If you’ve ever wondered what additive metal (also known as metal additive manufacturing or 3D metal printing) is and how it’s changing industries, you’re in the right place. At its core, additive metal is a manufacturing process that builds metal parts layer by layer, using materials like powdered metals, instead of cutting or shaping metal from a solid block (the traditional “subtractive” method). This approach lets you create complex, custom parts that would be impossible or too expensive to make with old-school techniques—think lightweight aerospace components, patient-specific medical implants, or intricate automotive parts. The biggest benefits? Less material waste (often 90% less than subtractive methods), faster prototyping, and the ability to make parts with unique geometries, like internal channels or lattice structures, that boost performance.

What Exactly Is Additive Metal Manufacturing?

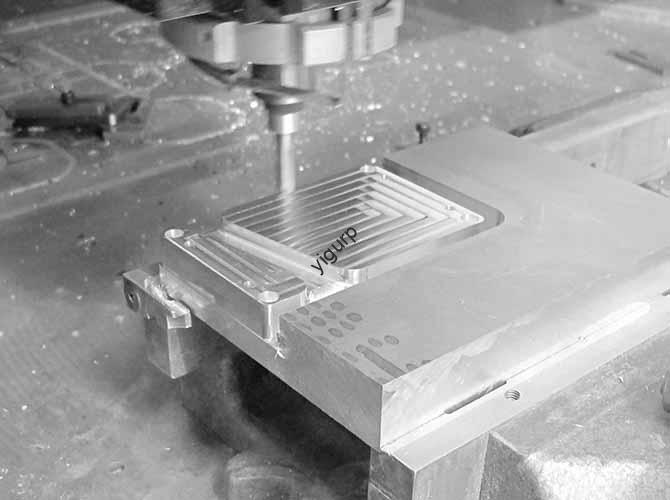

To break it down simply: additive metal works by depositing or fusing tiny layers of metal (usually powder, wire, or sheet) one on top of another, following a 3D digital design (from CAD software). Unlike subtractive manufacturing (such as milling or turning), which removes material to get the desired shape, additive builds parts “from scratch.” This fundamental difference is why it’s revolutionizing how we make metal components—especially for industries where precision, weight, and customization matter most.

A real-world example helps illustrate this. Let’s say an aerospace engineer needs a fuel injector for a jet engine. Traditional methods might require welding multiple pieces together, which adds weight and creates weak points. With additive metal (specifically a process called SLM, which we’ll cover next), they can print the injector as a single piece with internal fuel channels that are perfectly smooth and precisely shaped. This not only cuts weight by 30% (critical for fuel efficiency) but also reduces the risk of leaks or failures. According to the Aerospace Industries Association, additive metal has helped aerospace companies reduce part counts by up to 70% for some components—saving time and money on assembly.

The Most Common Additive Metal Technologies (And How They Work)

Not all additive metal processes are the same. Each uses different tools, materials, and techniques, making them better suited for specific projects. Below’s a breakdown of the four most widely used technologies, with their pros, cons, and typical applications.

| Technology | How It Works | Key Advantages | Key Limitations | Common Applications |

| Selective Laser Melting (SLM) | A high-powered laser melts and fuses metal powder layer by layer in a controlled, inert atmosphere (to prevent oxidation). | Creates dense, high-strength parts; excellent precision (down to 0.1mm); works with many metals. | Slow for large parts; expensive equipment; requires post-processing (e.g., removing support structures). | Aerospace components (turbine blades), medical implants (hip stems), high-performance automotive parts. |

| Direct Metal Laser Sintering (DMLS) | Similar to SLM, but the laser sinters (heats without fully melting) metal powder to bind layers together. | Faster than SLM; lower heat input (reduces warping); works with mixed-metal powders. | Parts are less dense than SLM (may need infiltration); lower strength for high-stress uses. | Prototypes, custom tools, jewelry, low-stress industrial parts. |

| Directed Energy Deposition (DED) | A nozzle deposits metal wire or powder while a laser, electron beam, or plasma arc melts it—ideal for repairing or building large parts. | Can repair damaged parts (e.g., turbine blades); builds large components; works with thick materials. | Lower precision than SLM/DMLS; rougher surface finish (needs more post-processing). | Repairing heavy machinery parts, building large aerospace structures, custom tooling for construction. |

| Binder Jetting | A printhead deposits a liquid binder onto metal powder to “glue” layers together; after printing, the part is heated (sintered) to remove the binder and fuse the metal. | Fastest for high-volume production; low cost per part; minimal warping. | Parts need sintering (adds time); lower strength than SLM; limited metal options. | Mass-produced small parts (fasteners, brackets), custom medical devices (dental crowns), architectural models. |

A Practical Example: Choosing the Right Tech

Let’s say a dental lab wants to make custom crowns. Binder Jetting would be a great fit—It’s fast, cost-effective for high volumes, and can produce precise crowns that just need a final sintering step. But if a medical device company needs a hip implant that must withstand years of wear, SLM is better: It creates dense, strong parts that meet strict biocompatibility standards.

