If you’ve ever needed high-strength, precise 3D printed parts—like aerospace components or automotive prototypes—but struggled with flimsy materials or rough surfaces, 3D printing rigid resin is your solution. This light-sensitive material creates robust, detailed parts, but how do you choose the right type? What’s the step-by-step printing process? And how can you fix common issues like brittleness or poor adhesion? This guide answers all these questions, helping you master 3D printing rigid resin for reliable results.

What Is 3D Printing Rigid Resin?

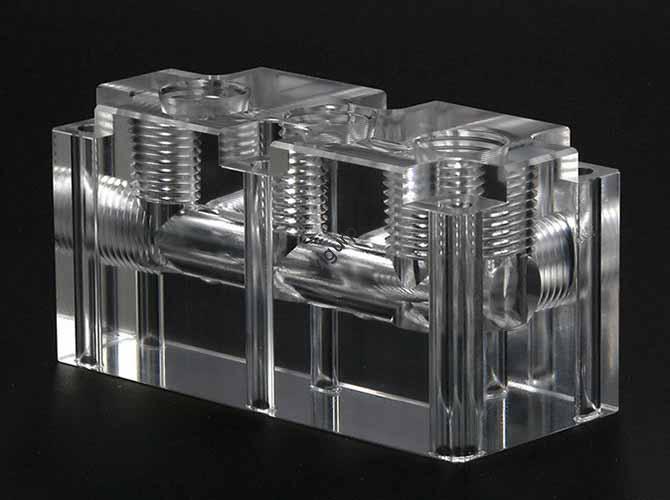

3D printing rigid resin is a light-sensitive polymer designed for light-curing 3D printing technologies (e.g., SLA, MSLA). Unlike flexible resins (which bend easily) or standard resins (which lack strength), rigid resin cures into hard, stiff parts under UV light—think of it like casting a concrete statue vs. a rubber toy: concrete (rigid resin) holds its shape and resists impact, while rubber (flexible resin) deforms easily.

Key traits that make rigid resin unique:

- Mechanical strength: It has a tensile strength of 50-80 MPa (similar to some metals like aluminum alloy), making it ideal for load-bearing parts.

- Precision: It captures tiny details (down to 0.1mm), perfect for intricate designs like medical device components.

- Fast curing: Most rigid resins cure in 10-30 seconds per layer, speeding up print times vs. FDM plastics.

Step-by-Step Process for 3D Printing with Rigid Resin

Printing with rigid resin follows a linear, repeatable workflow—critical for consistency. Below is a detailed breakdown, from design to post-processing:

- Design the 3D Model & Prepare Files

Start with CAD software (e.g., SolidWorks, Blender) to create your part’s 3D model. Focus on:

- Adding fillets (rounded edges) to high-stress areas (prevents cracking after printing).

- Avoiding thin walls (<1mm)—rigid resin is strong but brittle, and thin walls break easily.

Export the model as an STL file (the standard format for 3D printing) and check for errors (use tools like Meshlab to fix gaps or overlapping faces).

- Slice the Model for Rigid Resin

Import the STL into resin slicing software (e.g., Chitubox, Lychee Slicer) and tweak these key settings:

- Layer height: 0.05-0.1mm (thinner layers = smoother surfaces; 0.1mm balances speed and quality).

- Exposure time: 2-4 seconds per layer (follow the resin manufacturer’s recommendation—too short = poor adhesion; too long = brittle parts).

- Bottom layers: 5-10 layers with 20-40 seconds exposure (strengthens adhesion to the build plate).

- Set Up the 3D Printer

- Fill the resin tank with 3D printing rigid resin—avoid overfilling (resin may spill during printing).

- Level the build plate (use the printer’s auto-leveling tool or a feeler gauge) to ensure even layer adhesion.

- Preheat the resin (if needed): Some rigid resins work best at 25-30°C (cold resin cures unevenly).

- Run the Print

Start the printer— it will cure the resin layer by layer using UV light:

- For SLA printers: A laser traces each layer, curing the resin into the desired shape.

- For MSLA printers: An LCD screen projects UV light patterns, curing entire layers at once.

Pro tip: Monitor the first 5 layers—if they peel off the build plate, pause and adjust exposure time or plate leveling.

- Post-Process for Optimal Performance

After printing, follow these steps to boost strength and appearance:

- Remove supports: Use flush cutters to snip supports—take care not to crack the part (rigid resin is brittle when fresh).

- Wash the part: Soak it in isopropyl alcohol (90%+ concentration) for 5-10 minutes to remove uncured resin.

- Post-cure: Place the part in a UV curing station for 10-20 minutes—this increases tensile strength by 20-30% and reduces brittleness.

- Finish (optional): Sand with 400-800 grit sandpaper for a smooth surface, or paint with resin-compatible paint for aesthetics.

