If you’re tackling high-pressure oil and gas projects, heavy-duty construction, or demanding engineering tasks, you need a steel that can keep up.X70 pipeline structural steel is exactly that—it’s a high-strength solution trusted for its durability, универсальность, and reliability in tough conditions. This guide will break down everything you need to choose, использовать, and get the most out of X70 steel for your next project.

1. Material Properties of X70 Pipeline Structural Steel

X70’s performance starts with its carefully designed properties. Let’s break them into clear categories to make it easy to understand.

Химический состав

Ахимический состав of X70 is optimized to balance strength, стойкость, and workability—following global standards like API 5L. Вот типичный срыв:

| Элемент | Контент диапазон (wt%) | Ключевая роль |

|---|---|---|

| Углерод (В) | 0.22 максимум | Boosts strength without making the steel too brittle for welding/forming |

| Марганец (Мнжен) | 1.70 максимум | Enhances toughness and improves weldability |

| Кремний (И) | 0.40 максимум | Removes oxygen during steelmaking (prevents defects in the final product) |

| Фосфор (П) | 0.025 максимум | Строго ограничен (low levels avoid brittleness in cold weather) |

| Сера (С) | 0.010 максимум | Minimized to prevent cracking during rolling or welding |

| Хром (Герметичный) | 0.50 максимум | Улучшает коррозионную стойкость (critical for underground/marine pipelines) |

| Молибден (МО) | 0.25 максимум | Увеличивает высокую температуру прочность (ideal for hot oil pipelines) |

| Никель (В) | 0.30 максимум | Укрепляет низкотемпературную выносливость (works in freezing regions like Alaska) |

| Ванадий (V.) | 0.08 максимум | Refines grain structure for better overall mechanical performance |

Физические свойства

These traits affect how X70 behaves in real-world scenarios—from weight calculations to temperature changes:

- Плотность: 7.85 G/CM³ (то же самое, что и большинство структурных сталей, so it’s easy to estimate project weight)

- Точка плавления: ~1450–1520°C (compatible with standard steel manufacturing processes)

- Теплопроводность: 43 ж/(м · к) (spreads heat evenly, reducing stress during welding)

- Коэффициент термического расширения: 13.3 × 10⁻⁶/° C. (low enough to avoid warping in extreme heat or cold)

- Электрическое удельное сопротивление: 0.19 × 10⁻⁶ ω · м (не используется для электрических деталей, but useful for safety planning)

Механические свойства

X70’s mechanical strength is what makes it a top choice for high-pressure projects. Here are its key traits:

- Предел прочности: 570–720 МПа (can handle intense pulling forces without breaking)

- Урожайность: Минимум 483 МПА (stays strong even when stretched—vital for high-pressure pipelines)

- Твердость: 180–210 HB (сопротивляется износу из почвы, fluids, или движущиеся части)

- Воздействие на выносливость: ≥ 45 J при -40 ° C. (performs reliably in freezing climates)

- Пластичность: ≥ 18% удлинение (can bend or form into pipes without cracking)

- Устойчивость к усталости: Excellent for repeated stress (ideal for vibrating pipeline components or machine parts)

- Требование переломов: Высокий (prevents sudden, catastrophic failure in oil/gas lines)

Другие ключевые свойства

- Хорошая сварка: Works with common methods like MIG, Тиг, and stick welding—no special equipment needed, Экономия времени на проектах.

- Хорошая формируемость: Can be hot-rolled into large pipes, cold-bent into structural shapes, or forged into custom parts.

- Коррозионная стойкость: Holds up well in soil, fresh water, и мягкие химические вещества (add a coating for harsh environments like saltwater).

- Стойкость: Maintains strength in extreme temperatures—from -40°C (freezing) to 65°C (hot deserts).

2. Applications of X70 Pipeline Structural Steel

X70 isn’t just for pipelines—it solves problems across multiple industries. Here’s how it’s used in real-world projects:

Трубопроводная промышленность

А #1 use forX70 pipeline structural steel являетсяoil and gas pipelines. Its high yield strength and corrosion resistance make it perfect for transporting high-pressure crude oil, природный газ, and refined fuels over long distances.

Тематическое исследование: A major energy company used X70 steel for a 2,000 km natural gas pipeline in Canada. The pipeline had to handle 12 MPa of pressure and survive -35°C winter temperatures. После 10 годы, inspections showed zero leaks or corrosion (thanks to a 3-layer polyethylene coating) and no signs of stress—proving X70’s reliability in harsh northern conditions.

