High-temperature silicone plugs are specialized elastomeric components designed to withstand extreme heat while sealing or protecting openings (НАПРИМЕР., отверстия, нить) in industrial, медицинский, and food-related applications. Made from high-purity silicone rubber blended with heat-resistant additives, they maintain elasticity and structural integrity even at temperatures far beyond standard silicone products. But what sets them apart from regular silicone plugs, how are they made, and how do you choose the right one?

1. Ключевые характеристики: Why High-Temperature Silicone Plugs Excel

High-temperature silicone plugs outperform standard silicone plugs and other sealing materials (НАПРИМЕР., резина, пластик) in four critical areas. The table below highlights their unique advantages:

| Характеристика | High-Temperature Silicone Plugs | Standard Silicone Plugs | Rubber/Plastic Plugs |

| Температурная стойкость | Выдерживает 200–350°C (короткий срок: 350° C для 2 часы); no cracking or hardening | Only tolerates up to 150°C; deforms above 180°C | Melts or brittle at 80–120°C |

| Physical Durability | Предел прочности: 3–8MPa; elongation at break: >400%; no permanent deformation after compression | Предел прочности: 2–5MPa; удлинение: <300%; prone to set after repeated use | Low tensile strength (<2МПА); cracks easily with friction |

| Химическая стабильность | Сопротивляется кислотам (PH 2–12), щелочи, масла, и растворители; no corrosion or swelling | Limited resistance to strong acids/alkalis; swells in oil | Dissolves or degrades in most chemicals |

| Safety Compliance | Food-grade variants meet FDA/GB standards; medical-grade options are biocompatible (no tissue irritation) | Rarely food/medical certified; may contain harmful additives | Often non-toxic but not suitable for food/medical contact |

2. Материалы & Процесс производства: Building Heat Resistance

The performance of high-temperature silicone plugs starts with material selection and strict production control. Below is a linear breakdown of the key steps:

Шаг 1: Material Blending (The Foundation of Heat Resistance)

- Base Silicone: Использовать fumed silica gel (Высокая чистота, low impurity content) as the base—this boosts density and heat resistance compared to precipitated silica.

- Additive Integration: Mix in specialized additives:

- Heat stabilizers (НАПРИМЕР., оксид железа) to prevent thermal oxidation at 300°C+.

- Антиоксиданты to extend aging resistance (service life: 5+ years in high-heat environments).

- For food/medical grades: Add non-toxic plasticizers (no phthalates) to maintain flexibility.

Шаг 2: Формование (Shaping for Precision)

Choose a molding method based on the plug’s shape and volume:

- Сжатие литья: Ideal for high-volume standard shapes (НАПРИМЕР., blind hole plugs). Heat silicone compound in a mold (160–180 ° C.) under pressure (10–20MPa) to form the plug.

- Extrusion Molding: Используется долго, cylindrical plugs (НАПРИМЕР., through-hole types). Push silicone through a die, then cut to length after cooling.

Шаг 3: Vulcanization (Locking in Performance)

- Primary Vulcanization: Cure the molded plug in an oven (180–200 ° C.) for 5–10 minutes to set the basic shape.

- Secondary Vulcanization: Post-cure at 200–220°C for 2–4 hours to remove volatile by-products. This step critical—without it, the plug may lose heat resistance over time.

Шаг 4: Quality Testing

- Проверять температурная стойкость: Expose samples to 350°C for 2 часы; ensure no deformation or hardness change.

- Проверять Точность размеров: Use calipers to confirm diameter (±0.1mm tolerance for precision plugs).

- For food/medical grades: Conduct toxicity tests (no heavy metals, no VOCs).

3. Приложения по промышленности: Where Heat Resistance Matters

High-temperature silicone plugs solve unique problems across sectors. Here’s how they’re used in key industries:

| Промышленность | Типичные варианты использования | Recommended Plug Type | Ключевые преимущества |

| Промышленное производство | – Protecting screw holes/process holes during high-temperature spraying (250° C+) or electroplating.- Sealing communication cabinet through-holes to prevent dust/chemical ingress. | Countersunk thread type (for threaded holes); large-diameter plugs (25–50mm for big process holes) | Resists paint/chemicals; многоразовый (до 50 раз) |

| Медицинские устройства | – Sealing medicine bottle necks (prevents drug contamination).- Protecting medical instrument ports during autoclave sterilization (134° C., высокое давление). | Small-diameter blind hole plugs (3–10 мм); medical-grade silicone | Биосовместимый; withstands repeated sterilization |

| Продовольственная обработка | – Sealing food can lids (maintains freshness).- Covering baking mold holes (prevents batter leakage during oven heating, 220° C.). | Food-grade transparent plugs; heat-resistant up to 250°C | Нетоксичный; Легко чистить (Безбелевая посудомоечная машина) |

| Научные исследования | – Sealing laboratory flasks/test tubes during high-temperature experiments (НАПРИМЕР., distillation at 200°C).- Protecting sensor ports in environmental chambers (температура езда на велосипеде: -40° C до 300 ° C.). | Heat-resistant through-hole plugs; flexible variants (for irregular openings) | Withstands extreme temperature swings; ensures airtight seals |

