In modern manufacturing, why do aerospace engineers choose 5-axis CNC machines while a small workshop uses 3-axis models? The answer lies in understanding the classifications of CNC machining—a framework that groups CNC systems by their capabilities, processes, and use cases. Choosing the wrong category leads to wasted costs, slow production, or failed parts. This article breaks down the 6 core classifications of CNC machining, their key features, real-world applications, and selection tips, helping you match the right CNC solution to your project needs.

What Are the Core Classifications of CNC Machining?

CNC machining (Computer Numerical Control machining) uses automated systems to shape materials, but not all CNC setups are the same. The industry classifies CNC machining based on 6 critical factors: processing technology, machine tool movement, automation degree, number of axes (degrees of freedom), application field, and special functional designs. Each classification solves unique manufacturing challenges—for example, metal cutting CNC machines handle shafts and gears, while laser cutting systems process non-metallic materials like glass.

1. Classification by Processing Technology

This category groups CNC machining by the type of material and the method used to shape it. It’s the most fundamental classification, as it directly ties to the material you’re working with. The table below details the two main subcategories and their key methods:

| Processing Category | Key Methods | Material Compatibility | Ideal Applications |

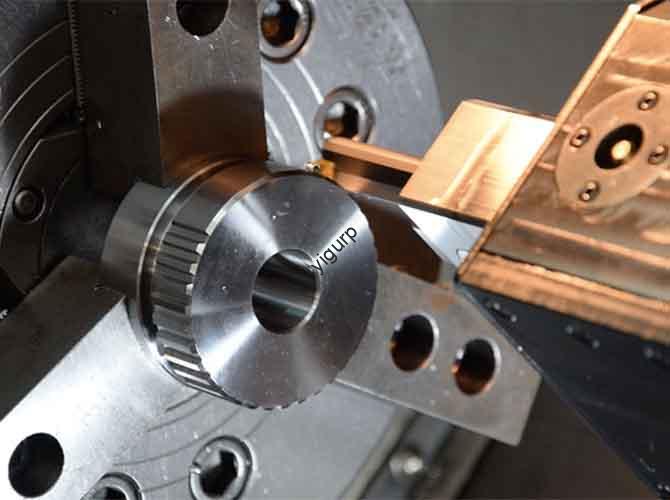

| Metal Cutting Processing | – Turning: Shapes rotating workpieces (e.g., shafts) to create outer circles, end faces. – Milling: Cuts complex shapes (slots, holes) with rotating tools. – Boring: Expands existing holes for higher accuracy. – Drilling: Creates through/blind holes with drill bits. – Reaming: Finishes drilled holes to improve surface smoothness. – Tapping: Adds internal threads to holes. | Ferrous metals (steel, iron), non-ferrous metals (aluminum, copper, titanium). | – Turning: Automotive engine shafts, bike pedals. – Milling: Mold cavities, laptop chassis. – Drilling: Electronic enclosure mounting holes. |

| Non-Metallic Material Processing | – Laser Cutting: Uses high-energy lasers to melt/vaporize materials. – Water Jet Cutting: Cuts with high-velocity water (plus abrasives for hard materials). – Electrical Discharge Machining (EDM): Removes material via electrode-workpiece discharge (for conductive materials). – Ultrasonic Machining: Uses high-frequency vibrations + abrasives to shape brittle materials. | Plastics (ABS, PEEK), glass, ceramics, composites (carbon fiber). | – Laser Cutting: Acrylic signage, plastic packaging. – Water Jet Cutting: Stone countertops, glass panels. – EDM: Carbide tooling, mold inserts. – Ultrasonic Machining: Ceramic medical implants, glass lenses. |

2. Classification by Machine Tool Movement Mode

This classification focuses on how the CNC machine’s tool and workpiece move relative to each other. It determines the complexity of shapes you can produce—from simple holes to curved aerospace parts.

| Movement Mode | Key Capabilities | Accuracy Level | Ideal Applications |

| Point Control Machines | Only controls tool position (no continuous path); moves directly from one point to another. | ±0.01mm (position accuracy); no path control. | Drilling machines (hole positioning), boring machines (single-hole expansion). |

| Linear Control Machines | Moves tool along straight paths (X, Y, Z axes) while cutting; supports constant feed rates. | ±0.005mm (linear accuracy); uniform surface finish. | Simple milling machines (flat surface cutting), lathes (straight shaft turning). |

| Contour Control Machines | Moves tool along complex curved trajectories (e.g., circles, parabolas); supports multi-axis linkage. | ±0.003mm (contour accuracy); handles 3D shapes. | Multi-axis machining centers (aerospace wing parts), mold-making machines (curved cavities). |

3. Classification by Degree of Automation

Automation level dictates how much human intervention is needed—critical for production volume and labor costs.

| Automation Level | Key Features | Labor Requirement | Ideal Production Scale |

| Semi-Automatic CNC Machines | Automates cutting/machining but needs manual steps (e.g., workpiece clamping, tool changes). | 1 operator per machine; constant supervision for manual tasks. | Small batches (10–50 parts), custom prototypes (e.g., one-off mold inserts). |

| Fully Automatic CNC Machines | Handles the entire process automatically: auto loading/unloading, auto tool change, auto quality checks. | 1 operator manages 2–3 machines; minimal supervision. | High-volume production (1,000+ parts), mass manufacturing (e.g., automotive components). |