Строительная отрасль

В строительстве, X70 is used for heavy-duty structural needs:

- Компоненты конструкционной стали (supports for industrial factories)

- Балки и колонны (for long-span bridges and high-rise buildings)

- Строительные рамки (for power plants and warehouses)

Why X70? It’s stronger than lower-grade steels (like X52 or X65) but more cost-effective than ultra-high-strength options. Например, a highway bridge in Brazil used X70 beams to span 50 meters without extra supports. После 7 годы, the beams showed no bending or wear—even with heavy truck traffic.

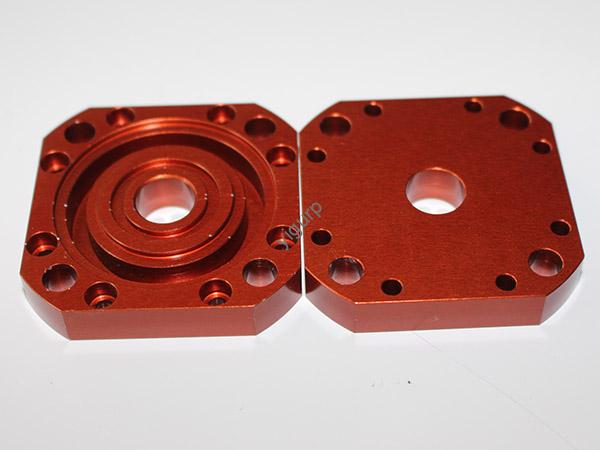

Машиностроение

Mechanical engineers rely on X70 for parts that need extreme strength:

- Передачи (его твердость и устойчивость к усталости prevent wear from constant movement)

- Валы (handles high rotational stress in industrial pumps and motors)

- Машины (durable for heavy equipment like mining conveyors)

A mining company switched to X70 for its conveyor shafts. The X70 shafts lasted 5x longer than the mild steel shafts they replaced—cutting downtime by 40%.

Морская промышленность

X70 works well in saltwater and offshore environments:

- Судовые сооружения (hulls and deck supports for large cargo ships)

- Оффшорные платформы (legs and braces for deep-sea oil rigs)

Тематическое исследование: An offshore oil platform in the North Sea used X70 steel for its support legs. The steel was coated with zinc-aluminum alloy to boost corrosion resistance. После 15 годы, the legs showed only minor rust—far better than the 8-year lifespan of the previous carbon steel legs.

Сельскохозяйственная техника

Farmers use X70 for heavy-duty equipment that faces rough terrain:

- Tractor parts (frames and engine blocks for large farm tractors)

- Плуги и борьба (resist wear from rocks and hard soil)

A farm equipment maker tested X70 plows against standard steel plows. The X70 plows lasted 3 growing seasons (против. 1 Для стандартной стали) and required fewer repairs—saving farmers thousands in replacement costs.

3. Manufacturing Techniques for X70 Pipeline Structural Steel

Making X70 steel requires precise steps to ensure it meets API 5L standards. Вот разрушение процесса:

Процессы создания стали

Two main methods produce X70, depending on volume and raw materials:

- Основная кислородная печь (Боф): The most common method for large-scale production. It uses molten iron (из взрывной печи) and blows oxygen into it to remove impurities. Легирующие элементы (like Mn and Mo) are added to hit X70’s chemical specs. Fast and cost-effective for mass-produced pipelines.

- Электрическая дуговая печь (Eaf): Использует электричество для таяния лома. Great for smaller batches or custom orders (НАПРИМЕР., specialized X70 parts for machinery). More flexible but slightly slower than BOF.

Термическая обработка

Heat treatment fine-tunes X70’s mechanical properties:

- Нормализация: Heats the steel to 870–970°C, then cools it in air. Improves ductility and makes the steel’s structure uniform (good for parts that need bending).

- Утомить и отпуск: Heats to 910–960°C, quenches (быстро охлаждается) в воде или масле, then tempers (reheats) to 560–660°C. This process boosts Урожайность и стойкость—critical for high-pressure pipelines.

- Отжиг: Heats to 810–860°C, cools slowly in a furnace. Reduces stress from forming (used for precision parts like gears).

Формирование процессов

X70 is shaped into final products using these methods:

- Горячая катящика: Heats the steel to 1100–1250°C, then rolls it through machines to make pipes, балки, или простыни. Fast and ideal for large-volume pipeline production.

- Холодный катание: Rolls the steel at room temperature. Creates smoother surfaces and tighter dimensions (used for precision parts like shafts).

- Ковкость: Молот или прижимает горячую сталь в сложные формы (НАПРИМЕР., Индивидуальные детали машины). Improves strength by aligning the steel’s grain structure.

- Экструзия: Pushes heated steel through a die to make tubes or hollow parts (used for small-diameter pipelines).

- Штамповка: Uses presses to cut or bend flat steel into parts like brackets (common in construction).

