CNC Machining PP Materials: A Practical Guide to Precision and Efficiency

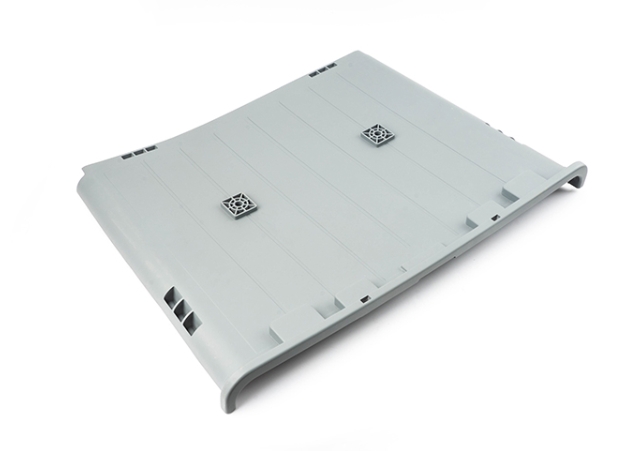

PP (polypropylene) is a widely used thermoplastic in industries like packaging, automotive, and medical—thanks to its chemical stability and processability. But achieving high-quality results with CNC machining PP materials requires addressing unique challenges, such as low melting points and deformation risks. This guide solves these pain points by breaking down PP’s properties, tool selection, process […]