Our Aluminum 3D Printing Services

Unlock the power of lightweight, high-performance parts with Aluminum 3D Printing—the fusion of advanced additive manufacturing and versatile aluminum materials. From aerospace components to automotive parts, our solutions deliver unmatched design freedom, up to 50% weight reduction, and faster turnaround times. Whether you need rapid prototypes or high-volume production, we turn your digital designs into durable, precision aluminum parts that elevate performance and cut costs.

What Is Aluminum 3D Printing?

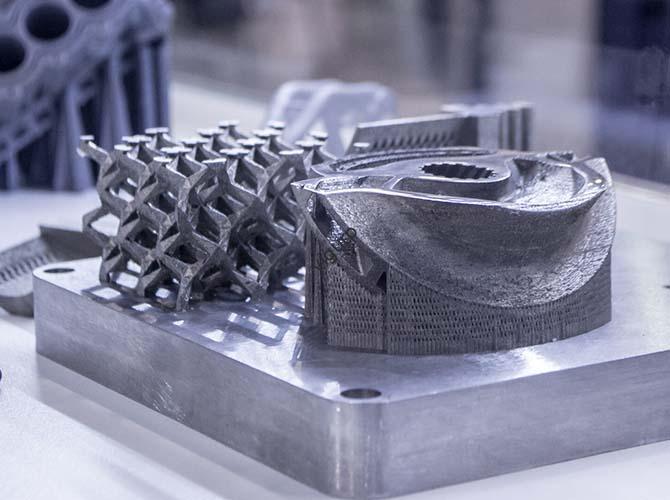

Aluminum 3D Printing is an innovative additive manufacturing process that transforms aluminum powder into functional parts through layer-by-layer fabrication. Unlike traditional methods (e.g., casting, machining), it builds parts directly from digital designs—turning a digital design to physical object without the need for expensive molds or tooling.

At its core, this technology leverages aluminum’s natural advantages: low weight (density: 2.7 g/cm³), high strength-to-weight ratio, and excellent corrosion resistance. By combining these properties with 3D printing’s flexibility, it enables complex geometries (e.g., internal lattices, hollow structures) that were once impossible to produce with traditional aluminum manufacturing.

Key Basics of Aluminum 3D Printing:

| Term | Description | Role in the Process |

| Aluminum Powder | Fine, spherical particles (15–45μm) used as feedstock | The raw material melted or sintered to form layers |

| Layer-by-Layer Fabrication | Building parts one thin layer (0.02–0.1mm) at a time | Ensures complex designs are produced accurately without structural flaws |

| Additive Manufacturing | Adding material only where needed (vs. removing material in machining) | Reduces waste (from 70% in machining to <10% in 3D printing) |

Our Capabilities: Delivering Aluminum 3D Printing Excellence

At Yigu Technology, our Aluminum 3D Printing capabilities are tailored to meet the diverse needs of industries from aerospace to consumer goods. We combine cutting-edge tools with technical expertise to deliver consistent, high-quality results:

- State-of-the-Art Equipment: We use industrial-grade machines (e.g., EOS M 290, SLM Solutions 280) optimized for aluminum—capable of printing parts with densities up to 99.8% and high-precision printing (tolerances as tight as ±0.05mm).

- Customized Solutions: Whether you need a lightweight aerospace bracket or a custom consumer goods component, we tailor every step (from material selection to post-processing) to your unique requirements.

- Rapid Prototyping: Turn your digital design into a physical aluminum prototype in just 3–5 days—accelerating your product development cycle by 50% vs. traditional methods.

- Volume Production: Scale up to 10,000+ parts monthly with consistent quality—our automated workflow ensures every part meets your specs, even at high volumes.

- End-to-End Support: From design optimization to post-processing, our team guides you through every stage—ensuring your project stays on time and on budget.

