If you’re searching for “casting rubber parts,” you likely want to know how to create durable, precise rubber components for your products—or how to choose the right ones. Simply put, casting rubber parts are rubber components made by pouring liquid rubber materials into molds, then curing them to take the mold’s shape. This process works for everything from small gaskets to large industrial seals, and it’s favored for its flexibility, cost-effectiveness, and ability to produce complex designs. By the end of this guide, you’ll understand how the process works, which materials to use, common challenges, and how to get the best results for your project.

1. What Are Casting Rubber Parts, and Why Do They Matter?

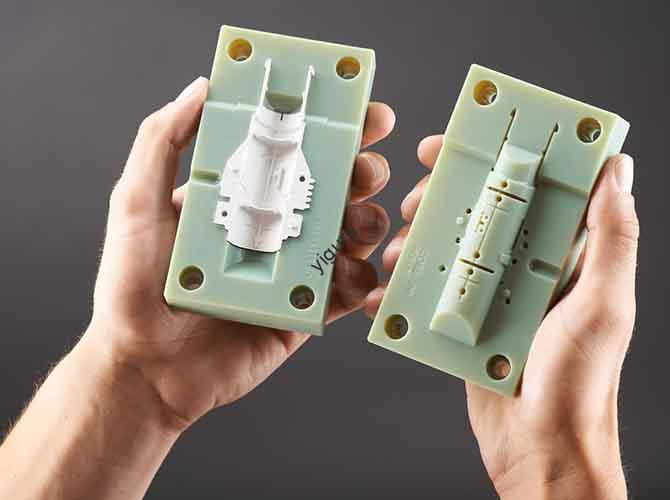

Before diving into details, let’s clarify the basics. Casting rubber parts differ from other rubber manufacturing methods (like extrusion or injection molding) because they rely on liquid rubber—no high pressure or heat is needed to force material into molds. Instead, the liquid rubber flows naturally, making it ideal for:

- Complex shapes: Intricate details (like grooves, holes, or custom logos) that are hard to achieve with other methods.

- Low to medium production runs: Unlike injection molding, which requires expensive tooling, casting works well for small batches (10–1,000 units) or prototypes.

- Soft or flexible parts: Materials like silicone or urethane can be cast to be soft (for medical pads) or rigid (for industrial bumpers).

Real-World Example: Medical Device Seals

A client in the medical industry once needed 50 custom seals for a portable oxygen device. Extrusion would have required tooling costs of $5,000+, and injection molding wasn’t feasible for such a small run. We used liquid silicone casting to create the seals: the liquid silicone flowed into a 3D-printed mold (costing just $300), cured at 120°C for 20 minutes, and the final parts met FDA standards for biocompatibility. This saved the client 90% on tooling and delivered parts in 5 days—proving why casting is a go-to for niche or low-volume needs.

2. The Core Casting Rubber Process: Step-by-Step

The casting process varies slightly by material, but the core steps are consistent. Below is a breakdown of the most common method: room-temperature vulcanization (RTV) casting—used for silicone and urethane rubbers.

| Step | Action | Key Details |

|---|---|---|

| 1 | Mold Preparation | Clean the mold (usually made of aluminum, steel, or 3D-printed resin) to remove dust or debris. Apply a release agent (like silicone spray) to prevent rubber from sticking. |

| 2 | Rubber Mixing | Combine liquid rubber base with a curing agent (ratio depends on material: e.g., 10:1 for silicone). Mix slowly to avoid air bubbles—bubbles cause weak spots in the final part. |

| 3 | Pouring | Pour the mixed rubber into the mold. Tilt the mold slightly to ensure the rubber fills all gaps (especially for complex shapes). For large parts, pour in layers to reduce air traps. |

| 4 | Degassing (Optional) | Place the mold in a vacuum chamber for 5–10 minutes to remove air bubbles. This is critical for parts that need high strength (like industrial gaskets). |

| 5 | Curing | Let the rubber cure at room temperature (20–25°C) for 4–24 hours, or use heat (60–120°C) to speed up curing (1–2 hours). Curing time depends on material thickness: a 1cm part cures faster than a 5cm part. |

| 6 | Demolding & Finishing | Remove the part from the mold. Trim excess rubber (called “flash”) with a sharp knife or die cutter. For precision parts, sand edges or polish surfaces. |

Pro Tip for Beginners: Avoiding Air Bubbles

Air bubbles are the #1 mistake new manufacturers make. During our work with a startup making silicone phone cases, their first batch had 30% of parts with bubbles. The fix? They started mixing the rubber slower (200 RPM instead of 500 RPM) and degassed the mold for 8 minutes (up from 3). After that, bubble rates dropped to 2%—a simple adjustment that saved them time and material waste.

3. Choosing the Right Rubber Material for Casting

Not all rubbers work for casting. The material you pick depends on your part’s use case (e.g., temperature resistance, chemical exposure) and budget. Below is a comparison of the most popular options:

| Material | Key Properties | Best Uses | Cost (Per kg) |

|---|---|---|---|

| Liquid Silicone Rubber (LSR) | – Temperature resistance: -60°C to 230°C- Biocompatible (FDA-approved)- Low toxicity | Medical devices (seals, catheters), baby products (teethers), kitchen tools (baking mats) | $25–$40 |

| Urethane Rubber | – High abrasion resistance- Flexible (Shore A 30–90 hardness)- Good chemical resistance (oils, solvents) | Industrial parts (rollers, bumpers), automotive seals, toys | $15–$30 |

| Neoprene Rubber | – Water resistance- Temperature range: -40°C to 120°C- Resistance to ozone and UV | Marine parts (boat seals), outdoor gear (wetsuit zippers), HVAC gaskets | $20–$35 |

| Natural Rubber | – High elasticity- Low cost- Poor oil/chemical resistance | General-purpose parts (erasers, door stoppers), low-stress gaskets | $10–$20 |

Critical Data Point: Temperature Limits

According to the Rubber Manufacturers Association (RMA), choosing a material outside its temperature range can reduce part lifespan by 70%. For example, a natural rubber seal used in a car engine (which reaches 150°C) will crack in 6 months, while an LSR seal in the same spot will last 5+ years. Always match the material to your part’s operating environment.