4. Classification by Degrees of Freedom (Number of Axes)

The number of axes (linear + rotary) determines the machine’s ability to access complex part geometries. This is the most widely used classification for industrial CNC selection.

| Number of Axes | Key Axes Configuration | Capabilities | Ideal Industries/Parts |

| 3-Axis CNC Machines | 3 linear axes (X, Y, Z); tool moves along these axes to cut fixed workpieces. | Handles 2D/3D parts with simple geometries; no undercutting or complex curves. | General manufacturing (brackets, simple gears), consumer goods (plastic enclosures). |

| 4-Axis CNC Machines | 3 linear axes + 1 rotary axis (e.g., A-axis: rotates around X-axis). | Accesses side/angled features; reduces workpiece repositioning by 50%. | Aerospace (simple engine parts), medical (bone screws with angled holes). |

| 5-Axis CNC Machines | 3 linear axes + 2 rotary axes (e.g., A + B axes); tool can tilt/rotate freely. | Machines complex 3D surfaces (e.g., turbine blades) in one setup. | Aerospace (jet engine components), mold & die (deep cavities with undercuts), luxury automotive (curved body panels). |

5. Classification by Application Field

CNC machines are often tailored to specific industries—optimized for their unique materials and part requirements.

| Application Field | Machine Features | Material Focus | Example Parts |

| General-Purpose CNC Machines | Versatile; works with multiple materials and part types; easy to reconfigure. | Metals, plastics, composites. | General machinery (gearboxes), furniture hardware (hinges), electronic brackets. |

| Specialized CNC Machines | Customized for industry-specific needs (e.g., high-temperature resistance, small part precision). | Industry-specific materials (e.g., titanium for aerospace, food-grade stainless steel for medical). | – Automotive: Engine block machining lines. – Medical: Dental implant mills. – Aerospace: Titanium component lathes. |

6. Other Special Classifications

These include machines with unique, combined functions—designed to solve niche manufacturing challenges.

| Special Type | Key Functions | Key Advantage | Ideal Use Cases |

| Multi-Processing Machines | Combines 2+ machining types (e.g., turning + milling, drilling + laser cutting) in one machine. | Eliminates workpiece transfer between machines; cuts production time by 40%. | Complex parts needing multiple processes (e.g., automotive shafts with milled slots, medical tools with drilled holes + threaded ends). |

| Micromachining Machines | Focuses on ultra-small parts/features; achieves nanometer-level resolution. | Processes parts as small as 0.1mm (e.g., microelectronic components); high precision (±0.0001mm). | Microelectronics (semiconductor chips), medical devices (micro-needles), aerospace (micro-sensors). |

How to Choose the Right CNC Machining Classification?

Follow this 4-step process to avoid mismatched selections:

- Define Material & Geometry:

- If working with metal shafts → Metal cutting (turning) + 3-axis CNC.

- If making complex aerospace turbine blades → Contour control + 5-axis CNC.

- Match Automation to Volume:

- Small batches (10 parts) → Semi-automatic CNC.

- Mass production (10,000 parts) → Fully automatic CNC.

- Consider Budget & ROI:

- 5-axis machines cost 2–3x more than 3-axis models—only invest if complex parts justify the expense.

- Test with Prototypes:

- For high-stakes projects (e.g., medical implants), run a prototype on the chosen CNC type to validate accuracy and efficiency.

Yigu Technology’s Perspective

At Yigu Technology, we believe understanding classifications of CNC machining is the first step to smart manufacturing. Our product line covers all key classifications: 3/4/5-axis CNC machines for metal cutting, fully automatic lines for high-volume production, and specialized micromachining systems for microelectronics. We help clients select the right category by analyzing their material, volume, and geometry needs—for example, a automotive supplier switched from 3-axis to 5-axis machines, cutting part rework by 60%. As Industry 4.0 advances, we’re integrating AI into all classifications to auto-optimize tool paths, making CNC selection and operation even more accessible.

FAQ

- Q: Can a 5-axis CNC machine replace a 3-axis machine for simple parts?

A: Technically yes, but it’s not cost-effective. 5-axis machines have higher upfront costs (2–3x more) and longer setup times for simple parts. Stick to 3-axis machines for brackets, gears, or enclosures to save money.

- Q: Which CNC classification is best for non-metallic materials like glass?

A: Non-metallic material processing—specifically ultrasonic machining (for brittle glass) or laser cutting (for precise glass panels). Avoid metal cutting CNC machines, as they’ll crack or shatter glass.

- Q: How much more productive is a fully automatic CNC machine vs. a semi-automatic one?

A: Fully automatic machines are 2–3x more productive. For example, a semi-automatic CNC makes 50 parts/day (with operator breaks), while a fully automatic one makes 120–150 parts/day (24/7 operation with minimal labor).