Our CNC Polishing Services

Elevate your parts’ aesthetics and performance with our CNC Polishing services—the gold standard for precision polishing and consistent surface finishes across industries. Использование продвинутого automated polishing технология, Мы трансформируем металлы (нержавеющая сталь, титан), пластмассы, композиты, and glass into flawless components with Ra values as low as 0.02μm. Whether you need mirror-like medical tools, corrosion-resistant aerospace parts, or sleek consumer goods, our custom solutions blend efficiency, универсальность, and uncompromising quality—reducing manual labor and ensuring every part shines.

What Is CNC Polishing?

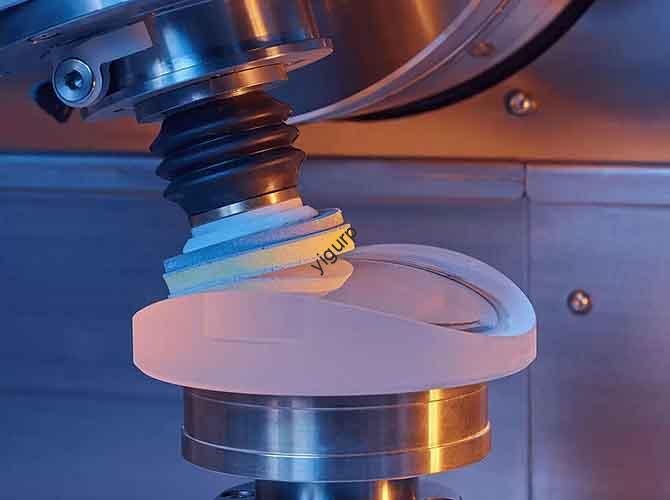

Полировка с ЧПУ is an advanced surface-finishing технология that uses computer-controlled machines to smooth, уточнить, and enhance the surface of materials—replacing manual polishing with automated precision. Unlike manual polishing (which relies on human skill and is prone to inconsistency), it uses pre-programmed tool paths and specialized abrasives to achieve uniform, repeatable results.

А Обзор процесса просто: A CNC (Компьютерное числовое управление) system interprets design files to guide polishing tools (НАПРИМЕР., полировки колеса, abrasive pads) across the material’s surface. The machine adjusts pressure, скорость, and abrasive grit based on the material and desired finish—removing micro-imperfections (царапины, Оценки инструмента) without altering the part’s dimensions.

To explain “Как это работает” simply: Imagine a robot armed with a series of fine sandpapers and buffing pads, following a digital map to polish every inch of a part. For a stainless steel medical tool, the CNC machine first uses a coarse abrasive to remove machining marks, then progresses to finer grits to create a mirror finish—all without human error. This blend of automation and precision is what makes Полировка с ЧПУ superior to manual methods, especially for complex or high-volume parts.

Our CNC Polishing Capabilities

We offer comprehensive polishing capabilities tailored to diverse materials and finish requirements, с акцентом на точные уровни, surface finish quality, и гибкость. Below is a detailed breakdown of our key capacities:

| Способность | Спецификация |

| Точные уровни | – Шероховатость поверхности (Раствор): 0.02μm–1.6μm (mirror finish to matte finish)- Dimensional tolerance retention: ± 0,001 мм (no part distortion) |

| Tolerance Achievements | – Maintains original part tolerances (встречает ISO 2768-1 прекрасная оценка)- Uniformity: ±0.05μm Ra variation across the part surface |

| Максимальный размер детали | – Небольшие части: 0.5mm × 0.5mm × 0.5mm (micro-components like medical needles)- Большие части: 3000mm × 1500mm × 800mm (аэрокосмические панели, Автомобильные части кузова)- Масса: Up to 500kg |

| Совместимость материала | – Металлы: Нержавеющая сталь, алюминий, титан, латунь, медь, экзотические металлы (inconel, тантал)- Non-Metals: Пластмассы (АБС, поликарбонат), композиты, стекло, керамика- Special Materials: Высокопроизводительные полимеры (Заглядывать), optical glass |

| Custom Polishing | – Finish types: Зеркало (Ra ≤ 0.05μm), атласный (Ra 0.1–0.2μm), матовый (RA 0,8–1,6 мкм), почистота (linear grain)- Сложная геометрия: Внутренние полости, Изогнутые поверхности, подписаны (via 5-axis polishing heads) |

| Surface Finish Quality | – Meets industry standards: ASTM B607 (metal polishing), Iso 8785 (шероховатость поверхности)- Specialized finishes: Электрополирован (для коррозионной стойкости), chemically polished (для пластмасс) |

| Гарантия качества | – Встроенная проверка: Laser profilometers (real-time Ra measurement)- Post-polishing: Оптические компараторы, CMMS (verify dimensions and finish)- Согласие: Iso 9001, AS9100 (аэрокосмическая), Iso 13485 (медицинский) |

Нужно ли вам 100 titanium orthopedic implants with a 0.03μm Ra finish or 10,000 aluminum smartphone casings with a satin finish, our capabilities scale to match your project’s needs.