Поверхностная обработка

To boost corrosion resistance and lifespan, X70 gets these surface treatments:

- Гальванизация: Dips the steel in molten zinc. Creates a protective layer that prevents rust (длится 25+ лет на открытом воздухе).

- Рисование: Applies epoxy or polyurethane paint. Ideal for above-ground pipelines or structural parts.

- Выстрел в взрыв: Blasts the steel with tiny metal balls to remove rust, шкала, or dirt. Prepares the surface for coating.

- Покрытие: Uses fusion-bonded epoxy (FBE) or 3-layer polyethylene (3LPE) for pipelines. These coatings resist chemicals, soil, and saltwater—extending the steel’s life by 40+ годы.

4. X70 Pipeline Structural Steel vs. Другие материалы

How does X70 compare to other common materials? Let’s break it down to help you choose the right option.

X70 vs. Углеродные сталики (НАПРИМЕР., A36)

| Фактор | X70 Pipeline Structural Steel | Мягкая углеродистая сталь (A36) |

|---|---|---|

| Урожайность | 483 MPA Min | 250 MPA Min |

| Стойкость | Отличный (-40° C.) | Хороший (0°C only) |

| Сварка | Хороший | Очень хороший |

| Затрат | Better for high-pressure projects | Cheaper for light use (НАПРИМЕР., ограждение) |

| Лучше всего для | Oil/gas pipelines, длинные мосты | Маленькие здания, некритические части |

X70 vs. Высокопрочный сплав (HSLA) Стали (НАПРИМЕР., X80)

- Химический состав: X80 has more alloying elements (НАПРИМЕР., ниобий, титан) than X70, Делает его сильнее.

- Характеристики: X80 has a higher yield strength (551 MPA Min) but is less ductile than X70. X70 is easier to form and weld.

- Приложения: X80 is for ultra-high-pressure pipelines; X70 is better for most standard high-pressure projects (more cost-effective and easier to work with).

X70 vs. Нержавеющие стали (НАПРИМЕР., 304)

| Фактор | X70 Pipeline Structural Steel | Нержавеющая сталь (304) |

|---|---|---|

| Коррозионная стойкость | Хороший (с покрытием) | Отличный (без покрытия) |

| Урожайность | 483 MPA Min | 205 MPA Min |

| Расходы | Ниже ($1.20–$1.70/lb) | Выше ($3.00–$4.00/lb) |

| Лучше всего для | High-pressure pipelines | Продовольственная обработка, Медицинское оборудование |

X70 vs. Алюминиевые сплавы (НАПРИМЕР., 6061)

- Масса: Алюминий есть 1/3 the weight of X70 (great for aircraft), but X70 is 2.5x stronger.

- Коррозионная стойкость: Aluminum resists rust better, but X70 (с покрытием) handles soil and oil better.

- Расходы: X70 is cheaper than high-grade aluminum (saves money on large projects like pipelines).

- Производство: Aluminum is easier to cut, but X70 is better for high-temperature or high-pressure uses.

5. Yigu Technology’s Perspective on X70 Pipeline Structural Steel

В Yigu Technology, Мы поддерживали десятки клиентов в использованииX70 pipeline structural steel for high-stakes projects—from cross-country pipelines to offshore platforms. We see X70 as a “sweet spot” material: it offers the high strength needed for 10+ MPa pipelines while keeping weldability and formability intact. For oil and gas clients, X70’s cold-temperature toughness (-40° C.) solves the problem of winter-related brittleness. Для строительных клиентов, it’s a cost-effective upgrade from lower grades, cutting the need for extra supports. We also optimize X70’s manufacturing—using BOF for large pipeline orders and EAF for custom parts—to meet tight deadlines. Общий, X70 is our top recommendation for projects that need strengthи Гибкость.

FAQ About X70 Pipeline Structural Steel

1. Can X70 pipeline structural steel be used for offshore pipelines?

Да! X70 works perfectly for offshore pipelines when paired with a corrosion-resistant coating (like 3LPE). Егостойкость handles wave stress, and the coating prevents saltwater rust. We’ve supplied X70 for offshore projects in the Gulf of Mexico that have lasted 12+ лет без проблем.

2. Do I need special equipment to weld X70 steel?

No—X70 hasХорошая сварка and works with standard welding equipment (МНЕ, Тиг, палка). The only tip: use low-hydrogen electrodes to avoid weld cracking, especially in humid weather. Most fabricators don’t need extra training to weld X70.

3. How long does X70 steel last in underground pipelines?

With a proper coating (like FBE), X70 can last 35–50 years underground. Без покрытия, it lasts 20–25 years (depending on soil moisture). We recommend ultrasonic inspections every 5 years to catch small issues early and extend its life even further.