If you’re searching for “Vacuum Casting Germany,” you’re likely a product developer, инженер, or manufacturer needing high-precision, low-volume parts—whether for prototyping, Предварительное производство, или небольшая партия производства. Germany is a global leader in this technology, thanks to its strict quality standards, advanced machinery, and expertise in materials science. Суммируя, vacuum casting in Germany доставляет последовательно, detailed parts with excellent surface finishes, making it ideal for industries like automotive, медицинский, и аэрокосмическая. This guide will break down everything you need to know, from how the process works to choosing the right partner and understanding the latest trends.

What Is Vacuum Casting, and Why Does Germany Excel at It?

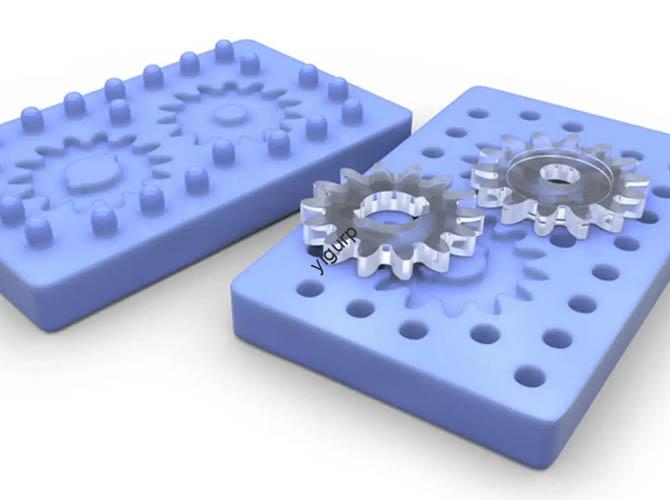

Вакуумный кастинг (также называется вакуумной репликацией) is a low-volume manufacturing process that uses a silicone mold to produce plastic or resin parts. В отличие от инъекционного литья, который требует дорогого металлического инструмента, vacuum casting uses flexible silicone molds—making it cost-effective for runs of 10 к 1000 части. The process works by placing a master model (часто 3D-печать) into a mold frame, pouring liquid silicone around it, and curing the silicone to create a mold. Как только форма будет готова, liquid resin is poured into it under vacuum pressure (to eliminate bubbles), cured, and then removed—resulting in parts that match the master’s detail.

Germany stands out in vacuum casting for three key reasons:

- Стандарты качества: German manufacturers adhere to DIN (Deutsches Institut für Normung) and ISO standards, ensuring parts meet strict tolerances (often as tight as ±0.1mm for small components).

- Материальные инновации: German suppliers offer a wide range of high-performance resins, в том числе огнестойкий, медицинский состав, and heat-resistant options—critical for industries like automotive and healthcare.

- Техническая экспертиза: German engineers have decades of experience optimizing the vacuum casting process, от дизайна плесени до постобработки, reducing defects and improving consistency.

Пример реального мира: A Berlin-based automotive startup needed 500 prototype dashboard components for testing. Using vacuum casting from a Bavarian supplier, they received parts with a matte finish (matching the final production spec) в просто 10 days—at 70% the cost of injection molding tooling.

Key Applications of Vacuum Casting in Germany’s Top Industries

Germany’s industrial landscape relies heavily on vacuum casting for its flexibility and precision. Below are the sectors where it’s most widely used, with specific use cases:

Automotive and Mobility

Немецкая автомобильная промышленность (home to BMW, Мерседес-Бенц, and Volkswagen) uses vacuum casting for prototyping and low-volume parts like:

- Внутренние компоненты (НАПРИМЕР., Дверные ручки, center console prototypes)

- Exterior trim pieces (НАПРИМЕР., bumper caps, зеркальные корпусы)

- Части под рукой (НАПРИМЕР., Корпуса датчиков, Кабельные организаторы)

Точка данных: According to the German Association of the Automotive Industry (VDA), 65% of automotive prototypes in Germany are produced using vacuum casting or 3D printing—with vacuum casting preferred for parts requiring high surface quality.

Medical Technology

Germany is a leader in medical device manufacturing (companies like Siemens Healthineers and B. Браун), and vacuum casting is ideal here because it:

- Uses biocompatible resins (Соответствует ISO 10993 and FDA standards)

- Produces parts with smooth surfaces (critical for devices like surgical tools or diagnostic equipment)

- Enables quick iterations for prototype testing

Тематическое исследование: A Hamburg-based medical device firm needed 200 prototypes of a new insulin delivery pen. A German vacuum casting provider used a medical-grade polycarbonate resin, delivering parts that passed biocompatibility tests and were ready for clinical trials in 2 недели.