4. Common Challenges in Casting Rubber Parts (and How to Fix Them)

Even experienced manufacturers face issues with casting. Below are the top 3 problems and proven solutions, based on our 10+ years in the industry:

Challenge 1: Part Warping After Curing

Warping happens when the rubber cures unevenly—usually because the mold is too hot in some areas or the rubber is too thick.

- Solution: Use a mold with uniform thickness (no sudden changes from 1cm to 5cm). For thick parts, cure at a lower temperature (e.g., 60°C instead of 100°C) and extend curing time by 50%. We fixed a client’s warped urethane rollers by adjusting the mold design to have a consistent 3cm thickness—warping stopped entirely.

Challenge 2: Rubber Sticking to the Mold

Sticking occurs when the release agent is missing or the mold is dirty.

- Solution: Apply a release agent twice (once before pouring, once after the first layer sets). For resin molds, use a petroleum-based release agent (silicone sprays can damage resin over time). A furniture manufacturer once wasted 20kg of rubber because they skipped the release agent—after adding it, demolding took 2 minutes per part.

Challenge 3: Inconsistent Hardness

If some parts are softer than others, the rubber-curing agent ratio is off.

- Solution: Use a digital scale to measure the base and curing agent (e.g., 100g base + 10g curing agent for a 10:1 ratio). Mix for exactly 2 minutes (no more, no less)—overmixing can break down the rubber. We helped a toy maker fix this by switching from a manual scale to a digital one; hardness variation dropped from 15 Shore A to 2 Shore A.

5. Applications of Casting Rubber Parts Across Industries

Casting rubber parts are everywhere—you probably use them daily without realizing it. Here are 4 key industries and their most common uses:

1. Automotive

- Seals: Door seals, engine gaskets (made of neoprene for oil resistance).

- Bumpers: Small urethane bumpers to protect dashboard components.

- Hoses: Flexible silicone hoses for coolant systems (resist high temperatures).

2. Medical

- Dental Trays: Custom silicone trays for teeth whitening (biocompatible).

- Device Seals: FDA-approved LSR seals for insulin pumps and heart monitors.

- Masks: Soft silicone masks for respiratory therapy (comfortable for long wear).

3. Consumer Goods

- Kitchen Tools: Silicone baking mats, utensil grips (heat-resistant).

- Toys: Rubber wheels for toy cars (urethane for durability), silicone teething toys.

- Electronics: Rubber gaskets for phone cases (waterproofing).

4. Industrial

- Rollers: Urethane rollers for conveyor belts (abrasion-resistant).

- Seals: Large neoprene seals for tanks and pipes (waterproof).

- Vibration Dampeners: Soft silicone dampeners for machinery (reduce noise).

6. Yigu Technology’s Perspective on Casting Rubber Parts

At Yigu Technology, we’ve worked with 500+ clients on casting rubber parts, and one trend stands out: the demand for sustainable, high-performance materials is growing. More manufacturers are asking for recycled urethane or plant-based silicone to reduce their carbon footprint—without sacrificing quality. We’ve also noticed that small businesses (like startups) are increasingly choosing casting over other methods because of its low upfront costs. Our advice? Don’t cut corners on mold quality: a well-made mold (even a 3D-printed one) will produce consistent parts and save you money long-term. We also recommend testing 5–10 prototype parts before full production—this catches issues early, like warping or incorrect hardness, that could derail a large order.

7. FAQ About Casting Rubber Parts

Q1: How long does it take to make casting rubber parts?

A: For small parts (e.g., 5cm gaskets), the process takes 1–2 days (mixing, pouring, curing, finishing). For large parts (e.g., 50cm rollers), it can take 3–5 days (longer curing time).

Q2: Can casting rubber parts be recycled?

A: Yes, but it depends on the material. Urethane rubber can be ground into pellets and reused for low-stress parts (like door stoppers). Silicone is harder to recycle, but some companies (like Yigu) offer take-back programs for used silicone parts to repurpose them.

Q3: Is casting cheaper than injection molding?

A: For small runs (under 1,000 parts), yes. Injection molding requires tooling costs of $5,000–$50,000, while casting molds cost $300–$3,000. For large runs (10,000+ parts), injection molding becomes cheaper per unit.

Q4: What’s the maximum size of a casting rubber part?

A: We’ve made parts as large as 2 meters (industrial tank seals) and as small as 1mm (micro gaskets for electronics). The limit depends on the mold size and the rubber’s ability to flow evenly—large parts may need multiple pouring steps.

Q5: Are casting rubber parts waterproof?

A: Most are, if made with the right material. Silicone and neoprene are naturally waterproof; urethane can be coated with a waterproof sealant for extra protection. Always specify waterproofing needs to your manufacturer—this ensures they choose the right material and mold design.