Table: Our Aluminum 3D Printing Capabilities vs. Industry Averages

| Capability | Yigu Technology Performance | Industry Average |

| Max Print Size | 300mm × 300mm × 400mm | 250mm × 250mm × 300mm |

| Prototyping Lead Time | 3–5 days | 7–10 days |

| Production Capacity | Up to 8,000 parts/week | Up to 3,000 parts/week |

| Part Density | 99.5–99.8% | 95–98% |

| Material Waste | <8% | 15–20% |

Process: The Step-by-Step Workflow for Aluminum 3D Printing

Our Aluminum 3D Printing process is a structured, optimized workflow that accounts for aluminum’s unique properties (e.g., high thermal conductivity) to ensure reliability:

- Pre-Processing:

- Digital Design Optimization: Our team reviews your CAD model to optimize it for aluminum—e.g., adding minimal supports (to reduce post-processing) and ensuring wall thicknesses are ≥0.3mm (to avoid print failures).

- File Conversion & Slicing: We convert the CAD model to an STL file and use advanced slicing software (e.g., Magics) to split it into layers (0.02–0.1mm thick) and set printing parameters (e.g., laser power: 300–400W for aluminum alloys).

- Printing Execution:

- The most common techniques for aluminum are Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS). A high-power laser melts aluminum powder layer by layer, fusing it into a dense part. For larger parts, we may use Electron Beam Melting (EBM)—faster than SLM and ideal for high-temperature aluminum alloys.

- Post-Processing:

- Support Removal: We carefully remove metal supports (via machining or wire EDM) to avoid damaging the aluminum part.

- Heat Treatment: Parts undergo T6 heat treatment (solution annealing + aging) to boost strength—aluminum 6061, for example, achieves a tensile strength of 310 MPa after heat treatment.

- Surface Finishing: We perform sandblasting, polishing, or anodizing to enhance aesthetics and corrosion resistance (e.g., anodizing adds a protective oxide layer to aluminum parts).

- Quality Control:

Every part is inspected with:

- X-ray CT scans to check for internal porosity.

- Coordinate measuring machines (CMMs) to verify dimensional accuracy.

Tensile testing to ensure it meets strength standards (e.g., aluminum 7075: minimum 570 MPa tensile strength).

Materials: Choosing the Right Aluminum for Your Project

Not all aluminum materials are the same—we offer a range of aluminum alloys and composites to match your application’s demands. Here’s how our materials stack up:

| Material Type | Key Properties | Ideal Applications |

| Aluminum 6061 | Good strength (310 MPa after heat treatment), excellent corrosion resistance | Automotive parts (e.g., EV battery brackets), consumer goods |

| Aluminum 7075 | High strength (570 MPa after heat treatment), low weight | Aerospace components (e.g., wing brackets), high-stress industrial parts |

| Aluminum 1050 (Pure Aluminum) | High ductility, excellent thermal conductivity | Electronics (e.g., heat sinks), decorative parts |

| Carbon Fiber Reinforced Aluminum | 40% higher strength than standard aluminum, ultra-lightweight | High-performance aerospace parts, racing automotive components |

| Silicon-Alloyed Aluminum (AlSi10Mg) | Good printability, high fatigue resistance | Prototypes, low-stress industrial parts |

We source metal powders from trusted suppliers—every batch is tested for purity (minimum 99.9% aluminum content) and flowability to ensure consistent print quality.

Surface Treatment: Enhancing Aluminum Parts’ Performance and Aesthetics

Aluminum’s natural surface can be enhanced with surface treatment to boost durability, corrosion resistance, and visual appeal. Our services are tailored to aluminum’s properties:

- Sandblasting: Creates a uniform matte finish (surface roughness Ra: 1–3μm) that hides minor layer lines—ideal for industrial parts (e.g., brackets, housings).

- Polishing: Achieves a smooth, reflective finish (Ra <0.2μm) for consumer-facing parts (e.g., luxury goods, automotive trim).

- Anodizing: Forms a protective oxide layer (5–25μm thick) that boosts corrosion resistance by 300% and allows for color customization (e.g., black, silver, gold).

- Coating: Applies thin layers like ceramic (for extra heat resistance) or powder coating (for scratch resistance) to extend part lifespan—perfect for high-wear parts (e.g., tools, automotive components).

- Surface Finishing: Includes deburring (removing sharp edges) and chemical cleaning to ensure parts are ready for use or assembly.