The CNC Polishing Process (Шаг за шагом)

Наш Пошаговый процесс is optimized to deliver consistent, high-quality finishes while preserving the part’s original dimensions:

- Design and CAD Modeling: We start by reviewing your part’s CAD model and finish requirements (НАПРИМЕР., Ra value, finish type). Our engineers identify critical areas (НАПРИМЕР., bearing surfaces that need ultra-smooth finishes) and select the best polishing technique (механический, химический, or electrochemical) for the material.

- CAM программирование: The CAD model is imported into CAM software (Мастеркам, SolidWorks CAM) to generate пути инструментов—mapping the polishing tool’s movement across the part. We program parameters like tool speed (500–3000 RPM), давление (1–10 н), and abrasive grit sequence (coarse → medium → fine) to achieve the desired finish.

- Setup and Calibration: The part is secured in custom дизайн приспособления (НАПРИМЕР., vacuum chucks for thin parts, soft jaws for delicate plastics) чтобы предотвратить движение. We calibrate the polishing tool’s pressure and alignment using laser sensors—ensuring it follows the tool path without altering the part’s dimensions. Abrasives and coolant systems (for heat-sensitive materials) are loaded.

- Polishing Execution: The CNC machine runs the program, progressing through the abrasive sequence. Например:

- Механическая полировка: Uses rotating buffing wheels with abrasive compounds (alumina for metals, diamond for ceramics) to remove imperfections.

- Электрохимическая полировка: Applies an electric current and chemical solution to dissolve surface imperfections (ideal for stainless steel medical parts).

- Vibratory Polishing: Tumbles small parts with abrasive media (керамические бусы) for uniform finishing (great for high-volume small components like brass connectors).

Post-Polishing Inspection: Parts undergo rigorous Контроль качества—we measure surface roughness with a profilometer, check for uniformity with an optical comparator, and verify dimensions with a CMM. Parts that meet the Ra requirement move to final packaging; those that don’t are reworked with adjusted parameters.

Materials We Work With

Полировка с ЧПУ works with almost every material, but the technique and abrasives vary based on the material’s hardness and properties. Below is a breakdown of our supported materials, recommended polishing techniques, and ideal finishes:

| Материальная категория | Примеры | Ключевые свойства | Recommended Polishing Technique | Ideal Finish (Ra value) | Общие приложения |

| Металлы | Нержавеющая сталь | Коррозионная устойчивость, hard | Electrochemical polishing, mechanical | 0.02μm–0.1μm (зеркало) | Медицинские инструменты, Продовольственное оборудование |

| | Алюминий | Легкий вес, мягкий, prone to oxidation | Механическая полировка (with oxide inhibitors) | 0.05μm–0.2μm (атласный) | Автомобильная отделка, Электроника кожухи |

| | Титан | Высокая сила, биосовместимый, hard | Механическая полировка (diamond abrasives) | 0.03μm–0.1μm (зеркало) | Ортопедические имплантаты, аэрокосмические компоненты |

| | Латунь | Податливый, проводящий, tarnishes easily | Механическая полировка (полировки колеса) | 0.05μm–0.1μm (зеркало) | Электрические разъемы, декоративные детали |

| | Медь | Мягкий, проводящий, prone to oxidation | Chemical polishing (acid-based) | 0.05μm–0.2μm (атласный) | Теплообменники, Музыкальные инструменты |

| Non-Metals | Пластмассы (ABS/Polycarbonate) | Легкий вес, мягкий, prone to melting | Механическая полировка (fine abrasive pads) | 0.1μm–0.8μm (матовый) | Consumer goods casings, прототипы |

| | Композиты | Layered structure, abrasive-sensitive | Механическая полировка (low-pressure, fine grit) | 0.2μm–1.6μm (матовый) | Аэрокосмические панели, racing car parts |

