When choosing a material for projects like heating ducts or custom building work, the details really matter. For many different jobs, 22 gauge galvanized sheet metal stands out as an excellent choice. It offers a perfect mix of being thin enough to work with easily while still being strong and reliable. This material is popular with both professional workers and serious DIY enthusiasts for good reasons. Its name tells us about what it’s made of, how thick it is, and what protects it from rust.

This guide will help anyone who is thinking about using this material. We will explain its basic properties, look at the many ways it can be used, compare it to other thicknesses, and give practical tips on how to cut, shape, and buy it. Whether you are a contractor, metal worker, or someone who loves building projects, this article will give you the expert knowledge you need to confidently choose and use 22 gauge galvanized sheet metal for your next project.

What Galvanized Steel Really Means

To really understand what this material can do, you need to know what each part of its name means. The term “22 gauge galvanized sheet metal” is a specific description that tells us about its thickness, what it’s made of, and how it’s protected. For beginners, these terms can be confusing, but breaking them down shows a logical system that explains the material’s main features and how it should be used.

Breaking Down the Name

The name has three separate parts, each describing an important aspect of the product.

- Steel: The base of the sheet is carbon steel. This gives it the natural strength, stiffness, and structural qualities that make it useful for building. Steel itself is a mixture of iron and carbon, valued for its balance of toughness and reasonable cost.

- 22 Gauge: This tells us how thick the sheet is. In the gauge system for sheet metal, the relationship works backwards: a higher gauge number means a thinner sheet of metal. This often confuses people who are new to metalworking. A 22 gauge sheet is about 0.0299 inches thick or 0.76 millimeters. It’s important to know that small differences in manufacturing can cause slight changes from this standard measurement.

- Galvanized: This describes the protective coating put on the steel. The galvanizing process covers the steel with a layer of zinc to prevent rust and corrosion. This zinc layer is what makes the material last so long in different environments.

How the Protection Works

The galvanizing process protects the steel underneath in two main ways, making it much better than untreated steel.

1. Barrier Protection: At the most basic level, the zinc coating acts like a physical wall. It seals the steel so moisture and oxygen can’t touch it directly. These are the two main things needed for rust (iron oxide) to form. As long as this barrier stays intact, the steel is protected from environmental damage.

2. Sacrificial Protection: This is the more advanced and important part of galvanizing. Zinc is more chemically active than steel. This means that if the surface gets scratched or damaged, the zinc will rust first, “sacrificing” itself to protect the exposed steel. This protection keeps working even at cut edges and small scratches. Over time, the zinc reacts with the air to form a tough, dull gray coating that further seals the surface and slows down rust.

Important Physical Properties

The combination of its thickness and zinc coating gives 22 gauge galvanized steel a specific set of characteristics that determine how it’s used.

- Thickness & Weight: At about 0.0299 inches thick, 22 gauge steel is relatively lightweight, weighing about 1.25 pounds per square foot. This makes it manageable for one person to handle, lift, and position in reasonable sheet sizes, making installation easier and less labor-intensive.

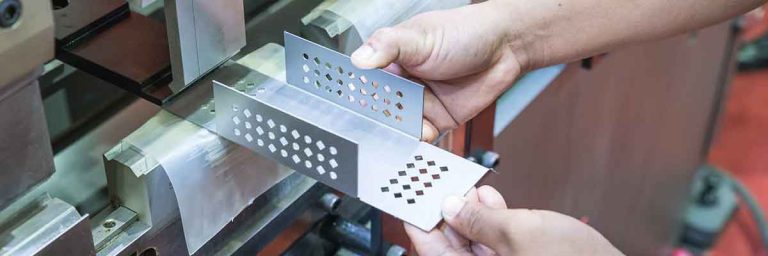

- Bendability: This material strikes an excellent balance. It is thin enough to be easily bent, cut, and shaped using common hand and power tools, allowing you to create complex fittings and shapes. Yet, it is thick enough to hold its shape once formed, providing good stiffness and resisting minor impacts without significant bending.

- Welding & Fastening: 22 gauge galvanized steel can be joined easily. It can be attached mechanically with self-tapping screws and rivets, which is the most common method. It can also be welded, typically using a MIG welder, but this requires special care. The zinc coating must be ground away from the weld area, and proper ventilation and breathing protection are absolutely necessary to avoid inhaling the dangerous zinc fumes produced by the high heat.

Main Benefits of Using This Material

Choosing galvanized steel is a smart decision that provides several long-term advantages over other materials like raw steel or even some types of aluminum. These benefits come directly from the galvanizing process and contribute to a more durable, reliable, and cost-effective final product.

