If you’re in product development—whether for electronics, medical devices, or consumer goods—you’re always looking for ways to make prototypes faster, cheaper, and more accurately. That’s where vacuum casting (also called vacuum replication) shines. But what exactly makes it stand out from other methods like injection molding or 3D printing?

In this guide, we’ll break down the 9 key advantages of vacuum casting, with real-world examples, data, and practical insights to help you decide if it’s the right fit for your next project. Our goal is to answer the question: Why should you choose vacuum casting over other manufacturing methods?

1. Cost-Effectiveness: Save Money on Low-Demand & Complex Parts

One of the biggest draws of vacuum casting is its low cost—especially for small batches or complex designs. Unlike traditional steel molds (used in injection molding), which can cost $10,000–$50,000 and take weeks to make, vacuum casting uses affordable silicone molds that cost just $500–$2,000.

This makes it perfect for:

- Early-stage prototypes (you don’t want to invest in expensive tooling before validating your design).

- Low-demand products (e.g., custom medical devices for a small clinic, limited-edition consumer goods).

- Complex parts (silicone molds are cheaper to make than steel molds for intricate shapes).

Example: A startup developing a new smart thermostat needed 30 prototypes to test user interaction. Using vacuum casting, they spent $800 on a silicone mold and $300 on casting materials—total $1,100. If they’d used injection molding, the steel mold alone would have cost $12,000.

2. Fast Speed: Shorten Your Production Cycle

Time is critical in product development, and vacuum casting delivers speed that’s hard to beat. The entire process—from creating a master prototype to getting finished parts—takes just 3–5 days, compared to 2–4 weeks for injection molding.

Here’s a breakdown of the timeline to show how fast it is:

- Make the master prototype (1–2 days, using SLA 3D printing or CNC machining).

- Create the silicone mold (1–2 days: mix silicone, pour, cure, and demold).

- Cast and finish parts (1 day: pour material, cure, and add small touches like sanding).

Pro Tip: For urgent projects, you can speed up curing time (e.g., heat the silicone mold to 30–35°C to cut curing time from 8–12 hours to 4–6 hours).

Case Study: A medical device company needed 20 syringe prototypes for a regulatory test in 4 days. Using vacuum casting, they delivered the parts on time—something injection molding (which needs 2+ weeks for a mold) couldn’t have done.

3. High Precision: Meet Tight Tolerances for Most Prototypes

Vacuum casting isn’t just fast and cheap—it’s also precise. The standard replication accuracy is ±0.20mm per 100mm of part size, which meets the needs of 90% of prototype and small-batch projects.

To put this in perspective:

- A typical phone case is 150mm long—vacuum casting would keep the error to just ±0.30mm (smaller than a grain of rice).

- A small medical sensor (50mm wide) would have an error of ±0.10mm—perfect for parts that need to fit with other components.

Why it’s so precise: The vacuum removes air bubbles from both the silicone mold and the casting material, ensuring every detail (even tiny textures or logos) is captured accurately.

Example: An electronics company used vacuum casting to make 50 wireless earbud prototypes. The charging port (which needs to fit a USB-C cable) had an accuracy of ±0.15mm—all 50 prototypes worked with standard cables, no adjustments needed.

4. Excellent for Complex Structures & Uniform Wall Thickness

Traditional methods like injection molding struggle with complex parts (e.g., parts with undercuts, thin walls, or intricate textures)—they often require expensive, multi-piece steel molds. Vacuum casting, however, excels at complex designs because silicone molds are flexible and can easily replicate even the most detailed shapes.

It’s also great for parts with uniform wall thickness (critical for structural strength and consistent curing). The vacuum ensures the casting material flows evenly into every corner of the mold, preventing thin spots or unevenness.

Common complex parts made with vacuum casting:

- Medical devices (e.g., syringe plungers with tiny channels for fluid).

- Automotive components (e.g., sensor housings with multiple ports).

- Electronics (e.g., laptop hinge covers with small gears).

Case Study: A robotics company needed a prototype arm joint with 3 small gears and 2 undercuts. Injection molding would have required a $15,000 3-piece mold, but vacuum casting used a single $1,200 silicone mold—and the parts worked perfectly in testing.

5. Color Variety: Customize Appearance for Marketing & Testing

Unlike 3D printing (which often requires post-paint work) or injection molding (which needs color-matched pellets), vacuum casting lets you easily create parts in almost any color—right during the casting process.

How it works:

- Add liquid dye to the casting material (e.g., PU resin, ABS) before pouring it into the mold.

- Choose from standard colors (black, white, red, blue) or custom Pantone shades to match your brand.

This is a big advantage for:

- Marketing prototypes (you want to show stakeholders a part that looks like the final product).

- User testing (color can affect how users perceive a product—e.g., a medical device in soft blue vs. bright red).

Example: A toy company tested 3 color versions of a new action figure (red, blue, green) using vacuum casting. They made 20 of each color for user testing—and found that kids preferred the blue version, which they used for the final product.

6. Wide Material Selection: Match Your Part’s Function

Vacuum casting works with a range of materials, so you can choose one that fits your part’s purpose (e.g., flexibility, heat resistance, transparency). Here’s a table of the most popular materials and their uses:

| Material | Key Properties | Best For | Example Parts |

|---|---|---|---|

| PU Resin | Flexible (Shore A 30–90), low cost | Soft components, housings | Phone cases, remote control grips |

| ABS | Rigid, impact-resistant | Structural parts, electronics | Laptop frames, toy bodies |

| PC (Polycarbonate) | Heat-resistant (up to 130°C), transparent | High-temperature or clear parts | Light covers, medical device windows |

| PA (Nylon) | Wear-resistant, chemical-resistant | Gears, fasteners | Small gears, screw holders |

Pro Tip: For most prototypes, start with PU resin—it’s affordable, easy to work with, and comes in flexible or rigid options.