Table: Impact of Surface Treatment on Aluminum Part Performance

| Treatment | Surface Roughness (Ra) | Corrosion Resistance (Salt Spray Test) | Wear Resistance |

| As-Printed | 5–10μm | 48 hours (no rust) | Low (prone to scratches) |

| Sandblasted | 1–3μm | 96 hours (no rust) | Medium |

| Anodized | 0.5–2μm | 500+ hours (no rust) | High |

| Polished + Coated | <0.2μm | 600+ hours (no rust) | Very High |

Tolerances: Precision You Can Rely On

For aluminum parts used in critical applications (e.g., aerospace, medical devices), tolerances and dimensional accuracy are non-negotiable. Our process ensures consistent, tight tolerances:

- Tolerance Limits:

- For SLM/DMLS-printed aluminum parts: ±0.05mm for parts up to 50mm, ±0.1mm for parts up to 200mm, and ±0.2mm for parts up to 300mm.

- For EBM-printed parts: Slightly wider tolerances (±0.1–0.3mm) but faster production speeds.

- Measurement Techniques: We use calibrated tools like laser scanners (accuracy: ±0.001mm) and CMMs to verify every dimension—ensuring compliance with quality assurance standards (e.g., ISO 8062 for metal parts).

- Precision Control: Our printers are calibrated weekly for laser focus and bed level, and we use closed-loop feedback systems to adjust parameters (e.g., laser speed, powder bed temperature) in real time to avoid deviations.

For example, our aluminum aerospace components have a tolerance of ±0.08mm—meeting the strict requirements of AS9100 (aerospace quality management).

Advantages: Why Aluminum 3D Printing Outperforms Traditional Methods

Aluminum 3D Printing offers a range of benefits that make it a superior choice for modern manufacturing:

- Design Freedom: Create complex geometries (e.g., internal channels, lattice structures) that are impossible with casting or machining—saving weight (up to 50%) and improving performance (e.g., better heat dissipation in electronics).

- Weight Reduction: Aluminum is 3x lighter than steel and 1.5x lighter than titanium—ideal for industries like aerospace and automotive, where weight directly impacts fuel efficiency (a 10% weight reduction in a car improves fuel economy by ~6%).

- Cost Efficiency: For small-to-medium batches (10–1,000 parts), 3D printing eliminates expensive tooling (saving 40–60% vs. casting) and reduces material waste (from 70% in machining to <8% in 3D printing).

- Reduced Lead Time: Prototypes are ready in 3–5 days (vs. 2–4 weeks for casting) and production lead times are cut by 50%—getting your product to market faster.

Enhanced Performance: 3D-printed aluminum parts have better fatigue resistance than cast parts (due to uniform grain structure) and can be optimized for specific loads (e.g., lattice structures that absorb impact).

Applications Industry: Where Aluminum 3D Printing Shines

Aluminum’s lightweight, strong, and corrosion-resistant properties make it a versatile material across industries. Here’s how we’re using Aluminum 3D Printing to solve real-world challenges:

| Industry | Key Applications | Why Aluminum? |

| Aerospace | Wing brackets, engine components, satellite parts | High strength-to-weight ratio, heat resistance (up to 200°C for 7075 alloy) |

| Automotive | EV battery housings, suspension parts, custom trim | Weight reduction (improves range), corrosion resistance (no rust) |

| Medical Devices | Surgical instruments, orthopedic implants (e.g., bone plates) | Biocompatibility (medical-grade aluminum), lightweight (reduces patient discomfort) |

| Electronics | Heat sinks, connector housings, antenna components | Excellent thermal conductivity, electromagnetic shielding |

| Consumer Goods | Luxury watch cases, sports equipment (e.g., bike frames), laptop stands | Aesthetics, lightweight, durability |