3D Printing Rigid Resin: Types & Application Comparison

Not all rigid resins work for every project. Below is a table to help you choose the right type based on your industry and needs:

| Resin Type | Key Properties | Ideal Applications | Best Printer Tech |

| Standard Rigid Resin | Tensile strength: 50-60 MPa; good surface finish | Prototypes (e.g., automotive dashboard parts), consumer goods (e.g., phone cases) | MSLA (cost-effective for small parts) |

| High-Temp Rigid Resin | Heat resistance: Up to 150°C; tensile strength: 65-75 MPa | Aerospace components (e.g., engine brackets), industrial tools (e.g., mold inserts) | SLA (higher precision for high-stress parts) |

| Impact-Resistant Rigid Resin | Less brittle (impact strength: 10-15 kJ/m²); tensile strength: 55-65 MPa | Medical devices (e.g., surgical instruments), robotics parts (e.g., gear housings) | MSLA or SLA (balances strength and durability) |

| Food-Safe Rigid Resin | FDA-certified; non-toxic; tensile strength: 50-60 MPa | Kitchenware (e.g., custom utensils), food packaging prototypes | SLA (better control over material purity) |

Advantages & Challenges of 3D Printing Rigid Resin

Like any 3D printing material, rigid resin has strengths and limitations. Below is a balanced breakdown to help you set expectations:

Advantages (Why It’s Worth Using)

- High strength & precision: It creates parts that are both strong enough for load-bearing use and detailed enough for intricate designs—solving the “strength vs. detail” dilemma of other materials.

- Smooth surface finish: Cured rigid resin has a matte, almost glass-like surface (Ra 0.8-1.6 μm)—no sanding needed for most prototypes, saving time.

- Fast print times: Even complex parts (e.g., a 10cm aerospace bracket) print in 4-8 hours vs. 12-24 hours with FDM rigid plastics like ABS.

Challenges (And How to Overcome Them)

- Brittleness: Freshly printed parts may crack if dropped—especially thin sections.

Solution: Post-cure the part for 20 minutes (instead of 10) to cross-link more polymer chains; avoid printing walls thinner than 1.5mm.

- High cost: Rigid resin costs \(50-\)100 per liter (vs. \(20-\)30 per kg for PLA)—a barrier for large parts.

Solution: Use rigid resin only for critical parts; combine it with FDM for non-load-bearing components (e.g., a rigid resin gearbox with an FDM housing).

- Toxicity: Uncured resin contains chemicals that irritate skin—safety is a concern.

Solution: Wear nitrile gloves and safety glasses when handling resin; work in a well-ventilated area (use a fume hood if possible).

Real-World Applications of 3D Printing Rigid Resin

Rigid resin solves unique problems across industries. Below are specific examples of how it’s used:

1. Aerospace Industry

A leading aerospace manufacturer needed a prototype of a fuel line bracket— it required high strength (to withstand 500 psi pressure) and precise holes (to fit bolts). They used high-temp rigid resin (heat-resistant to 140°C) and an SLA printer. The prototype:

- Withstood pressure tests without cracking (tensile strength of 72 MPa).

- Had hole accuracy of ±0.05mm (bolts fit perfectly).

- Took 6 hours to print—vs. 3 days with traditional machining.

2. Automotive Industry

A car startup tested an engine sensor housing prototype. They chose impact-resistant rigid resin to handle engine vibrations. The prototype:

- Survived 1,000 vibration cycles (200 Hz) without breaking.

- Captured tiny details (e.g., a 0.5mm wiring hole) that FDM couldn’t replicate.

- Let the team iterate 3 design versions in a week—speeding up the sensor’s launch by a month.

3. Medical Device Industry

A hospital needed a custom surgical retractor prototype (used to hold tissue during operations). They used food-safe rigid resin (FDA-certified) and an MSLA printer. The prototype:

- Was non-toxic (safe for contact with skin).

- Had a smooth surface (no sharp edges to irritate tissue).

- Took 4 hours to print—traditional manufacturing would have taken 2 weeks.

Future Trends of 3D Printing Rigid Resin

As material science advances, rigid resin will become even more versatile. Here are three trends to watch:

- Lower Cost: New formulations (using recycled polymers) will reduce resin prices by 30-40%—making it accessible for small businesses and hobbyists.

- Better Durability: Researchers are developing rigid resins with impact strength similar to nylon (20+ kJ/m²)—eliminating brittleness and expanding use in high-impact applications (e.g., automotive bumpers).

- Multi-Functional Additives: Resins with built-in properties (e.g., flame resistance, electrical conductivity) will let manufacturers print parts like aerospace wire housings (flame-resistant) or sensor brackets (conductive) in one step—no post-processing needed.

Yigu Technology’s Perspective on 3D Printing Rigid Resin

At Yigu Technology, we see 3D printing rigid resin as a game-changer for high-precision manufacturing. Our MSLA printers (e.g., Yigu Tech R5) come with pre-set “rigid resin modes” that optimize exposure time and layer height for common resins—no manual tweaking needed. We also offer a custom rigid resin line: our high-temp variant resists 160°C, and our impact-resistant version has a 18 kJ/m² impact strength. For beginners, we provide a free post-processing guide to fix brittleness and improve adhesion. Rigid resin isn’t just a material—it’s a way to turn complex designs into strong, functional parts faster than ever.

FAQ: Common Questions About 3D Printing Rigid Resin

- Q: Can I use rigid resin in an FDM printer?

A: No—rigid resin is designed for light-curing printers (SLA/MSLA), which use UV light to cure the material. FDM printers melt plastic filaments, so resin won’t work. Using resin in an FDM printer will clog the nozzle and damage the machine.

- Q: How long do 3D printed rigid resin parts last?

A: It depends on use: Indoor parts (e.g., prototypes) last 5-10 years (resists UV yellowing if kept out of sunlight). Outdoor parts (e.g., automotive components) last 2-3 years—use a UV-resistant clear coat to extend life to 5+ years.

- Q: Can I paint 3D printed rigid resin parts?

A: Yes! First, sand the part with 400-grit sandpaper (to help paint adhere). Use acrylic or enamel paint (resin-compatible). For best results, apply a primer first—this ensures the paint doesn’t peel and gives a smooth finish.