| | Стекло | Жесткий, хрупкий, scratch-prone | Механическая полировка (diamond abrasives) | 0.02μm–0.05μm (оптический) | Оптические линзы, display screens |

| | Керамика | Жесткий, теплостойкий, brittle | Механическая полировка (diamond pads) | 0.02μm–0.1μm (зеркало) | Медицинские имплантаты, промышленные клапаны |

| Special Materials | Экзотические металлы (Insonel) | Теплостойкий, hard | Механическая полировка (ceramic abrasives) | 0.1μm–0.3μm (атласный) | Aerospace engine parts |

| | Высокопроизводительные полимеры (Заглядывать) | Теплостойкий, химический устойчивый | Механическая полировка (non-abrasive pads) | 0.2μm–0.8μm (матовый) | Медицинские оболочки, промышленные печати |

Поверхностная обработка & Варианты отделки

Полировка с ЧПУ is often paired with complementary Поверхностная обработка techniques to enhance durability, эстетика, или функциональность. Below are our most popular finishing options, along with their benefits and ideal uses:

| Finishing Option | Описание процесса | Ключевые преимущества | Совместимость материала | Расходы (per sq. метр, avg.) | Лучше всего для |

| Механическая полировка | Uses rotating abrasive tools (полировки колеса, pads) to remove imperfections | Быстрый, рентабельный, настраиваемая отделка | Все металлы, пластмассы, композиты | 50–150 | High-volume parts (Автомобильная отделка) |

| Электрохимическая полировка | Uses electric current + chemical solution to dissolve surface flaws | Коррозионная устойчивость, единообразная отделка, no tool marks | Нержавеющая сталь, титан, латунь | 80–200 | Медицинские инструменты, food-grade parts |

| Химическая полировка | Uses acid/base solutions to etch away surface imperfections | No contact (ideal for delicate parts), fast | Медь, латунь, пластмассы | 40–120 | Маленький, complex plastic parts |

| Vibratory Polishing | Tumbles parts with abrasive media (керамические бусы, plastic chips) | Uniform finish for small parts, low labor | Small metals (медные булавки), пластмассы | 20–80 | Разъемы электроники, ювелирные изделия |

| Buffing | Uses soft cloth wheels + polishing compounds (воск, rouge) to create shine | Зеркальное отделка, enhanced aesthetics | Нержавеющая сталь, латунь, алюминий | 60–180 | Декоративные детали, потребительские товары |

| Brushed Finishing | Uses linear abrasive pads to create parallel grain patterns | Hides fingerprints, matte aesthetic | Алюминий, нержавеющая сталь | 45–130 | Панели приборов, smartphone casings |

| Coating Removal | Uses fine abrasives to strip old coatings (краска, покрытие) before re-polishing | Prepares parts for re-finishing, cost-saving | Все металлы, пластмассы | 30–100 | Refurbished parts (Промышленная техника) |

Например, we use electrochemical polishing for stainless steel medical tools (Для обеспечения коррозионной стойкости) and brushed finishing for aluminum smartphone casings (to hide fingerprints while maintaining a sleek look).

Допуски & Гарантия качества

Допуски for CNC Polishing focus on two key metrics: шероховатость поверхности (Ra value) и размерная стабильность (ensuring polishing doesn’t alter the part’s original dimensions). Наш quality control processes are designed to meet strict industry standards:

| Материал | Target Ra Range | Ra Uniformity Tolerance | Dimensional Tolerance Retention | Accuracy Standard Used | Техника измерения |

| Нержавеющая сталь | 0.02μm–0.1μm | ±0.05μm | ± 0,001 мм | ASTM B607, ISO 8785 | Laser Profilometer + CMM |

| Алюминий | 0.05μm–0.2μm | ±0.08μm | ± 0,002 мм | Iso 8785, AMS 2750 | Profilometer + Оптический компаратор |

| Титан | 0.03μm–0.1μm | ±0.06μm | ± 0,001 мм | Iso 8785, AMS 4928 | Laser Profilometer + CMM |

| Glass | 0.02μm–0.05μm | ±0.03μm | ± 0,0005 мм | Iso 10110, ASTM C1036 | Optical Profilometer + Interferometer |

| ABS Plastic | 0.1μm–0.8μm | ±0.1μm | ± 0,005 мм | Iso 8785, ASTM D638 | Profilometer + Микрометр |

Наш quality control processes включать:

- Предварительно полишись: Inspecting parts for initial surface condition (НАПРИМЕР., machining marks, царапины) and verifying dimensions.

