3D Printing Materials Requirements: A Practical Checklist for Every Project

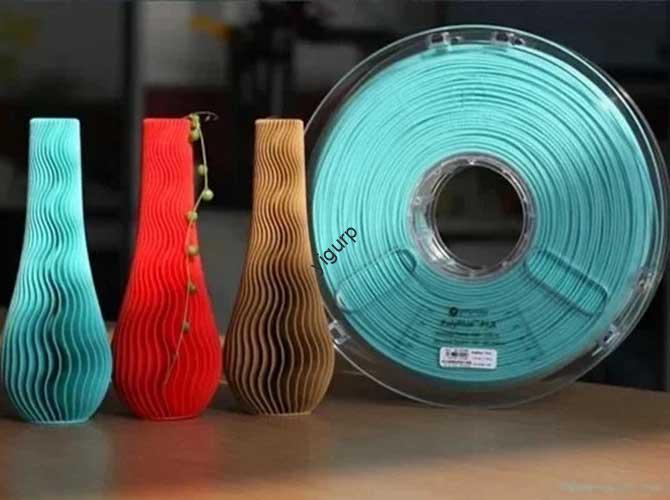

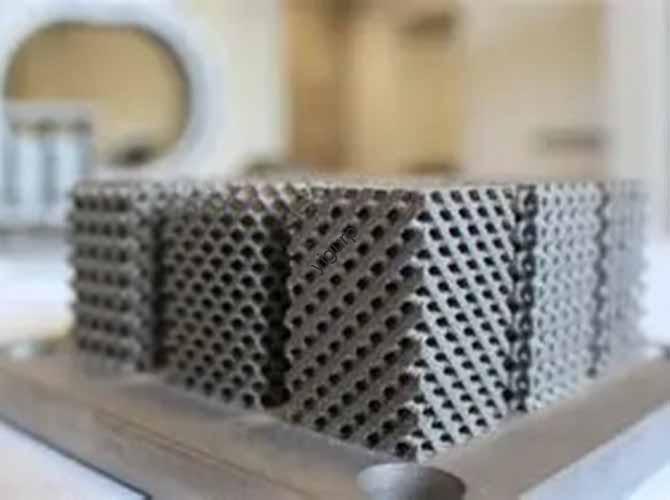

Choosing the right 3D printing material isn’t just about picking something that “works”—it’s about ensuring the material meets strict 3D printing materials requirements that align with your project’s goals. Whether you’re printing a medical implant, an outdoor bracket, or a decorative figurine, four core areas define material suitability: physical/chemical properties, processability, economy, and safety. Overlooking […]