yes | If you spot damaged wires |

| Servo Drive Repair | No | Always (requires specialized tools) |

| PLC Program Recovery | No | Always (requires programming expertise) |

4. Accuracy Verification & Calibration: Keeping Your Cuts Precise

What’s the point of a CNC machine if it’s not accurate? Accuracy Verification & Calibration ensures your machine is cutting parts to the right specs—every time. Even small inaccuracies (e.g., 0.001 inches off) can ruin a part, especially in industries like aerospace or medical manufacturing. Let’s cover the key tests and how often you need them.

Essential Calibration Tests

- Laser Interferometer Calibration: This test measures how accurately your machine’s axes move. It can detect errors like backlash or pitch error. We recommend doing this once a year—for a shop making precision parts, a 0.0005-inch error can mean the difference between a usable part and a scrap one. A defense contractor we worked with used this test to fix a 0.0008-inch inaccuracy, which helped them win a $500,000 contract.

- Ballbar Testing: This quick test (it takes about 2 hours) checks for circular interpolation errors—critical for parts with curves. If your ballbar test shows errors over 0.001 inches, it’s time to adjust your machine. We once did a ballbar test for a automotive parts shop that was struggling with uneven cylinder bores; after calibration, their scrap rate dropped by 35%.

- Probe & Tool Setter Calibration: Your probe and tool setter ensure your machine knows where the part and tool are. If they’re out of calibration, your cuts will be off. Calibrate these tools every 3 months—we had a client who skipped this and ended up scrapping 50 parts before realizing their probe was off by 0.002 inches.

Why Accuracy Matters: The Cost of Inaccuracy

A study by the Manufacturing Technology Association found that **inaccurate CNC machines cost U.S. shops an average of \(12,000 a year in scrap parts and rework**. For high-precision industries (like medical devices), that number jumps to \)50,000 or more. Regular calibration isn’t just a “nice-to-have”—it’s a cost-saver.

5. Process Optimization & Support: Get More Out of Your CNC Machine

CNC machine service isn’t just about fixing problems—it’s about making your machine work better for you. Process Optimization & Support helps you reduce cycle time, extend tool life, and improve part quality. Let’s look at practical strategies and how they’ve helped real shops.

Practical Strategies for Better Performance

- Cutting Parameter Optimization: Adjusting your feed rate, spindle speed, and depth of cut can reduce cycle time by 10–20%. We worked with a aluminum extrusion shop that was running their spindle at 10,000 RPM for a cut that only needed 8,000 RPM—by lowering the speed, they extended their tool life by 40% and reduced cycle time by 15%.

- Vibration Damping Solutions: Vibration during cutting can lead to poor surface finish and shorter tool life. Simple fixes like adding a vibration dampener to your tool holder or securing your machine to the floor can make a big difference. A furniture shop we helped reduced their tool replacement costs by 25% with a $200 vibration dampener.

- Operator Training: Even the best machine won’t perform well if your operators don’t know how to use it. We offer 1-day training sessions that cover everything from basic troubleshooting to advanced parameter adjustments. A small machine shop we trained saw a 30% reduction in operator-caused errors after the session.

- Remote Technical Assistance: Many service providers (including us) offer remote support—we can log into your machine’s controller to diagnose issues without being on-site. This saves time: we once fixed a parameter issue for a client in 15 minutes, compared to the 2 days it would have taken for an on-site visit.

6. Retrofits & Modernization: Bring Old CNC Machines Up to Date

If you have an older CNC machine (10+ years old), you might be thinking: “Should I replace it or upgrade it?” Retrofits & Modernization is often the better choice—it costs 50–70% less than buying a new machine and can give your old equipment new life. Let’s cover the most impactful upgrades and when they’re worth it.

Top Retrofits for Older Machines

- CNC Control System Retrofit: Replacing an old control system (e.g., Fanuc 16i) with a new one (e.g., Fanuc 0i-F) can improve accuracy by 20% and make the machine easier to operate. We retrofitted a 15-year-old milling machine for a metal shop—after the upgrade, they could run more complex parts and reduced setup time by 40%.

- Safety System Modernization: Older machines often lack modern safety features like light curtains or emergency stop buttons. Adding these can help you comply with OSHA regulations and keep your operators safe. We upgraded a 20-year-old lathe for a job shop that was facing OSHA fines— the retrofit cost \(3,000, compared to the \)10,000 fine they would have paid.

- Fifth-Axis Integration: Adding a fifth axis to a 3-axis machine lets you cut complex parts (e.g., aerospace components) that you couldn’t before. This retrofit costs \(15,000–\)30,000, but it can open up new revenue streams. A custom parts shop we worked with added a fifth axis and won a $200,000 contract for aerospace parts they couldn’t have made before.

- Energy-Efficient Motor Retrofits: Old motors are inefficient—replacing them with energy-efficient models can reduce your electricity costs by 15–25%. We retrofitted a client’s 3 machines with new motors; they saved $12,000 a year on their energy bill.

Yigu Technology’s Perspective on CNC Machine Service

At Yigu Technology, we believe CNC machine service is more than just repairs—it’s a partnership to keep your production running smoothly. Too many shops see service as a “react” task (wait for a breakdown, then fix it), but we advocate for a “proactive” approach: combine regular preventive maintenance with strategic upgrades to minimize downtime and maximize efficiency. We’ve worked with over 500 shops across industries, and the ones that succeed are the ones that invest in service before problems happen. For example, a client who uses our monthly preventive maintenance program has reduced their unexpected downtime by 60% over 2 years. We also prioritize transparency—we always give you a detailed quote and timeline before starting any work, so you never have surprises. Whether you need a quick repair, a calibration, or a full retrofit, our goal is to help you get the most out of your CNC equipment.

FAQ: Your Top CNC Machine Service Questions Answered

Q1: How often should I schedule preventive maintenance for my CNC machine?

A: For high-use machines (running 8+ hours a day), we recommend monthly inspections and quarterly deep dives (vibration analysis, fluid testing). For low-use machines (2–3 hours a day), quarterly inspections and semi-annual deep dives are enough.

Q2: Is it better to repair a spindle or replace it?

A: It depends on the cost and age of the spindle. A rebuild typically costs 40–60% less than a replacement. If your spindle is less than 5 years old and the damage is minor (e.g., worn bearings), a rebuild is the way to go. If it’s over 10 years old or has major damage (e.g., a cracked housing), replacement is better.

Q3: How long does a CNC control system retrofit take?

A: Most retrofits take 1–2 weeks. We work around your schedule—many clients choose to do the retrofit during a weekend or holiday to avoid production downtime.

Q4: Can remote technical assistance fix most electrical issues?

A: Yes! About 70% of electrical issues (e.g., parameter errors, servo drive faults) can be fixed remotely. We only need access to your machine’s controller (via Ethernet or a USB drive) and can diagnose and fix the issue in 30 minutes to 2 hours.

Q5: How much does CNC machine calibration cost?

A: Calibration costs vary by the type of test: laser interferometer calibration is \(800–\)1,500, ballbar testing is \(400–\)800, and probe calibration is \(300–\)500. We offer a calibration package that includes all three tests for \(1,800–\)2,500 (a 15–20% discount compared to buying them separately).