Our Soft Silicone Vacuum Casting Services

Elevate your prototyping and production with soft silicone vacuum casting—the go-to solution for high-quality, custom parts with tight tolerances, short lead times, and cost-effectiveness. Whether for automotive components, medical devices, or consumer electronics, our expertise in silicone mold making and precision casting ensures your projects meet the highest standards of durability and dimensional accuracy.

What Is Soft Silicone Vacuum Casting?

Soft silicone vacuum casting is a specialized manufacturing process that uses flexible silicone molds to produce small to medium batches of plastic or rubber parts. Unlike traditional injection molding, it relies on a vacuum molding process to eliminate air bubbles, ensuring uniform part quality. At its core, this technique involves two key steps: silicone mold making (creating a reusable mold from a master pattern) and casting (pouring liquid materials into the mold to form the final part).

In short, soft material casting (as it’s often called) bridges the gap between rapid prototyping and low-volume production, making it ideal for testing designs or fulfilling small-batch orders without the high costs of hard tooling.

Our Capabilities: Delivering Precision and Customization

At Yigu Technology, we leverage decades of experience to offer a full suite of soft silicone vacuum casting services tailored to your needs. Our capabilities include:

| Capability | Key Benefit |

| Custom silicone casting | Create parts in unique shapes, sizes, or textures to match your design specs. |

| High-quality casting | Rigorous quality checks ensure parts are free of defects (e.g., air bubbles). |

| Precision casting | Achieve tight dimensional accuracy, critical for medical or automotive parts. |

| Rapid prototyping | Turn design files into physical parts in as little as 3–5 days. |

| Production capabilities | Scale from 10 to 500+ parts per mold, perfect for low-volume production runs. |

Whether you need a single prototype or a small batch of end-use parts, our team ensures consistency and reliability across every project.

Process: Step-by-Step Breakdown of Soft Silicone Vacuum Casting

The vacuum casting process is streamlined yet precise, with each step designed to optimize quality and efficiency. Below is a detailed overview of the key stages:

- Master Pattern Creation: First, we produce a master pattern (usually 3D-printed or CNC-machined) that matches your desired part design. This pattern is the blueprint for the silicone mold.

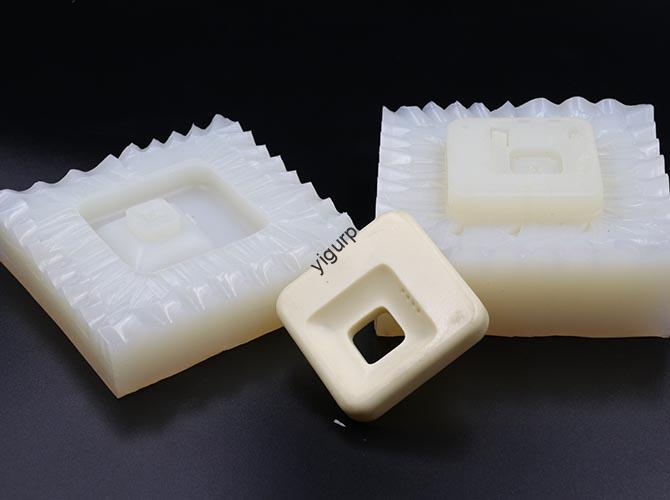

- Silicone Mold Creation: The master pattern is placed in a mold box, and liquid silicone is poured around it. The silicone cures (hardens) to form a flexible mold—typically in 4–8 hours, depending on the silicone type.

- Mold Preparation: Once cured, the silicone mold is split open, and the master pattern is removed. The mold now has a cavity that mirrors the part’s shape.

- Pouring Process: Liquid materials (e.g., polyurethane or rubber) are mixed with additives (if needed) and poured into the silicone mold. A vacuum chamber removes air bubbles to prevent defects.

- Curing Process: The mold is placed in a controlled environment (e.g., heated oven) to speed up curing. Curing times range from 1–24 hours, depending on the material and part thickness.