Outstanding Rust Resistance

The main and most celebrated benefit of galvanized steel is its exceptional resistance to rust. The double protection of the zinc coating allows the material to withstand long exposure to weather. It works reliably in environments with high humidity, condensation, and direct contact with rain. This makes it an ideal material for any application where moisture is a concern, from exterior building parts to the inside of a heating and cooling system, ensuring the steel base stays strong for years.

Toughness and Long Life

The protective zinc coating dramatically extends how long the steel will last. Depending on how thick the coating is and how harsh the environmental conditions are, a galvanized product can last for decades with little to no maintenance. Galvanized coatings are often rated using a system like G60 or G90, which shows the total weight of zinc per square foot of steel. A G90 coating, for example, is thicker and more protective than a G60 coating and is rated to last over 30 years in many rural and suburban atmospheric conditions before significant maintenance is needed. This longevity makes it a “install and forget” solution for many structural and functional parts.

Good Value for Money

While the initial purchase price of galvanized steel may be slightly higher than that of untreated “black” steel, it is often the more economical choice over the product’s entire life. The upfront cost includes the protection that would otherwise need to be added later through painting, powder coating, or other finishing processes. By eliminating these extra steps and drastically reducing future maintenance and replacement costs associated with rust, galvanized steel offers a better total cost of ownership.

Appearance and Finishing

Hot-dip galvanized steel is easily recognizable by its unique crystalline or “spangled” surface pattern. While many find this industrial look appealing for certain projects, the material also serves as an excellent base for painting. For a successful and long-lasting paint job, the galvanized surface must be properly prepared. This typically involves cleaning the surface to remove any oils or treatments, followed by applying a specialized primer designed to stick to a zinc surface. This versatility allows for both functional, unfinished applications and colored, decorative finishes.

Common Uses and Applications

The versatility of 22 gauge galvanized steel makes it a preferred material across a wide range of industries and projects. Its balance of properties allows it to serve equally well in demanding professional applications and creative DIY projects. Understanding where this material excels can provide inspiration and confidence for your own projects.

Heating and Cooling Ductwork

In the heating, ventilation, and air conditioning (HVAC) industry, 22 gauge galvanized steel is a workhorse material, particularly for light commercial and high-end residential systems. Its thickness provides enough stiffness to form long, straight runs of rectangular ductwork that resist rattling and “oil-canning” from air pressure. At the same time, it is bendable enough to be crafted into the complex transitions, elbows, and take-offs required for an efficient system. The galvanized coating is crucial here, as it prevents rust from forming due to condensation that can occur inside the ducts when moving cool air.

Roofing Parts

While rarely used for the main surface of a large roof, 22 gauge galvanized steel is an industry standard for many critical roofing parts where durability and weather resistance are extremely important.

- Flashing: It is commonly used to create valley flashing, step flashing around chimneys, and apron flashing where a roof meets a vertical wall. Its ability to be bent into precise shapes creates a watertight seal.

- Drip Edges: A strip of 22 gauge metal is installed along the eaves to direct water away from the fascia board, preventing rot and water damage.

- Gutters and Downspouts: The material’s strength and rust resistance make it an excellent choice for making durable, long-lasting gutter and downspout systems.

Project Suitability Guide

To help you decide if 22 gauge is the right fit for your specific needs, we’ve created a suitability guide. This table provides expert guidance on a variety of common projects.

| Project / Application | 22 Gauge Suitability | Reasoning / Expert Tip |

| HVAC Ducts (Light Commercial) | Ideal | Industry standard. Excellent balance of bendability for fittings and stiffness for straight runs. |

| Roof Flashing & Drip Edge | Ideal | Durable, weatherproof, and easily formed into the required shapes for a watertight seal. |

| Magnetic Memo Board | Good Choice | Provides a large, durable magnetic surface. The galvanized finish can be an attractive industrial look. |

| Workbench Top Liner | Acceptable (with support) | Provides a durable, easy-to-clean surface. Must be fully supported by a wood base to prevent denting from heavy impacts. |

| Small Animal Enclosure | Good Choice | Strong enough to contain small animals and resistant to corrosion from waste. Make sure all cut edges are smoothed or covered. |

| Automotive Patch Panels | Acceptable | Can be used for non-structural rust repair. Requires careful shaping and welding with proper safety precautions. |

| Truck Toolbox (Large) | Not Recommended | Too thin for the structural demands and security of a large toolbox. Use a thicker 16 or 14 gauge aluminum or steel. |

Comparison to Other Gauges

Choosing the correct sheet metal thickness is one of the most critical decisions in any project. Selecting a gauge that is too thin can result in a flimsy, failed part, while choosing one that is too thick can make the project unnecessarily heavy, expensive, and difficult to work with. Understanding how 22 gauge compares to similar thicknesses is key to making an informed choice.