4. Спецификация & Shape Guide: Choose the Right Fit

Selecting the wrong size or shape leads to leaks or damage. Use this table to match plugs to your needs:

| Specification/ Shape | Ключевые детали | Идеально подходит для |

| Диаметр (Общие размеры) | – Маленький: 3–10 мм (medical bottles, пробирки)- Середина: 11–20 мм (industrial process holes)- Большой: 21–50 мм (automotive/communication cabinets) | Choose based on the hole’s inner diameter (add 0.5–1mm for a tight seal) |

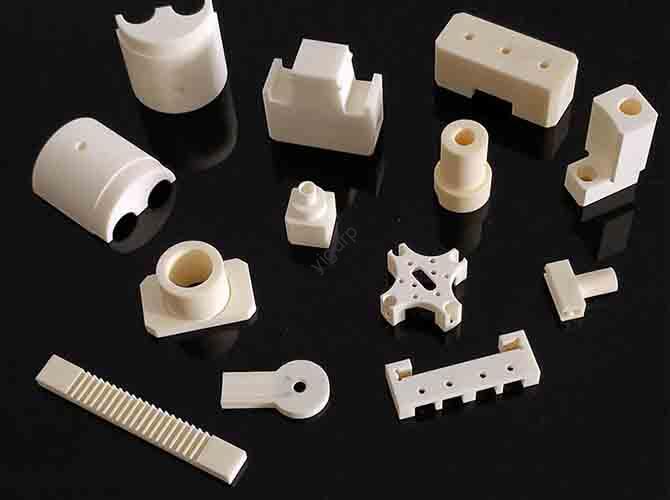

| Shape Types | – Through-Hole Type: Hollow center; fits holes that need to be penetrated (НАПРИМЕР., sensor wires).- Blind Hole Type: Solid bottom; seals one-end closed holes (НАПРИМЕР., medicine bottle necks).- Countersunk Thread Type: Has a recessed top; fits countersunk threaded holes (НАПРИМЕР., Машины). | Through-hole: Wire/cable pass-throughsBlind hole: Full sealing needsCountersunk: Threaded hole protection |

5. Yigu Technology’s Perspective on High-Temperature Silicone Plugs

В Yigu Technology, we see high-temperature silicone plugs as “heat-resistant guardians” for critical components. Для промышленных клиентов, наш countersunk thread plugs reduce rework rates by 60% during high-temperature spraying—they stay in place even at 300°C and leave no residue. For medical partners, наш FDA-certified blind hole plugs undergo 100+ autoclave cycles without losing flexibility, ensuring drug safety.

Заглядывая в будущее, we’ll focus on two innovations: 1) Developing ultra-high-temperature plugs (до 400 ° C.) for aerospace applications, и 2) Creating custom shapes (НАПРИМЕР., irregular holes) with 3D printing technology to reduce lead time by 30%. Our goal is to make high-temperature silicone plugs more adaptable to extreme and niche scenarios.

Часто задаваемые вопросы

- How to clean and reuse high-temperature silicone plugs?

For industrial plugs: Wipe with a solvent (НАПРИМЕР., изопропиловый спирт) to remove paint/chemicals; avoid sharp tools that scratch the surface. For food/medical plugs: Wash with warm soapy water or autoclave (134° C.). Most plugs can be reused 30–50 times if no cracks or deformation occur.

- Can high-temperature silicone plugs be used in low-temperature environments?

Yes—they maintain flexibility from -60°C to 350°C. This makes them ideal for applications with temperature swings (НАПРИМЕР., outdoor industrial equipment that faces cold nights and hot days).

- What’s the difference between food-grade and industrial-grade high-temperature silicone plugs?

Food-grade plugs use non-toxic additives (no heavy metals/VOCs) and meet FDA/GB food safety standards; they’re safe for direct food contact. Industrial-grade plugs may contain cost-effective additives (НАПРИМЕР., carbon black for UV resistance) that are not food-safe—never use them in food processing.