Our Stereolithography (SLA) 3D Printing Services

Unlock unparalleled precision in additive manufacturing with Yigu Technology’s Stereolithography (SLA) solutions. Our cutting-edge resin-based printing delivers smooth surface finishes, rapid prototyping, and customized designs for industries from medical to aerospace—turn your most complex geometries into reality, faster and more cost-effectively than ever before.

What Is Stereolithography (SLA)?

Stereolithography (SLA) is a leading 3D Printing Technology and the first commercialized additive manufacturing method, pioneered in the 1980s. At its core, SLA relies on photopolymerization—a process where UV light cures liquid photopolymer resin layer by layer to build 3D objects. This layer-by-layer fabrication technique differs from traditional subtractive manufacturing (which cuts away material) by adding material only where needed, making it ideal for intricate designs.

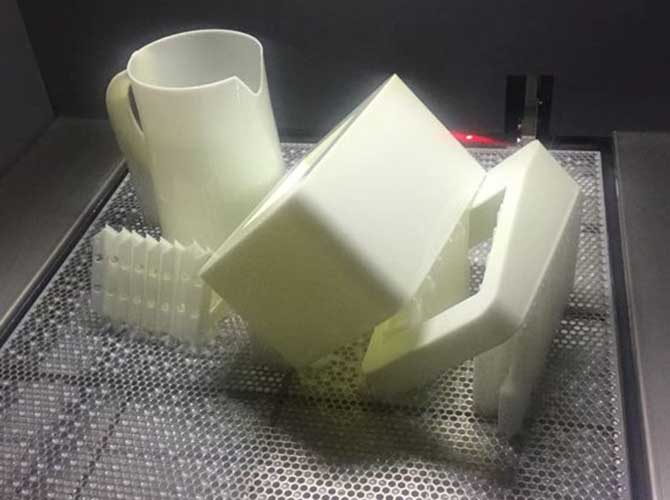

A quick SLA Process Overview reveals its simplicity: a build platform dips into a resin tank, UV light traces the first layer of the design, the platform lifts slightly, and the process repeats until the part is complete. Unlike other 3D printing methods, SLA excels at producing detailed, smooth parts right out of the printer.

SLA 3D Printing Capabilities

At Yigu Technology, we’ve refined our SLA Capabilities to meet the most demanding industrial needs. Our team combines advanced equipment with engineering expertise to deliver solutions that balance speed, precision, and flexibility. Below is a breakdown of our key strengths:

| Capability | Details & Benefits |

| High Precision Printing | Achieves dimensional accuracy down to ±0.1mm, critical for medical and aerospace parts. |

| Customized Solutions | Tailors SLA processes to unique project needs—from material selection to post-processing. |

| Rapid Prototyping | Turns CAD designs into physical prototypes in as little as 24 hours, accelerating product development. |

| Large Build Volume | Offers build chambers up to 500x500x600mm, supporting large parts or batch production of small components. |

| Multi-Material Printing | Works with engineering, flexible, and high-temperature resins to match part functionality. |

| Complex Geometry Handling | Prints undercuts, hollow structures, and fine details (down to 0.1mm) that traditional manufacturing can’t achieve. |

The SLA 3D Printing Process: Step-by-Step Breakdown

The SLA Process is a streamlined sequence of steps that ensures consistent, high-quality results. Each phase is optimized to minimize errors and maximize efficiency:

- Design Preparation: A 3D CAD model is sliced into thin layers (0.025–0.1mm thick) using specialized software.

- Resin Setup: A tank is filled with liquid photopolymer resin (selected for the part’s intended use).

- Layer Curing: A UV laser or LED array exposes the first resin layer, curing it into a solid shape based on the sliced design.

- Build Platform Movement: The platform lifts by the layer height, allowing fresh resin to flow beneath the cured layer.

- Repeat: Steps 3–4 repeat until the entire part is built.

- Post-Curing Process: The part is removed from the resin tank, cleaned (to remove excess resin), and exposed to additional UV light to fully harden—this step boosts strength and stability.

This layered manufacturing process ensures every detail of the original design is preserved, with minimal waste compared to traditional methods.

SLA 3D Printing Materials: Options for Every Application

The right SLA Materials are key to part performance, and Yigu Technology offers a diverse range of photopolymer resins to match industry needs. Below is a comparison of our most popular materials:

| Material Type | Key Properties | Typical Applications |

| Engineering Resins | High strength, impact resistance | Automotive components, industrial tooling |

| Dental Resins | Biocompatible, precise detail | Dental crowns, aligners, surgical guides |

| Medical Resins | FDA-approved, sterilizable | Prosthetics, surgical instruments |

| Clear Resins | Transparent, scratch-resistant | Consumer electronics, display parts |

| Flexible Resins | Elasticity (Shore A 50–90) | Gaskets, seals, wearable devices |

| High-Temperature Resins | Heat resistance (up to 200°C) | Aerospace components, mold inserts |

SLA 3D Printing Surface Treatment: Enhancing Part Quality

While SLA parts have a smooth surface right out of the printer, SLA Surface Treatment can further improve aesthetics, durability, or functionality. Yigu Technology offers the following post-processing techniques:

- Sanding: Uses fine-grit sandpaper (400–2000 grit) to remove layer lines and create a matte finish.

- Polishing: Applies compounds or ultrasonic cleaning to achieve a glossy, mirror-like surface (ideal for consumer products).