The Gauge System

As a brief reminder, the gauge system for sheet metal works in reverse. A higher number means a thinner piece of metal. Think of it like slicing a loaf of bread: more slices (a higher number) means each individual slice is thinner. Therefore, 26 gauge is significantly thinner and more flexible than 18 gauge, which is much stiffer and heavier. 22 gauge sits squarely in a versatile middle ground.

Gauge Comparison Table

This table provides a direct comparison of common gauges, highlighting the trade-offs between thickness, weight, and stiffness.

| Gauge | Thickness (inch / mm) | Weight (lbs/sq. ft.) | Relative Stiffness | Common Use Case |

| 26 ga | 0.0179″ / 0.45 mm | ~0.75 lbs | Very Flexible | Liners, appliance skins, small signs |

| 24 ga | 0.0239″ / 0.61 mm | ~1.00 lbs | Flexible | Residential HVAC ductwork, some flashing |

| 22 ga | 0.0299″ / 0.76 mm | ~1.25 lbs | Good Balance | Light commercial HVAC, robust flashing, general building work |

| 20 ga | 0.0359″ / 0.91 mm | ~1.50 lbs | Stiff | Durable work surfaces, truck bed liners, small brackets |

| 18 ga | 0.0478″ / 1.21 mm | ~2.00 lbs | Very Stiff | Structural brackets, support members, security panels |

Choosing the Right Gauge

Using the table as a guide, you can make a smart decision based on your project’s main requirements.

- Choose a thinner gauge (24-26 ga) if: Your top priorities are low cost, light weight, and ease of bending. These gauges are best for applications that are not subject to physical stress or impact and may require detailed bending, such as decorative elements or liners.

- Choose 22 gauge when: You need the ultimate “all-rounder.” It provides a fantastic balance of reasonable cost, manageable weight, good bendability, and respectable stiffness. It is the go-to choice for a vast array of general-purpose applications where you need a reliable material that isn’t overkill.

- Choose a thicker gauge (20-18 ga) if: Strength, impact resistance, and structural stiffness are non-negotiable. These gauges are used for applications that need to bear weight or withstand abuse. Be aware that you will need more powerful tools to cut and bend these heavier materials, and the cost and weight will increase significantly.

Working with Galvanized Steel

Knowing the properties of 22 gauge steel is only half the battle. Knowing how to handle and work with it safely and effectively is what turns a sheet of metal into a finished project. This section provides practical, experience-based guidance for working with this versatile material.

Essential Safety Steps

Safety must be the first consideration in any metalworking project. Galvanized steel presents specific dangers that must be respected.

- Cut-resistant gloves are required. The edges of cut sheet metal are razor-sharp and can cause severe cuts. Never handle the material without proper hand protection.

- Wear safety glasses at all times. Cutting and drilling can send small, sharp pieces of metal flying. Eye protection is absolutely necessary.

- Use proper ventilation for welding or heavy grinding. The heat from these processes can vaporize the zinc coating, creating fumes that are toxic to breathe and can cause a condition known as metal fume fever. Always work in a well-ventilated area or use a respirator designed for metal fumes.

Cutting Methods

Several tools can be used to cut 22 gauge steel, with some being better suited for certain types of cuts.

- For straight cuts: A pair of aviation snips (also called tin snips) is the most common tool. They come in three main types: yellow-handled for straight cuts, red-handled for left-curving cuts, and green-handled for right-curving cuts. For longer, faster straight cuts, a power shear is an excellent investment.

- For complex cuts: A jigsaw equipped with a fine-toothed metal-cutting blade works well. Use a slow speed and steady pressure to avoid overheating the material. A nibbler is another power tool that is excellent for cutting curves and complex shapes without distorting the metal.

- Expert Tip: We strongly advise against using an abrasive cutoff wheel on an angle grinder for cutting galvanized steel. The intense heat generated by the abrasive wheel will burn off the protective zinc coating in a wide band along the cut, creating an immediate and significant weak point for rust to develop.

Bending and Shaping

Clean, crisp bends are the hallmark of quality metalwork.

