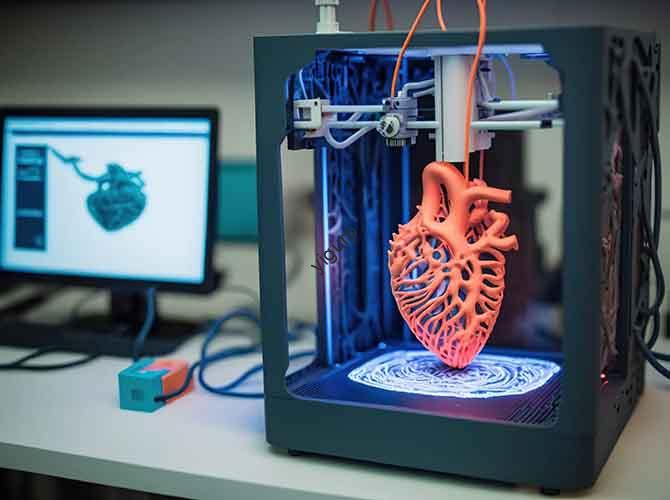

10 High-Strength 3D Printing Materials: A Guide for Engineers and Buyers

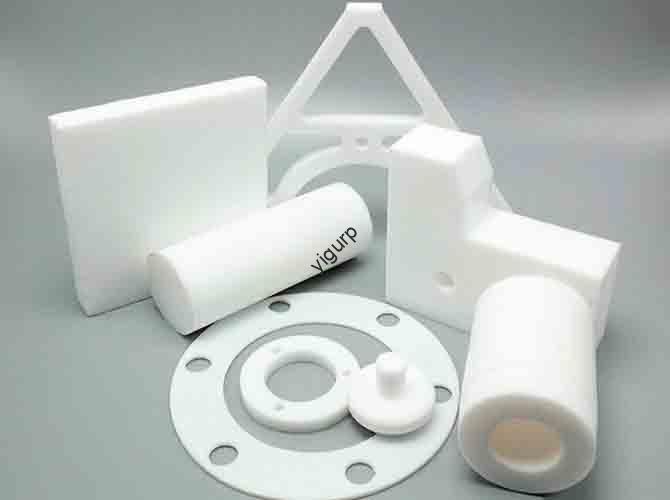

When it comes to 3D printing, strength and durability are make-or-break factors for many projects—whether you’re creating automotive parts, aerospace components, or industrial tools. Not all 3D printing materials are built to handle heavy loads, high temperatures, or harsh chemicals. That’s why we’ve put together this guide to 10 high-strength 3D printing materials from industry […]