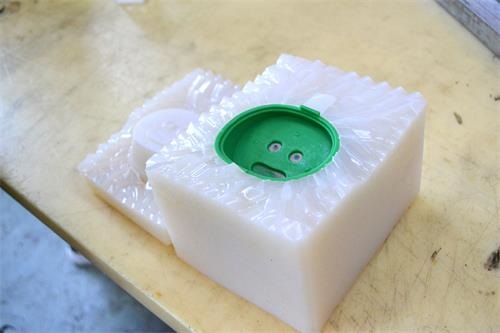

7. Good Operability: Simplify Mold Making & Demolding

Silicone molds (used in vacuum casting) are flexible and easy to work with—unlike rigid steel molds (injection molding) that require specialized equipment to handle.

Key operability benefits:

- Easy to cut: After curing, you can use a utility knife to split the silicone mold along the parting line—no need for complex tools.

- Simple demolding: The flexible silicone peels away from the part easily, reducing the risk of damage (critical for delicate prototypes).

- Translucent design: Most silicone molds are translucent, so you can check if the casting material has filled all areas of the mold.

Example: A hobbyist making custom jewelry used vacuum casting. They cut the silicone mold with a regular craft knife, demolded the parts by hand, and had no issues with breakage—even for tiny, delicate pendants.

8. Good Repeatability: Consistent Quality Across Batches

When you need multiple identical parts (e.g., 50 prototypes for testing), repeatability is key. Vacuum casting delivers consistent quality because:

- The silicone mold captures every detail of the master prototype—so each part is a near-perfect copy.

- The vacuum ensures no air bubbles (which cause defects) in any part of the batch.

In most cases, you’ll get 95%+ consistent parts with vacuum casting—meaning only 1–2 defective parts per 50-piece batch.

Case Study: A consumer electronics company made 100 prototypes of a new tablet stand using vacuum casting. They tested 20 random parts for size and strength—all were within ±0.20mm of the master prototype, and none failed the strength test (holding a 500g tablet for 24 hours).

9. Environmental Friendliness: Reduce Waste

Compared to traditional large-scale production (like injection molding), vacuum casting is more environmentally friendly because it produces less waste:

- No excess material: You only mix as much casting material as you need for the batch—no leftover pellets or scrap.

- Reusable molds: A silicone mold can be used 15–25 times before it wears out—reducing the need to make new molds.

- Low energy use: Vacuum casting doesn’t require high heat (unlike injection molding, which needs 200–300°C to melt plastic)—so it uses less electricity.

Example: A small eco-friendly brand used vacuum casting to make 50 reusable water bottle lids. They produced just 2g of waste (from trimming small edges) and reused the silicone mold 18 times—cutting their environmental impact by 60% compared to injection molding.

10. Wide Applicability: Fit for Multiple Industries

Vacuum casting isn’t limited to one industry—it works for products in almost every sector that needs rapid prototyping or small batches. Here are the most common industries using it:

| Industry | Common Uses | Example Parts |

|---|---|---|

| 3C Electronics | Housings, connectors, sensor parts | Phone cases, laptop hinges, earbud chargers |

| Medical Devices | Syringes, sensor housings, tool parts | Syringe barrels, small surgical tool handles |

| Automotive | Prototypes for interior/exterior parts | Dashboard buttons, sensor covers |

| Robotics | Joints, gears, small structural parts | Robot arm joints, tiny gears |

| Consumer Goods | Toys, kitchen tools, jewelry | Action figures, custom spoon handles, pendants |

Yigu Technology’s Perspective on the Advantages of Vacuum Casting

At Yigu Technology, we’ve seen firsthand how vacuum casting’s advantages transform product development for our clients. From startups saving on tooling costs to medical device companies getting precise parts fast, it’s a versatile solution that solves real pain points. We especially value its repeatability (critical for consistent testing) and material flexibility (letting clients match final-product performance). For most low-batch, complex projects, vacuum casting isn’t just an option—it’s the most efficient, cost-effective choice. We often recommend it as the first step before moving to large-scale injection molding, as it lets clients validate designs without big investments.

(FAQ)

Q1: Is vacuum casting still cost-effective for very small batches (e.g., 5 parts)?

Yes! Even for 5 parts, vacuum casting is cheaper than injection molding (which requires a $10k+ mold). For 5 parts, you’ll spend ~$600 (mold + material)—vs. $12k+ for injection molding. The only time 3D printing might be cheaper is for 1–2 parts, but vacuum casting is better for consistency.

Q2: Can vacuum casting handle parts with very thin walls (e.g., 0.5mm)?

Yes, but you need to use a low-viscosity casting material (like thin PU resin) and ensure the vacuum is strong (-0.095MPa to -0.1MPa). We’ve made parts with 0.4mm walls for medical devices—just make sure the silicone mold is properly filled to avoid thin spots.

Q3: How does vacuum casting’s precision compare to 3D printing?

Vacuum casting is more precise for most parts: it has an accuracy of ±0.20mm/100mm, while FDM 3D printing is ±0.30mm/100mm and SLA 3D printing is ±0.15mm/100mm. For parts that need to fit together (e.g., a gear and a housing), vacuum casting’s consistency across batches also makes it better than 3D printing.