Аэрокосмическая и защита

For aerospace applications (НАПРИМЕР., parts for drones, спутники, or aircraft interiors), vacuum casting in Germany offers:

- Resistance to extreme temperatures (using high-performance resins like PEEK or epoxy)

- Lightweight parts with high strength-to-weight ratios

- Compliance with aerospace standards (НАПРИМЕР., В 9100)

Потребительская электроника

Brands like Siemens and Bosch use vacuum casting for small-batch production of electronics parts, такой как:

- Custom enclosures for IoT devices

- Prototypes for smartphones or wearables

- Cable connectors with tight tolerances

How Vacuum Casting Works in German Facilities: Пошаговый сбой

German manufacturers follow a standardized, detail-oriented process to ensure consistent results. Ниже приведен пошаговый обзор, with insights into how German practices differ from global standards:

- Главная подготовка модели

The master model (the “template” for the final part) is usually 3D-printed using SLA (Стереолитмикромография) или Sls (Селективное лазерное спекание) технология. German facilities often use high-precision 3D printers (with layer heights as low as 0.025mm) to ensure the master has no defects. If the part requires a specific finish (НАПРИМЕР., глянцевый, текстурированная), the master is post-processed (sanded, окрашен) to match.

- Создание силиконовой плесени

The master is placed in a mold frame, and liquid silicone (often a two-part silicone rubber) Облится вокруг него. German manufacturers use vacuum chambers during this step to remove air bubbles from the silicone—ensuring the mold captures every detail of the master. The silicone is then cured in an oven (typically at 60–80°C for 2–4 hours). После вылечения, the mold is cut open to remove the master, leaving a cavity that matches the part’s shape. Most silicone molds can produce 20–50 parts before needing replacement (German silicones often last longer than standard silicones, до 100 parts for high-quality grades).

- Resin Pouring and Curing

Liquid resin is mixed (with colorants or additives if needed) и залил в силиконовую форму. The mold is then placed in a vacuum chamber to eliminate air bubbles—this is critical for parts with complex geometries (НАПРИМЕР., тонкие стены, маленькие дыры). German facilities use digital vacuum controllers to maintain precise pressure (обычно -0.95 бар) throughout the process. The mold is then cured (either with heat or UV light, в зависимости от смолы) for 1–4 hours.

- Пост-обработка

После лечения, the part is removed from the mold. German manufacturers then perform post-processing steps like trimming excess resin, шлифование, рисование, or adding inserts (НАПРИМЕР., metal threads). Some facilities also offer additional treatments, such as plating (for metal-like finishes) or annealing (Чтобы улучшить силу части).

Ключевое различие: German facilities often use automated systems for resin mixing and pouring, reducing human error and ensuring consistent resin ratios. They also conduct 100% visual inspections of parts (using high-magnification cameras) to check for defects—something not all global providers do.

Choosing the Right Vacuum Casting Partner in Germany: Что искать

With so many providers in Germany, selecting the right partner can be overwhelming. Below is a checklist of factors to consider, based on industry best practices:

| Фактор | Что искать | Почему это важно |

| Качественные сертификаты | DIN EN ISO 9001 (Управление качеством), Iso 13485 (медицинские устройства), В 9100 (аэрокосмическая) | Certifications ensure the provider follows strict quality control processes—critical for regulated industries. |

| Материал | Access to high-performance resins (НАПРИМЕР., медицинский состав, Пламя-возобновляющий, теплостойкий) and the ability to source custom materials | Ensures the part meets your application’s requirements (НАПРИМЕР., Биосовместимость для медицинских деталей). |

| Сроки выполнения | Ability to deliver parts in 5–10 business days (standard for German providers) | Fast turnaround is key for prototyping or pre-production testing. |

| Поддержка дизайна | In-house engineers who can review your 3D model for manufacturability (ДФМ) | DFM reviews help avoid design flaws that could ruin the mold or part. |

| Volume Capacity | Experience with runs of 10–1000 parts (the sweet spot for vacuum casting) | Some providers specialize in small runs (10–50 деталей), while others handle larger batches (500–1000 деталей). |

| Отзывы клиентов | Positive feedback from clients in your industry (НАПРИМЕР., Автомобиль, медицинский) | Отзывы свидетельствуют о надежности и качестве — ищите поставщиков с 4.5+ звездный рейтинг на таких платформах, как Trustpilot. |

Кончик: Попросите образец детали перед размещением большого заказа.. Большинство немецких поставщиков производят один образец. (за небольшую плату) продемонстрировать свое качество.

Cost of Vacuum Casting in Germany: Чего ожидать

Вакуумное литье в Германии дороже, чем в таких странах, как Китай., но более высокая стоимость отражает лучшее качество, более быстрые сроки выполнения, и более строгие стандарты. Ниже приведена разбивка типичных затрат (по состоянию на 2025):

- Мастер-модель: 150–500 евро (в зависимости от размера и сложности; 3Модели SLA, напечатанные на D-печати, более доступны, чем модели, изготовленные на станках с ЧПУ.).

