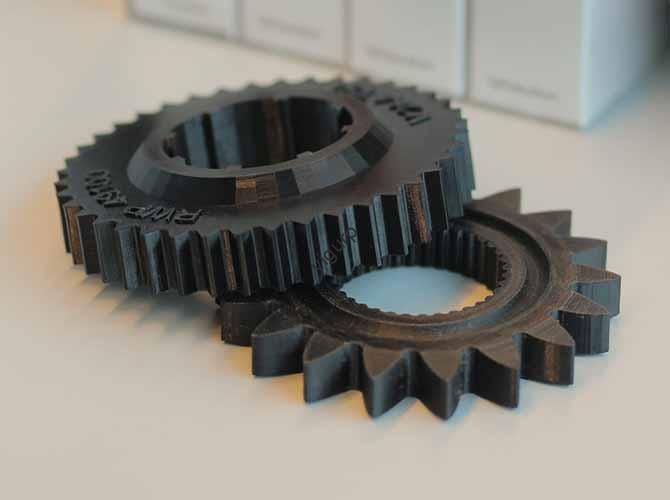

Production Processes of Plastic Prototypes: From Traditional Methods to Modern CNC Machining

If you’ve ever wondered how new product ideas transform from digital designs into physical objects you can hold and test, the answer lies in plastic prototype production processes. These processes have evolved dramatically over the years, moving from manual craftsmanship to high-precision digital manufacturing. In this guide, we’ll explore the journey of plastic prototype production—from […]