- Painting: Uses acrylic or spray paints to add color, UV protection, or chemical resistance.

- Coating: Adds epoxy or polyurethane coatings to boost strength and resistance to moisture or chemicals.

- Priming: Applies a base coat to improve paint adhesion (critical for parts used in harsh environments).

Our surface finishing experts work with you to choose the right treatment based on your part’s end use—whether it’s a visible consumer product or a durable industrial component.

SLA 3D Printing Tolerances: Delivering Dimensional Precision

SLA Tolerances are a defining advantage of the technology, making it suitable for parts that require strict dimensional control. Yigu Technology’s SLA systems consistently achieve:

| Tolerance Metric | Typical Range | Industry Standard Comparison |

| Dimensional Precision | ±0.1mm (for parts <100mm) | Tighter than FDM (±0.2mm) and SLS (±0.15mm) |

| Layer Height | 0.025–0.1mm | Thinner layers = smoother surface finish |

| Feature Resolution | Down to 0.1mm | Enables fine details like tiny holes or text |

This high accuracy and tight tolerances make SLA the top choice for medical devices, aerospace components, and other applications where even small deviations can cause failure.

Key Advantages of SLA 3D Printing

SLA Advantages set it apart from other 3D printing and manufacturing methods, making it a favorite for prototyping and production:

- High Resolution: Captures fine details (e.g., 0.1mm features) that are impossible with FDM or CNC machining.

- Smooth Surface Finish: Requires minimal post-processing compared to other 3D printing methods—parts often look “production-ready” right after curing.

- Fast Prototyping: Reduces lead times from weeks (traditional manufacturing) to days, speeding up product development cycles.

- Design Flexibility: Prints complex geometries (undercuts, hollow parts, lattice structures) without the need for molds or tooling.

Cost-Effective: Lowers upfront costs for small-batch production (no expensive molds) and reduces material waste (only uses resin needed for the part).

SLA 3D Printing Applications by Industry

SLA Applications span nearly every industry, thanks to its versatility and precision. Below are key use cases for each sector:

| Industry | Common SLA Applications |

| Automotive | Prototypes for dashboards, brackets, and lighting; functional test parts |

| Aerospace | Lightweight components, engine prototypes, and tooling |

| Medical | Custom prosthetics, surgical guides, and implant prototypes |

| Dental | Crowns, bridges, aligners, and model casts |

| Consumer Electronics | Phone cases, headphone parts, and display prototypes |

| Architecture | Detailed scale models of buildings and landscapes |

| Jewelry | Intricate wax patterns for casting gold/silver pieces |

| Industrial Design | Concept models for furniture, appliances, and toys |

SLA Manufacturing Techniques: How It Fits Into Production

SLA Manufacturing Process is a versatile addition to both prototyping and low-volume production. It complements other manufacturing techniques by addressing their limitations:

- Layered Manufacturing: Unlike CNC machining (which removes material), SLA adds material layer by layer—reducing waste by up to 90% for complex parts.

- Additive Fabrication: Works alongside SLS (selective laser sintering) but offers smoother surfaces and higher resolution, making it better for visible parts.

- Rapid Prototyping Techniques: Faster than traditional injection molding (which requires weeks to make molds) and more precise than FDM (fused deposition modeling).

At Yigu Technology, we integrate SLA with other processes (e.g., CNC finishing) to create end-use parts that meet even the strictest industry standards.

SLA Case Studies: Real-World Success Stories

Our SLA Case Studies demonstrate how we solve unique challenges for clients across industries:

Case Study 1: Medical Device Prototyping

A leading medical company needed a prototype of a surgical drill guide—with tight tolerances (±0.05mm) and biocompatible material. Using our medical resins and high-precision SLA systems, we delivered the prototype in 3 days (vs. 2 weeks with traditional methods). The client tested the guide, made design tweaks, and moved to production in just 2 weeks.

Case Study 2: Automotive Component Batch Production

An automotive manufacturer required 50 custom bracket prototypes for a new electric vehicle. Using our large build volume SLA printer, we produced all 50 parts in a single run (saving 40% on time and cost vs. FDM). The brackets, made with engineering resin, passed impact and heat tests, allowing the client to start road testing ahead of schedule.

Case Study 3: Dental Aligner Molds

A dental clinic needed 100 custom aligner molds for patients. Our dental resins and precise SLA process delivered molds with accurate tooth details, and post-processing (polishing) ensured smooth aligners. The clinic reduced mold production time by 50% and improved patient satisfaction with better-fitting aligners.

Why Choose Yigu Technology for SLA Services?

When you partner with Yigu Technology as your SLA Service Provider, you get more than just 3D printing—you get a team dedicated to your success. Here’s why clients choose us:

- Expertise: Our engineers have 10+ years of experience in SLA, with certifications in medical and aerospace standards.

- Quality: We use only industry-leading resins and equipment, with 100% quality checks on every part.

- Experience: We’ve completed 500+ SLA projects for clients in 20+ countries, from startups to Fortune 500 companies.

- Customer Service: Our team provides 24/7 support, from design consultation to post-processing, ensuring on-time delivery.

- Innovation: We invest in the latest SLA technology (e.g., faster UV LEDs, new resins) to keep your projects ahead of the curve.

Cost-Effective Solutions: We optimize processes to reduce waste and offer flexible pricing for small-batch and large-scale projects.