Key Materials Used in Additive Metal

Additive metal works with a wide range of metals, but the choice depends on the part’s purpose—whether it needs to be strong, lightweight, corrosion-resistant, or biocompatible. Here are the most popular options, with their uses:

- Titanium Alloys (Ti-6Al-4V): Lightweight (half the weight of steel) and extremely strong, with excellent corrosion resistance and biocompatibility. Perfect for aerospace (aircraft frames) and medical (implants) because it doesn’t react with the human body. A study by the American Society for Testing and Materials (ASTM) found that titanium additive metal parts have 95-99% of the strength of traditionally made titanium parts.

- Stainless Steel (316L, 17-4 PH): Affordable, corrosion-resistant, and easy to work with. Used for industrial parts (valves, pumps), consumer goods (watches, cookware), and medical tools (surgical instruments). 316L stainless steel is especially popular for marine or chemical industry parts because it resists rust in harsh environments.

- Aluminum Alloys (AlSi10Mg): Lightweight (even lighter than titanium) and good for high-temperature applications. Common in automotive (engine parts, lightweight frames) and aerospace (satellite components). According to the Aluminum Association, additive metal aluminum parts can reduce the weight of automotive components by up to 40% compared to traditional aluminum parts.

- Nickel Alloys (Inconel 718, Hastelloy): Exceptionally heat-resistant and strong at high temperatures (up to 1,000°C). Used for aerospace (jet engine turbine blades) and energy (gas turbine parts) because they can handle extreme conditions without deforming.

- Cobalt-Chromium Alloys: Biocompatible and wear-resistant, making them ideal for medical implants (knee replacements, dental abutments) and high-wear industrial parts (bearings). They’re also used in jewelry because they have a silver-like finish and don’t tarnish.

Industries Transformed by Additive Metal (With Real-World Cases)

Additive metal isn’t just a “future tech”—it’s already changing how industries operate, from healthcare to aerospace. Below are key sectors and examples of how they’re using the technology to solve problems.

1. Aerospace & Defense

The aerospace industry was one of the first to adopt additive metal, and for good reason: It needs lightweight, high-strength parts that meet strict safety standards. A prime example is Boeing, which uses additive metal to make over 300 different parts for its 787 Dreamliner. One of these parts is a bracket that holds wiring—traditionally, it was made by machining two pieces and welding them together. With SLM, Boeing prints it as a single piece, cutting weight by 40% and reducing production time by 50%. According to Boeing’s 2024 Sustainability Report, additive metal has helped the company reduce fuel consumption for its planes by 1-2% (a huge saving when you consider a single 787 flies thousands of hours a year).

2. Healthcare

In healthcare, additive metal is a game-changer for patient-specific care. Take orthopedics: When a patient needs a hip implant, doctors can scan the patient’s hip, create a 3D model, and print an implant that fits perfectly—unlike standard implants, which often require adjustments during surgery. A study published in the Journal of Orthopaedic Research found that patients with additive metal hip implants had 30% fewer post-surgery complications (like pain or implant loosening) compared to those with traditional implants. Another example is dental care: Companies like Straumann use binder jetting to print custom dental crowns that match the shape and color of a patient’s natural teeth—often ready in just 24 hours, compared to the 1-2 weeks for traditional crowns.

3. Automotive

The automotive industry uses additive metal for both prototyping and production. Ford, for instance, uses DMLS to prototype parts like engine brackets—instead of waiting 4-6 weeks for a traditional prototype, Ford can print one in 2-3 days, speeding up the design process. For production, Tesla uses SLM to print parts for its electric vehicles (EVs), like the rotor in the Model Y’s motor. This part is lighter and stronger than the traditionally made version, helping the Model Y achieve a longer range. According to Tesla’s 2024 Impact Report, additive metal has reduced the number of parts in the Model Y’s motor by 20%, cutting assembly time and costs.

4. Energy

In the energy sector, additive metal is used to make parts for oil and gas drilling, wind turbines, and solar panels. For example, Siemens Energy uses DED to repair turbine blades for gas power plants. Traditional repair methods involve welding, which can weaken the blade—with DED, Siemens melts metal onto the damaged area, restoring the blade to its original strength. This extends the blade’s life by 5-7 years, saving power plants millions in replacement costs. Siemens reports that additive metal repairs for turbine blades are 30% cheaper than replacing the entire blade.

Challenges of Additive Metal (And How to Overcome Them)

While additive metal has huge benefits, it’s not without challenges—especially for businesses just starting out. Below are the most common issues and practical solutions:

1. High Upfront Costs

The biggest barrier for many small businesses is the cost of equipment: A basic SLM machine can cost \(100,000-\)500,000, and high-end models go up to \(1 million. Plus, there are costs for materials (metal powder can be \)50-$500 per kilogram) and software.

Solution: Instead of buying a machine, use a contract manufacturer (like Protolabs or Xometry) for small-scale projects. These companies let you upload your 3D design and get parts printed for a per-unit cost, without the upfront investment. For example, a small automotive shop might use Xometry to print 10 prototype brackets for \(500-\)1,000, instead of spending $200,000 on a machine.