- В процессе: Real-time Ra measurement with laser profilometers (adjusting tool pressure/speed if Ra deviates from target).

- Post-polishing: 100% Инспекция на критические части (медицинский, аэрокосмическая); statistical sampling (5–10%) Для больших объемов. We also conduct adhesion tests (for coated parts) and corrosion tests (для металлов).

Документация: Providing a finish report with every order, including Ra values, measurement locations, and compliance certificates.

Key Advantages of CNC Polishing

Compared to manual polishing or other finishing methods, Полировка с ЧПУ offers unmatched benefits for consistency, эффективность, и качество:

- Высокая точность: Achieves surface roughness as low as 0.02μm—critical for parts like optical lenses (where even tiny imperfections affect performance) or medical implants (where smooth surfaces reduce tissue irritation).

- Consistency and Repeatability: CNC programming ensures every part has the same finish—no variation from part to part (unlike manual polishing, where results depend on the operator’s skill).

- Сложная геометрия: 5-axis CNC polishing heads reach internal cavities, Изогнутые поверхности, and undercuts—finishing areas manual methods can’t access (НАПРИМЕР., the inside of a titanium knee implant).

- Снижение времени настройки: CAM programming and automated tool changes cut setup time by 60–80% compared to manual polishing—ideal for high-volume runs (НАПРИМЕР., 10,000 aluminum casings).

- Increased Efficiency: CNC machines run 24/7 with minimal supervision—producing 3–5x more parts per hour than manual polishers.

- Универсальность: Works with almost every material (металлы, пластмассы, стекло, композиты) and can create any finish (зеркало, атласный, почистота).

- Экономическая эффективность: While upfront costs are higher than manual polishing, reduced labor costs (no need for skilled operators) and lower rework rates (fewer inconsistent parts) save money long-term—especially for high-volume orders.

- Improved Surface Finish: Removes micro-imperfections (machining marks, царапины) that manual polishing misses—enhancing aesthetics and functionality (НАПРИМЕР., smooth surfaces reduce friction in moving parts).

- Усовершенствованная эстетика: Creates uniform, professional finishes that boost product value—critical for consumer goods (НАПРИМЕР., смартфоны, ювелирные изделия) и декоративные детали.

Reduced Manual Labor: Eliminates repetitive, labor-intensive manual polishing—reducing worker fatigue and improving workplace safety.

Промышленные приложения

Полировка с ЧПУ is used across industries where surface finish impacts performance, эстетика, or compliance. Вот его наиболее распространенные приложения:

| Промышленность | Общее использование | Key Benefit of CNC Polishing |

| Аэрокосмическая | Titanium engine components, aluminum fuselage panels, stainless steel fuel lines | Коррозионная стойкость + размерная стабильность |

| Автомобиль | Aluminum trim, stainless steel exhaust tips, plastic interior panels | Эстетика + consistency for high-volume production |

| Медицинские устройства | Stainless steel surgical tools, titanium orthopedic implants, plastic device casings | Smooth surfaces (reduces tissue irritation) + compliance |

| Промышленное производство | Steel machinery parts, ceramic valves, composite conveyor belts | Уменьшенное трение + долговечность |

| Электроника | Aluminum heat sinks, brass connectors, plastic smartphone casings | Эстетика + improved heat dissipation (плавные поверхности) |

| Защита | Titanium weapon components, stainless steel vehicle armor parts | Коррозионная стойкость + долговечность в суровых условиях |

Advanced Manufacturing Techniques in CNC Polishing

To deliver exceptional finishes across diverse materials and geometries, we leverage specialized методы полировки and optimized processes:

9.1 Core Polishing Techniques

- Механическая полировка:

The most versatile technique—uses rotating tools (полировки колеса, abrasive pads) with graded grits (80–10,000 grit) Чтобы удалить недостатки поверхности. We tailor tools to material:

- Buffing Wheels: Cotton/polyester wheels for metals (нержавеющая сталь, латунь) to create mirror finishes; foam wheels for plastics to avoid melting.

- Abrasive Pads: Diamond-impregnated pads for hard materials (керамика, стекло); alumina pads for metals; silica pads for composites.

- Приложение: Идеально подходит для больших частей (аэрокосмические панели) and high-volume runs (Автомобильная отделка).

- Электрохимическая полировка (ECP):

Uses an electrolytic cell (part as anode, conductive tank as cathode) and a specialized electrolyte (НАПРИМЕР., phosphoric acid for stainless steel). When current is applied, surface metal dissolves uniformly—removing tool marks and creating a passive oxide layer.