- The ideal tool for making long, straight bends is a sheet metal brake. This machine clamps the material and allows for precise, clean bends along a straight line.

- For those without a brake, a simple DIY method can work. Clamp the sheet firmly between two straight, sturdy pieces of wood or angle iron, with the bend line aligned with the edge. Then, use a mallet and a block of wood to carefully and evenly hammer the metal over the edge to create the bend.

- 22 gauge is quite forgiving and can be bent to a relatively tight radius without cracking, making it easier to work with than thicker, less bendable gauges.

Connecting and Joining

Connecting pieces of 22 gauge steel is straightforward.

- Screws: Self-tapping sheet metal screws are the fastest and most common method. They drill their own pilot hole and cut their own threads in a single action.

- Rivets: Pop rivets create a strong, clean, and permanent mechanical bond. This method requires drilling a hole through both pieces of metal and then using a rivet gun to set the rivet.

- Welding: As mentioned, MIG welding is possible but requires significant preparation. The galvanized coating must be completely ground off the areas to be welded to ensure a strong, clean weld and to minimize dangerous fumes.

Where to Buy Locally

Finding 22 gauge galvanized sheet metal is generally straightforward, as it is a common material. Knowing where to look can save you time and money.

Common Local Suppliers

Different types of suppliers cater to different needs, from small DIY jobs to large commercial orders.

- HVAC Supply Houses: These are often the best source for high-quality, ductwork-grade sheets. They typically sell full sheets and have knowledgeable staff who understand the application.

- Metal Suppliers / Steel Service Centers: For those needing multiple full sheets (e.g., 4’x8′ or 4’x10′) or custom-cut pieces, a dedicated metal supplier is the most economical choice. They offer the best bulk pricing.

- Big-Box Home Improvement Stores: Retailers like Home Depot or Lowe’s usually stock smaller, pre-cut “project panels” (e.g., 2’x2′ or 2’x4′). While more expensive per square foot, they are very convenient for small repairs or projects.

- Specialty Roofing Suppliers: These businesses are a good source for galvanized steel in coil form or pre-bent flashing profiles.

What to Ask For

To ensure you get the right product, it helps to use the correct terms. Walk in and confidently state, for example, “We are looking for a 4-foot by 8-foot sheet of 22 gauge G90 galvanized steel.” The “G90” specifies a common, high-quality zinc coating thickness that is heavier and more protective than a standard G60 coating. Being specific shows you’ve done your research and helps the supplier provide exactly what you need.

Understanding Cost

Budgeting is a key part of any project. The price of 22 gauge galvanized sheet metal can vary based on several factors, and understanding them will help you set realistic expectations.

Price Influencing Factors

The final price you pay is influenced by more than just the raw material.

- Sheet Size: The single biggest factor in cost per square foot. Small, pre-cut project panels from a home improvement store carry a significant convenience markup compared to full-sized sheets from a steel supplier.

- Quantity: Buying in bulk from a metal service center will almost always result in a lower price per sheet. Suppliers offer discounts for larger volume orders.

- Coating Thickness: A sheet with a heavier zinc coating, like G90, may have a slight price premium over a lighter G60 or G40 coated sheet, but it offers greater longevity.

- Market Changes: The price of steel and zinc are global commodities. Their prices can change based on supply, demand, and economic factors, which will be reflected in the retail price.

Typical Price Ranges

While prices are subject to change and location, we can provide a general estimate to aid in planning. As of the current year, you can generally expect to pay:

- For small project panels: A range of $10 to $15 per square foot.

- For a full 4’x8′ sheet: A range of $60 to $100 per sheet, which translates to a much more economical $1.80 to $3.15 per square foot.

These are estimates only. We always recommend calling a few local suppliers to get current, accurate quotes for your specific needs before finalizing your project budget.

Conclusion

Throughout this guide, we have explored the properties and applications that make 22 gauge galvanized sheet metal a cornerstone material for professionals and hobbyists alike. Its unique position in the gauge system provides an optimal compromise that few other materials can match.

A Versatile Partner

22 gauge galvanized steel delivers an exceptional balance of durability, workability, and cost-effectiveness. The protective zinc coating ensures a long, maintenance-free service life, even in challenging environments. It is light enough to handle easily and thin enough to be formed with common tools, yet it retains the strength and stiffness needed for countless functional applications. From the ductwork that heats and cools our buildings to the flashing that keeps them dry, this material is a silent, reliable partner. By understanding its characteristics and how to work with it, you are now equipped to make it the smart choice for your next project.