2. Post-Processing Requirements

Most additive metal parts need post-processing to be ready for use—this can include removing support structures (the extra material used to hold the part up during printing), smoothing the surface (via sandblasting or machining), or heat-treating (to improve strength). Post-processing can add 20-50% to the total production time.

Solution: Plan for post-processing in your design phase. Use CAD software that lets you minimize support structures (e.g., by angling parts so they don’t need as much support). For example, a designer creating a turbine blade can adjust the blade’s orientation in the 3D model to reduce support material by 30%, cutting post-processing time. Also, invest in automated post-processing tools (like robotic sandblasters) to speed up the work.

3. Quality Control and Consistency

Because additive metal relies on precise conditions (like laser temperature, powder bed density, and atmosphere), parts can sometimes have defects—like pores (tiny holes) or warping (when the part bends during cooling). These defects can weaken the part, which is a problem for safety-critical applications (like aerospace or medical).

Solution: Use in-process monitoring tools (like cameras or sensors) that track the printing process in real time. For example, SLM Solutions’ machines have built-in cameras that check each layer for defects—if a pore is detected, the machine alerts the operator, who can fix the issue before it ruins the whole part. Also, follow industry standards (like ASTM F2924 for additive metal parts) to ensure consistency. A study by the National Institute of Standards and Technology (NIST) found that companies using in-process monitoring had 40% fewer defective parts.

4. Limited Material Options (For Some Processes)

While additive metal works with many metals, some processes (like binder jetting) have fewer material options—for example, you can’t use high-temperature nickel alloys with most binder jetting machines. This limits what you can make with certain technologies.

Solution: Combine processes if needed. For example, if you need a part that uses both aluminum (for lightweight) and stainless steel (for strength), you could use DED to add stainless steel to an aluminum part printed with SLM. This “hybrid” approach lets you use the best material for each part of the component. Companies like DMG MORI make hybrid machines that combine additive metal with subtractive machining, giving you more flexibility.

The Future of Additive Metal: Trends to Watch (2024-2030)

Additive metal is growing fast—according to Grand View Research, the global additive metal market is expected to reach \(35.8 billion by 2030 (up from \)8.4 billion in 2023). Below are the key trends that will shape the industry in the next few years:

1. Faster Printing Speeds

One of the biggest complaints about additive metal is that it’s slow—especially for large parts. But new technologies are changing that. For example, companies like VulcanForms use high-power lasers and advanced powder bed systems to print parts up to 10 times faster than traditional SLM machines. VulcanForms’ machines can print a turbine blade in 2 hours, compared to 20 hours with older SLM technology. This will make additive metal feasible for high-volume production (like making thousands of automotive parts) instead of just prototyping.

2. More Sustainable Practices

Sustainability is a top priority for many industries, and additive metal is becoming greener. One trend is recycling metal powder—most additive metal machines use only 30-50% of the powder in a single print, but companies are now recycling the unused powder (by sieving and reprocessing it) to reduce waste. For example, Airbus recycles 95% of its titanium powder, cutting material waste by 80%. Another trend is using renewable energy to power additive metal machines—Siemens Energy’s additive metal facility runs on wind power, reducing its carbon footprint by 35%.

3. AI-Powered Design and Printing

Artificial intelligence (AI) is making additive metal more efficient. AI can help with two key steps: design and printing. For design, AI tools (like Autodesk Generative Design) can create optimal part geometries—you input the part’s requirements (weight, strength, cost), and the AI generates hundreds of designs that meet those needs. For example, a NASA engineer used generative design to create a Mars rover part that was 40% lighter and 20% stronger than the human-designed version. For printing, AI can predict and prevent defects—AI algorithms analyze data from past prints (like laser temperature and powder density) to adjust the printing process in real time, reducing defects by up to 50% (according to a 2024 study by MIT).

4. Larger Part Sizes

Traditionally, additive metal was limited to small parts (like implants or brackets). But new machines can print much larger components. For example, Relativity Space’s Stargate machine can print a rocket engine (which is over 1 meter tall) in just 30 days—something that would take months with traditional manufacturing. This will open up additive metal to industries like construction (printing large structural parts) and marine (printing ship components).

Yigu Technology’s Perspective on Additive Metal

At Yigu Technology, we see additive metal as a catalyst for innovation—especially for small and medium-sized enterprises (SMEs) looking to compete with larger companies. Too often, SMEs are held back by traditional manufacturing’s high costs and inflexibility, but additive metal levels the playing field: It lets SMEs create custom, high-quality parts without the need for expensive tooling or large production runs. We’ve worked with clients in the automotive and medical sectors who used our additive metal consulting services to cut prototyping time by 60% and launch products 3 months faster than their competitors. We also believe sustainability will be key—by helping clients recycle powder and optimize designs for minimal material use, we’re making additive metal not just efficient, but responsible. As AI and faster printing technologies become more accessible, we expect additive metal to become a standard tool for SMEs, not just a luxury for big corporations.