- Силиконовая плесень: €300–€1,200 (cost varies by mold size and silicone grade; medical-grade silicone is more expensive).

- Стоимость за участие: €5–€50 (for small to medium parts; larger or more complex parts can cost up to €100 each).

Пример: Для 100 small automotive prototype parts (НАПРИМЕР., a 5cm x 3cm sensor housing), total costs would be:

- Master model: € 200

- Silicone mold: €400

- Per-part cost: €8 x 100 = €800

- Общий: €1,400

Сравните это с литьем под давлением., which would cost €5,000–€10,000 for metal tooling (plus €1–€2 per part)—vacuum casting is far more cost-effective for low volumes.

Cost-Saving Tip: If you need multiple similar parts, ask the provider to design a “family mold” (a single mold with multiple cavities). This reduces mold costs and per-part costs.

Latest Trends in Vacuum Casting Technology in Germany

German manufacturers are constantly innovating to improve vacuum casting’s speed, качество, и устойчивость. Here are the top trends to watch:

1. Устойчивые материалы

As Germany pushes for carbon neutrality (per its Energiewende, or “energy transition”), providers are switching to eco-friendly resins. These include:

- Bio-based resins (made from plant-based materials like corn starch)

- Recycled resins (using post-consumer plastic waste)

- Low-VOC (volatile organic compound) смолы (reducing environmental impact and improving workplace safety)

Точка данных: According to the German Federation of the Chemical Industry (VCI), the use of sustainable resins in vacuum casting has increased by 35% since 2022.

2. Automation and Digitalization

German facilities are adopting Industry 4.0 technologies to streamline the process:

- Digital Mold Monitoring: Sensors in silicone molds track temperature and pressure, alerting operators to issues (НАПРИМЕР., mold degradation) before they affect parts.

- AI-Powered DFM: Artificial intelligence tools analyze 3D models to predict potential manufacturing issues (НАПРИМЕР., thin walls that could crack) and suggest design changes.

- Automated Post-Processing: Robots handle tasks like trimming and sanding, reducing labor costs and improving consistency.

3. Гибридное производство

Some German providers are combining vacuum casting with 3D printing to create “hybrid parts.” For example:

- A 3D-printed core (для силы) is encapsulated in a vacuum-cast resin outer layer (for surface finish).

- This approach is ideal for parts that need both high strength (НАПРИМЕР., структурные компоненты) and a smooth appearance (НАПРИМЕР., consumer-facing parts).

Yigu Technology’s Perspective on Vacuum Casting Germany

Yigu Technology recognizes that Germany sets the global benchmark for vacuum casting excellence, particularly in quality control and material innovation. The country’s focus on compliance with strict standards (like DIN and ISO) aligns with our commitment to delivering reliable, application-ready parts for clients worldwide.

What stands out most about German vacuum casting is its balance of precision and flexibility—critical for today’s fast-paced product development cycles. While costs are higher than in some regions, the reduced risk of defects, более быстрые сроки выполнения, and access to specialized materials (like medical-grade resins) often justify the investment, especially for industries where quality cannot be compromised.

В Yigu Technology, we often collaborate with German partners to leverage their expertise for complex projects, ensuring our clients benefit from the best of global manufacturing capabilities.

FAQ About Vacuum Casting Germany

1. How long does vacuum casting in Germany take?

Most providers deliver parts in 5–10 business days. This includes master model preparation (1–2 дней), silicone mold creation (2–3 дней), resin casting and curing (1–2 дней), и пост-обработка (1 день).

2. What materials are used in German vacuum casting?

Common materials include polyurethane resins (the most popular, для общего использования), epoxy resins (for high strength), acrylic resins (для прозрачности), and specialty resins (НАПРИМЕР., медицинский состав, Пламя-возобновляющий, или термостойкий).

3. Is vacuum casting in Germany suitable for large production runs?

No—vacuum casting is ideal for low to medium runs (10–1000 деталей). Для пробежек 1000+ части, injection molding is more cost-effective (once tooling costs are amortized).

4. Can vacuum casting in Germany produce parts with tight tolerances?

Yes—German providers can achieve tolerances of ±0.1mm for small parts (up to 10cm) and ±0.2mm for larger parts (10–30cm). This is due to high-precision master models and strict process control.

5. Do German vacuum casting providers offer design support?

Most do—many have in-house engineers who provide DFM (Дизайн для производства) reviews to ensure your 3D model is optimized for vacuum casting (НАПРИМЕР., avoiding undercuts, ensuring adequate wall thickness).