In the competitive world of product development, time is money. If you’ve ever struggled with long wait times for traditional tooling or high costs for small-batch production, аrapid tooling process Ваше решение. This efficient manufacturing technique bridges the gap between prototype design and finished products, helping teams verify ideas fast and get to market sooner. Давайте разберемся, как это работает, его ключевые преимущества, and when to use it.

1. What Is the Rapid Tooling Process?

Проще говоря, Быстрое инструмент is a set of manufacturing methods designed to create tooling (формы, умирает, и т. д.) quickly and cost-effectively—without the long lead times of traditional tooling. Unlike conventional processes that can take months to make molds, rapid tooling cuts this time to weeks (or even days).

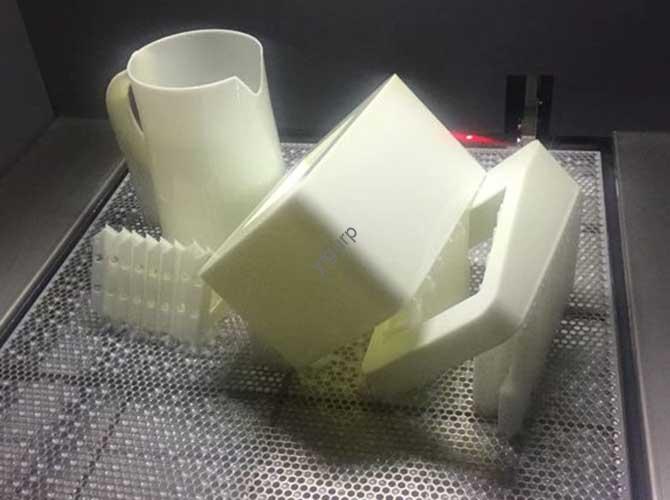

Think of it as “fast-track tooling”: instead of building a tool from scratch with slow, manual steps, it uses modern tech (like 3D printing or CNC machining) to streamline the process. It’s perfect for theearly stages of product development—when you need to test designs, make adjustments, or produce small batches (usually 10–1,000 units) before full-scale production.

2. When Should You Use Rapid Tooling?

Not sure if rapid tooling fits your project? The table below highlights the top scenarios where it delivers the most value:

| Сценарий | Why Rapid Tooling Works | Пример реального мира |

|---|---|---|

| Product Design Verification | Tests if your design is feasible before big investments | Создание стартапа 50 plastic prototypes of a new water bottle to check fit and function |

| Маленькая партийная производство | Avoids high costs of traditional tooling for low volumes | A electronics brand producing 200 custom phone cases for a limited-edition launch |

| Дизайн итерация | Lets you tweak designs fast without redoing tooling | A toy company revising a doll’s arm shape and making 100 Новые прототипы в 2 недели |

| Emergency Production | Fills gaps when traditional tooling is delayed | A medical device maker using rapid tooling to make 50 replacement parts for a urgent order |

3. Step-by-Step Rapid Tooling Workflow

The rapid tooling process follows a clear, linear path—from design to finished product. Below is a detailed timeline to show how each phase fits together:

Фаза 1: Дизайн & Оптимизация (1–3 Days)

This is where you lay the groundwork for successful tooling.

- 3D Моделирование: Используйте профессиональное программное обеспечение CAD (НАПРИМЕР., Солидворкс, Autocad) to create a detailed 3D model of your product. This model is the “blueprint” for everything next.

- Анализ & Оптимизация: Run structural simulations (НАПРИМЕР., стрессовые тесты) on the 3D model. Fix flaws (like weak spots) to ensure the design works for mold manufacturing.

Фаза 2: Подготовка плесени (3–7 Days)

Now you’ll create the tool (форма) itself—this is where rapid tooling saves the most time.

| Шаг | Ключевые действия |

|---|---|

| Выбор материала | Pick the right mold material (silicone for flexibility, metal for durability) based on your product (НАПРИМЕР., plastic vs. резина). |

| Mold Base Creation | Make the mold’s base usingОбработка с ЧПУ (для точности) или3D Печать (для скорости). This base holds the mold’s shape. |

| Master Mold Making (If Using Silicone) | For silicone molds, first make a precise master mold (via 3D printing or CNC) — this is the “template” for the final silicone mold. |

| Silicone Depositing | Pour liquid silicone over the master mold. Let it cure (usually 6–24 hours) to form a flexible, reusable mold. |

Фаза 3: Инъекционное формование & Производство (2–5 Days)

With the mold ready, it’s time to make the finished products.

- Mold Assembly: Attach the mold to an injection molding machine. Make sure it’s secured tightly to avoid leaks.

- Raw Material Prep: Gather the materials for your product (НАПРИМЕР., Пластиковые гранулы, resin powders). Melt them down into a liquid state.

- Настройка параметров: Adjust the injection molding machine’s key settings: температура (180–250°C for plastic), давление (500–2,000 psi), и время охлаждения (10–30 секунд).

- Инъекция & Выклятый: Inject the molten material into the mold. Let it cool and harden, then remove the finished part.

Фаза 4: После лечения & Проверка качества (1–2 Days)

Finish the products to meet your standards.

- Выслушивание: Use a blade or sandpaper to remove small flaws (нормы, вспышка) from the edges of the part.

- Шлифование & Рисование: Sand the surface for smoothness, then paint it (При необходимости) Чтобы улучшить внешний вид.

- Качественная проверка:

- Проверка размеров: Use calipers or 3D scanners to ensure the part’s size matches the original 3D model.

- Функциональное тестирование: Test how the part works (НАПРИМЕР., if it’s a hinge, Проверьте, открывается ли это и закрывается плавно).

4. Rapid Tooling vs. Traditional Tooling: A Quick Comparison

How does rapid tooling stack up against the conventional method? Let’s break down the key differences:

| Фактор | Быстрое инструмент | Traditional Tooling |

|---|---|---|

| Время выполнения | 1–4 недели | 2–6 месяцев |

| Расходы (Для небольших партий) | Низкий (no expensive manual labor) | Высокий (requires skilled labor and long setup) |

| Batch Size Ideal For | 10–1000 единиц | 10,000+ единицы |

| Гибкость | Высокий (easy to tweak designs) | Низкий (hard to change once tooling is made) |

| Tech Used | 3D Печать, Обработка с ЧПУ | Manual machining, Эдм (Электрическая обработка) |

5. Yigu Technology’s Take on Rapid Tooling

В Yigu Technology, Мы использовалиrapid tooling process to help 300+ clients cut product development time by 40% в среднем. It’s a game-changer for startups and SMEs—letting them test ideas without risky, big investments. We often combine silicone molds (для гибкости) and CNC machining (для точности) to tailor solutions. For clients in consumer goods and medical devices, it’s not just about speed; it’s about getting high-quality parts that meet industry standards fast. Rapid tooling isn’t just a process—it’s how we help our clients stay ahead in a fast-moving market.

Часто задаваемые вопросы

1 квартал: How long does a rapid tooling mold last?

Это зависит от материала: silicone molds last 10–50 uses (Отлично подходит для небольших партий), while metal rapid tooling molds can last 1,000–10,000 uses (better for repeated production).

2 квартал: Can rapid tooling make parts as strong as traditional tooling?

Да! If you use high-quality materials (like engineering-grade plastic or metal), rapid tooling parts match the strength of traditional ones. The key is choosing the right material for your product’s use case.

Q3: Is rapid tooling only for plastic parts?

No—you can use it for a range of materials, including rubber, смола, И даже некоторые металлы (как алюминий). It’s versatile enough for products from toys to medical devices.