- Demolding and Finishing: The cured part is removed from the mold, and any excess material (flash) is trimmed. Optional surface treatments (e.g., painting or polishing) are applied next.

This step-by-step approach ensures that every part meets your design requirements and quality standards.

Materials: Choosing the Right Substrates for Your Project

The success of soft silicone vacuum casting depends on selecting the right materials for both the mold and the final part. Below is a breakdown of the most common materials we use:

| Material Category | Examples | Key Properties | Ideal Applications |

| Silicone materials | RTV-2 silicone, High-temperature silicone | Flexible, heat-resistant, reusable (20–50 casts) | Mold making for parts with complex details |

| Casting resins | Epoxy resin, Polyester resin | Rigid, strong, low shrinkage | Prototypes for consumer electronics |

| Polyurethane materials | TPU, TPE, PU foam | Soft, elastic, durable (resistant to wear/tear) | Medical devices, toy components |

| Rubber materials | Silicone rubber, Nitrile rubber | High flexibility, chemical resistance | Seals, gaskets for automotive parts |

| Additives and fillers | Pigments, Flame retardants, Reinforcements | Customize color, fire resistance, or strength | Parts for medical/industrial use |

Our engineers work with you to select materials that balance performance, cost, and lead time—ensuring your parts meet both functional and aesthetic needs.

Surface Treatment: Enhancing Aesthetics and Functionality

After casting, surface treatment plays a critical role in improving a part’s appearance, durability, or performance. We offer a range of finishing options to match your project goals:

- Surface finishing: Removes rough edges or flash to create a smooth, professional look—essential for consumer-facing parts (e.g., electronics cases).

- Painting and coating: Applies color-matched paints, UV-resistant coatings, or soft-touch finishes to enhance aesthetics or protect against wear.

- Texturing: Adds patterns (e.g., matte, glossy, or grip-friendly textures) to improve usability (e.g., medical device handles) or hide minor defects.

- Polishing: Creates a high-gloss finish for parts that require a premium look (e.g., automotive interior components).

- Surface enhancement: Includes processes like plasma treatment (to improve adhesion) or antimicrobial coatings (for medical devices).

Each treatment is tailored to your part’s material and application, ensuring long-lasting results.

Tolerances: Ensuring Dimensional Accuracy

Casting tolerances are critical for parts that need to fit with other components (e.g., automotive sensors or medical instruments). At Yigu Technology, we prioritize precision tolerances to meet even the strictest industry standards.

Our typical tolerance ranges for soft silicone vacuum casting are:

| Feature | Tolerance Range (mm) |

| Overall part dimensions | ±0.1–0.3 mm |

| Hole diameters | ±0.05–0.2 mm |

| Wall thickness | ±0.05–0.15 mm |

| Flatness | 0.1 mm/m |

To maintain dimensional accuracy, we use:

- High-precision master patterns (CNC-machined or 3D-printed with ±0.02 mm tolerance).

- Advanced tolerance control tools (e.g., coordinate measuring machines, or CMMs) to inspect parts post-production.

- Strict process controls (e.g., temperature/humidity monitoring during curing) to minimize shrinkage.

For projects requiring tight tolerances (e.g., medical device components), our engineers work closely with you to refine designs and adjust processes for optimal results.

Advantages: Why Choose Soft Silicone Vacuum Casting?

Soft silicone vacuum casting offers unmatched benefits for prototyping and low-volume production, making it a top choice for industries worldwide:

- Cost-effectiveness: No expensive hard tooling required—silicone molds cost 50–80% less than metal molds, ideal for small budgets.

- Short lead times: From design to part, the process takes 3–7 days (vs. 4–6 weeks for injection molding), accelerating time-to-market.

- High-quality parts: The vacuum process eliminates air bubbles, resulting in smooth, defect-free parts with consistent quality.