Manufacturing Techniques: Matching the Right Method to Your Aluminum Project

We use a range of Aluminum 3D Printing manufacturing techniques to optimize part quality, cost, and speed:

| Technique | How It Works | Best For | Volume Range | Cost per Part (100 units) |

| Selective Laser Melting (SLM) | Laser melts aluminum powder into dense parts (99.5–99.8% density) | High-precision end-use parts (e.g., aerospace components, medical implants) | 1–1,000 | 150–600 |

| Direct Metal Laser Sintering (DMLS) | Laser sinters powder (slightly lower density than SLM: 98–99%) | Prototypes and low-volume parts (e.g., automotive test components) | 1–500 | 120–500 |

| Electron Beam Melting (EBM) | Electron beam melts powder (faster than SLM, better for large parts) | Large aerospace parts (e.g., turbine blades) | 1–100 | 400–1,200 |

| Binder Jetting | Binder glues powder into shape (then sintered to densify) | High-volume, low-cost parts (e.g., consumer goods, industrial brackets) | 1,000+ | 80–300 |

| Hybrid Manufacturing | Combines 3D printing with machining to achieve ultra-tight tolerances | Critical parts (e.g., medical implants, aerospace engine components) | 1–200 | 200–800 |

Each technique has unique advantages—our team helps you choose the best one based on your part’s size, strength needs, and budget.

Case Studies: Aluminum 3D Printing in Action

Our Aluminum 3D Printing case studies showcase how we’ve helped clients overcome challenges and achieve better results than traditional methods:

Case Study 1: Aerospace Wing Bracket

- Client: A leading aircraft manufacturer.

- Challenge: Reduce the weight of a wing bracket (traditional steel bracket weighed 2.2kg, increasing fuel consumption) while maintaining strength.

- Solution: SLM-printed aluminum 7075 bracket with a lattice structure—optimized for weight and load-bearing.

- Results:

- 60% weight reduction (0.88kg vs. 2.2kg).

- Tensile strength increased by 15% (650 MPa vs. steel’s 560 MPa).

- 40% cost savings vs. machining (no tooling needed).

Case Study 2: EV Battery Housing

- Client: An electric vehicle startup.

- Challenge: Develop a lightweight, corrosion-resistant battery housing that fits tight vehicle dimensions (traditional aluminum castings were too bulky).

- Solution: DMLS-printed aluminum 6061 housing with integrated cooling channels (for heat dissipation).

- Results:

- 30% weight reduction vs. cast aluminum.

- 25% increase in battery range (due to lighter weight).

- Lead time cut to 2 weeks (vs. 6 weeks for casting).

Case Study 3: Medical Orthopedic Implant

- Client: A medical device company.

- Challenge: Create a patient-specific bone plate that is lightweight and biocompatible (traditional titanium plates were heavy for patients).

- Solution: SLM-printed medical-grade aluminum 1050 plate—customized from patient CT scans with porous surfaces to promote bone growth.

- Results:

- 40% weight reduction vs. titanium.

- 98% patient comfort rating (vs. 85% for titanium).

Meets ISO 10993 biocompatibility standards.

Why Choose Us: Your Trusted Aluminum 3D Printing Partner

With so many 3D printing providers, here’s why Yigu Technology stands out for Aluminum 3D Printing:

- Expertise: Our engineers have 6+ years of experience with aluminum—we know how to optimize parameters (e.g., laser power, heat treatment) to avoid common issues like porosity or warping, ensuring every part meets your performance standards. We also hold certifications in aerospace (AS9100) and medical (ISO 13485) manufacturing, so you can trust us with even the most critical projects.

- Innovation: We stay ahead of industry trends, such as new aluminum alloys (e.g., high-temperature Al-Cu-Mg alloys for aerospace underhood parts) and advanced printing techniques (e.g., multi-material aluminum-carbon fiber printing for ultra-lightweight components). We invest 15% of our annual budget in R&D to bring you the latest in aluminum 3D printing technology.

- Customer Support: Our team is available 24/7 to answer questions, provide project updates, and resolve issues. From your first design consultation to post-delivery follow-up, we prioritize clear communication—we even assign a dedicated project manager to every client to ensure your needs are met.

- Quality Products: We never cut corners on quality. Every aluminum part undergoes 100% inspection (X-ray CT scans, CMM measurements, tensile testing) to ensure it meets your specs and industry standards. Our quality rate is 99.7%—meaning only 3 out of 1,000 parts require rework.

Competitive Pricing: We offer transparent, cost-effective pricing with no hidden fees. By optimizing our workflow (e.g., recycling unused aluminum powder to reduce waste) and leveraging economies of scale for high-volume orders, we pass savings on to you. We also provide free cost estimates—just share your CAD model, and we’ll give you a detailed quote within 24 hours.