- Выгода: No contact (avoids part distortion) and enhances corrosion resistance.

- Приложение: Медицинские инструменты (нержавеющая сталь), продовольственные детали (латунь), and parts with internal cavities (Титановые имплантаты).

- Химическая полировка:

Uses acid/base solutions (НАПРИМЕР., nitric acid for copper, sodium hydroxide for plastics) to etch away surface flaws. Unlike ECP, it requires no electricity—parts are dipped or sprayed with the solution, then rinsed.

- Выгода: Быстрый, low-cost for small, сложные части (НАПРИМЕР., plastic electronics connectors).

- Приложение: Copper heat exchangers, ABS plastic casings, and brass decorative parts.

- Vibratory Polishing:

Places small parts (НАПРИМЕР., медные булавки, медицинские иглы) in a vibrating tub filled with abrasive media (керамические бусы, plastic chips) and a polishing compound. Vibration causes media to rub against parts, creating a uniform finish.

- Выгода: Низкий труд (unattended operation) and consistent results for high-volume micro-parts.

- Приложение: Разъемы электроники (латунь), jewelry findings (gold-plated brass), and medical micro-components.

- 5-Axis CNC Polishing:

Uses a 5-axis machine (3 линейный + 2 rotary axes) with a flexible polishing head (НАПРИМЕР., foam or felt) to reach complex geometries—internal cavities, подписаны, и изогнутые поверхности (НАПРИМЕР., titanium knee implants).

- Выгода: Finishes areas manual or 3-axis polishing can’t access.

- Приложение: Аэрокосмические турбинные лопасти (inconel), ортопедические имплантаты (титан), and optical molds (сталь).

9.2 Supporting Technologies

- Abrasive Selection:

Grit size and material determine finish quality:

- Coarse grit (80–240): Удаляет отметки обработки (initial step).

- Medium grit (400–800): Smooths surface (intermediate step).

- Fine grit (1000–10 000): Creates desired finish (Последний шаг).

Для твердых материалов (керамика, стекло), we use diamond abrasives; for soft materials (алюминий, пластмассы), we use alumina or silica.

- Системы охлаждающей жидкости:

Предотвращает перегрев (critical for plastics and soft metals):

- Water-Based Coolants: For mechanical polishing of metals—reduces friction and flushes away abrasive debris.

- Oil-Based Coolants: For plastics—avoids warping and improves finish uniformity.

- Mist Coolants: For 5-axis polishing of micro-parts—delivers a fine mist to avoid residue buildup.

- Fixture Design:

Custom fixtures ensure parts stay stable during polishing:

- Вакуумные патроны: Для тонких деталей (алюминиевые листы, glass panels) to avoid deformation.

- Soft Jaws: For delicate plastics (поликарбонат) and polished metals (латунь) to prevent scratches.

Magnetic Fixtures: For ferrous metals (steel dies) to enable fast setup.

Тематические исследования: CNC Polishing Success Stories

Наш CNC Polishing services have solved finish challenges for clients across medical, аэрокосмическая, и промышленность потребительских товаров. Ниже два успешные проекты showcasing our expertise:

Тематическое исследование 1: Medical Device Company (Stainless Steel Surgical Scissors)

- Испытание: Клиент нужен 50,000 stainless steel surgical scissors monthly—requiring a mirror finish (Ra ≤ 0.05μm) for corrosion resistance and easy sterilization. Their previous supplier used manual polishing, which caused 12% of scissors to have inconsistent finishes (some too rough, some with scratches) and failed FDA compliance checks. Lead time was 4 недели, delaying product launches.

- Решение: Мы использовали electrochemical polishing (ECP)—the scissors were mounted on a custom fixture and submerged in a phosphoric acid electrolyte. We programmed the ECP system to apply 12V current for 3 минуты (optimized for stainless steel), then rinsed and passivated the scissors to enhance corrosion resistance. We added in-line laser profilometers to inspect Ra values in real time, rejecting parts with Ra > 0.05μm.

- Результаты:

- Finish consistency improved from 88% to 99.8%—only 100 scissors failed per month (против. 6,000 previously).

- The scissors passed FDA compliance (corrosion resistance test: 500+ hours in salt spray).

- Lead time shortened from 4 недели до 10 days—helping the client meet launch deadlines.