- Customization: Easily adjust designs, materials, or surface finishes without retooling—perfect for iterative prototyping.

Durability: Parts made with polyurethane or rubber materials are resistant to impact, chemicals, and temperature changes, ensuring long-term performance.

Applications Industry: Where Soft Silicone Vacuum Casting Shines

This versatile process is used across a wide range of industries, thanks to its flexibility and precision. Below are key sectors we serve:

- Automotive industry: Produces custom gaskets, sensor housings, and interior trim parts—with materials that withstand high temperatures and vibration.

- Medical devices: Creates biocompatible parts (e.g., catheter tips, device grips) that meet FDA and ISO standards for safety and sterility.

- Consumer electronics: Manufactures prototypes for phone cases, wearables, and remote controls—with surface finishes that match final production parts.

- Toys and games: Makes soft, durable components (e.g., doll limbs, game controllers) with custom colors and textures.

Industrial components: Produces seals, O-rings, and housings for machinery—with chemical-resistant materials that stand up to harsh environments.

Manufacturing Techniques: Innovations in Soft Silicone Vacuum Casting

At Yigu Technology, we combine traditional expertise with advanced manufacturing techniques to deliver superior results. Our key techniques include:

- Vacuum casting technique: Uses a high-pressure vacuum (up to -95 kPa) to remove air from the mold, ensuring no bubbles in the final part.

- Silicone molding technique: Uses dual-component RTV silicone for molds that capture fine details (e.g., logos or textures) and last for 20–50 casts.

- Precision manufacturing: Integrates 3D scanning and CMM inspection to ensure parts match design files within ±0.1 mm.

- Rapid manufacturing: Streamlines workflows (e.g., automated material mixing) to reduce lead times for urgent projects.

Advanced casting techniques: Includes overmolding (combining two materials in one part) and insert molding (adding metal components for strength).

Case Studies: Success Stories in Soft Silicone Vacuum Casting

Our work speaks for itself—here are two examples of how we’ve helped clients achieve their goals with soft silicone vacuum casting:

Case Study 1: Medical Device Prototyping

A client needed 50 prototypes of a silicone grip for a surgical tool. Key challenges: biocompatible material, tight tolerance (±0.05 mm for the grip’s inner diameter), and a 1-week lead time.

- Solution: We used medical-grade silicone rubber for the part and a high-precision CNC master pattern. The vacuum casting process eliminated bubbles, and CMM inspection confirmed all parts met tolerance requirements.

- Outcome: The client tested the prototypes with surgeons, made minor design tweaks, and ordered 200 more parts—all delivered within 5 days.

Case Study 2: Automotive Component Production

An automotive supplier needed 300 custom gaskets for a new electric vehicle (EV) battery. Key challenges: heat resistance (up to 150°C), chemical resistance to battery fluids, and a low-cost solution.

- Solution: We used flame-retardant polyurethane for the gaskets and a reusable silicone mold. The vacuum process ensured uniform thickness, and thermal testing confirmed the gaskets met heat resistance standards.

Outcome: The client saved 60% on tooling costs compared to injection molding and received the gaskets in 7 days—helping them meet their EV production timeline.

Why Choose Us: Partnering for Success

When you choose Yigu Technology for soft silicone vacuum casting, you get more than a supplier—you get a partner dedicated to your success. Here’s why clients trust us:

- Expertise in silicone casting: Our engineers have 15+ years of experience in mold design and material selection, ensuring optimal results for every project.

- Quality assurance: We follow ISO 9001 standards, with 100% inspection of parts before delivery (including dimensional checks and material testing).

- Customer service: Our team provides 24/7 support—from design 咨询 (consultation) to post-delivery follow-up—to address any questions or concerns.

- Experience in the industry: We’ve worked with 500+ clients across automotive, medical, and electronics sectors, understanding their unique challenges.

Competitive pricing: Our streamlined processes and bulk material purchasing let us offer rates that are 10–20% lower than competitors, without compromising quality.