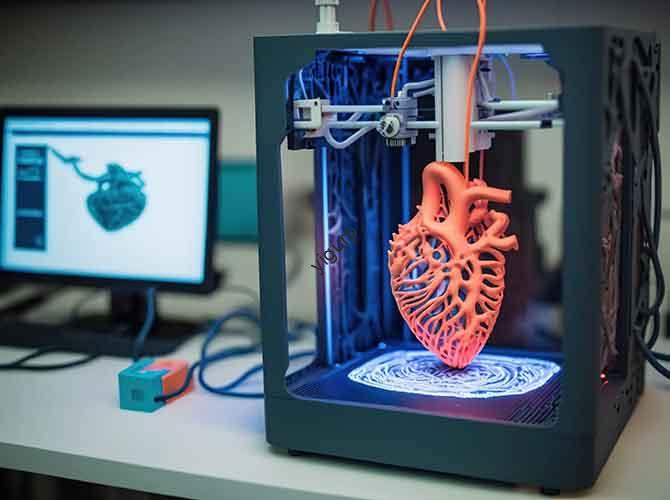

FDM Process 3D Printed Nylon Prototype Model: Guide for Engineers & Buyers

If you’re an engineer testing product designs or a buyer sourcing cost-effective prototypes, the FDM process 3D printed nylon prototype model is a game-changer. It blends speed, affordability, and flexibility—making it ideal for industries from automotive to consumer goods. This guide breaks down everything you need to know, with real cases and hard data to help you […]