- Клиентский отзыв: “CNC ECP transformed our scissors’ quality. The mirror finish is perfect every time, and the FDA approval was seamless. We’ve expanded our order to include hemostats and forceps.” — Maria L., Medical Device Production Manager.

- Before and After: Manual polished scissors had visible scratches and uneven shine; ECP scissors featured a uniform mirror finish that resisted rust and simplified sterilization.

Тематическое исследование 2: Consumer Electronics Brand (Aluminum Smartphone Casings)

- Испытание: Клиент нужен 100,000 aluminum smartphone casings monthly—requiring a brushed finish (Ra 0.15μm, linear grain) to hide fingerprints and match their brand aesthetic. Their previous supplier used manual brushing, which caused 15% of casings to have misaligned grain (some curved, some uneven) and inconsistent Ra values (0.1–0.3μm). The client needed a 2-week lead time to support their phone launch.

- Решение: Мы использовали 5-axis CNC mechanical polishing—equipping the machine with a linear abrasive pad (800 зернистый) and programming it to create parallel grain lines (0.5мм друг от друга) across the casing’s curved surfaces. We used a custom vacuum fixture to secure the casings (avoiding scratches) and water-based coolant to prevent aluminum oxidation. We sampled 1% of casings hourly with a profilometer to ensure Ra stayed at 0.15μm.

- Результаты:

- Grain alignment accuracy improved from 85% to 99.5%—only 500 casings had misaligned grain (против. 15,000 previously).

- Ra uniformity was maintained at ±0.02μm (all casings 0.13–0.17μm)—meeting the brand’s strict aesthetic standards.

- Lead time was met (2 недели)—enabling the client’s on-schedule phone launch.

- Challenge Overcome: Manual brushing couldn’t follow the casing’s curved edges; 5-axis CNC ensured grain lines stayed straight and uniform across all surfaces.

Клиентский отзыв: “The brushed casings look identical to our design specs—no more customer complaints about fingerprint visibility. The consistency and speed have made them our sole supplier for aluminum parts.” — David K., Consumer Electronics Procurement Director.

Why Choose Our CNC Polishing Services?

With numerous CNC polishing providers, here’s what sets us apart as a trusted partner for medical, аэрокосмическая, and consumer industries:

- Expertise in CNC Polishing: Наша команда имеет 18+ years of specialized experience—we master all core techniques (механический, ECP, химический, vibratory) and tailor them to material properties. Our engineers are certified in AS9100 (аэрокосмическая) и ISO 13485 (медицинский) and can solve complex challenges (НАПРИМЕР., 0.02μm finishes for optical glass, brushed grain on curved aluminum).

- Experience in Various Industries: Мы служили 650+ Клиенты по всему 10 industries—from small medical startups to Fortune 500 electronics brands. This cross-industry experience means we understand sector-specific needs: FDA compliance for medical parts, scratch resistance for consumer goods, and corrosion resistance for aerospace components.

- High-Quality Equipment: We invest in state-of-the-art machines—12 CNC polishing systems (включая 5 5-Осины), 8 ECP tanks, 5 vibratory polishing tubs, and in-line laser profilometers. All equipment is calibrated weekly (using NIST-traceable standards) to maintain precision.

- Отличное обслуживание клиентов: Наша команда доступна 24/7 to support your project—from finish selection (helping you choose the right Ra value) Поступивное наблюдение. We offer free sample polishing (до 5 части) so you can verify finish quality before placing large orders. Для срочных проектов (НАПРИМЕР., medical supply shortages), we assign a dedicated project manager.

- Быстрое время переключения: Our optimized processes deliver industry-leading lead times:

- Прототипы (1–100 деталей): 1–3 дней

- Низкий объем (100–1000 деталей): 3–7 дней

- Большое объем (1,000+ части): 7–14 дней

Для приказов (НАПРИМЕР., consumer goods launches), Мы можем доставить 10,000+ части в 5 days by running machines 24/7.

- Рентабельные решения: We help you save money through:

- Автоматизация: Unattended operation (vibratory, ECP) reduces labor costs by 60% против. manual polishing.

- Abrasive Optimization: Reusing fine grit abrasives (for final steps) cuts material costs by 20%.

- Volume discounts: 10% off orders over 10,000 parts and 15% off orders over 50,000 parts—ideal for consumer electronics and medical high-volume runs.

Commitment to Quality: Мы ИСО 9001, AS9100, и ISO 13485 certified—our quality control processes гарантировать 99.9% of parts meet your finish requirements. We also provide full traceability (each batch’s Ra reports, process logs) for compliance.